Do Redding dies, and for that matter, lee, rcbs and hornady dies work ok in a Forster press? I need a press and like the Forster (I think). Not sure about Forster dies though. Seems like maybe Redding are the best. I need the BEST neck sizer, full length sizer and bullet seater (I have Wilson for that) for both 308 and 260.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Redding dies in a Forster Press

- Thread starter sniperaviator

- Start date

Re: Redding dies in a Forster Press

As stated any standard dies will work, it is best to have a full round ring, like the Forster rings for the press, but not absolutely necessary, I use some of the Hornady split rings that have flats on them, but prefer the full round like the Forster rings.

I have only had problems with one type of die ever--twice, with Redding sizer dies. Their dies are good dies, but I dislike that they don't have a vent hole, and have had issues with that...I have had zereo problems with Forster dies in any way, and in fact they are my favorite dies, and I have had every type I've ever heard of, except Lee sizing or seater dies--I do have, and ocassionally use the Hornady collet neck sizer die.

Don't let having dies other than Forster's keep you from a Coax, they are great presses. As for buying dies, try some Forsters--they are great.

As stated any standard dies will work, it is best to have a full round ring, like the Forster rings for the press, but not absolutely necessary, I use some of the Hornady split rings that have flats on them, but prefer the full round like the Forster rings.

I have only had problems with one type of die ever--twice, with Redding sizer dies. Their dies are good dies, but I dislike that they don't have a vent hole, and have had issues with that...I have had zereo problems with Forster dies in any way, and in fact they are my favorite dies, and I have had every type I've ever heard of, except Lee sizing or seater dies--I do have, and ocassionally use the Hornady collet neck sizer die.

Don't let having dies other than Forster's keep you from a Coax, they are great presses. As for buying dies, try some Forsters--they are great.

Re: Redding dies in a Forster Press

Will the tall Redding Competition dies with the micrometers clear the Coax handle?

Will the tall Redding Competition dies with the micrometers clear the Coax handle?

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sniperaviator</div><div class="ubbcode-body">Will the tall Redding Competition dies with the micrometers clear the Coax handle?</div></div>

Yep

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sniperaviator</div><div class="ubbcode-body">Will the tall Redding Competition dies with the micrometers clear the Coax handle?</div></div>

Yep

Re: Redding dies in a Forster Press

My Redding dies work great with my CO-AX.

But I <span style="text-decoration: underline">COULD NOT</span> get my Hornady seater die to work with it.

The yoke cleared the handle with plenty of room to spare but the problem I had was that I couldn't adjust it high enough to keep it away from the crimp ring and having it crimp my brass...A LOT!

So, for the record, some dies will not work on the CO-AX. My particular die was a Hornady Custom Grade Seater die for .300 WBY MAG.

I fixed it by getting a non crimping die (Redding Competition).

YMMV

My Redding dies work great with my CO-AX.

But I <span style="text-decoration: underline">COULD NOT</span> get my Hornady seater die to work with it.

The yoke cleared the handle with plenty of room to spare but the problem I had was that I couldn't adjust it high enough to keep it away from the crimp ring and having it crimp my brass...A LOT!

So, for the record, some dies will not work on the CO-AX. My particular die was a Hornady Custom Grade Seater die for .300 WBY MAG.

I fixed it by getting a non crimping die (Redding Competition).

YMMV

Re: Redding dies in a Forster Press

I run all Redding competition dies in my CO-AX...but I do use the Forster lock rings on all of them.

I run all Redding competition dies in my CO-AX...but I do use the Forster lock rings on all of them.

Re: Redding dies in a Forster Press

260 Remington? Found some at Midway. Are these what you're after?

Woops! you said Forster. Sorry!

Late night...teething babies...I'm spent.

260 Remington? Found some at Midway. Are these what you're after?

Woops! you said Forster. Sorry!

Late night...teething babies...I'm spent.

Re: Redding dies in a Forster Press

I just upgraded to a Forster press last night (From an OLD RCBS JR3). I am using Redding dies. The best lock rings out of all that I have on hand is the Sinclair Stainless, Socket Head. They are tick enough to have little play, but still allows the dies to float like they should.

The Sinclair lock rings are stainless and will out-live all aluminum rings I have seen.

I just upgraded to a Forster press last night (From an OLD RCBS JR3). I am using Redding dies. The best lock rings out of all that I have on hand is the Sinclair Stainless, Socket Head. They are tick enough to have little play, but still allows the dies to float like they should.

The Sinclair lock rings are stainless and will out-live all aluminum rings I have seen.

Re: Redding dies in a Forster Press

I have a Forster co-ax and a Bonanza co-ax and many dozens of various brands of dies. It all works, with the Forster lock rings.

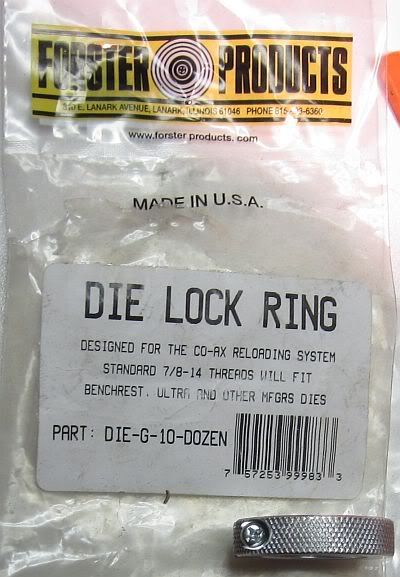

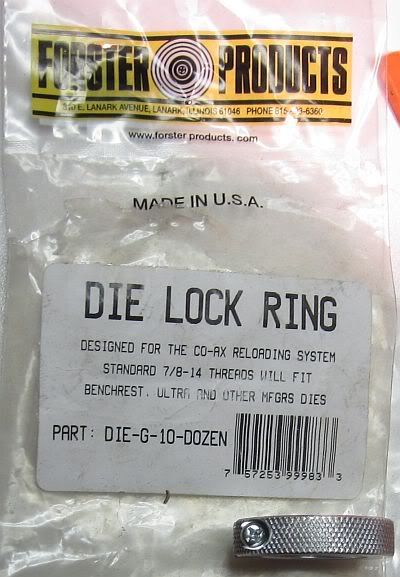

I have bought few bags of these. I buy them by the 12 pack.

It is 7/8-14 thread. If you make your own dies, they will work too.

I have a Forster co-ax and a Bonanza co-ax and many dozens of various brands of dies. It all works, with the Forster lock rings.

I have bought few bags of these. I buy them by the 12 pack.

It is 7/8-14 thread. If you make your own dies, they will work too.

Re: Redding dies in a Forster Press

I have yet to see an aluminum lock ring wear out, and I've seen some on dies that were all but "worn out".

The current production co-ax (B3 model) has a taller handle yoke and will clear any 7/8" die out there. I use several Hornady seating dies in my older B2 with never a problem, except it won't clear their optional micrometer stem. Check with Hornady to make sure they installed the right sleeve in the die. The seating stem can also get caught above the sleeve, and keep it from sliding up as far as normal before crimping. Check that too.

I have an older B2 model, and Hornady seating dies with the micrometer adjuster will not fit under the handle yoke.

Forster dies are great, especially the seater, with or without the micrometer adjustment, the insides (and performance) are the same. The sizing die has a raised expander ball that enters the bottom of the case neck while the neck is still held at the top in the neck portion of the die, keeping it centered. Works very well.

Andy

I have yet to see an aluminum lock ring wear out, and I've seen some on dies that were all but "worn out".

The current production co-ax (B3 model) has a taller handle yoke and will clear any 7/8" die out there. I use several Hornady seating dies in my older B2 with never a problem, except it won't clear their optional micrometer stem. Check with Hornady to make sure they installed the right sleeve in the die. The seating stem can also get caught above the sleeve, and keep it from sliding up as far as normal before crimping. Check that too.

I have an older B2 model, and Hornady seating dies with the micrometer adjuster will not fit under the handle yoke.

Forster dies are great, especially the seater, with or without the micrometer adjustment, the insides (and performance) are the same. The sizing die has a raised expander ball that enters the bottom of the case neck while the neck is still held at the top in the neck portion of the die, keeping it centered. Works very well.

Andy

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BigJakeJ1s</div><div class="ubbcode-body">...Check with Hornady to make sure they installed the right sleeve in the die. The seating stem can also get caught above the sleeve, and keep it from sliding up as far as normal before crimping. Check that too...

Andy </div></div>

I didn't consider an incorrect seating stem being installed in my die.

I contacted Hornady and explained my issue to them (and Forster at the same time). The response I got from Hornady was "abandon the CO-AX and buy a Lock & Load Classic...it's a much better press..." I can understand promoting ones own product but I at least thought I'd hear a little more thoughtful response to the issue than what I got.

Hell, I'd have been happy to hear that a simple stem swap might help, but...

I was a little put off by the lack of specific advice but I still have their press mounted on my bench. The seating die, however, is a paper weight

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: BigJakeJ1s</div><div class="ubbcode-body">...Check with Hornady to make sure they installed the right sleeve in the die. The seating stem can also get caught above the sleeve, and keep it from sliding up as far as normal before crimping. Check that too...

Andy </div></div>

I didn't consider an incorrect seating stem being installed in my die.

I contacted Hornady and explained my issue to them (and Forster at the same time). The response I got from Hornady was "abandon the CO-AX and buy a Lock & Load Classic...it's a much better press..." I can understand promoting ones own product but I at least thought I'd hear a little more thoughtful response to the issue than what I got.

Hell, I'd have been happy to hear that a simple stem swap might help, but...

I was a little put off by the lack of specific advice but I still have their press mounted on my bench. The seating die, however, is a paper weight

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sniperaviator</div><div class="ubbcode-body">Do Redding dies, and for that matter, lee, rcbs and hornady dies work ok in a Forster press? I need a press and like the Forster (I think). Not sure about Forster dies though. Seems like maybe Redding are the best. I need the BEST neck sizer, full length sizer and bullet seater (I have Wilson for that) for both 308 and 260. </div></div>

Are the dies for a bolt gun? Do you mix or sort your brass? Overall Redding's Competition bushing dies seem to be the best. Which of the Redding dies is best for your purposes depends on how and what you plan to shoot your handloads with. Redding's competition seating dies are notiably better than Wilson's seater with much improved concentricity and repeatable ogive based seating depth.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sniperaviator</div><div class="ubbcode-body">Do Redding dies, and for that matter, lee, rcbs and hornady dies work ok in a Forster press? I need a press and like the Forster (I think). Not sure about Forster dies though. Seems like maybe Redding are the best. I need the BEST neck sizer, full length sizer and bullet seater (I have Wilson for that) for both 308 and 260. </div></div>

Are the dies for a bolt gun? Do you mix or sort your brass? Overall Redding's Competition bushing dies seem to be the best. Which of the Redding dies is best for your purposes depends on how and what you plan to shoot your handloads with. Redding's competition seating dies are notiably better than Wilson's seater with much improved concentricity and repeatable ogive based seating depth.

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">I have a Forster co-ax and a Bonanza co-ax and many dozens of various brands of dies. It all works, with the Forster lock rings.

I have bought few bags of these. I buy them by the 12 pack.

It is 7/8-14 thread. If you make your own dies, they will work too. </div></div>

see that flat head screw......it is not your friend , you need hornady lock, rings with allen socket head , MUCH better . or save yourself some money and just replace the screw with allen socket head

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">I have a Forster co-ax and a Bonanza co-ax and many dozens of various brands of dies. It all works, with the Forster lock rings.

I have bought few bags of these. I buy them by the 12 pack.

It is 7/8-14 thread. If you make your own dies, they will work too. </div></div>

see that flat head screw......it is not your friend , you need hornady lock, rings with allen socket head , MUCH better . or save yourself some money and just replace the screw with allen socket head

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: procovert45</div><div class="ubbcode-body">

see that flat head screw......it is not your friend , you need hornady lock, rings with allen socket head , MUCH better . or save yourself some money and just replace the screw with allen socket head </div></div>

The screw is a fillister type.

I have seen slot, slot or Philips, and Philips.

The latest bag [within the last year] was Philips.

The screw is 6-32 with 0.5" long threads.

The screw head is ~ .22" diameter and ~ .23" long.

The counter sink in the die lock ring for the screw head is .25" diameter.

http://www.use-enco.com/CGI/INSRIT?PARTPG=INLMKD&PMPXNO=942013&PMAKA=430-0029

Midway for the die lock rings

It would be a shame if you have to buy a Forster die lock ring for $3.50 because the die came with a crummy ring, and then pay 5 cents for a different screw, because the Forster part came with a crummy screw.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: procovert45</div><div class="ubbcode-body">

see that flat head screw......it is not your friend , you need hornady lock, rings with allen socket head , MUCH better . or save yourself some money and just replace the screw with allen socket head </div></div>

The screw is a fillister type.

I have seen slot, slot or Philips, and Philips.

The latest bag [within the last year] was Philips.

The screw is 6-32 with 0.5" long threads.

The screw head is ~ .22" diameter and ~ .23" long.

The counter sink in the die lock ring for the screw head is .25" diameter.

http://www.use-enco.com/CGI/INSRIT?PARTPG=INLMKD&PMPXNO=942013&PMAKA=430-0029

Midway for the die lock rings

It would be a shame if you have to buy a Forster die lock ring for $3.50 because the die came with a crummy ring, and then pay 5 cents for a different screw, because the Forster part came with a crummy screw.

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Mutt</div><div class="ubbcode-body">

I contacted Hornady and explained my issue to them (and Forster at the same time). The response I got from Hornady was "abandon the CO-AX and buy a Lock & Load Classic...it's a much better press..."

</div></div>

I hope they said it tongue-in-cheek, as most everybody concurs that the Forster Co-Ax is the best press around for precision reloading (Dillon is in the running as well), and certainly better than Hornaday, RCBS, etc. Once you've had your hands on a few others, I think you'll look to fix or replace the die and not the press.

John

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Mutt</div><div class="ubbcode-body">

I contacted Hornady and explained my issue to them (and Forster at the same time). The response I got from Hornady was "abandon the CO-AX and buy a Lock & Load Classic...it's a much better press..."

</div></div>

I hope they said it tongue-in-cheek, as most everybody concurs that the Forster Co-Ax is the best press around for precision reloading (Dillon is in the running as well), and certainly better than Hornaday, RCBS, etc. Once you've had your hands on a few others, I think you'll look to fix or replace the die and not the press.

John

Re: Redding dies in a Forster Press

What do you all think about using the stainless steel Sinclair lock rings instead of the Alum. Forster rings?

I'm not so worried about the Alum. rings wearing out but they fit kinda loose and the Sinclair rings are supposed to fit snugger but are the Forster Alum. rings fitting loose good or bad?

What do you all think about using the stainless steel Sinclair lock rings instead of the Alum. Forster rings?

I'm not so worried about the Alum. rings wearing out but they fit kinda loose and the Sinclair rings are supposed to fit snugger but are the Forster Alum. rings fitting loose good or bad?

Re: Redding dies in a Forster Press

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: samson</div><div class="ubbcode-body">What do you all think about using the stainless steel Sinclair lock rings instead of the Alum. Forster rings?

I'm not so worried about the Alum. rings wearing out but they fit kinda loose and the Sinclair rings are supposed to fit snugger but are the Forster Alum. rings fitting loose good or bad? </div></div>

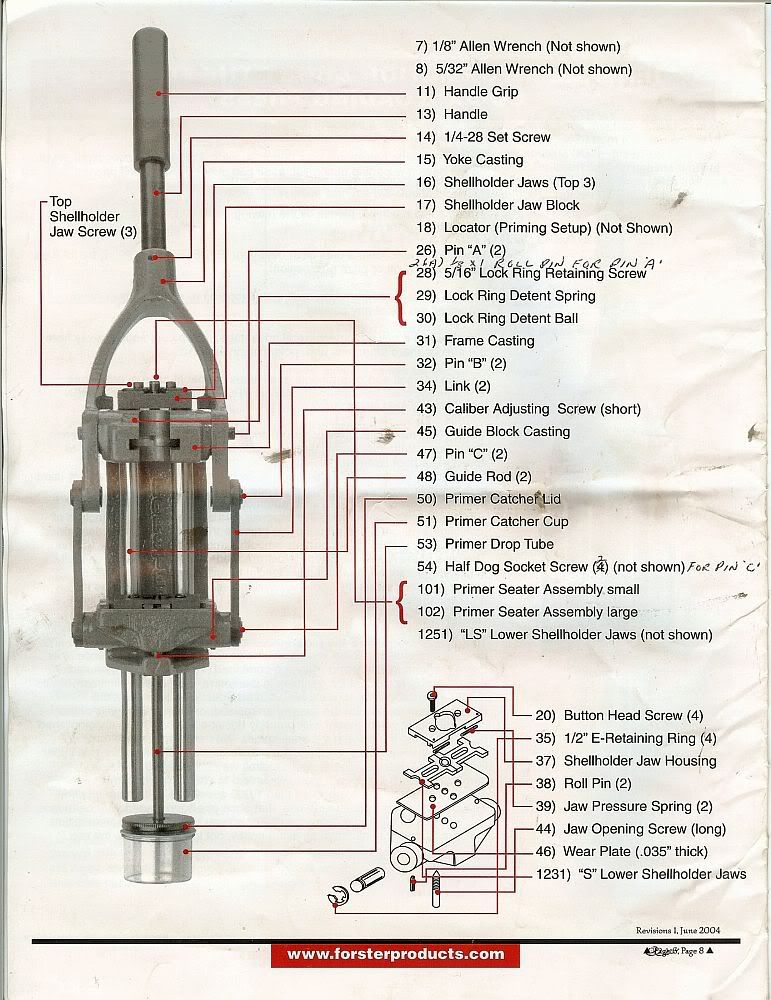

The slot the ring slides into and locks is in the

028271-031 RELOADING PRESS - FRAME CASTING (machined)$98.70

1) The Aluminum is die ring is softer than the cast iron frame, but stainless steel rings might gall when rubbed by insertion and removal of the die assembly.

http://en.wikipedia.org/wiki/Galling

Galling is two metals were rubbing of equal hardness.

2) Also the screw in the Aluminum die ring can make as tight as needed.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: samson</div><div class="ubbcode-body">What do you all think about using the stainless steel Sinclair lock rings instead of the Alum. Forster rings?

I'm not so worried about the Alum. rings wearing out but they fit kinda loose and the Sinclair rings are supposed to fit snugger but are the Forster Alum. rings fitting loose good or bad? </div></div>

The slot the ring slides into and locks is in the

028271-031 RELOADING PRESS - FRAME CASTING (machined)$98.70

1) The Aluminum is die ring is softer than the cast iron frame, but stainless steel rings might gall when rubbed by insertion and removal of the die assembly.

http://en.wikipedia.org/wiki/Galling

Galling is two metals were rubbing of equal hardness.

2) Also the screw in the Aluminum die ring can make as tight as needed.

Similar threads

- Replies

- 2

- Views

- 981