Trying to get more into developing more accurate loads. Trying to wrap my head around the hole primer seating depth thing but, kind of lost here. Normally just seat the primers with a hand tool or on my single stage lnl. Seat until they bottom out and move on. But, now I’m reading all this on primer depth uniformity and not sure what the best way to go about seating the primers. In my head, It seems if I seat the primers to an exact same depth beyond flush, than some might bottom out less than others. Is this actually better than running them in until they bottom out? Maybe I’m missing something in the process.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Primer seating depth?

- Thread starter berry79

- Start date

I just bottom them out and make sure they’re not protruding.

In the chase for precision, I would advise

There is a lot more low hanging fruit in your process, and your fundamentals, which would yield more measurable results long before primer seating depth would actually be noticeable.

In the chase for precision, I would advise

There is a lot more low hanging fruit in your process, and your fundamentals, which would yield more measurable results long before primer seating depth would actually be noticeable.

Ideally the primer cup will contact the bottom of the primer pocket to prevent primer creep and the anvil will come into contact with the primer compound. Primer pocket depth can vary from one brass mfg to another, so you will want to measure it with your caliper depth guage. Seating consistency can be affected by factors such as the priming tool being used, case rim thickness, or the user.

I would not take these measurements as gospel, but come up with your own instead:

I would not take these measurements as gospel, but come up with your own instead:

In my head, It seems if I seat the primers to an exact same depth beyond flush, than some might bottom out less than others. Is this actually better than running them in until they bottom out? Maybe I’m missing something in the process.

Primers aren't a one-piece thing. There's the cup, the anvil, and the compound. The primer as a whole should be seated deep enough to where the anvil is contacting the bottom of the pocket, but (usually) not so far as bottom out the cup in the pocket. You can't (generally) compress the cup itself. The post before this shows this graphically.

Measure the depth of the primer pocket - say 0.125". Measure the height of the entire primer - including the legs - e.g. 0.121". Now take the tip of the blades of your calipers and measure the height of the cup itself. This part is a little tricky, getting in between the legs of the anvil, and with the radius of the cup, etc. Let's say this part is 0.113".

Given those numbers, you'd ideally want the primers seated at least 4 thou below flush - the primer pocket depth (0.125") minus the primer height (0.121"). The primer pocket depth (0.125") minus the primer *cup* height (0.113") gives you a total depth range of about 12 thou. So somewhere between 4 and 12 thou would be an acceptable range, given these specific numbers. 3-5 thou of 'crush' seems to be a pretty common range that works for various folks.

Usually when you see people refer to primer 'crush', they're referring to feeling the primer 'bottom out' in the pocket, and then begin to compress, consolidate or 'crush' (depending on which literature you're referring to) the anvil a small amount. Lots of people do it entirely by feel, and have perfectly good results. Other people like being able to attach a number to things, and go down that path. Whatever works for you.

You can take some/most of those measurements using a simple set of dial calipers, though they're not really ideal for the task. For a long time, Accuracy One / Hoover was about the only game in town with a dedicated tool that made measuring primer pocket depth / primer seating depth a lot easier / more consistent. There's a new option on the market now... not cheap, but it does all of the above plus some (rim thickness).

Last edited:

I seat all mine with a rcbs hand priming tool. Never seen a reason to chase primer depth

I’d make sure you have all other items in relation to effects on accuracy ironed out before chasing primer depth. The reloading rabbit hole is deep and you’re almost standing at the bottom here

If you’re chasing BR or high end fclass accuracy it may be worth it. But for occasional shooting or PRS I wouldn’t bother

Just my opinion

I’d make sure you have all other items in relation to effects on accuracy ironed out before chasing primer depth. The reloading rabbit hole is deep and you’re almost standing at the bottom here

If you’re chasing BR or high end fclass accuracy it may be worth it. But for occasional shooting or PRS I wouldn’t bother

Just my opinion

In the chase for precision, I would advise

There is a lot more low hanging fruit in your process, and your fundamentals, which would yield more measurable results long before primer seating depth would actually be noticeable.

^ this

Can't emphasize this enough. It's all well and good to go down the rabbit hole chasing the last nth degree of perfection... sometimes it's a matter of priorities. Not at least bottoming out the primer in the pocket will lead to inconsistent ignition, but beyond that... there's a whole lotta other things to worry about before you start getting too fussy about exact primer seating depth, IMO.

Well said. Worrying about primer seating depth is one of those last 1% things that do not affect an average shooter as we simply are not a good enough shot to see a change if the primer is seated a couple thou more.I just bottom them out and make sure they’re not protruding.

In the chase for precision, I would advise

There is a lot more low hanging fruit in your process, and your fundamentals, which would yield more measurable results long before primer seating depth would actually be noticeable.

If using quality brass, just bottom the primer out in the primer pocket but do not crush it as that can create ignition issues.

Perfect. Thanks for all the replies. Definitely went down the rabbit hole, lol. Loads are shooting very accurately already. I’m just always looking for something else to tinker with.

On my 50 BMG, using RWS brass and primers, I was seating to the depth that the psychologist on the other forum suggests or 0.007 inches which is about where I seat my large rifle primers

Several knowledgeable people said I should be seating them about twice as far so I did that and my standard deviation shrunk by half

This is my latest rabbit hole, but I do think there might be something to the whole “crush” and seating depth debate

Several knowledgeable people said I should be seating them about twice as far so I did that and my standard deviation shrunk by half

This is my latest rabbit hole, but I do think there might be something to the whole “crush” and seating depth debate

Last edited:

My biggest problem in inconsistent ignition. Can't tell if its the primers I use or not.

Winchester Magnum primers give me fits. Winchester Large rifle is pretty fool proof. (A pox upon the covid shortage!) A lot of people talk about feel and crush--I can't feel a damn thing (I'm probably a pussy with my hand strength)--and its tough to measure seating depth. Specially those magnum primers, smash em all the way in as hard as I can--even moved to using my Dillon 550. Even with all that BS, my ammo is "good enough" for PRS. (I've gotten single digit SD across 20 shots for an f-class match) Unless you are HM in f-class--chase something else in the meantime.

Winchester Magnum primers give me fits. Winchester Large rifle is pretty fool proof. (A pox upon the covid shortage!) A lot of people talk about feel and crush--I can't feel a damn thing (I'm probably a pussy with my hand strength)--and its tough to measure seating depth. Specially those magnum primers, smash em all the way in as hard as I can--even moved to using my Dillon 550. Even with all that BS, my ammo is "good enough" for PRS. (I've gotten single digit SD across 20 shots for an f-class match) Unless you are HM in f-class--chase something else in the meantime.

Yes, seating primers to the "exact same depth beyond flush" you get variations in they amount of anvil crush and distance from the bottom of the pockets. . . unless the pockets are uniformed. Also note that from a study done a few years back to see how consistent hand seating primers was, it was found that even though experienced reloaders saying their seating by feel, they're getting their primers seated to the bottom of the pockets; but the measurements showed that just wasn't so. There was quite a bit of variance. However, that variance apparently doesn't make much difference, for reloaders other the those like high end competitive bench rest shooters. This YouTube video showing a good experiment about this shows the effects of such variance:Trying to get more into developing more accurate loads. Trying to wrap my head around the hole primer seating depth thing but, kind of lost here. Normally just seat the primers with a hand tool or on my single stage lnl. Seat until they bottom out and move on. But, now I’m reading all this on primer depth uniformity and not sure what the best way to go about seating the primers. In my head, It seems if I seat the primers to an exact same depth beyond flush, than some might bottom out less than others. Is this actually better than running them in until they bottom out? Maybe I’m missing something in the process.

Since I like things to be as consistent as possible, I'll uniform my primer pockets and measure the particular primers I'm using to find how far down they need to be seated (different brands of primers are different heights) as I want the firing pin to provide consistent strikes. That kind of consistency is probably not really needed for me, but it takes one thing out of the equation when trying to figure out what to do to improve my reloading results. As I coached in baseball, I taught control what you can control and forget about all the rest.

The people who make those adjustable primer seating tools are just trying to make money on a problem that doesn't exist. And some of those people ask a commanding price for these tools. Save your money. Seat the primers until they bottom out and leave it at that. Anything less and you might have misfires. Anything more (what some call "crush") and you risk distorting the primer.

I actually tested this a couple of years ago and ran them across the magneto. Groups of 20 if I recall correctly. I tried various depths plus bottomed out. There was no appreciable difference in es or sd. I just bottom them out and roll on now. This was on a fairly well refined load and rifle. It shot .3-.4s throughout the test, as it did before and since.

That's what I've been doing.Seat them as deep as you reasonably can.

I've had better results seating deeper than shallower. Doesn't seem to matter much beyond a certain point.

Variance in cup height, anvil protrusion & rim thickness led me to seating the cup to the bottom of the pocket then applying a specific crush. This is with a uniformed pocket.

Even if you're pockets are within a thou and you measure every primer and get it installed exactly as the math would indicate you still get a variance from rim thickness.

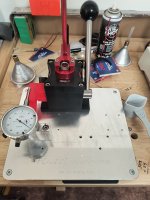

I use a Primal Rights seater on an F Class products base with indicator to measure the crush.

From there I'll sort the primed cases for below flush of the case head. I know it sounds like a lot but I'm still only handling the case one time in the priming operation.

The ladder test pic was at 600 yards in 2022 after winning a 16 target benchrest agg match. 8 targets at 600 and 8 targets at 1000 over 3 days setting a new 16 target group agg record that's still standing.

I shot the match with .004" crush the test after showed .002" & .003" to be better.

6 BRA HH barrel on a Kelbly F Panda action

Even if you're pockets are within a thou and you measure every primer and get it installed exactly as the math would indicate you still get a variance from rim thickness.

I use a Primal Rights seater on an F Class products base with indicator to measure the crush.

From there I'll sort the primed cases for below flush of the case head. I know it sounds like a lot but I'm still only handling the case one time in the priming operation.

The ladder test pic was at 600 yards in 2022 after winning a 16 target benchrest agg match. 8 targets at 600 and 8 targets at 1000 over 3 days setting a new 16 target group agg record that's still standing.

I shot the match with .004" crush the test after showed .002" & .003" to be better.

6 BRA HH barrel on a Kelbly F Panda action

Attachments

Regarding "variance from rim thickness", while that's true for almost all primer seating tools, it's not so for the Lee ACP (which I have and use) and Sinclair has one that won't index off the rim thickness.Variance in cup height, anvil protrusion & rim thickness led me to seating the cup to the bottom of the pocket then applying a specific crush. This is with a uniformed pocket.

Even if you're pockets are within a thou and you measure every primer and get it installed exactly as the math would indicate you still get a variance from rim thickness.

I use a Primal Rights seater on an F Class products base with indicator to measure the crush.

From there I'll sort the primed cases for below flush of the case head. I know it sounds like a lot but I'm still only handling the case one time in the priming operation.

The ladder test pic was at 600 yards in 2022 after winning a 16 target benchrest agg match. 8 targets at 600 and 8 targets at 1000 over 3 days setting a new 16 target group agg record that's still standing.

I shot the match with .004" crush the test after showed .002" & .003" to be better.

6 BRA HH barrel on a Kelbly F Panda action

Regarding "variance from rim thickness", while that's true for almost all primer seating tools, it's not so for the Lee ACP (which I have and use) and Sinclair has one that won't index off the rim thickness.

Yeah I'm aware there are tools now that may account for rim thickness. When I went down the rabbit hole there was not and I'm still happy with my priming process and see no reason to change at this time.

I'd say when one is happy with their process . . . IMHO, that's all that really counts.Yeah I'm aware there are tools now that may account for rim thickness. When I went down the rabbit hole there was not and I'm still happy with my priming process and see no reason to change at this time.

I'd say when one is happy with their process . . . IMHO, that's all that really counts.

There are many ways, for now I like this one

No data, but seating the primer, turning the case 45 degrees, and seating again, makes me, and hopefully the primer, happy.

Funny you say that: every now and again after I jam it in all the way I turn it sideways a little bit and it really seems to get her going

I always thought it was the element of surprise

I always thought it was the element of surprise

Similar threads

- Replies

- 3

- Views

- 536

- Replies

- 18

- Views

- 492