Would love some input from those who've done one.

Here's the plan so far:

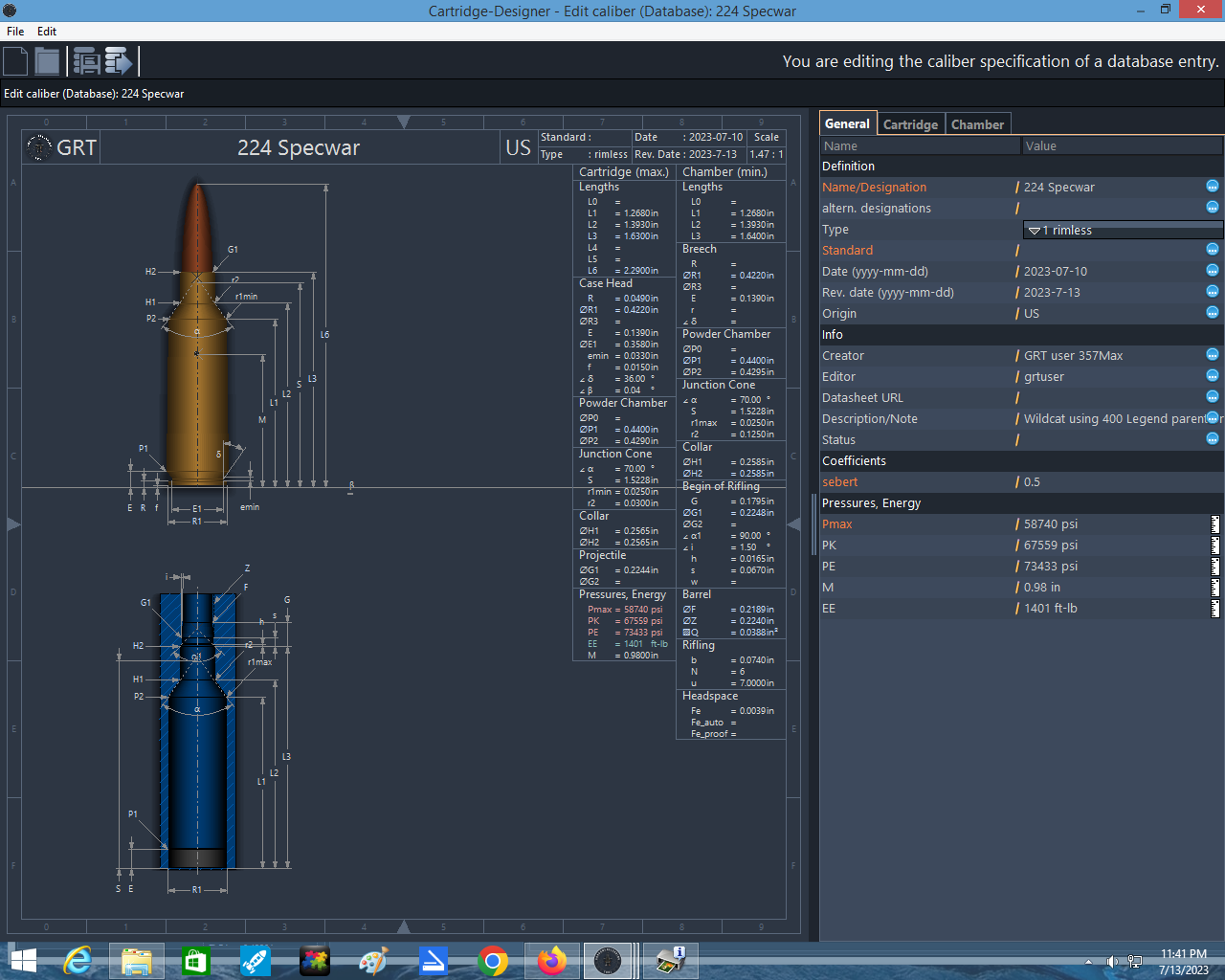

Small frame Wildcat "224 SpecWar"

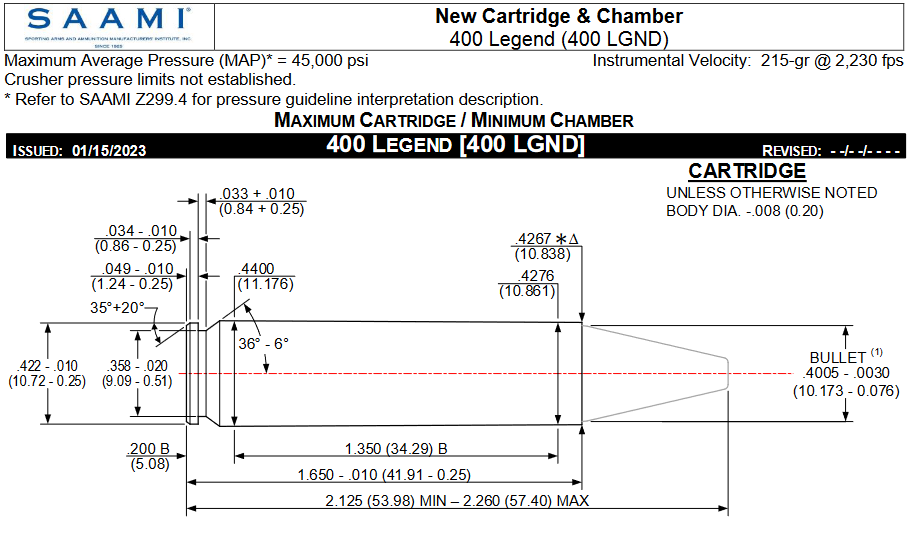

Parent Brass 400Legend

Reamer will be either Manson or JGS, any reason to pick one over the other? I'm thinking this would require 3 reamers. 1 x Finish & 2 die reamers to neck down. Might need 3 steps?? Any advice on this would be appreciated.

Die blanks will be from Newlon

First barrel will be a $138.0 Green Mountain 21" 7T semi finished Blank. Comes chambered for 223W so I'll have to pull the extension & set it back 1 thread.

Considering using a Bartlain 4R 7T from White oak if the first one works out.

Bolt will be 6.8/.224 Valk LWRC. These IMO are the strongest SPC bolt available & currently been abusing one in a 224 Valkyrie.

Thanks to 400L, we will for the first time have Grendel sized brass with a rim rebated to the SPC bolt size. I'm also hopeful the Winchester brass will be pretty decent

I kind of did a similar concept by forming 24 Nosler brass into .224 Valkyrie. The formed Nosler had +1 full grain more capacity than std Valk brass & uses a 223 bolt. Primer pockets have been dying fast (2-3 firings) with the Nosler brass, but I was pushing it pretty hard.

Performance with the formed 24 Nosler has been pretty impressive for it's 32.7 gr capacity.

18" Rock barrel +1" Rifle gas Craddock

H4350 with 88eldm @2.290

27.2gr = 2691 SD 4.2

27.5gr (C) = 2725 SD 4.8

Lever 88eldm @2.290

25.9 = 2724 SD 14.2

26.1 = 2752 SD 7.5

Lever 77RDF @2.238

27.6 x 10 = 2950 SD 8.4 This load is my go to. Shoots .5 - .75 consistently.

Based on the above I think my proposed case shown below will meet the objectives on a better 6.8 bolt. The + 4.5gr capacity should also open the door to some good powders.

Let me know what you all think. Dumb idea or worth the effort?

As an aside I'll be chambering with a slant bed CNC & that's a whole other topic itself.

Here's the plan so far:

Small frame Wildcat "224 SpecWar"

Target objectives

- Case capacity 37.3gr

- Run 77gr @2950+fps from 18" barrel @ std max metal mag length 2.290

- 88eldm/90smk @2750 from 18" barrel @2.290

- Respectable brass life at speeds listed 5x min.

- Reliable feeding

- Good bolt longevity

- Run heavy pills with RL-16, H4350, Vit N550

- Ability to stretch out load length on heavies should metal mags ever be produced for either the LWRC or New Frontier 6.8 receivers. This would also be a plus for bolt gun builds. +50fps to above in 6.8 receivers with metal mags @2.380" coal

- Max pressure 58,700psi

Reamer will be either Manson or JGS, any reason to pick one over the other? I'm thinking this would require 3 reamers. 1 x Finish & 2 die reamers to neck down. Might need 3 steps?? Any advice on this would be appreciated.

Die blanks will be from Newlon

First barrel will be a $138.0 Green Mountain 21" 7T semi finished Blank. Comes chambered for 223W so I'll have to pull the extension & set it back 1 thread.

Considering using a Bartlain 4R 7T from White oak if the first one works out.

Bolt will be 6.8/.224 Valk LWRC. These IMO are the strongest SPC bolt available & currently been abusing one in a 224 Valkyrie.

Thanks to 400L, we will for the first time have Grendel sized brass with a rim rebated to the SPC bolt size. I'm also hopeful the Winchester brass will be pretty decent

I kind of did a similar concept by forming 24 Nosler brass into .224 Valkyrie. The formed Nosler had +1 full grain more capacity than std Valk brass & uses a 223 bolt. Primer pockets have been dying fast (2-3 firings) with the Nosler brass, but I was pushing it pretty hard.

Performance with the formed 24 Nosler has been pretty impressive for it's 32.7 gr capacity.

18" Rock barrel +1" Rifle gas Craddock

H4350 with 88eldm @2.290

27.2gr = 2691 SD 4.2

27.5gr (C) = 2725 SD 4.8

Lever 88eldm @2.290

25.9 = 2724 SD 14.2

26.1 = 2752 SD 7.5

Lever 77RDF @2.238

27.6 x 10 = 2950 SD 8.4 This load is my go to. Shoots .5 - .75 consistently.

Based on the above I think my proposed case shown below will meet the objectives on a better 6.8 bolt. The + 4.5gr capacity should also open the door to some good powders.

Let me know what you all think. Dumb idea or worth the effort?

As an aside I'll be chambering with a slant bed CNC & that's a whole other topic itself.