For those who have an AMP press, I thought it would be interesting to see others' plots and what prep they did to get said plots.

To kick it off:

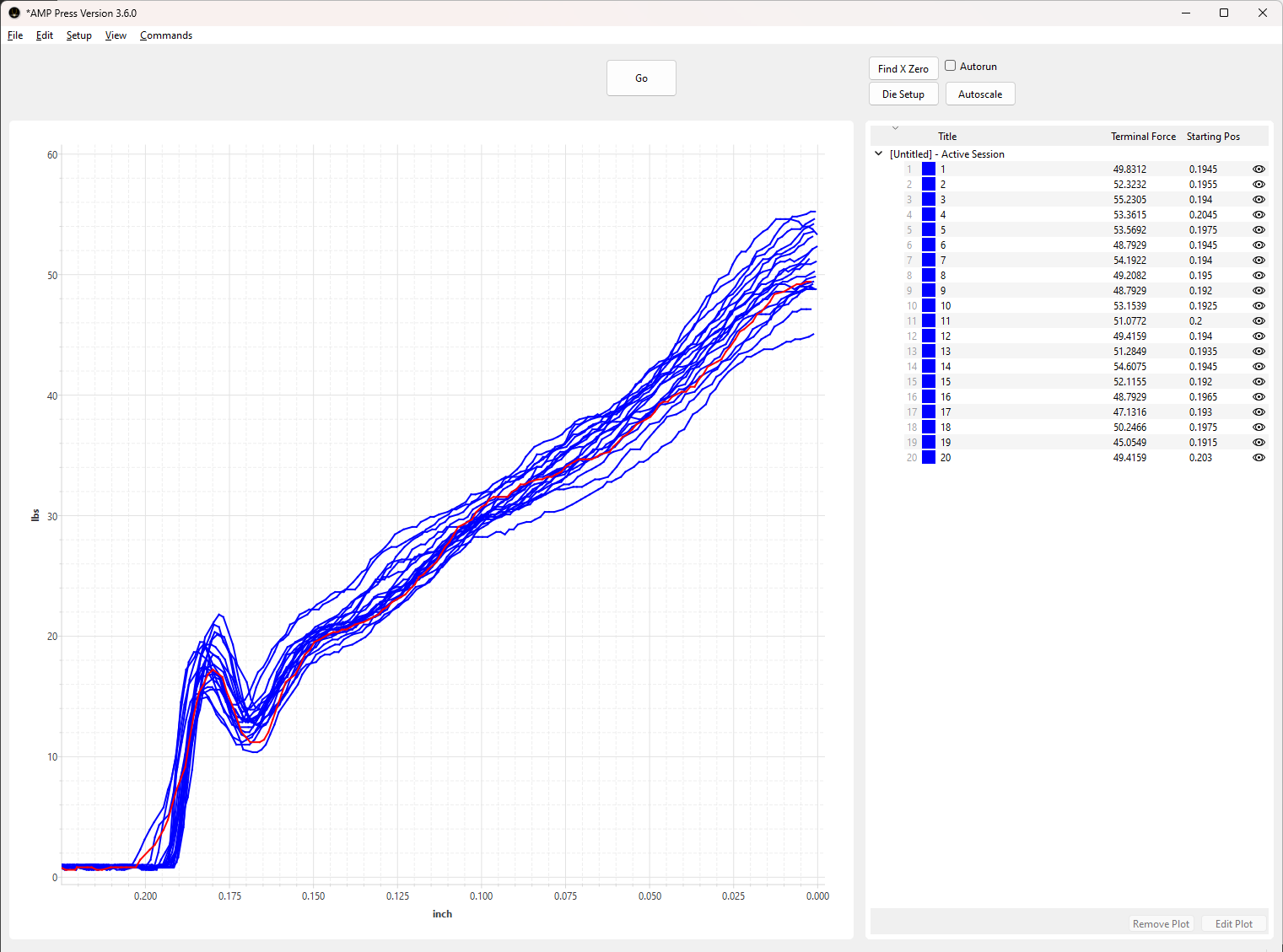

6 BRA

105 Berger Hybrid

Lapua Brass (once-fired/formed)

FL sized and mandrelled (sp?)

Moly neck lube twice - once before mandrel, once after

LE Wilson seater

20 rounds seated

The bummer is that I was running about a 6 lb spread until #s 17 and 19, which pushed the spread out to about 10 lb.

To kick it off:

6 BRA

105 Berger Hybrid

Lapua Brass (once-fired/formed)

FL sized and mandrelled (sp?)

Moly neck lube twice - once before mandrel, once after

LE Wilson seater

20 rounds seated

The bummer is that I was running about a 6 lb spread until #s 17 and 19, which pushed the spread out to about 10 lb.