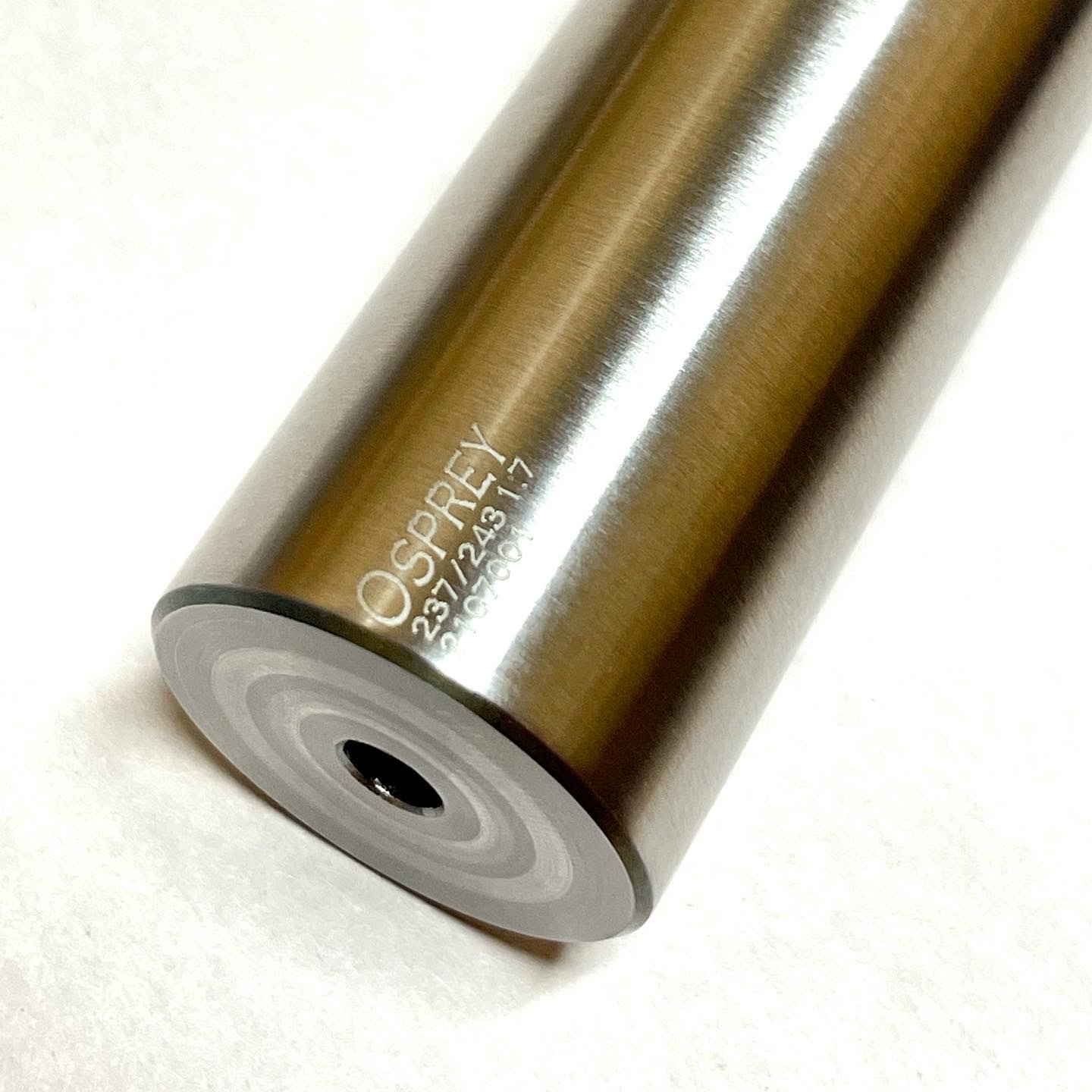

Osprey Barrel Works is a new offering through Patriot Valley Arms. They barrels are 100% CNC produced from double stress relieved 416RR CReS (Stainless). Right now they're available in 22, 6mm, 6.5mm in the associated fast twists required for modern rifle bullets. As production increases there will be more calibers added to the list, likely in early 2022.

The project is a long term endeavor to bring more barrel production in house and vertically integrate more of the product line.

I've been pretty quiet on the forum about them for a while, even though we've been selling them for about 6 weeks. Approximately 70 are in shooters' hands at this point. We have gotten 1 big PRS match win, two local match wins, and numerous comments from those initial shooters and gunsmiths telling us how impressed they were with the first time out at the range.

Recently (last weekend) Aaron Hipp used PVA Seneca 6mm 95gr bullets and an Osprey Barrel Blank (installed by Alamo Precision) to win the PA-OH Border Wars Finale.

The barrels are top shelf, micro-honed, lapped, stainless barrels. The current production rate is ~200pcs a month and can expand as needed. They are available as contoured blanks as well as a full Prefit barrel. Each barrel blank is individually serialized for QA Tracking.

www.patriotvalleyarms.com

They are also available as part of the PVA Labor Day sale through 9/6/21

"TaxationIsTheft1787" for 17.87% off

Barrel Questions

Prefits & Contoured Blanks

The project is a long term endeavor to bring more barrel production in house and vertically integrate more of the product line.

I've been pretty quiet on the forum about them for a while, even though we've been selling them for about 6 weeks. Approximately 70 are in shooters' hands at this point. We have gotten 1 big PRS match win, two local match wins, and numerous comments from those initial shooters and gunsmiths telling us how impressed they were with the first time out at the range.

Recently (last weekend) Aaron Hipp used PVA Seneca 6mm 95gr bullets and an Osprey Barrel Blank (installed by Alamo Precision) to win the PA-OH Border Wars Finale.

The barrels are top shelf, micro-honed, lapped, stainless barrels. The current production rate is ~200pcs a month and can expand as needed. They are available as contoured blanks as well as a full Prefit barrel. Each barrel blank is individually serialized for QA Tracking.

www.patriotvalleyarms.com

They are also available as part of the PVA Labor Day sale through 9/6/21

"TaxationIsTheft1787" for 17.87% off

Barrel Questions

Prefits & Contoured Blanks