Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello,

I am trying to get the barrel off my RPR, but the barrel nut is tight. Can I put the action in a vise so I can apply more torque to the nut? Is that the proper way to do it? I have seen Franks vids and it shows the action in a vise, but not while he applying torque to the barrel nut. How do you guys get the nut off?

Thanks in advance.

I am trying to get the barrel off my RPR, but the barrel nut is tight. Can I put the action in a vise so I can apply more torque to the nut? Is that the proper way to do it? I have seen Franks vids and it shows the action in a vise, but not while he applying torque to the barrel nut. How do you guys get the nut off?

Thanks in advance.

Hello,

I am trying to get the barrel off my RPR, but the barrel nut is tight. Can I put the action in a vise so I can apply more torque to the nut? Is that the proper way to do it? I have seen Franks vids and it shows the action in a vise, but not while he applying torque to the barrel nut. How do you guys get the nut off?

Thanks in advance.

Better to put the barrel in a barrel vise. Then, if you really need to apply some extra ordinary force, you won't be damaging the receiver in any way. You don't want to warp the receiver in any way.

Anyone ever used the MDT AICS mags in the .308 with binder plate removed, 2.960 OAL internal. (Berger 185)

I use them in my 6.5 CM RPR. Work great. (I don't reload yet).

I use them in my 6.5 CM RPR. Work great. (I don't reload yet).

Okie, checking for a friend who wants to run the long Berger loads. The MDT site mentions maybe not working with three lug actions and/or catching on feed ramps.

Which Buttstock is that? Looks greatWell got around reloading some ammo, sadly my RPR doesn’t really like 100 gr bullets, but I got them on sale so have 455 rounds of plinking/practice rounds.

Also few new items, titanium fluted bolt shroud, accu-shot mono pod.

View attachment 7088531

Upgrading the RPR, does anyone have any great options for replacing the Buttstock. I have seen the Magpul PRS and Luth AR options but was looking to see if anyone had gone with something different while stile being an adjustable.

I was thinking of doing an MDT stock, but I hadn’t looked into it any further as of yet. They sell adapters, but not sure if they would work on the RPR.Upgrading the RPR, does anyone have any great options for replacing the Buttstock. I have seen the Magpul PRS and Luth AR options but was looking to see if anyone had gone with something different while stile being an adjustable.

Which Buttstock is that? Looks great

That’s an XLR stock. I had one on my AR15. They’re really nice. I had a Luth AR which was nice too. The Luth AR is a little lighter I think and no tools required to adjust it. The XLR is a little more quality in my opinion, and is heavier (I like weight on my rig), but you need a hex key to adjust it. I don’t do a whole lot of adjusting though so that didn’t matter to me

Krieger has barrels for the .300 win mag

Krieger Direct - Buy Krieger Barrels Online Today

Krieger Barrels Krieger Direct Productsdirect.kriegerbarrels.com

Im thinking about replacing the barrel on my .300 win mag. Only have 150 rounds through it but it's not very consistent. Sometimes can get a decent group but often not. I just think that you really need at least 10 round groups to see what a rifle is truly capable of achieving.

My stock Ruger RPR barrel Cooper fouls pretty quickly and in reality probably a 1.25-1.5 MOA rifle when looking at 10 round groups.

I think this rifle needs a true match grade barrel with a chamber that's better than the SAAMI MIN version Ruger uses. I think that why the creedmoore and PRC shoot better than the .308 and .300 win mag, the chamber design.

I hope the a new barrel with a match chamber delivers better accuracy than the stock barrel.

Too bad Ruger doesn't machine a chamber like the mk248 mod1 because then there might be some usefulness to the rifle as purchased in this caliber.

His website: https://ttprecisionproducts.com/Upgrading the RPR, does anyone have any great options for replacing the Buttstock. I have seen the Magpul PRS and Luth AR options but was looking to see if anyone had gone with something different while stile being an adjustable.

After reading through all 81 pages, i finally got to mount my Scope and Bipod last night (was waiting on the new rings) on my just purchased Gen 2 308 RPR. I got in on that killer GanderOutdoor $700 deal. The trigger is as crisp as my SAC .260 trigger, i cant wait to get her out to see how she shoots.

Im thinking about replacing the barrel on my .300 win mag. Only have 150 rounds through it but it's not very consistent. Sometimes can get a decent group but often not. I just think that you really need at least 10 round groups to see what a rifle is truly capable of achieving.

My stock Ruger RPR barrel Cooper fouls pretty quickly and in reality probably a 1.25-1.5 MOA rifle when looking at 10 round groups.

I think this rifle needs a true match grade barrel with a chamber that's better than the SAAMI MIN version Ruger uses. I think that why the creedmoore and PRC shoot better than the .308 and .300 win mag, the chamber design.

I hope the a new barrel with a match chamber delivers better accuracy than the stock barrel.

Too bad Ruger doesn't machine a chamber like the mk248 mod1 because then there might be some usefulness to the rifle as purchased in this caliber.

I decided to go for a kreiger prefit barrel. 26", 4 groove, 1:9 heavy contour with their match chamber that is SAAMI MIN spec but more importantly with a .165" long, .3085" diameter freebore. Not to mention truly precision cut rifling .

I have some other accurate rifles in my inventory so the mediocre performance of the stock RPR barrel made it a ho-hum shooting experience. Yeah it's extra $, but i figure if I'm going to spend a buck everytime I pull the trigger (handloads) then I might as well maximize the pleasure.

Anyone had any luck finding a magnum bolt head for a regular RPR? Looking at my current bolt (6mm Creed) I doubt it has enough material to open it up to magnum size. Wanting to rebarrel to 25 SAUM

After reading through all 81 pages, i finally got to mount my Scope and Bipod last night (was waiting on the new rings) on my just purchased Gen 2 308 RPR. I got in on that killer GanderOutdoor $700 deal. The trigger is as crisp as my SAC .260 trigger, i cant wait to get her out to see how she shoots. View attachment 7142959

Nice. Feel the power of the .308! The best factory ammo I’ve used was Nosler Custom 168 gr. Long range factory it liked 178 gr Hornady Superformance. Reloading it likes it heavy. Very heavy.

@REL1203 Is that how you have the rifle set to actually shoot? I Got a RPR 6.5GenIII for my son and he says that he needs the stock set just about at the limits, like yours is. It seems waaay long to me, but he is 6"1' and I'm 5" Worked it out to 550yards and are pretty happy with the accuracy.

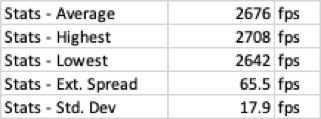

RPRIII with Hornday 6.5CM 147gr (20 shots)

RPRIII with Hornday 6.5CM 140Gr (10 Shots)

I was surprised that the 140s weren't faster.

RPRIII with Hornday 6.5CM 147gr (20 shots)

RPRIII with Hornday 6.5CM 140Gr (10 Shots)

I was surprised that the 140s weren't faster.

With 2700 rounds through my RPR 6.5-CM, I thought I should try to break down the bolt and give it a cleaning for the first time.  I've had some light primer strikes out at the range recently. I thought maybe cleaning the bolt and firing pin might help.

I've had some light primer strikes out at the range recently. I thought maybe cleaning the bolt and firing pin might help.

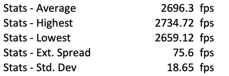

I watched Ruger's video on Youtube. Easy enough. When I pivoted the plastic firing pin removal tool, the two tabs broke! On the very first use! That's pretty pathetic! So, I just ordered the titanium shroud and tool from Anarchy Outdoors. There goes another $100! LOL!

I watched Ruger's video on Youtube. Easy enough. When I pivoted the plastic firing pin removal tool, the two tabs broke! On the very first use! That's pretty pathetic! So, I just ordered the titanium shroud and tool from Anarchy Outdoors. There goes another $100! LOL!

@REL1203 Is that how you have the rifle set to actually shoot? I Got a RPR 6.5GenIII for my son and he says that he needs the stock set just about at the limits, like yours is. It seems waaay long to me, but he is 6"1' and I'm 5" Worked it out to 550yards and are pretty happy with the accuracy.

Nice work!

I’m 6’2” and my stock is pretty much maxed as well. Me thinks that cheek riser will come up a bit though..

With 2700 rounds through my RPR 6.5-CM, I thought I should try to break down the bolt and give it a cleaning for the first time.I've had some light primer strikes out at the range recently. I thought maybe cleaning the bolt and firing pin might help.

I watched Ruger's video on Youtube. Easy enough. When I pivoted the plastic firing pin removal tool, the two tabs broke! On the very first use! That's pretty pathetic! So, I just ordered the titanium shroud and tool from Anarchy Outdoors. There goes another $100! LOL!

View attachment 7143245

View attachment 7143246

That blows! LRI sells one for $34.99. Everyone should just buy one now lol

LRI Ruger RPR Fire Control Disassembly Tool

LRI's RPR Fire Control Disassembly Tool is designed as a replacement of the plastic piece included when you purchase a new RPR rifle. Our tool is CNC machined from bar stock 4140 Chromoly Steel and is heat treated to last a lifetime. With the addition of the key ring, this tool can be...

www.longriflesinc.com

@REL1203 Is that how you have the rifle set to actually shoot? I Got a RPR 6.5GenIII for my son and he says that he needs the stock set just about at the limits, like yours is. It seems waaay long to me, but he is 6"1' and I'm 5" Worked it out to 550yards and are pretty happy with the accuracy.

RPRIII with Hornday 6.5CM 147gr (20 shots)

I was surprised that the 140s weren't faster.

I am 6'5 so yeah, it feels best when its maxed out like that for me. I will update you if you like once I get to shoot her this friday finally. I am generally a Benchrest shooter (not a prone shooter), so longer works for me. I am still not 100% sold on this stock though, I have a spare Magpul PRS that might find its home on this one next month if things dont go well.

I am 6'5 so yeah, it feels best when its maxed out like that for me. I will update you if you like once I get to shoot her this friday finally. I am generally a Benchrest shooter (not a prone shooter), so longer works for me. I am still not 100% sold on this stock though, I have a spare Magpul PRS that might find its home on this one next month if things dont go well.

The factory stock works well for me. Especially since I don’t really adjust it much. I guess a little more weight would be nice. The only thing I don’t like about it is how many smaller pieces it’s actually made up from. This part has come loose. That part has come loose. I’ve ended up blue loctiting the whole thing.

I haven't had any real issue with the factory stock. I really like how I can fit it to me and shrink it down so my 7 year old can shoot it. Its not the best looking stock, but it is very adjustable.The factory stock works well for me. Especially since I don’t really adjust it much. I guess a little more weight would be nice. The only thing I don’t like about it is how many smaller pieces it’s actually made up from. This part has come loose. That part has come loose. I’ve ended up blue loctiting the whole thing.

Okie, checking for a friend who wants to run the long Berger loads. The MDT site mentions maybe not working with three lug actions and/or catching on feed ramps.

I haven't had a problem with mine.

Hello,

I am trying to get the barrel off my RPR, but the barrel nut is tight. Can I put the action in a vise so I can apply more torque to the nut? Is that the proper way to do it? I have seen Franks vids and it shows the action in a vise, but not while he applying torque to the barrel nut. How do you guys get the nut off?

Thanks in advance.

Use a dead-blow hammer on the barrel nut wrench. 2-3 solid hits and the barrel nut should break loose and spin right off. Gently increasing torque with a cheater bar ain't gonna do it. You need a sharp impact.

Picked mine up from my local FFL shop yesterday, but it is still in the box (3rd gen, 6.5 creedmoor). Will hopefully get it all set it up this weekend. Psyched!!

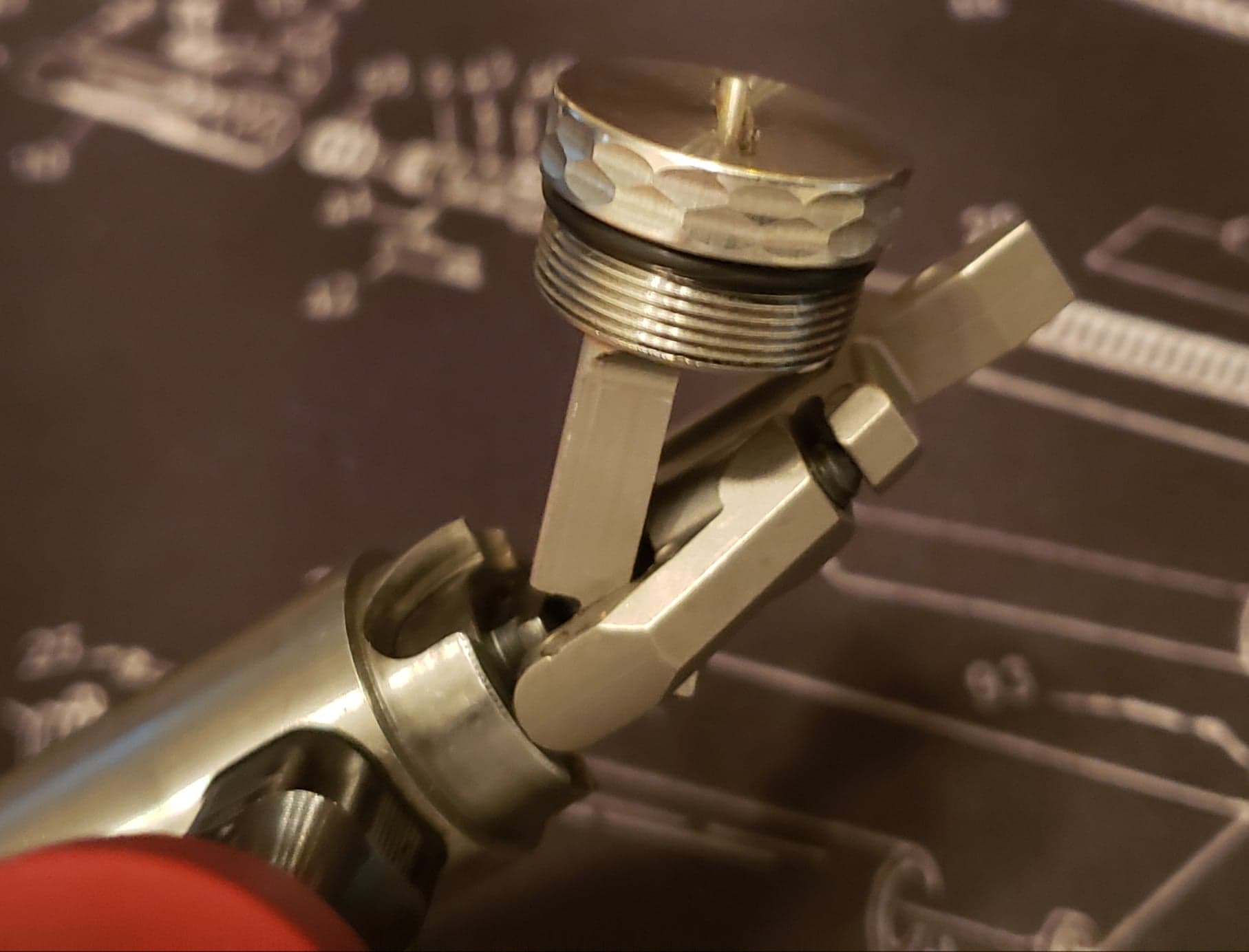

Just installed a new, pre-fit Krieger barrel on my .300 win mag RPR.

26", 1:9 rifling, with match chamber (0.165" long, 0.3085 diameter lead), slightly heavier contour than stock.

Anxious to try it out. Gonna start with the load that worked best with stock barrel but with CBTO tweaked for this chamber

225gr Hornady ELD M

76.8gr H1000

FED GMM215M primer

Win brass

.030" off lands

Hint get the LRI barrel nut wrench if you plan to swap barrels on a magnum. Expensive but works great. The standard AR15 wrench wont work on the magnum. I spent extra $ on the LRI barrel nut wrench , good barrel vise and gauges but they are essential. If you plan on doing more than one barrel swap then buy the tools vs sending it out for a swap.

Last edited:

Did you take any pics while you did the swap? Hope it shoots great, I'm sure it will. How many rounds did you get out of the stock barrel?

No pics. I got 163 rounds out of the stock barrel. Wanted better accuracy and I didn't want to shoot another 1000 rounds before it wore out and got a true match grade barrel. Ruger uses a standard SAAMI min chamber which isn't conducive to consistent accuracy. Yeah you could get an occasional .75 MOA 5 shot group but not without some bigger groups as well. The 6.5 creedmoor has a much better saami chamber so they shoot better stock. Ruger should sell the magnum rifle without a barrel to lower the cost. That way you can invest in one decent barrel and not have a worthless pipe when you're done.

I do not have the magnum, but I am getting ready to change my first RPR barrel (first barrel on anything other than a 10/22). What tools did you use? Did you use a barrel vise, action wrench, combination of the two?No pics. I got 163 rounds out of the stock barrel. Wanted better accuracy and I didn't want to shoot another 1000 rounds before it wore out and got a true match grade barrel. Ruger uses a standard SAAMI min chamber which isn't conducive to consistent accuracy. Yeah you could get an occasional .75 MOA 5 shot group but not without some bigger groups as well. The 6.5 creedmoor has a much better saami chamber so they shoot better stock. Ruger should sell the magnum rifle without a barrel to lower the cost. That way you can invest in one decent barrel and not have a worthless pipe when you're done.

I do not have the magnum, but I am getting ready to change my first RPR barrel (first barrel on anything other than a 10/22). What tools did you use? Did you use a barrel vise, action wrench, combination of the two?

Barrel vice, barrel nut/acton wrench and an action rod: https://www.anarchyoutdoors.com/action-rod-for-ruger-precision-ruger-american-rifles/

And don't forget, you'll need the go and no-go gauges too.

Pretty easy with these tools.

Last edited:

I do not have the magnum, but I am getting ready to change my first RPR barrel (first barrel on anything other than a 10/22). What tools did you use? Did you use a barrel vise, action wrench, combination of the two?

Barrel vise, LRI action wrench, torque wrench , go / no-go gauges

I just traded a howa to a buddy for his 6.5 rpr. I had the 6CM RPR and miss it dearly. Probably going to build this out like my las. Prs stock, Timney and put a 6mm barrel on it so I don’t have 3 6.5’s lol

I am looking at changing the Buttstock on the RPR to the XLR industries Tactical stock. Aside from the stock what else do i need to purchase to swap it out? Also will the folding mechanism stay in place?

Thanks!

XLR will provide you with everything you need and since the buffer tube threads into the RPR’s folding mechanism, the ability to fold will remain in tact. I had an XLR stock on an AR15 and they are the bomb

I got one in last week. Have not made it to the range yet and still need to get it set-up correctly. Post back if you make it to the range and how it performed.Anyone get a RPR in .300 PRC yet? Just mounted my scope to mine. Ammo comes this week.

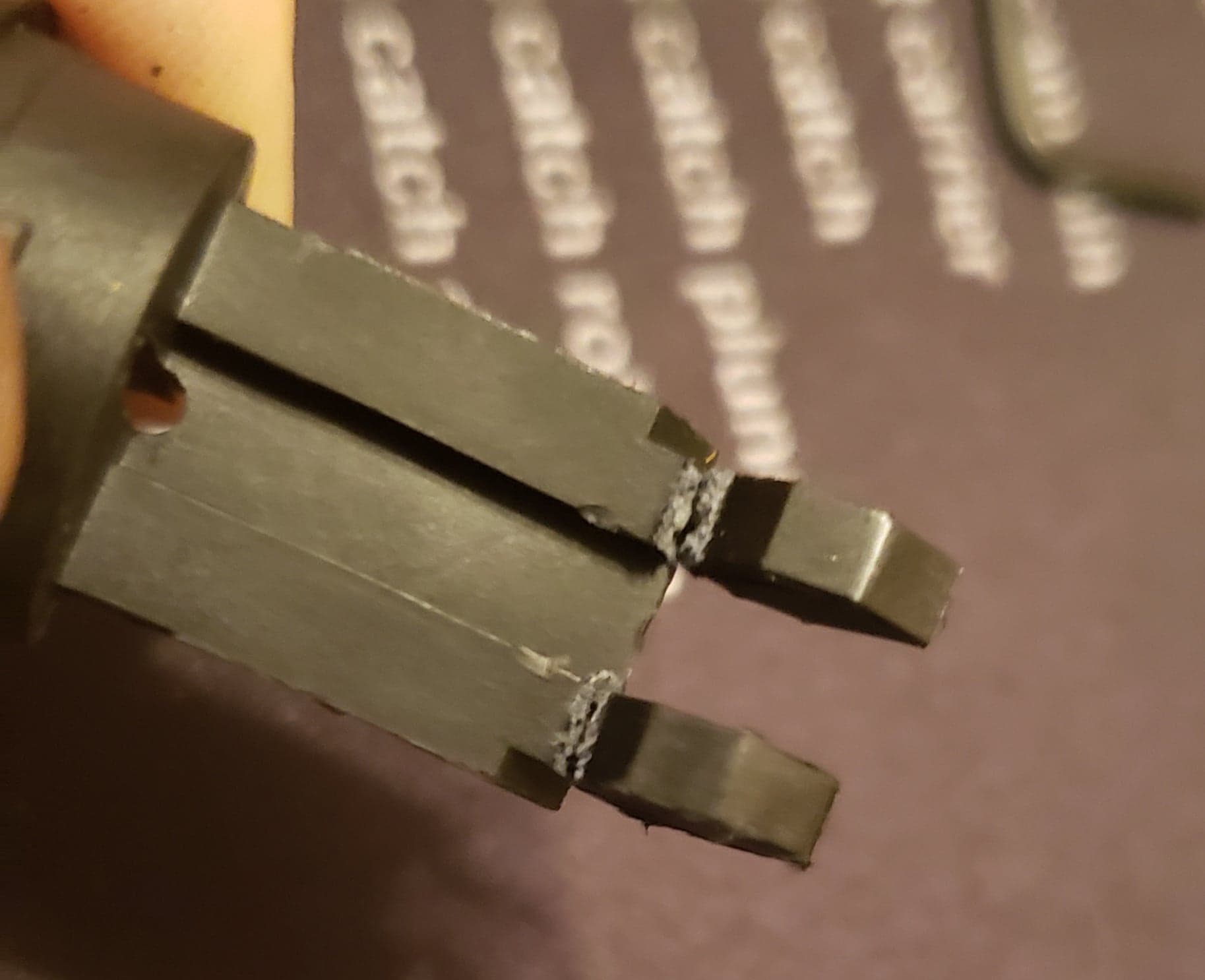

Following up to my RPR bolt tool breaking on me while trying to disassemble my bolt.

I got my titanium bolt shroud and bolt tool from Anarchy. It's a nice bit of kit.

But, now I know why the plastic tool broke. My bolt WILL NOT come apart. Even with the titanium tool. I insert it, and I can pivot the tool about 45-degrees, and THAT'S IT. It will not swing around to 90-degrees. Will. Not. I've tried and tried, using a fairly significant amount of force.

WTF is the problem??

Bolt rotated and aligned

This is as far as I can pivot the tool. I can put all my weight on it, and it will not budge any further.

Another view of the tool in place. It will not go past this position. It will not pivot to 90 degrees.

I've tried inserting the tool from both sides... It will not budge past 45-degrees. I've already suffered injuries from trying so hard to make this thing work!

In every video I've seen, the tool pivots EASILY. This is driving me crazy. I've tried inserting the tool from both sides. Same problem. I cannot get it to swing past 45-degrees. What is going on here? Thanks for any help!

I got my titanium bolt shroud and bolt tool from Anarchy. It's a nice bit of kit.

But, now I know why the plastic tool broke. My bolt WILL NOT come apart. Even with the titanium tool. I insert it, and I can pivot the tool about 45-degrees, and THAT'S IT. It will not swing around to 90-degrees. Will. Not. I've tried and tried, using a fairly significant amount of force.

WTF is the problem??

Bolt rotated and aligned

This is as far as I can pivot the tool. I can put all my weight on it, and it will not budge any further.

Another view of the tool in place. It will not go past this position. It will not pivot to 90 degrees.

I've tried inserting the tool from both sides... It will not budge past 45-degrees. I've already suffered injuries from trying so hard to make this thing work!

In every video I've seen, the tool pivots EASILY. This is driving me crazy. I've tried inserting the tool from both sides. Same problem. I cannot get it to swing past 45-degrees. What is going on here? Thanks for any help!

I have a question for all of you out there that have an RPR but also have higher dollar custom guns. I am trying to figure out a way to ask this without sounding like an A-hole, but I am not having much luck.

When comparing an RPR against a custom or higher quality rifle, do you feel like it's missing out on anything other than fit and finish?

I like my RPR a lot, it has served me well, but I keep dreaming of something better. But if I spend a few thousand dollars on a new rifle, am I going to get that much more out of it, or is my vanity just getting the best of me?

When comparing an RPR against a custom or higher quality rifle, do you feel like it's missing out on anything other than fit and finish?

I like my RPR a lot, it has served me well, but I keep dreaming of something better. But if I spend a few thousand dollars on a new rifle, am I going to get that much more out of it, or is my vanity just getting the best of me?

I have a question for all of you out there that have an RPR but also have higher dollar custom guns. I am trying to figure out a way to ask this without sounding like an A-hole, but I am not having much luck.

When comparing an RPR against a custom or higher quality rifle, do you feel like it's missing out on anything other than fit and finish?

I like my RPR a lot, it has served me well, but I keep dreaming of something better. But if I spend a few thousand dollars on a new rifle, am I going to get that much more out of it, or is my vanity just getting the best of me?

In my opinion, the barrel quality is the biggest difference. Just budget an extra $500-600 for a premium barrel (e.g bartlein, Krieger, etc) and swap it on your RPR.

The trigger might be another upgrade but mine was pretty good from factory and certainly not limiting factor so not planning to change it .

A barrel swap is planned after my local season ends, I have just over 1600 6mm creedmoors through it now. A few people have suggested triggers, but I haven't had an issue with mine.In my opinion, the barrel quality is the biggest difference. Just budget an extra $500-600 for a premium barrel (e.g bartlein, Krieger, etc) and swap it on your RPR.

The trigger might be another upgrade but mine was pretty good from factory and certainly not limiting factor so not planning to change it .

Following up to my RPR bolt tool breaking on me while trying to disassemble my bolt.

I got my titanium bolt shroud and bolt tool from Anarchy. It's a nice bit of kit.

But, now I know why the plastic tool broke. My bolt WILL NOT come apart. Even with the titanium tool. I insert it, and I can pivot the tool about 45-degrees, and THAT'S IT. It will not swing around to 90-degrees. Will. Not. I've tried and tried, using a fairly significant amount of force.

WTF is the problem??

Bolt rotated and aligned

View attachment 7150347

This is as far as I can pivot the tool. I can put all my weight on it, and it will not budge any further.

View attachment 7150348

Another view of the tool in place. It will not go past this position. It will not pivot to 90 degrees.

View attachment 7150350

I've tried inserting the tool from both sides... It will not budge past 45-degrees. I've already suffered injuries from trying so hard to make this thing work!

View attachment 7150351

In every video I've seen, the tool pivots EASILY. This is driving me crazy. I've tried inserting the tool from both sides. Same problem. I cannot get it to swing past 45-degrees. What is going on here? Thanks for any help!

Hello Racer88, I have the same Anarchy bolt shroud but had never used the take down tool until now. Slipped in and rotated just fine. From the photos it appears you might have inserted the tool too far and the tool is binding on the rear of the firing pin, that it is supposed to depress. Just a thought.

Hello Racer88, I have the same Anarchy bolt shroud but had never used the take down tool until now. Slipped in and rotated just fine. From the photos it appears you might have inserted the tool too far and the tool is binding on the rear of the firing pin, that it is supposed to depress. Just a thought.

Thanks for replying. I've tried it in every way possible... including not inserting it so far. I'm really quite mechanically-inclined and do not normally have trouble with things like this. I cannot figure this one out. It goes to 45-degrees and stops dead. Not a tiny bit more. It's enough to actually get the firing pin assembly out, but I'm afraid that once I do that, the tool will slip out (since it's not locked in) and then make things VERY difficult to get back together.

Can you provide photos of the take down tool from a few different angles. I could compare it to mine, there might be some machining irregularities that are not to spec.

Also are the lugs of the firing pin in alignment with the rear bolt housing?

I have also allowed the tool to slip out and it is a pain to put back together. Thought I had it reassembled correctly. Went to the range posted my targets and got everything setup to shoot. Inserted mag and pushed the bolt handle forward. The bolt will disassemble inside the rifle if the lugs of the firing pin are not seated properly in the bolt handle. Not something easily fixed at the range!

Best of luck

Also are the lugs of the firing pin in alignment with the rear bolt housing?

I have also allowed the tool to slip out and it is a pain to put back together. Thought I had it reassembled correctly. Went to the range posted my targets and got everything setup to shoot. Inserted mag and pushed the bolt handle forward. The bolt will disassemble inside the rifle if the lugs of the firing pin are not seated properly in the bolt handle. Not something easily fixed at the range!

Best of luck

Can you provide photos of the take down tool from a few different angles. I could compare it to mine, there might be some machining irregularities that are not to spec.

Also are the lugs of the firing pin in alignment with the rear bolt housing?

I have also allowed the tool to slip out and it is a pain to put back together. Thought I had it reassembled correctly. Went to the range posted my targets and got everything setup to shoot. Inserted mag and pushed the bolt handle forward. The bolt will disassemble inside the rifle if the lugs of the firing pin are not seated properly in the bolt handle. Not something easily fixed at the range!

Best of luck

I don't believe it's the tool. It's the bolt or pin assembly. I tried using the OEM plastic tool, and it broke on the first try to pivot it into the slots.

I don't believe it's the tool. It's the bolt or pin assembly. I tried using the OEM plastic tool, and it broke on the first try to pivot it into the slots.

View attachment 7150569

In comparing mine to your pic, it appears it's different at the top of the bolt where the firing pin assembly makes contact with it. Now . . . mine is a Gen 2 RPR with over 5500 firings. I've not had any issues that you're having. But I don't know if this difference between yours and mine is the problem for you . . .???

In comparing mine to your pic, it appears it's different at the top of the bolt where the firing pin assembly makes contact with it. Now . . . mine is a Gen 2 RPR with over 5500 firings. I've not had any issues that you're having. But I don't know if this difference between yours and mine is the problem for you . . .???

View attachment 7150646

What is different? Mine is also a Gen 2. Looks exactly the same to me, except mine has a "3" engraved, where yours has a "4."

View attachment 7150652

What is different? Mine is also a Gen 2. Looks exactly the same to me, except mine has a "3" engraved, where yours has a "4."

The shadow on top makes it unclear, but it appears to me that that notched down part that is in contact with the bolt is lower than mine (the part just above the firing pin "T"). . . .??? The shadow appears to be level with where contact is made with the bolt???

Similar threads

- Replies

- 0

- Views

- 153

- Replies

- 13

- Views

- 599

- Replies

- 3

- Views

- 401

- Replies

- 17

- Views

- 934