Hey guys, I figured some of you might like to see this.

After seeing the thread awhile back on precision cut foam, I remembered that arfcom thread about hot wire case cutting. I finally had some free time to make the cutter recently, and here are the results. I plan to put both the scope and suppressor in the bottom left of the case, and the sling under the grip in between the bipod and mags.

Gun is a LWRC REPR 18" FDE. I still have room for my Shark suppressor above the scope to cut out too, so I was pretty happy with the size of this case for my application.

I cut out all the templates out of cardboard and went to work, a couple hours later I'm pretty happy with the results.

For anyone wanting the AR15 link, here it is.

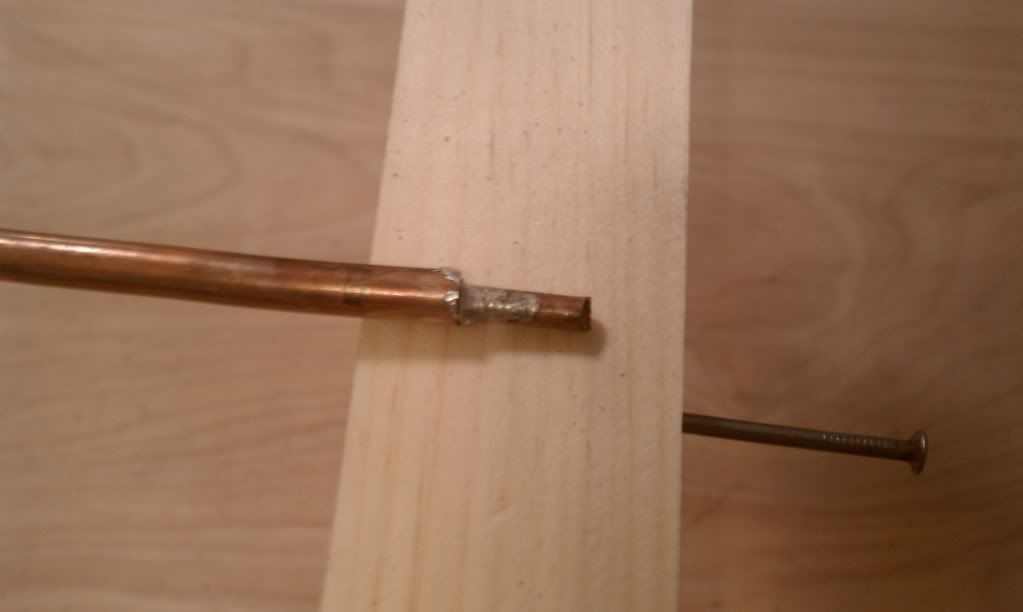

Click this for foam cutter instructions

Let me know what you guys think!

EDIT: Completed.

After seeing the thread awhile back on precision cut foam, I remembered that arfcom thread about hot wire case cutting. I finally had some free time to make the cutter recently, and here are the results. I plan to put both the scope and suppressor in the bottom left of the case, and the sling under the grip in between the bipod and mags.

Gun is a LWRC REPR 18" FDE. I still have room for my Shark suppressor above the scope to cut out too, so I was pretty happy with the size of this case for my application.

I cut out all the templates out of cardboard and went to work, a couple hours later I'm pretty happy with the results.

For anyone wanting the AR15 link, here it is.

Click this for foam cutter instructions

Let me know what you guys think!

EDIT: Completed.