you're a fking tool, a fanboi worse than the Colt guys of old. Your'e only retort is to call me a troll, lol, that's rich. I can see through yours and OPs stench of virtually kicking the dirt off your kneepads over a rifle that quite frankly, is overpriced, offers nothing innovative, a company with shitty customer support, continuously drops products and lines in favor of the next soup du jour and so on and so on. You are the biggest fking tool here, at least the OP has some fun with it but you act like your boyfriend gave you a reacharound while biting your ear!Don’t try to act holier then thou.. you have been stinking up this thread for a while.. and no, many think Sigs customer service is solid. You are just another troller on here trying to.disguise yourself and solid. You aren’t. Seen through your BS early. Do you even own a Sig? No..

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The SIG 716I TREAD .308 may be the best AR-308 / AR-10 type battle rifle for the money.

- Thread starter GLD1980

- Start date

@AngryKoala

In all seriousness I didn't know he passed. I apologize for any offense that has been caused regarding @Ravenworks. He busted my balls up pretty good and it was a sort of a huge misunderstanding between me and him on my part that just snowballed. Regardless of how he responded to me, I would never disrespect the deceased so I apologize if it was ever taken that way. I sincerely hope @Ravenworks is resting in peace. My condolences to his family & friends for your loss.

@AngryKoala

I didn't post any dumb shit and it's unfortunate you interpreted it as such, and there was no way for me to know he had passed. A polite pm or post would have been sufficient but you chose to be rude. I may be a degenerate in your eyes but my Mother still raised me to have class.

In all seriousness I didn't know he passed. I apologize for any offense that has been caused regarding @Ravenworks. He busted my balls up pretty good and it was a sort of a huge misunderstanding between me and him on my part that just snowballed. Regardless of how he responded to me, I would never disrespect the deceased so I apologize if it was ever taken that way. I sincerely hope @Ravenworks is resting in peace. My condolences to his family & friends for your loss.

@AngryKoala

I didn't post any dumb shit and it's unfortunate you interpreted it as such, and there was no way for me to know he had passed. A polite pm or post would have been sufficient but you chose to be rude. I may be a degenerate in your eyes but my Mother still raised me to have class.

I do. That's how it comes across to me when he's replying to me about things that aren't related to anything I've said. That's irrational. He says, "You can laugh at me all you'd like" when I said nothing of the sort, while on the other hand he directly stated that's what he was doing. That doesn't seem insecure? The 'bend the knee' comment... really? Do you think anyone that has spent 5 seconds on the internet, and/or this forum, expects some internet stranger to change their minds, let alone one so obviously ate up with SIG? I can't imagine a single person who has responded to him had any thought that he would 'bend the knee' to their rifle of choice.You are reaching…. Irrational and insecurity?? You don’t even believe the BS you are spewing.

So, while I appreciate that you feel compelled to defend your tribe, it really doesn't make any sense to. I'm not attacking him. I just don't get his response to me, at all.

since we're on it

Common SIG Sauer 716i Problems and Solutions – GunAnalyst

The owners deal with many common SIG Sauer 716i problems. Here are some of the issues and how to solve them.gunanalyst.com

discussion of NOT renewing the order out of India

India Not to Repeat Sig Sauer Rifle Contract, Cites ‘Performance’

The Indian government has decided against repeating a $90 million order for 72,400 Sig Sauer assault rifles due to performance issues.www.thedefensepost.com

With 'Snags' Reported, Defence Ministry Decides Against Repeating US Assault Rifle Order

The supplementary procurement of SIG716 7.62x51 mm rifles had been abandoned following severalthewire.in

this one is in Hindi but the comments are in English and point to gas system, broken extractors, bad ammo, and chamber issues with guns jamming often

just food for thought

There are vids on KACs, DD (although you coudldn't give me anything DD), Colt, Geiselle, and even LMT. Ironically, nothing out there bad mouthing Centurion Arms

@RUTGERS95

Good find and thanks for keeping me on my toes! So I'd be willing to wager a gun, and I've got plenty that aren't SIG if that's your fancy, that any of the rifles you just mentioned, and though I don't know centurion arms I'll throw them in too, but they would all fail! I just read the links and the video you posted. Good info but it got me thinking.... I know my Indian Juwan buddies might be small but there not stupid so I asked them the truth.... They said it's only experiencing problems with their (Indian MFR) ammo. Read the last page.... They get more into OFB specs.... Come on @RUTGERS95 .... I was just getting a laugh busting Aero owners chops for busting mine but this is by no means even close to a fair indicator of failure.... They even said it doesn't happen with import NATO specd ammo.... Only there OFB! Hey but good on them for becoming self reliant!

https://defenceforumindia.com/threads/indian-army-sig-sauer-716-assault-rifle.81277/page-101

oh and I forgot to add that running that rifle with zero lube until 2400 rds is outstanding by any measure. I don't care if it was a DPMS or BCA, 2400rds with no lube is impressive

I did more digging because your buddy gunner annoyed the shit out of me earlier and lets just say, I can post more as the view on the ground regarding these rifles is less than stellar. This brings me to what I said earlier in this thread, 308s will beat rifles up. Now KAC and LMT have high round count rigs in service but they are the top of the foodchain, I don't expect many rifles to sustain high round counts of 308 in short order and not have some issues@RUTGERS95

Good find and thanks for keeping me on my toes! So I'd be willing to wager a gun, and I've got plenty that aren't SIG if that's your fancy, that any of the rifles you just mentioned, and though I don't know centurion arms I'll throw them in too, but they would all fail! I just read the links and the video you posted. Good info but it got me thinking.... I know my Indian Juwan buddies might be small but there not stupid so I asked them the truth.... They said it's only experiencing problems with their (Indian MFR) ammo. Read the last page.... They get more into OFB specs.... Come on @RUTGERS95 .... I was just getting a laugh busting Aero owners chops for busting mine but this is by no means even close to a fair indicator of failure.... They even said it doesn't happen with import NATO specd ammo.... Only there OFB! Hey but good on them for becoming self reliant!

https://defenceforumindia.com/threads/indian-army-sig-sauer-716-assault-rifle.81277/page-101

@GLD1980, look man, different strokes for different folks. I know this forum is tough to have a calm, friendly conversation in. I think you've lumped me in with a group of people that I'm not part of. I'm NOT attacking SIG. I'm not defending Aero. I did choose Aero, and have the convictions that led me to that choice, but I'm not committed to the rifle in spite of any evidence.

The results of the torture test, which again... I appreciate you bringing my attention to... speak for themselves; I listened to the entire ~2 hrs vid to learn what I could. I look forward to seeing the results of similar torture tests on other AR10s, and would really enjoy seeing one with the SIG 716. Between that video and my own personal and recent experience with an Aero BCG and their multi-week communication requirement between messages for a warranty claim (see my thread if interested), I'm pretty sure I will not order another Aero BCG. In the vid, TREX stated that Aero doesn't even make their BCG. I wonder who does. I like JP as an alternative for now, but I'm still trying to learn more before deciding on the next purchase.

If the 716 passes the same torture test without any significant issues, maintains better performance through it, then that would be the best evidence I've seen to date from which to make a comparison to the rifle I prefer. I still am very committed to a non-proprietary rifle so that I am not beholden to a single company. So, when the next non-prop rifle came along that was better or better for the $, then I'm sure I'd end up with it. As far as prop-rifles are concerned, I also purchased a KAC SR-25, already. I think of it as my Gucci rifle. I like that it comes with a trustworthy, reliable reputation, but it doesn't get a pass before my specific SR-25 has proven its reliability to me. Even though it's not an Aero, I still bought a very expensive spare bolt from them, and don't like that I'm beholden to them when anything goes wrong on the rifle. Their lead times are terrible (see my thread on that, if interested).

Not that you're claiming to be, but if you think you're open-minded, then you should probably be able to say that under such-and-such conditions, you would acquiesce on your position, and in that case would be open to recommending another rifle over the SIG. I just did that in the last paragraph in relation to Aero. What would that testing/evidence need to look like for you to change your opinion?

The results of the torture test, which again... I appreciate you bringing my attention to... speak for themselves; I listened to the entire ~2 hrs vid to learn what I could. I look forward to seeing the results of similar torture tests on other AR10s, and would really enjoy seeing one with the SIG 716. Between that video and my own personal and recent experience with an Aero BCG and their multi-week communication requirement between messages for a warranty claim (see my thread if interested), I'm pretty sure I will not order another Aero BCG. In the vid, TREX stated that Aero doesn't even make their BCG. I wonder who does. I like JP as an alternative for now, but I'm still trying to learn more before deciding on the next purchase.

If the 716 passes the same torture test without any significant issues, maintains better performance through it, then that would be the best evidence I've seen to date from which to make a comparison to the rifle I prefer. I still am very committed to a non-proprietary rifle so that I am not beholden to a single company. So, when the next non-prop rifle came along that was better or better for the $, then I'm sure I'd end up with it. As far as prop-rifles are concerned, I also purchased a KAC SR-25, already. I think of it as my Gucci rifle. I like that it comes with a trustworthy, reliable reputation, but it doesn't get a pass before my specific SR-25 has proven its reliability to me. Even though it's not an Aero, I still bought a very expensive spare bolt from them, and don't like that I'm beholden to them when anything goes wrong on the rifle. Their lead times are terrible (see my thread on that, if interested).

Not that you're claiming to be, but if you think you're open-minded, then you should probably be able to say that under such-and-such conditions, you would acquiesce on your position, and in that case would be open to recommending another rifle over the SIG. I just did that in the last paragraph in relation to Aero. What would that testing/evidence need to look like for you to change your opinion?

Last edited:

@RUTGERS95

I don't think the Aero did bad. I think it's accuracy was under par for what has been said and it's CS according to Lucas couldn't get a replacement for parts for a month, not that It matters they were helpful and most of you say have spare parts. Or you have harped on me to get a platform not so proprietary like the Aero, unlike the SIG, so if this happens I will have parts and not have to deal with SIG. I have listened it just hasn't been a problem.

I was actually laughing my ass of because this is what many here said would happen to the SIG. That's the only reason I was laughing.... Not at the machine, but like some of you laugh at me, I was laughing back for once.... I have nothing against the hardware. I would love to have any of the guns we've mentiined throughout the pages to defend my family. Once a grunt always a grunt, I'll get any of them to work.

All I said is for the money I think the SIG gives you the most!

I respect your difference of opinion and hope you can post the rest of the information you have regarding SIG 716I failures or shortcomings.... The same way I'm annoying here, if any of it is verifiable I will get a hold of SIG and try to work out fixes.

I don't think the Aero did bad. I think it's accuracy was under par for what has been said and it's CS according to Lucas couldn't get a replacement for parts for a month, not that It matters they were helpful and most of you say have spare parts. Or you have harped on me to get a platform not so proprietary like the Aero, unlike the SIG, so if this happens I will have parts and not have to deal with SIG. I have listened it just hasn't been a problem.

I was actually laughing my ass of because this is what many here said would happen to the SIG. That's the only reason I was laughing.... Not at the machine, but like some of you laugh at me, I was laughing back for once.... I have nothing against the hardware. I would love to have any of the guns we've mentiined throughout the pages to defend my family. Once a grunt always a grunt, I'll get any of them to work.

All I said is for the money I think the SIG gives you the most!

I respect your difference of opinion and hope you can post the rest of the information you have regarding SIG 716I failures or shortcomings.... The same way I'm annoying here, if any of it is verifiable I will get a hold of SIG and try to work out fixes.

@Praetorian_6

We are the same exact page. I have no loyalties to SIG. I just think it's a great rifle for the price. I think the SIG or any rifle for that matter under those conditions would fail or perform poorly. I'm not sure why Lucas chose his parameters but it's just brought up memories of people making unnecessary comments in a tech forum. I am guilty of it too and know better. Thanks for helping me get this back on track! I would donate my rifle to Lucas Botkin and some ammo to get this test done! I would also contact SIG to donate ammo to step up for their products and if they don't I'll let all of you know.

Technically speaking, I believe the SIG has a few finish and engineering upgrades & features that would help it out during this test. it's BCG is DLC coated and features some areas where mass has been removed to allow smoother fucntioning. Similar to an LMT bolt carrier, it has extra enlarged venting ports that will aid it under adverse & suppressed operations. It also has dual extracters to aid it once it starts building up massive carbon to get that casing out. The Extractor issue @RUTGERS95 is speaking of is a real problem apparently but only if your using Indian non Nato or SAMMI SPEC Ammo. The SIG also features rifle length gas paired to an H2 buffer and has had no issues shooting suppressed from many reported users. Pete, the Editor in Chief of TFB has written a few articles about how well the 716I shoots suppressed. The Handguard possibly loosening on the M5 may not occur on the SIG due to it's keyed to the upper handguard similar to H&K and it dual bolt clamp system the is top mounted through the barrel nut....

Shit just last week while helping a fellow owner get RET measurements I learned the 716I has water drainage holes in the RET... The 716I big ass is over the Beach capable possibly.... I thought that funny!

Honestly In my humble opinion, the only flaws of the 716I are it's charging handle and trigger. Once you drop a Geissele or whichever trigger you prefer and the SIG dual latch AMBI CH in your good to go.

Oh and it is built so tightly, has is all SIG's, like damn virgins.... I recommend light grease and oil mixed for the first 250rds to get her smooth like butter. Take care

We are the same exact page. I have no loyalties to SIG. I just think it's a great rifle for the price. I think the SIG or any rifle for that matter under those conditions would fail or perform poorly. I'm not sure why Lucas chose his parameters but it's just brought up memories of people making unnecessary comments in a tech forum. I am guilty of it too and know better. Thanks for helping me get this back on track! I would donate my rifle to Lucas Botkin and some ammo to get this test done! I would also contact SIG to donate ammo to step up for their products and if they don't I'll let all of you know.

Technically speaking, I believe the SIG has a few finish and engineering upgrades & features that would help it out during this test. it's BCG is DLC coated and features some areas where mass has been removed to allow smoother fucntioning. Similar to an LMT bolt carrier, it has extra enlarged venting ports that will aid it under adverse & suppressed operations. It also has dual extracters to aid it once it starts building up massive carbon to get that casing out. The Extractor issue @RUTGERS95 is speaking of is a real problem apparently but only if your using Indian non Nato or SAMMI SPEC Ammo. The SIG also features rifle length gas paired to an H2 buffer and has had no issues shooting suppressed from many reported users. Pete, the Editor in Chief of TFB has written a few articles about how well the 716I shoots suppressed. The Handguard possibly loosening on the M5 may not occur on the SIG due to it's keyed to the upper handguard similar to H&K and it dual bolt clamp system the is top mounted through the barrel nut....

Shit just last week while helping a fellow owner get RET measurements I learned the 716I has water drainage holes in the RET... The 716I big ass is over the Beach capable possibly.... I thought that funny!

Honestly In my humble opinion, the only flaws of the 716I are it's charging handle and trigger. Once you drop a Geissele or whichever trigger you prefer and the SIG dual latch AMBI CH in your good to go.

Oh and it is built so tightly, has is all SIG's, like damn virgins.... I recommend light grease and oil mixed for the first 250rds to get her smooth like butter. Take care

@AngryKoala

In all seriousness I didn't know he passed. I apologize for any offense that has been caused regarding @Ravenworks. He busted my balls up pretty good and it was a sort of a huge misunderstanding between me and him on my part that just snowballed. Regardless of how he responded to me, I would never disrespect the deceased so I apologize if it was ever taken that way. I sincerely hope @Ravenworks is resting in peace. My condolences to his family & friends for your loss.

@AngryKoala

I didn't post any dumb shit and it's unfortunate you interpreted it as such, and there was no way for me to know he had passed. A polite pm or post would have been sufficient but you chose to be rude. I may be a degenerate in your eyes but my Mother still raised me to have class.

The problem is your mother spread when she should have swallowed....but here we are.

Have a nice night though.

Lol that was a good one! I would like to hope my mother didn't prefer to suck or swallow unlike your mother who could suck start a jammed machine gun!The problem is your mother spread when she should have swallowed....but here we are.

Have a nice night though.

Take care.

Lol that was a good one! I would like to hope my mother didn't prefer to suck or swallow unlike your mother who could suck start a jammed machine gun!

Take care.

Must have been the gen 1 Sig MG

since we're on it

Common SIG Sauer 716i Problems and Solutions – GunAnalyst

The owners deal with many common SIG Sauer 716i problems. Here are some of the issues and how to solve them.gunanalyst.com

discussion of NOT renewing the order out of India

India Not to Repeat Sig Sauer Rifle Contract, Cites ‘Performance’

The Indian government has decided against repeating a $90 million order for 72,400 Sig Sauer assault rifles due to performance issues.www.thedefensepost.com

With 'Snags' Reported, Defence Ministry Decides Against Repeating US Assault Rifle Order

The supplementary procurement of SIG716 7.62x51 mm rifles had been abandoned following severalthewire.in

this one is in Hindi but the comments are in English and point to gas system, broken extractors, bad ammo, and chamber issues with guns jamming often

just food for thought

There are vids on KACs, DD (although you coudldn't give me anything DD), Colt, Geiselle, and even LMT. Ironically, nothing out there bad mouthing Centurion Arms

Indian made ammo being not-that-great is the problem. Bullets getting stuck in the barrels was one thing I read.

since we're on it

Common SIG Sauer 716i Problems and Solutions – GunAnalyst

The owners deal with many common SIG Sauer 716i problems. Here are some of the issues and how to solve them.gunanalyst.com

discussion of NOT renewing the order out of India

India Not to Repeat Sig Sauer Rifle Contract, Cites ‘Performance’

The Indian government has decided against repeating a $90 million order for 72,400 Sig Sauer assault rifles due to performance issues.www.thedefensepost.com

With 'Snags' Reported, Defence Ministry Decides Against Repeating US Assault Rifle Order

The supplementary procurement of SIG716 7.62x51 mm rifles had been abandoned following severalthewire.in

this one is in Hindi but the comments are in English and point to gas system, broken extractors, bad ammo, and chamber issues with guns jamming often

just food for thought

There are vids on KACs, DD (although you coudldn't give me anything DD), Colt, Geiselle, and even LMT. Ironically, nothing out there bad mouthing Centurion Arms

Ouch...

In all fairness, We use a lot of Indian subcontractors in Middle East and honestly this really doesn't surprise me. While I personally like these guys, they have quite a different approach to a lot of things that don't bode well for maintaining a modern weapon. I think I may have opined similar thoughts in early post.

Take all this and then add in that Indian 308 is pretty much bottom of the barrel and its not really a surprised how this exercise in futility played out. As much as we all love to rag of Sig, I really can't fault them too much on this.

@RUTGERS95

There is some shady business over in India going down regarding the 716I. It really looks like they needed a scapegoat to save money and face but something tells me many won't see it that Way. The Indian Government Ammo Manufacturing falls under the responsibility of the Ordinance Factory Board (OFB), and the 41 Ordinance Factories (OF) under their control.

https://ddpdoo.gov.in/

Here's the problem, the ORB and the 41OF's under them all still belong too the Indian Ministry of Defense, and between the ORB, the MoD and more specifically the Indian Army ordering the incorrect spec'd ammo seems to be the real problem. Corruption comes in many forms and you seem wise enough to know when there's smoke there's fire. Hopefully you don't fall for that B.S.! It would be the equivalent of me falling for Lucas' Aero Video, which I did not! I just think it is extremely funny because so many panties ended up in such a bunch.

I would still like to see the other information you had mentioned about the 716I from those down in the dirt. I am not a SIG cheerleader and if there are issues then I would like to address them. If you read through the longer posts of mine on SIGTalk and ARF, everytime a fellow owner has had a valid concern I have addressed it by investigating it and disseminating info amongst the hive, and built a bridge between the owner and SIG, and when necessary I've even reached out to SIG myself to gain clarity or request information. Honestly in my crazy head I think SIG loves me, but your right I am an idiot because they should be paying me, huh! I've probably sold more 716I's for them than anything else lol.... Funny thing is even though I can sell ice to Eskimos and probably sell you your shit stained underwear for more than you paid for them, that's not why I do it. For some reason I just have confidence in the design. It's a really good rifle!

I also think the whining, moaning, groaning and harsh remarks from the Teir 1 and Teir Slum AR-10/AR-308 owners, who can't stand the 716I and have opposed the 716I really bring the best out of me!

There is some shady business over in India going down regarding the 716I. It really looks like they needed a scapegoat to save money and face but something tells me many won't see it that Way. The Indian Government Ammo Manufacturing falls under the responsibility of the Ordinance Factory Board (OFB), and the 41 Ordinance Factories (OF) under their control.

https://ddpdoo.gov.in/

Here's the problem, the ORB and the 41OF's under them all still belong too the Indian Ministry of Defense, and between the ORB, the MoD and more specifically the Indian Army ordering the incorrect spec'd ammo seems to be the real problem. Corruption comes in many forms and you seem wise enough to know when there's smoke there's fire. Hopefully you don't fall for that B.S.! It would be the equivalent of me falling for Lucas' Aero Video, which I did not! I just think it is extremely funny because so many panties ended up in such a bunch.

I would still like to see the other information you had mentioned about the 716I from those down in the dirt. I am not a SIG cheerleader and if there are issues then I would like to address them. If you read through the longer posts of mine on SIGTalk and ARF, everytime a fellow owner has had a valid concern I have addressed it by investigating it and disseminating info amongst the hive, and built a bridge between the owner and SIG, and when necessary I've even reached out to SIG myself to gain clarity or request information. Honestly in my crazy head I think SIG loves me, but your right I am an idiot because they should be paying me, huh! I've probably sold more 716I's for them than anything else lol.... Funny thing is even though I can sell ice to Eskimos and probably sell you your shit stained underwear for more than you paid for them, that's not why I do it. For some reason I just have confidence in the design. It's a really good rifle!

I also think the whining, moaning, groaning and harsh remarks from the Teir 1 and Teir Slum AR-10/AR-308 owners, who can't stand the 716I and have opposed the 716I really bring the best out of me!

Last edited:

I seem to remember Indian M80 surplus hitting our shores about 15 years ago and it caused all kinds of problems in various weapon systems. I never touched any of it because I didn't find any satisfactory post about it.

It doesn't surprise me the 716i is having problems with Indian ammo...

It doesn't surprise me the 716i is having problems with Indian ammo...

just caught up on this thread… lol.

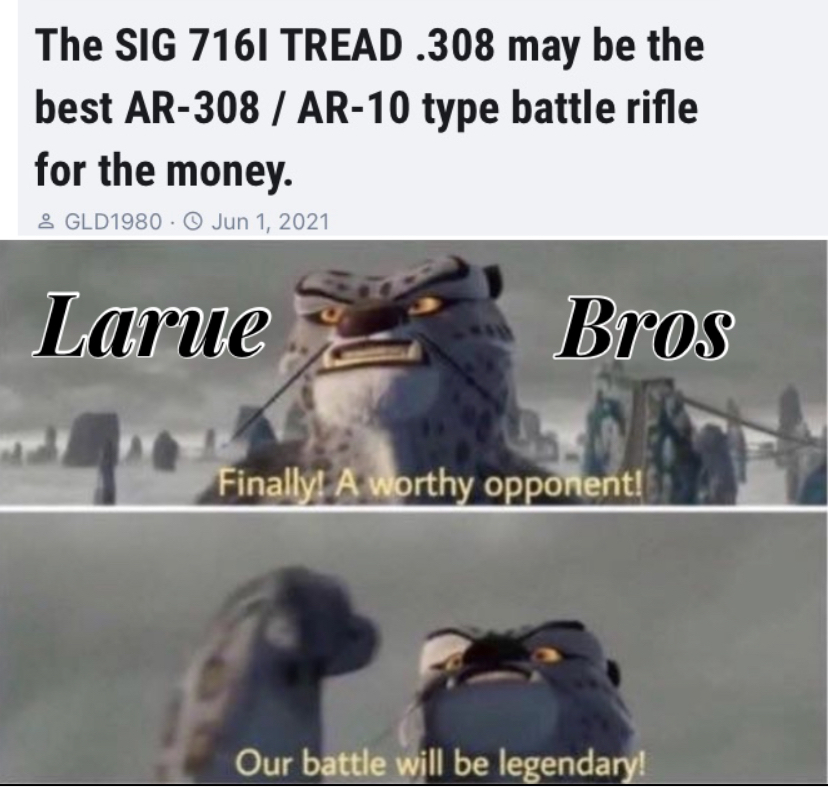

Please start a 716i vs OBR thread in the Larue forum on ARFCOM and post a link.

OP, all jokes aside, I’m glad you like your rifle. I hope Sig continues supporting and developing the 716i line.

Please start a 716i vs OBR thread in the Larue forum on ARFCOM and post a link.

OP, all jokes aside, I’m glad you like your rifle. I hope Sig continues supporting and developing the 716i line.

Last edited:

@Jsp556

Why do I get the feeling your setting me up for a lynching lol.

However I do agree with you and I think the SIG needs to continue to support and develop the 716I and offer more options in regards to modularity, caliber and barrel length offerings along with real parts support and an fully Ambi lower. They also need to offer just a bit more for the baseline intro rifle too (Ambi charging handle, better trigger, maybe sights, and a real stock) if they want to be considered more than entry or mid tier.

Funny you mentioned the LaRue OBR specifically! While deployed to Iraq with 2-3IN, our new PL just transitioned from being the OIC of the US Army Sniper School and took over our Platoon. He was a prior enlisted SFC 11B4V who was also B4 qualified and came from the 101st and had experience behind the M110 and the M24. He and I used to shoot recreationally after our tour and he'd tell me stories about the OBR. Apparently Cadre had the opportunity to shoot the OBR at Sniper School and he felt the LaRue OBR was better than the KAC M110. He often said that the OBR was the finest Semi Auto AR-308 out at that time. This was 2010 and things have changed since then but honestly not much. I've never personally shot the OBR but I held one and was very impressed. I respect his opinion and to this day I have a tremendous amount of respect for the OBR because of it. I would never pass up the opportunity to own one. The LaRue is awesome. Shit... I would never pass up the opportunity to own any of the big names although I'd prefer the H&K, LMT, LaRue or Noveske over the KAC. Maybe it's naivety but if probably take the DD & the SIG over the LMT. I honestly just feel the SIG 716I bridges the gap between the LaRue, LMT, H&K, Noveske, Knights, DD, LWRC and the lesser expensive rifles like Aero, PSA, Ruger, S&W, Springfield, Savage, Armalite etc...

With the SIG you get a gun capable of running with big dogs for the same price or better than many of the entry level .308 guns! Many obviously do not agree with me but anyone can see through the arguments presented I hope. Amongst the other sub $2k rifles, the only one I would honestly chose to add alongside the SIG is the Ruger SFAR. Rugers are highly underrated. My AR-556 MPR and Gen3 RPR .308 are definitely keepers.

Don't get me wrong.... Ofcourse I would own any of the Top Teir guns, but because I don't need modularity or a different caliber, I am fortunate the SIG can do everything else the Big Boys can IMO. The only thing it can't do is offer the amazing weight savings the Ruger SFAR offers... But then again, neither do any of the other $2k+ rifles, while most of the sub $2k rifles have less to offer in terms of benefits to cost compared to the SIG so it would seem.

In fact many have came to this thread talking shitty about SIG instead of telling me why their guns are better! It's either the SIG is too proprietary and the other guns can be easily modified or repaired... SIG CS is shit and doesn't treat customers properly or fix problems.... Or Indian MIM parts are shit and the 716I is a POS.... Honestly it's really just a bunch of hot air to the owners groups when the facts say something completely different! Until the Ruger SFAR recently dropped, SIG had begun to take a large part of the entry AR-10/AR-308 market of production rifles by simply offering more gun than everyone else for less coin. Honestly I am not concerned with most of the feelings mentioned in previous posts because I truly believe the SIG will run longer, shoot better and survive more than the other sub $2k rifles.

Why do I get the feeling your setting me up for a lynching lol.

However I do agree with you and I think the SIG needs to continue to support and develop the 716I and offer more options in regards to modularity, caliber and barrel length offerings along with real parts support and an fully Ambi lower. They also need to offer just a bit more for the baseline intro rifle too (Ambi charging handle, better trigger, maybe sights, and a real stock) if they want to be considered more than entry or mid tier.

Funny you mentioned the LaRue OBR specifically! While deployed to Iraq with 2-3IN, our new PL just transitioned from being the OIC of the US Army Sniper School and took over our Platoon. He was a prior enlisted SFC 11B4V who was also B4 qualified and came from the 101st and had experience behind the M110 and the M24. He and I used to shoot recreationally after our tour and he'd tell me stories about the OBR. Apparently Cadre had the opportunity to shoot the OBR at Sniper School and he felt the LaRue OBR was better than the KAC M110. He often said that the OBR was the finest Semi Auto AR-308 out at that time. This was 2010 and things have changed since then but honestly not much. I've never personally shot the OBR but I held one and was very impressed. I respect his opinion and to this day I have a tremendous amount of respect for the OBR because of it. I would never pass up the opportunity to own one. The LaRue is awesome. Shit... I would never pass up the opportunity to own any of the big names although I'd prefer the H&K, LMT, LaRue or Noveske over the KAC. Maybe it's naivety but if probably take the DD & the SIG over the LMT. I honestly just feel the SIG 716I bridges the gap between the LaRue, LMT, H&K, Noveske, Knights, DD, LWRC and the lesser expensive rifles like Aero, PSA, Ruger, S&W, Springfield, Savage, Armalite etc...

With the SIG you get a gun capable of running with big dogs for the same price or better than many of the entry level .308 guns! Many obviously do not agree with me but anyone can see through the arguments presented I hope. Amongst the other sub $2k rifles, the only one I would honestly chose to add alongside the SIG is the Ruger SFAR. Rugers are highly underrated. My AR-556 MPR and Gen3 RPR .308 are definitely keepers.

Don't get me wrong.... Ofcourse I would own any of the Top Teir guns, but because I don't need modularity or a different caliber, I am fortunate the SIG can do everything else the Big Boys can IMO. The only thing it can't do is offer the amazing weight savings the Ruger SFAR offers... But then again, neither do any of the other $2k+ rifles, while most of the sub $2k rifles have less to offer in terms of benefits to cost compared to the SIG so it would seem.

In fact many have came to this thread talking shitty about SIG instead of telling me why their guns are better! It's either the SIG is too proprietary and the other guns can be easily modified or repaired... SIG CS is shit and doesn't treat customers properly or fix problems.... Or Indian MIM parts are shit and the 716I is a POS.... Honestly it's really just a bunch of hot air to the owners groups when the facts say something completely different! Until the Ruger SFAR recently dropped, SIG had begun to take a large part of the entry AR-10/AR-308 market of production rifles by simply offering more gun than everyone else for less coin. Honestly I am not concerned with most of the feelings mentioned in previous posts because I truly believe the SIG will run longer, shoot better and survive more than the other sub $2k rifles.

agree on obr of old, maybe not new. where I have to shake my head and where your 'homerism' comes out is DD/SIG over LMT. LMT is battle proven, same as KAC, with excellent accuracy in multiple theatres. I just can't fathom choosing those two over LMT or KAC.@Jsp556

Why do I get the feeling your setting me up for a lynching lol.

However I do agree with you and I think the SIG needs to continue to support and develop the 716I and offer more options in regards to modularity, caliber and barrel length offerings along with real parts support and an fully Ambi lower. They also need to offer just a bit more for the baseline intro rifle too (Ambi charging handle, better trigger, maybe sights, and a real stock) if they want to be considered more than entry or mid tier.

Funny you mentioned the LaRue OBR specifically! While deployed to Iraq with 2-3IN, our new PL just transitioned from being the OIC of the US Army Sniper School and took over our Platoon. He was a prior enlisted SFC 11B4V who was also B4 qualified and came from the 101st and had experience behind the M110 and the M24. He and I used to shoot recreationally after our tour and he'd tell me stories about the OBR. Apparently Cadre had the opportunity to shoot the OBR at Sniper School and he felt the LaRue OBR was better than the KAC M110. He often said that the OBR was the finest Semi Auto AR-308 out at that time. This was 2010 and things have changed since then but honestly not much. I've never personally shot the OBR but I held one and was very impressed. I respect his opinion and to this day I have a tremendous amount of respect for the OBR because of it. I would never pass up the opportunity to own one. The LaRue is awesome. Shit... I would never pass up the opportunity to own any of the big names although I'd prefer the H&K, LMT, LaRue or Noveske over the KAC. Maybe it's naivety but if probably take the DD & the SIG over the LMT. I honestly just feel the SIG 716I bridges the gap between the LaRue, LMT, H&K, Noveske, Knights, DD, LWRC and the lesser expensive rifles like Aero, PSA, Ruger, S&W, Springfield, Savage, Armalite etc...

With the SIG you get a gun capable of running with big dogs for the same price or better than many of the entry level .308 guns! Many obviously do not agree with me but anyone can see through the arguments presented I hope. Amongst the other sub $2k rifles, the only one I would honestly chose to add alongside the SIG is the Ruger SFAR. Rugers are highly underrated. My AR-556 MPR and Gen3 RPR .308 are definitely keepers.

Don't get me wrong.... Ofcourse I would own any of the Top Teir guns, but because I don't need modularity or a different caliber, I am fortunate the SIG can do everything else the Big Boys can IMO. The only thing it can't do is offer the amazing weight savings the Ruger SFAR offers... But then again, neither do any of the other $2k+ rifles, while most of the sub $2k rifles have less to offer in terms of benefits to cost compared to the SIG so it would seem.

In fact many have came to this thread talking shitty about SIG instead of telling me why their guns are better! It's either the SIG is too proprietary and the other guns can be easily modified or repaired... SIG CS is shit and doesn't treat customers properly or fix problems.... Or Indian MIM parts are shit and the 716I is a POS.... Honestly it's really just a bunch of hot air to the owners groups when the facts say something completely different! Until the Ruger SFAR recently dropped, SIG had begun to take a large part of the entry AR-10/AR-308 market of production rifles by simply offering more gun than everyone else for less coin. Honestly I am not concerned with most of the feelings mentioned in previous posts because I truly believe the SIG will run longer, shoot better and survive more than the other sub $2k rifles.

can you show the numbers where SIG is taking a large part of the AR10 mkts cause I've yet to see one in the wild but I do see lots of LMTs, KACs, Aeros, and LaRues. Would love to see where the data is on that

respectfully of course

I just can't fathom choosing those two over LMT or KAC.

Price. I got my 716i used for 1250 bucks. Eventually sold mine but not for any fault of the rifle, just don't need 308 anymore. Might try the new ruger next but my days of blowing money on 308 are basically over. 223 and 9mm are easier for carbines.

I see this is listed as a 7.62. I see anecdotally that people are running .308W rounds through it, but could not find anywhere that the gun is specified for .308 in Sig's documentation. I am really between this and the M&P10 and Tikka T3 as I don't want to get into a MWS or aero build at this time.

@RUTGERS95

Nobody would choose the SIG or the DD over the LMT if they were free my friend but there not. In a world where some of us don't have the ability to simply spend $3-5k or more on just the gun, what is the next best alternative that still gives performance and reliability? I hope you understand I referring closing the gap between the top and bottom. Like the title states, "Best for the price" meaning most bang for the buck.

By the way, I am still waiting on your bad news about the SIG.... Surprisingly you've never seen one but you have heard stories from down in the dirt about failures. Are you sure your anger at SIG shortcomings isn't causing a bit of bias to the 716I? It's been a while since SIG got one right out of the gates, and instead of acknowledging that it's a pissing match. I am not trying to sell you a SIG but I do appreciate all of your feedback, the positive and negative. The SIG 716I should be scrutinized, but if it prevails then what?

I need to get to some business but I will be back to answer the market question too.

Cheers!

Nobody would choose the SIG or the DD over the LMT if they were free my friend but there not. In a world where some of us don't have the ability to simply spend $3-5k or more on just the gun, what is the next best alternative that still gives performance and reliability? I hope you understand I referring closing the gap between the top and bottom. Like the title states, "Best for the price" meaning most bang for the buck.

By the way, I am still waiting on your bad news about the SIG.... Surprisingly you've never seen one but you have heard stories from down in the dirt about failures. Are you sure your anger at SIG shortcomings isn't causing a bit of bias to the 716I? It's been a while since SIG got one right out of the gates, and instead of acknowledging that it's a pissing match. I am not trying to sell you a SIG but I do appreciate all of your feedback, the positive and negative. The SIG 716I should be scrutinized, but if it prevails then what?

I need to get to some business but I will be back to answer the market question too.

Cheers!

Last edited:

Picked up a 716I about a year ago used. I have put 1500 rnds through it. Has been 100% reliable and has shot a few sub moa 5 shot groups.

Fine rifle.

Fine rifle.

I see this is listed as a 7.62. I see anecdotally that people are running .308W rounds through it, but could not find anywhere that the gun is specified for .308 in Sig's documentation. I am really between this and the M&P10 and Tikka T3 as I don't want to get into a MWS or aero build at this time.

They're 308. It's a non issue. My big thing is I just don't need a 308 semi auto when I have cheap 223 carbines that shoot steel cased, 9mm carbines shooting steel cased, way cheaper and less recoil. For hunting I have a 30-06 bolt gun. Target shooting I have a 6.5 creedmoor I am working on.

& @GLD1980 Thanks.They're 308. It's a non issue. My big thing is I just don't need a 308 semi auto when I have cheap 223 carbines that shoot steel cased, 9mm carbines shooting steel cased, way cheaper and less recoil. For hunting I have a 30-06 bolt gun. Target shooting I have a 6.5 creedmoor I am working on.

I'm primarily medium game at 300yds max and we have a ton of black bear. To me, a 308 is a good balance and SA is more fun otherwise than BA.

I want to support local gun shops and this is what they have in my intended price range. I have ruled a few others out already - just have to pick between the 3.

As platforms, the SIG is proprietary, but I don't plan to dress up a 308. I'm after a good trigger on a reliable, reasonably accurate gun.

didn't you say above you'd choose sig over lmt, pretty sure you did...@RUTGERS95

Nobody would choose the SIG or the DD or the LMT if they were free my friend but there not. In a world where some of us don't have the ability to simply spend $3-5k or more on just the gun, what is the next best alternative that still gives performance and reliability? I hope you understand I referring closing the gap between the top and bottom. Like the title states, "Best for the price" meaning most bang for the buck.

By the way, I am still waiting on your bad news about the SIG.... Surprisingly you've never seen one but you have heard stories from down in the dirt about failures. Are you sure your anger at SIG shortcomings isn't causing a bit of bias to the 716I? It's been a while since SIG got one right out of the gates, and instead of acknowledging that it's a pissing match. I am not trying to sell you a SIG but I do appreciate all of your feedback, the positive and negative. The SIG 716I should be scrutinized, but if it prevails then what?

I need to get to some business but I will be back to answer the market question too.

Cheers!

'Maybe it's naivety but if probably take the DD & the SIG over the LMT. I honestly just feel the SIG 716I bridges the gap between the LaRue, LMT, H&K, Noveske, Knights, DD, LWRC and the lesser expensive rifles like Aero, PSA, Ruger, S&W, Springfield, Savage, Armalite etc...'

posted articles on India not renewing contract and will probably pick a new 308, you didn't read them?

let us know when you get the numbers on your claim of Sig taking mkt share away from other brands

Last edited:

the new ruger interests me as well. I just want to wait a bit and see how they hold up. Most people don't have long firing sessions with 308 in frequent manner so the odd 1k here or there over extended shooting periods doesn't tell me much.Price. I got my 716i used for 1250 bucks. Eventually sold mine but not for any fault of the rifle, just don't need 308 anymore. Might try the new ruger next but my days of blowing money on 308 are basically over. 223 and 9mm are easier for carbines.

you are right on cost, especially if one shoots it and it doesn't sit in the safe like so many. I'm seeing ammo recede in prices which is good

@RUTGERS95 did you not read the forum links from India.... Man I wonder sometimes if your just busting my balls for fun. Anyway the SIG sales are taking away sales from somewhere. Do I have graphs showing market shares, No, so I apologize for stating such but a little common sense would indicate someone is feeling the pain of their successes but no worries, I have nothing to prove and the gun does just fine without me.

@jcw001& @GLD1980 Thanks.

I'm primarily medium game at 300yds max and we have a ton of black bear. To me, a 308 is a good balance and SA is more fun otherwise than BA.

I want to support local gun shops and this is what they have in my intended price range. I have ruled a few others out already - just have to pick between the 3.

As platforms, the SIG is proprietary, but I don't plan to dress up a 308. I'm after a good trigger on a reliable, reasonably accurate gun.

What are your other choices? The SIG off the bat will require $150-$200 for the SIG Ambi Charging Handle and a Trigger.... Other than that which most will change on standard ARs, the SIG is pretty legit....

Honestly though I have a Ruger AR-556 MPR which has the same trigger, the Ruger Elite 452 trigger and for a OEM trigger it's pretty nice....

A buddy recently hooked me up with a Geissele Single Stage Precision and I can't wait to get this baby out and see how tight she is now.... If weight doesn't matter and price does the SIG is where it is at. I am going to be getting a Ruger too but my SIG is setup in a DMR type role whereas the Ruger is like a Carbine with big balls.... I love it.

Last edited:

the new ruger interests me as well.

I think they hit the ball out of the park. Unless there's some fundamental flaw with their design like the recievers fall apart after 500 rounds etc.

Armalite AR10, Tikka T3 and the SW M&P10@jcw001

What are your other choices? The SIG off the bat will require $150-$200 for the SIG Ambi Charging Handle and a Trigger.... Other than that which most will change on standard ARs, the SIG is pretty legit....

Honestly though I have a Ruger AR-556 MPR which has the same trigger, the Ruger Elite 452 trigger and for a OEM trigger it's pretty nice....

A buddy recently hooked me up with a Geissele Single Stage Precision and I can't wait to get this baby out and see how tight she is now.... If weight doesn't matter and price does the SIG is where it is at. I am going to be getting a Ruger too but my SIG is setup in a DMR type role whereas the Ruger is like a Carbine with big balls.... I love it.

I think I've ruled out the Tikka, so it's the Sig, AR10 (18" barrel) or M&P10.

Geissle's shop is about 15 mins from me.

For the purposes you seek I would imagine they will all perform. The post below started in 2017 and is one page long so I'm not sure how much data is out there but they have 5R barrels and I've heard they are very accurate.

https://www.snipershide.com/shooting/threads/s-w-m-p-10-308-win-unofficial-thread.6270277/

Personally I wouldn't mind owning an Armalite, but I don't know much about them and there seem to be several models available, which model specifically are you looking at?

In regards to the SIG, it will perform with the big boys but lacks modularity in regards to barrel length and caliber availability but as is it's built like a tank and shoots sub minute. If I were in your shoe's you already know which one I'd pick so hopefully some M&P owners and Armalite owners can join the conversation and tell us something different.

I still think the SIG is the best buy in this category and the only rifle available to take that crown away right now is the Ruger SFAR.... I still am precautious about small frame AR-308's but if Ruger stands behind it I will buy one.

When the rubber meets the road.... The SIG is a cumbersome battle Rifle built up to survive harsh environments and automatic fire, even though you'd be an idiot to try that under normal circumstances unless just for fun, it can handle it. The Ruger to me is a battle carbine, lightweight and ready to go out the box it seems.... If left to hump both the miniscule weight difference wouldn't bother me but after stalking prey, waiting for the perfect shot in the cold while half frozen I'm sure the Ruger is more of a pleasure to take aim with. Can it survive what the SIG can, I don't know, but I'd place money on there OEM barrels any day and though Ruger may not pump out Cadillac's, all shiny and high priced... Their guns are amazing for the price and very reliable! The SIG probably has a dog in the fight against any of the other competitors up or down the list pound for pound.... But who knows... The new SFAR might be the new Belle at the Ball...! If the SFAR continues without a hitch, good on Ruger. I won't be mad. Let's make .308 great again!

https://www.snipershide.com/shooting/threads/s-w-m-p-10-308-win-unofficial-thread.6270277/

Personally I wouldn't mind owning an Armalite, but I don't know much about them and there seem to be several models available, which model specifically are you looking at?

In regards to the SIG, it will perform with the big boys but lacks modularity in regards to barrel length and caliber availability but as is it's built like a tank and shoots sub minute. If I were in your shoe's you already know which one I'd pick so hopefully some M&P owners and Armalite owners can join the conversation and tell us something different.

I still think the SIG is the best buy in this category and the only rifle available to take that crown away right now is the Ruger SFAR.... I still am precautious about small frame AR-308's but if Ruger stands behind it I will buy one.

When the rubber meets the road.... The SIG is a cumbersome battle Rifle built up to survive harsh environments and automatic fire, even though you'd be an idiot to try that under normal circumstances unless just for fun, it can handle it. The Ruger to me is a battle carbine, lightweight and ready to go out the box it seems.... If left to hump both the miniscule weight difference wouldn't bother me but after stalking prey, waiting for the perfect shot in the cold while half frozen I'm sure the Ruger is more of a pleasure to take aim with. Can it survive what the SIG can, I don't know, but I'd place money on there OEM barrels any day and though Ruger may not pump out Cadillac's, all shiny and high priced... Their guns are amazing for the price and very reliable! The SIG probably has a dog in the fight against any of the other competitors up or down the list pound for pound.... But who knows... The new SFAR might be the new Belle at the Ball...! If the SFAR continues without a hitch, good on Ruger. I won't be mad. Let's make .308 great again!

@Jsp556just caught up on this thread… lol.

Please start a 716i vs OBR thread in the Larue forum on ARFCOM and post a link.

OP, all jokes aside, I’m glad you like your rifle. I hope Sig continues supporting and developing the 716i line. View attachment 8016970

Done... Let's see how interesting this gets.

https://www.ar15.com/forums/Industry/LaRue-OBR-vs-SIG-716I/219-302997/

Fellow SIG716I aficionados,

Guess what I'm doing right now besides still watching this video.....?

I am laughing my ass off thinking of all the people who said pass on SIG junk and get the Aero Precision M5E1. They said it was the way to go and a much better rifle for the money than the 716I. They said that Aero uses Ballistic Advantage barrels and BA guarantees 1MOA.

Frankly I am at a loss for words and I don't know what to say.... I seriously thought they had it all figured out. I don't know anymore lol, I am starting to think that maybe they were wrong.

I understand this is a small representation of Aero's total M5E1 sales but I'm sure SIG has also distributed more AR-308's to date compared to Aero, and there exist no such video of a 716I struggling to make accurate hits or operate.

I'm sure @Ravenworks or some other user will be over soon to remind me to mind my place when speaking of SIG716I's and show respect to real rifles, but I just found this video quite funny, and not in the laughing at Aero way either.

I seriously wonder how my 716I would perform. How do you think it would hold up?

True or false:

Aero conducted pyramid testing on complete M5 rifles, with at least 100,000 rounds like DPMS, ArmaLite, KAC, SIG, Daniel Defense, and Savage have done?

When I spoke with the production managers and engineers from the above companies over the years about extensive testing, the ammo budgets and testing schedules were quite substantial. KAC has been at it since the 1980s when they were still working with Stoner himself. Eagle Arms knocked-off the SR-25 when doing their work on their AR-10, but used a modified M-14 magazine and different lower that would accept that mag at an angle like on the M-14. They came up with some very cool innovations for dealing with the bolt balanced lug engagement, sprung firing pin to eliminate slam fires, and did overall really nice work (Karl Lewis and David Doerbeck did excellent work on developing the large frame further, which we know as the ArmaLite Inc. AR-10B and AR-10T).

When DPMS sat down around the table once Randy Luth sold it off to Freedom Group, the engineers and management people asked what they need to do to update the LR-308. Their production manager quipped, “We can start by making it work.” They listed 19 items that they wanted to improve or change, and determined they would basically need to start from scratch. That process resulted in the DPMS GII, which underwent extensive pyramid testing.

Pyramid testing involves at least 10 rifles for the start fleet, and 100,000 rounds. Numerous test employees are used and rotated through after basic mechanical safety of the pressure containment system is established, and then they move into the man-firing schedule, which is supervised by engineering staff.

Any time a malfunction is encountered, the testing stops, is assessed if immediate action, remedial action, or higher level intervention is needed to correct it, then documented. Higher-level intervention can result in design changes across the test fleet. This happened with the DPMS GII, when the feed ramps were getting beaten up, so they made a steel feed ramp insert that fits into a recess in the upper receiver, so that meplats of cartridges never impact aluminum.

As you progress through the pyramid-testing process, making design changes along the way, you will end up with 1 or 2 rifles that have climbed to the top of the pyramid with the least number of failures. That final rifle design is then evaluated by the engineers, and any changes they recommend are taken into consideration before nailing down the first production design Technical Data Packages.

Daniel Defense did this with their DDV5, and Savage did it with the MSR-10 series once they were merged with the Federal Cartridge company under the Vista Outdoor conglomerate. Savage still had to pay Federal for the ammo budget, and their engineers said, “I still remember the day I saw the ammo Purchasing Order. It was......huge and very expensive."

When you see things like firing pin heads breaking within several hundred rounds, and extractor pins shearing into pieces, you know that the likelihood of pyramid testing and any type of test-based TDP are non-existent. This is one of the several reasons I have personally avoided some of the companies cranking out large frame parts designed for DIY’ers.

This is where being a reputable rifle-manufacturer comes into play. Manufacturers get criticized by people for being assemblers, but when they specify a set of compliance orders for parts, take delivery of those parts, and do final QC based on the lessons from their extensive testing regimen, it produces a much more reliable, durable firearm. I would be shocked if SIG didn’t conduct pyramid testing on their 716I, or any of their firearms.

The Aero ran better without lube, since it’s gassed so hard. As soon as he started shooting it, I immediately thought, “That rifle is gassed way hard.” The nitrided carriers they use are pretty slick, which reduces coefficient of friction. More friction helps tame that gun’s excess cyclic rate. Adding lube will only make it cycle faster and out-run the magazines more often for FTFeed. I normally tell people to run AR-10s or AR-15s with nice, thick lube on the carrier rails, inside the cam pin area, and on the bolt tail. Light lube on the lugs, bolt face relatively dry.I'm actually impressed that the Aero ran so many rounds without lube. It would also still be covered under Aero's warranty. The same test would void Sig's warranty, same as using handloads/reloads or custom ammo.

That thing was a hot mess before he even started firing it. I would have broken down the upper, measured the gas port, and dealt with that before shooting it, but that’s something the manufacturer should really address way before it ever gets to customers. The challenge for cheap route DIY target market is that you know someone will shoot the weakest Wolf .308 ammo through it, so using a larger gas port makes sense when you’re just trying to sell volume with minimal testing.

Since most people can’t or won’t afford to shoot .308 much, it’s a good gamble from a strict business sense, as long as you don’t run into influencers who work around your ability to send them doctored samples. Lucas specifically addressed that in the video, as other manufacturers have tried to send him doctored product to get good reviews, without backing their fleet production samples with the same quality.

You can watch video of him taking the SCAR-17 and Remington RSASS through high volume without any hiccups, and I still think SCAR-17s are a bit hyped for the price. He’s been doing enough shooting with gas guns to break several LPVOs lately, mentioned in another video.

Not to stir shit up but you fellas know I can't help myself....

Now I realize that this article does not represent the Ruger SFAR's capabilities or value, it is just a sample size, but there doesn't exist stories or video of the SIG 716I displaying poor performance or issues. Just some retarded fucking users!

https://www.thefirearmblog.com/blog/2022/12/27/tfb-review-ruger-sfar/

Several users have commented on the Ruger SFAR being the new best bang value on the block but is it really? I'm curious to hear from users that have handled and fired both the 716I and the Ruger SFAR.... I went over to the ARFCOM AR-15 Other Variants Thread where an almost 10pg Ruger SFAR Thread has taken off to ask.

https://www.ar15.com/forums/ar-15/New-Ruger-SFAR-Small-Frame-Autoloading-rifle-/121-775813/

A lot of Shite has been expressed about the 716I with nothing more than some stupid SIG stories from the past but nothing of substance relating to the 716I specifically. You fuckers seriously got me wondering if the Ruger SFAR is equally as great, better, or just another good rifle thats niche is being light! One thing is for sure, I am going to find the truth! I still want to get an SFAR but I won't be throwing away my almost 2lb heavier SIG anytime soon.

Now I realize that this article does not represent the Ruger SFAR's capabilities or value, it is just a sample size, but there doesn't exist stories or video of the SIG 716I displaying poor performance or issues. Just some retarded fucking users!

https://www.thefirearmblog.com/blog/2022/12/27/tfb-review-ruger-sfar/

Several users have commented on the Ruger SFAR being the new best bang value on the block but is it really? I'm curious to hear from users that have handled and fired both the 716I and the Ruger SFAR.... I went over to the ARFCOM AR-15 Other Variants Thread where an almost 10pg Ruger SFAR Thread has taken off to ask.

https://www.ar15.com/forums/ar-15/New-Ruger-SFAR-Small-Frame-Autoloading-rifle-/121-775813/

A lot of Shite has been expressed about the 716I with nothing more than some stupid SIG stories from the past but nothing of substance relating to the 716I specifically. You fuckers seriously got me wondering if the Ruger SFAR is equally as great, better, or just another good rifle thats niche is being light! One thing is for sure, I am going to find the truth! I still want to get an SFAR but I won't be throwing away my almost 2lb heavier SIG anytime soon.

I actually bought another 716i, it was listed used online and I lowballed them but didn't think they'd actually say yes.

That Firearmblog review of the SFAR sounds like they gave the rifle to the Three Stooges.

That Firearmblog review of the SFAR sounds like they gave the rifle to the Three Stooges.

Dude, India is moving away from it after a year, that should tell you something. it's fine for plinking but it's got one military contract and they are abandoning it due to issues.Not to stir shit up but you fellas know I can't help myself....

Now I realize that this article does not represent the Ruger SFAR's capabilities or value, it is just a sample size, but there doesn't exist stories or video of the SIG 716I displaying poor performance or issues. Just some retarded fucking users!

https://www.thefirearmblog.com/blog/2022/12/27/tfb-review-ruger-sfar/

Several users have commented on the Ruger SFAR being the new best bang value on the block but is it really? I'm curious to hear from users that have handled and fired both the 716I and the Ruger SFAR.... I went over to the ARFCOM AR-15 Other Variants Thread where an almost 10pg Ruger SFAR Thread has taken off to ask.

https://www.ar15.com/forums/ar-15/New-Ruger-SFAR-Small-Frame-Autoloading-rifle-/121-775813/

A lot of Shite has been expressed about the 716I with nothing more than some stupid SIG stories from the past but nothing of substance relating to the 716I specifically. You fuckers seriously got me wondering if the Ruger SFAR is equally as great, better, or just another good rifle thats niche is being light! One thing is for sure, I am going to find the truth! I still want to get an SFAR but I won't be throwing away my almost 2lb heavier SIG anytime soon.

sell it and buy and LMT or KAC and you'll be happy

India isn't moving away from anything bud! They're trying to figure a better way ahead for their Army, but the rifle is not the problem and the 716I is not going anywhere anytime soon. India is in the process of unfucking their ammo situation, not the gun and they're pretty smart, just pretty cheap too sometimes. They'll get it right!Dude, India is moving away from it after a year, that should tell you something. it's fine for plinking but it's got one military contract and they are abandoning it due to issues.

sell it and buy and LMT or KAC and you'll be happy

Why do you insist on regurgitating the same bs information but you never take a peek at anything else I've provided. None of your sources are reliable just fluff and the rumors are nonsense. Do some real research to back up these claims. You are normally a wealth of knowledge and information on many topics but in this arena you are wrong. Your using Indian National Inquirer type sources to try and create factual info to support your arguments, it won't hold but keep feeding the B.S., I'll field'em like grounders man!

Oh and @RUTGERS95 , if you giving away LMT's or KAC's I'll be there to receive one! Until then, I need to make due with what I got, which is more than enough gun for the job!

Attn All....

There are some decent ranges here in WA. I live 30min away from JBLM formerly Fort Lewis. Range 15 is open FRI-SUN and is 300yds in length. I can escort you in, if you don't have access to base to shoot. I would be willing to meet up with any KAC, LMT, H&K or LaRue owner who wants to shoot and teach me a few things. I am like a new private when it comes to learning, I will soak the knowledge dump up! The Lord knows I need to get better, but if the 716I performs better than your expectations, and can hang with your guns, can you post an honest summary of it? If it doesn't, I'll pay your range fees and you can come to the boards and say I told you so, and I will tell the truth. I am a novice distance shooter and 300yds isn't far but it's enough to establish a baseline. I am sure we will have a great time.

Dan

India is moving away from it after a year

That part of the world needs Russian-licensed AK factories.

India apparently has exactly that or something similar, yet India seems to lack the Investment necessary and QC necessary to produce a completely domesticated quality product. That part of the world is capable when they want to be and whenrl they take their products seriously, just look at Caracal & IWI. Complete proof that side of the world is more than capable. Hopefully they get it right, whether it be with the 716I or with something better suited for the mission they are faced with.

agree!That part of the world needs Russian-licensed AK factories.

more importantly, China is pushing them around and India still can't decide on a rifle for 7k elevation! nuts

back on topic, Sig failed here, if India is moving away due to performance issues, one can only imagine what someone that is not a safe locker is experiencing with higher round counts

already provide links proving what I said. Within a year, a new platform will have been selectedIndia isn't moving away from anything bud! They're trying to figure a better way ahead for their Army, but the rifle is not the problem and the 716I is not going anywhere anytime soon. India is in the process of unfucking their ammo situation, not the gun and they're pretty smart, just pretty cheap too sometimes. They'll get it right!

Why do you insist on regurgitating the same bs information but you never take a peek at anything else I've provided. None of your sources are reliable just fluff and the rumors are nonsense. Do some real research to back up these claims. You are normally a wealth of knowledge and information on many topics but in this arena you are wrong. Your using Indian National Inquirer type sources to try and create factual info to support your arguments, it won't hold but keep feeding the B.S., I'll field'em like grounders man!

Oh and @RUTGERS95 , if you giving away LMT's or KAC's I'll be there to receive one! Until then, I need to make due with what I got, which is more than enough gun for the job!

Attn All....

There are some decent ranges here in WA. I live 30min away from JBLM formerly Fort Lewis. Range 15 is open FRI-SUN and is 300yds in length. I can escort you in, if you don't have access to base to shoot. I would be willing to meet up with any KAC, LMT, H&K or LaRue owner who wants to shoot and teach me a few things. I am like a new private when it comes to learning, I will soak the knowledge dump up! The Lord knows I need to get better, but if the 716I performs better than your expectations, and can hang with your guns, can you post an honest summary of it? If it doesn't, I'll pay your range fees and you can come to the boards and say I told you so, and I will tell the truth. I am a novice distance shooter and 300yds isn't far but it's enough to establish a baseline. I am sure we will have a great time.

Dan

Your Sig kinda sucks for the price

agree!

more importantly, China is pushing them around and India still can't decide on a rifle for 7k elevation! nuts

India's sig problems are due to their shitty ammo factories. Giving them KACs instead wouldn't fix it.

They have a deal going with Russia to set up ammo and weapons factories to produce AKs but it's not done yet, probably because some Russian oligarch hasn't gotten his bribe money.

I think it's more than that otherwise they wouldn't be moving away from the platform. Reading the links and what is out there, seems to be more than ammoIndia's sig problems are due to their shitty ammo factories. Giving them KACs instead wouldn't fix it.

They have a deal going with Russia to set up ammo and weapons factories to produce AKs but it's not done yet, probably because some Russian oligarch hasn't gotten his bribe money.

India is just a clusterfk to be honest

@BCP I think @RUTGERS95 is either busting our balls or he truly believes the shit he's putting out. He's definitely allowed to have an opinion and his opinion is that the 716I sucks. I'm just glad he was able to expose all of its flaws and put out such irrefutable information  ! I am going to sell all my SIG's so maybe I can fund a future LMT or KAC project immediately. Wait.... Oh shit @RUTGERS95.... I forgot SIG's are shit so what should I do

! I am going to sell all my SIG's so maybe I can fund a future LMT or KAC project immediately. Wait.... Oh shit @RUTGERS95.... I forgot SIG's are shit so what should I do  !

!

ETA....

You know I ain't getting rid of shit and I am doubling down bud!

ETA....

You know I ain't getting rid of shit and I am doubling down bud!

Last edited:

Similar threads

- Replies

- 25

- Views

- 7K