HI guys - this is sort of a bit of a...oh, I don't know.....question with what I think is an obvious answer but given the potential criticality of over pressure hand loads and my absolute zero experience in evaluating brass for pressure signs, I thought I'd ask the forum.

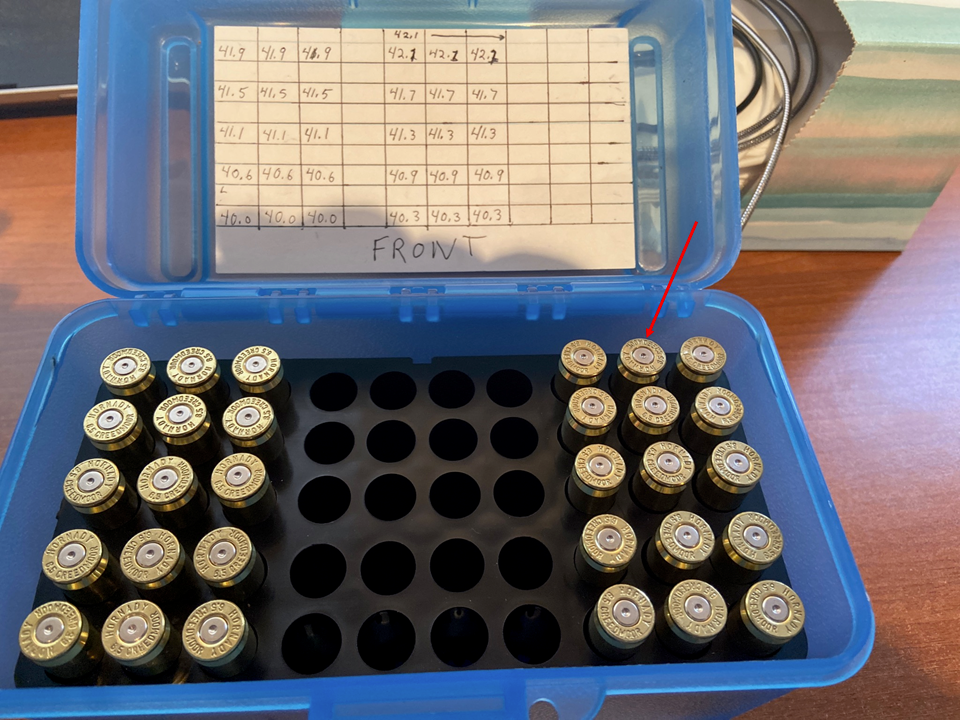

This is once fired Hornady 6.5 cm brass with CCI BR-2 primers running H4350 (charge amount is shown in the pic) and Berger 140 gr Hybrid Targets.

To me, all of this brass looks fine. No extractor marks, no ejector indentation, no flow of primer cup material into firing pin hole, and while the primers are flatter than they were (well, they were fired), there is still radius on all of them.

I had zero bolt opening issues except a small increase in force needed for the one cartridge with the red arrow pointing to it. But this cartridge looks fine to me also (yeah, zero experience me! haha) and I know that when I sized all of this Hornady brass, there were a handful that I caught where the base was just a bit fat and really wouldn't seat fully in a Sheridan case gauge. Any that didn't, I set aside but that doesn't mean some didn't get through. So, without any other indications, it seems to me that this is most probably why on this one cartridge (and yes, with the highest charge in the ladder) the bolt was just a bit balky in opening.

But I'm all ears and completely willing to discount any thoughts of mine in favor of your far more vast experience.

See any pressure signs?

This is once fired Hornady 6.5 cm brass with CCI BR-2 primers running H4350 (charge amount is shown in the pic) and Berger 140 gr Hybrid Targets.

To me, all of this brass looks fine. No extractor marks, no ejector indentation, no flow of primer cup material into firing pin hole, and while the primers are flatter than they were (well, they were fired), there is still radius on all of them.

I had zero bolt opening issues except a small increase in force needed for the one cartridge with the red arrow pointing to it. But this cartridge looks fine to me also (yeah, zero experience me! haha) and I know that when I sized all of this Hornady brass, there were a handful that I caught where the base was just a bit fat and really wouldn't seat fully in a Sheridan case gauge. Any that didn't, I set aside but that doesn't mean some didn't get through. So, without any other indications, it seems to me that this is most probably why on this one cartridge (and yes, with the highest charge in the ladder) the bolt was just a bit balky in opening.

But I'm all ears and completely willing to discount any thoughts of mine in favor of your far more vast experience.

See any pressure signs?