Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SD and ES inconsistencies

- Thread starter Gd33333

- Start date

I do have a bore scope so I will take a look for any carbon buildup. As far as the velocity node, I graph out 5-6 five shot groups shooting round robin looking for velocity plateaus only. Not worrying about small groups. Will tighten groups with seating depth later.My process starting from post-firing:

1) Deprime

2) Clean in ultrasonic

3) Anneal

4) FL Size

5) Neck lube with moly

6) Mandrel

7) Trim

8) Neck lube again

9) Charge

10) Seat with an arbor press and LE Wilson seaters

Three things:

1) If you're not using something that attacks carbon, then it is likely you've got some buildup going that could be causing what you're seeing. Get a good carbon cleaner and run patches through using the process I outline below - but let sit longer. Or you could plug the end of the barrel, stand it up with muzzle down, fill it with some carbon solvent, and let sit overnight, then do the process.

2) I only use brass brushes when absolutely necessary. If you scrub a barrel enough with them, it will negatively affect the barrel. Same thing with abrasive cleaners.

3) You might be getting some copper buildup as well. The process you're using will get some copper out, but certainly not all.

My process:

1) Run two wet patches soaked in Boretech Eliminator - I mean SOAKED

2) Let sit for 15 minutes or so

3) Run a couple dry patches through

4) Repeat the above steps until you get only very light blue (or none) and very light/no carbon.

Then:

5) Clean behind the lugs

6) Mop the chamber

If I'm fighting carbon, then putting patches around a used nylon brush (vs. a jag) will put more uniform pressure against the barrel and seems to be more effective in pulling the carbon out.

If I'm fighting a carbon ring in the chamber, then I put in a +1 size nylon brush (e.g. for my 300, I use a 338 brush) into the chamber with a patch around it soaked in carbon cleaner. The bigger brush + patch will be too big to get into the barrel, so stops at the end of the chamber. I let that sit for a long time (overnight usually), then twist it in the chamber. Repeat as necessary. Carbon rings are a bitch to remove, but I've found this to be at least somewhat effective.

Lastly, I just reread your original post. You mention finding a velocity node. I do a lot more ELR than anything else, so I care about SDs more than someone doing PRS, as an example. My definition of a velocity "node" is one that gives me the best SDs, not the best group size. Once you find that SD sweet spot, then tune for group size using seating depth.

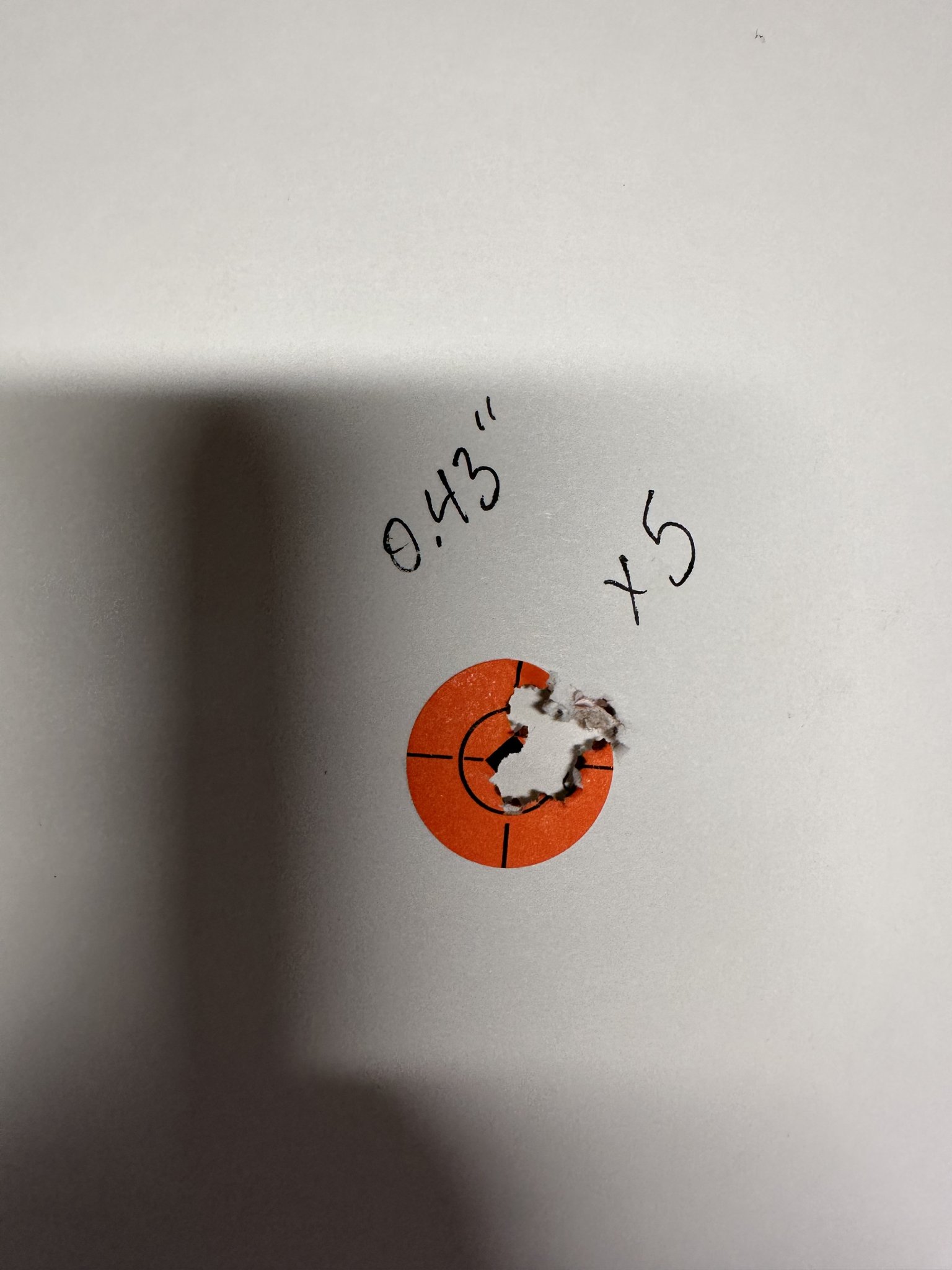

On my 300's new barrel, I found a velocity range that's delivering good SDs, then on my last trip to the range I did a seating depth test (then validated at 500 yards with 5 shots - then 850 with a bunch - no grouping pic because it was a frikking bog out there and I couldn't get to the target):

View attachment 8370939

View attachment 8370937

I’m shooting sub 1/2moa consistently which has me scratching my head on the chronograph. Will definitely be looking for a radar to compare.Put it on paper and see if it shoots to your satisfaction and work from there.

Numbers on a digital screen don’t equal results.

ThanksAdding thoughts to post #16: Primer seating....primer is seated correct when ,after firing and deprimed ,the primer pocket will look like 3 perfect pizza slices . Iffin the primer pocket is blacked all over the bottom....it ain't right imo.

I've used a hand primer, but couldn't get consistent results described above. "Shootin Buddy" gave me a rcbs ram primer and consistency improved greatly,resulting in a lot less "what da hell " happened there moments.All the " little" things done during handloading ,that some think unnecessary, add up to more consistent ammo ,for me.......and that's what we are trying to accomplish, right?

Last thought: as stated in noted post, if yo firing mechanism is out of wack.......you gonna be chasing your tail,until it is corrected.

So what do you do at that point if you’re getting varying results?Measuring before and after gives you a measurement of the "neck tension" without considering the neck wall thickness. Like, if the before measurement is .280" and after seating it measures .282", then you've got .002" "neck tension".

As BuildingConceptsIIc says, after cases are fire formed to your chamber (takes ~2 firings to really get that), the cartridges do become more consistent and gives better results. And at that point, it's actually good not to remove the powder residue from the inside of the necks as it acts as a lube.Will do. Thanks again!

If that's the case......at distance, 500 yrds and out... Throw chronograph in trash can and rock on rocker.I’m shooting sub 1/2moa consistently which has me scratching my head on the chronograph. Will definitely be looking for a radar to compare.

The neck wall thickness will vary on a single case. . . like it's not unusual to see .0015 and on poorer cases >.002". You can see this with a caliper as you turn the neck while measuring with the caliper. So, you can just see what the average of the change on a given case and to with that number. Better quality cases, like Lapua, have some variation, but it's not much over .001". That issue is only important if the variation is large as the smaller variations won't make any noticeable difference, especially out of an RPR.So what do you do at that point if you’re getting varying results?

I have to RPR's, one is .308 and the other is 6.5 PRC, and though I use Lapua brass that have small variations, I'd just like to make my brass as perfect as possible. Therefore, I turn my necks to make them without such variations.

"still hits within a half MOA 69% of the time"

That's why I still get 9's

I don't play that game, but isn't the 10 ring 1 MOA with a .5 MOA X ring? That would mean 20-14X, roughly?

In a tunnel, with a LaserI don't play that game, but isn't the 10 ring 1 MOA with a .5 MOA X ring? That would mean 200-14X, roughly?

I put a .22 group SD (about a half MOA gun) in the calc.In a tunnel, with a Laser

I’m tempted. Just bugging me. LolIf that's the case......at distance, 500 yrds and out... Throw chronograph in trash can and rock on rocker.

I don’t have a neck turning device but have contemplated getting one.The neck wall thickness will vary on a single case. . . like it's not unusual to see .0015 and on poorer cases >.002". You can see this with a caliper as you turn the neck while measuring with the caliper. So, you can just see what the average of the change on a given case and to with that number. Better quality cases, like Lapua, have some variation, but it's not much over .001". That issue is only important if the variation is large as the smaller variations won't make any noticeable difference, especially out of an RPR.

I have to RPR's, one is .308 and the other is 6.5 PRC, and though I use Lapua brass that have small variations, I'd just like to make my brass as perfect as possible. Therefore, I turn my necks to make them without such variations.

Dang, Maury....you just a gift that keeps on giving, ain't cha'? lolNo one cares about your rudimentary understanding of stats. No one is impressed by you conflating a non-issue to feel smart.

truth hurts - spot the lie.Dang, Maury....you just a gift that keeps on giving, ain't cha'? lol

As BuildingConceptsIIc says, after cases are fire formed to your chamber (takes ~2 firings to really get that), the cartridges do become more consistent and gives better results. And at that point, it's actually good not to remove the powder residue from the inside of the necks as it acts as a lube.

To drive this point home, I was out at the range today validating some loads before heading out to the hills this weekend. One such load was for my 300, which was still gaining velocity during my last trip, which took it out of the nice zone for SDs. I backed the load off a bit to get the speed back in "the zone" - which is in the ~2900 fps range. I loaded 10 rounds, ditched the cold bore shot from the group, and got the following:

Twice-fired

2897.8

2904.5

2902.8

2904.6

2898.4

2897.6

2899.8

2904.5

2904.0

Average 2901.56 fps

Std Dev 2.9 fps

I also loaded 6 rounds with the same load in virgin brass:

Virgin

2916.0

2910.6

2887.1

2921.1

2917.0

2905.3

Average 2909.5 fps

Std Dev 11.2 fps

Granted, the sample sizes are small, but there is a clear and substantial difference between the two.

^^^ THIS IS THE ESSENCE of small sample sizes! Things that look different aren't!

we're going to see a lot more of this now that guys are measuring every shot with the Garmin.

These small samples, selectively reported, showing SD of 3.4 over 5 shots are going to magically disappear like unicorn semen

we're going to see a lot more of this now that guys are measuring every shot with the Garmin.

These small samples, selectively reported, showing SD of 3.4 over 5 shots are going to magically disappear like unicorn semen

^^^ THIS IS THE ESSENCE of small sample sizes! Things that look different aren't!

we're going to see a lot more of this now that guys are measuring every shot with the Garmin.

These small samples, selectively reported, showing SD of 3.4 over 5 shots are going to magically disappear like unicorn semen

Sort of, but not really. When you have a substantial difference, even in a small sample size, the chances of two matching up with each other after a statistically valid sample size is run diminish over time.

As an example, for the two groups of rounds to match up at, say, an SD of 8 after 20 shots, the next 11 shots in the twice-fired group would have to drop from the 2.9 over the first nine shots to somewhere around 10 over the next 11 shots. Possible, but unlikely. For the virgin brass to match up at that same 8 SD over the next 14 shots, it would have to magically go from 11.2 over 6 shots to somewhere in the neighborhood of 4 for the next 14. Exceedingly unlikely.

I cannot from the data above tell you that twice-fired brass is exactly 11.2/2.9 = 3.86x better SDs than virgin - but I can tell you with good confidence that one set is measurably better than the other. You don't need sample size = 30 to tell you that.

yes, if P< alpha, you reject null, even if the sample size is way underpowered. However, if you're a Bayesian, the posterior probability is lower if you're underpowered (small sample size).

The problem is this does not account for selective reporting, which is a practical/philosophical matter more than a statistical matter. Discussed here: https://www.cambridge.org/core/book...vere-testing/D9DF409EF568090F3F60407FF2B973B2

Small samples, in my estimation, are not "severe tests" of the null hypothesis and are too easy to selectively report.

If he repeats them again, with larger sample and the results are replicable, we will have the bonus of a narrower confidence interval for the true difference, too.

The problem is this does not account for selective reporting, which is a practical/philosophical matter more than a statistical matter. Discussed here: https://www.cambridge.org/core/book...vere-testing/D9DF409EF568090F3F60407FF2B973B2

Small samples, in my estimation, are not "severe tests" of the null hypothesis and are too easy to selectively report.

If he repeats them again, with larger sample and the results are replicable, we will have the bonus of a narrower confidence interval for the true difference, too.

Last edited:

Update: I spoke with Caldwell regarding my chronograph and was told the erratic velocities may be because my muzzle was too close to the chrono (~10ft). I ran to the range today and tried 15ft and even 20ft. The numbers were worse than before. This group pictured is the once fired SL brass with small magnum primers. I tried the same load with once fired brass and non-magnum primers and only took one shot as the firing pin damn near poked through the primer. I also tried a box of Hornady Precision Hunter as suggested to see if my loading was the problem. Same results. I seen velocities from 3700 down to 2100. With those numbers and this group at 100, I think it’s fairly safe to say it’s the chronograph. I haven’t been able to locate a lab radar or Garmin to verify yet. May have to just bite the bullet and get one. Thanks everyone for your input. I appreciate your time.

I'd say the chrono is definitely a problem if you got those kind of readingsUpdate: I spoke with Caldwell regarding my chronograph and was told the erratic velocities may be because my muzzle was too close to the chrono (~10ft). I ran to the range today and tried 15ft and even 20ft. The numbers were worse than before. This group pictured is the once fired SL brass with small magnum primers. I tried the same load with once fired brass and non-magnum primers and only took one shot as the firing pin damn near poked through the primer. I also tried a box of Hornady Precision Hunter as suggested to see if my loading was the problem. Same results. I seen velocities from 3700 down to 2100. With those numbers and this group at 100, I think it’s fairly safe to say it’s the chronograph. I haven’t been able to locate a lab radar or Garmin to verify yet. May have to just bite the bullet and get one. Thanks everyone for your input. I appreciate your time.

View attachment 8373526

I wouldn’t hump a labgaydar with your dick, if building concepts were pushing

Just get a Garmin and never look back. Maybe a used magnet to speed, but not a labgaydar.

Just get a Garmin and never look back. Maybe a used magnet to speed, but not a labgaydar.

Yeah , there's really no point in even messing with it without a good chrono. There's plenty of magneto speeds available used for cheap. With a mount (though I modified my mk mount to make it a lot better), they are extremely reliable.I wouldn’t hump a labgaydar with your dick, if building concepts were pushing

Just get a Garmin and never look back. Maybe a used magnet to speed, but not a labgaydar.

That said, the Garmin makes it all SOOOOOOO much easier and better. It's probably the best $600 I've ever spent. Check out active junky and then buy from Cabelas or bass pro and get either 5 or 8% more off. Definitely worth the money

I wouldn’t hump a labgaydar with your dick, if building concepts were pushing

Just get a Garmin and never look back. Maybe a used magnet to speed, but not a labgaydar.

Update: so I purchased a MagneetoSpeed V3 and ran the same loads through. Ended with a SD of 2.4 with a ES of 7. What a waste of time and money a cheap chronograph can cause. Thanks for everyone’s input and help on the matter.

Similar threads

- Replies

- 4

- Views

- 563

- Replies

- 3

- Views

- 544