Man is it hot here in AZ, going to have to work nights this year.

There was a question about caliber, for an FYI I have a 30 cal can and the through diameter is .450,,, I'm guessing the 338 cans are .100 plus over bullet diameter (I could use a measurement for those)

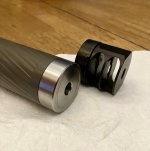

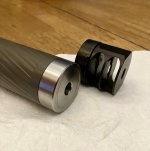

The RR brake weighs in at 3 1/8 oz (88 grams) and the prototype flat cap weighs in at 3 3/4 oz (108 grams)

Keep in mind I was unable to find a good pc of Ti without ordering so this part is all 304 stainless. The Ti version will for sure be lighter than the Brake.

There was a question about caliber, for an FYI I have a 30 cal can and the through diameter is .450,,, I'm guessing the 338 cans are .100 plus over bullet diameter (I could use a measurement for those)

The RR brake weighs in at 3 1/8 oz (88 grams) and the prototype flat cap weighs in at 3 3/4 oz (108 grams)

Keep in mind I was unable to find a good pc of Ti without ordering so this part is all 304 stainless. The Ti version will for sure be lighter than the Brake.