This is my first attempt at this. I bought this B&C M40 style stock and wanted to give the whole texturing thing a try. So I taped it off and had a hard time getting things to look nice and even using 1/8th inch blue fine line tape and then taping the rest off with some green masking tape.

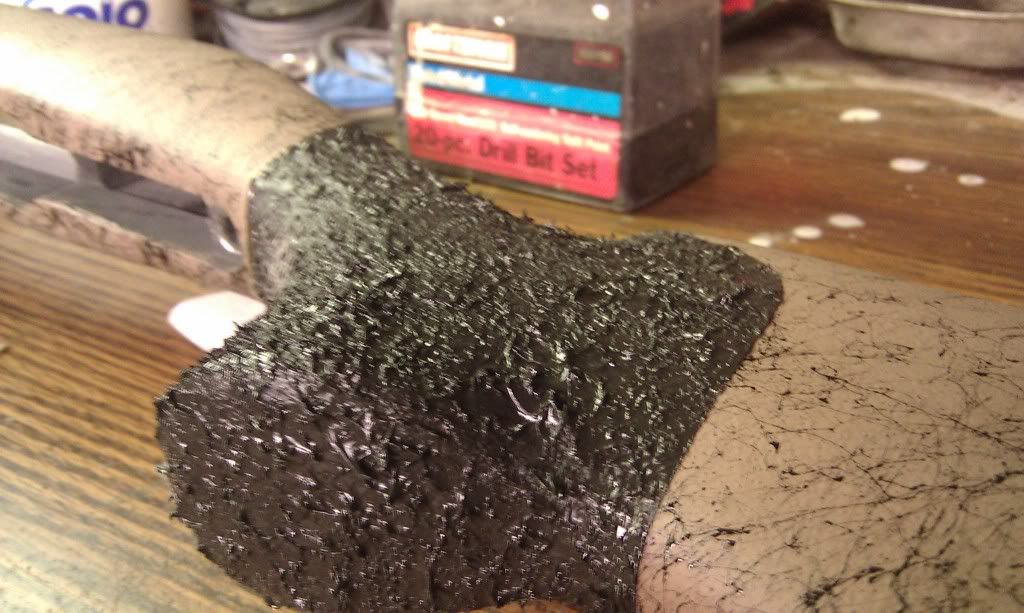

Then I sanded the open areas with 120 grit sand paper. I wiped it down with acetone a couple times to make sure it was clean. Next I mixed up some Marine-Tex and spread it on with a plastic knife that was serrated. I read previous threads and saw one where a guy said he cut 1/16th inch gaps in his spreader to apply and then smoothed it out with another straight spreader. I thought that was a good idea to get a nice even coating. The plastic serrated knife worked out well and I never hit it with a smooth spreader at all. Then I used a damp sponge to texture the Marine-Tex and it spread out and covered all the areas that were not really covered with Marine-Tex.

Now I'm just gonna let it set up some and remove the tape. I think I need to get it off before it gets completely set up, so I don't have any issues with the Marine-Tex peeling off.

So what do you think so far? I'll post finished pics, possibly tomorrow after it's all set up. I hope it turns out well or I just wasted my time, money, and sanded part of the tan/black web finish off!

Then I sanded the open areas with 120 grit sand paper. I wiped it down with acetone a couple times to make sure it was clean. Next I mixed up some Marine-Tex and spread it on with a plastic knife that was serrated. I read previous threads and saw one where a guy said he cut 1/16th inch gaps in his spreader to apply and then smoothed it out with another straight spreader. I thought that was a good idea to get a nice even coating. The plastic serrated knife worked out well and I never hit it with a smooth spreader at all. Then I used a damp sponge to texture the Marine-Tex and it spread out and covered all the areas that were not really covered with Marine-Tex.

Now I'm just gonna let it set up some and remove the tape. I think I need to get it off before it gets completely set up, so I don't have any issues with the Marine-Tex peeling off.

So what do you think so far? I'll post finished pics, possibly tomorrow after it's all set up. I hope it turns out well or I just wasted my time, money, and sanded part of the tan/black web finish off!