Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Time to Update Rifling Methods?

- Thread starter THEIS

- Start date

I kind of misread your post. Wasn't sure if trollin. In my second post in this thread I stated "If PECM lives up to marketing hype". I'm not in the camp that believes everything is perfect. What points I was trying to make with the quoted post was that overhead cost will be drastically reduced, and more predictable production cycles will be had. It won't replace high volume machinery anytime soon. If EDM is anything to compare to, PECM will be more precise than any current machining method used in shops today. It will just be limited to custom jobs or low volume type work.Yes and no

There's tons of people who honestly think that CNC machining can't make shit parts. That's who I'm referring to.

I don't know much about PECM. I don't know what tolerances it can hold when the process is done correctly by someone who knows what he's doing. What I do know is that gun forum dumbasses will continue to assume that if it's made by machines it will always be perfect and that every part will be exactly identical to the next. Neither of those assumptions will ever true.

The crappiness of it all depends on multiple factors like programmer's, set up person's, operator's skill, how well equipment is maintained. Does management source quality materials, machinery, and tooling? Is the QC dept. any good? etc.... I've ran jobs on CNC and screw machines that had +/- .0005 tolerances. Given the choice I would run those jobs on CNC every single time. For dialing tooling in on set ups, punching in numbers on a screen is a hell of a lot easier than dialing in a fine threaded set screw or turnbuckle to the nearest third or fourth decimal.True on that. There are tolerances for reasons. Sometimes you're closer to the edges but still good. They may not be perfect but they're pretty dang good (no I'm not talking about Pretty Dang Good Ammo®).

There are many ways to see who works in the real world. Cnc machines are good but they're not perfect. Manual machines are good and for some quantities may be faster. Cnc machines ran crappily put out crap parts. It is possible to make absolute correct parts but you can't afford them. Most of the time absolute correct parts aren't needed. Not all features are created equal.

I know there's a saying some thing along the lines that adding a decimal place to precision drives cost up 10 times or something like that. Numbers are probably off.

Good point about absolute perfection is not necessary in most circumstances. Has that point of diminishing returns in precision barrel manufacturing been reached yet?

Yes but even if one I’d paying $750 for a piece of bar stock, if a barrel now lasts 100k rounds instead of a a couple thousand, the upgrade cost is negligible.

barrels now just about become lifetime purchases

Agreed. Not to mention all the money saved on components for load development on new barrels and tweaking as the start to wear.

I was talking with someone familiar with military fasteners and iconel 718. He said the threads on these fasteners are rolled with a special profile (rounded over) as opposed to cut (sharp) in order to prevent stress cracking. There are also issues with galvanic corrosion.

Does this material require a specific thread profile or is that special profile necessary only for high torque applications?

Would there be any issues with galvanic corrosion inside the bore due to the presence of copper fouling and moisture?

Does this material require a specific thread profile or is that special profile necessary only for high torque applications?

Would there be any issues with galvanic corrosion inside the bore due to the presence of copper fouling and moisture?

I grind threads in inconel 718 on a regular basis. 1/2-28 unjf and 9/16-18 unjf. Larger root radius for the j and ground for better surface finish. They go in cruise missile engines. Also grind some bigger threads that go in commercial engines.I was talking with someone familiar with military fasteners and iconel 718. He said the threads on these fasteners are rolled with a special profile (rounded over) as opposed to cut (sharp) in order to prevent stress cracking. There are also issues with galvanic corrosion.

Does this material require a specific thread profile or is that special profile necessary only for high torque applications?

Would there be any issues with galvanic corrosion inside the bore due to the presence of copper fouling and moisture?

I grind threads in inconel 718 on a regular basis. 1/2-28 unjf and 9/16-18 unjf. Larger root radius for the j and ground for better surface finish. They go in cruise missile engines. Also grind some bigger threads that go in commercial engines.

So what are your thoughts on firearm barrel application of this material.

Is the special thread type required? Is it compatible with existing receiver threads?

Note I'm not an engineer. Just the guy who machines it.So what are your thoughts on firearm barrel application of this material.

Is the special thread type required? Is it compatible with existing receiver threads?

We run inconel on the hot back end of engines. Fuel slingers are made of the stuff. We use some other alloys as well back there that youve probably never heard of. Hastelloy x, udimet, and Mar m-247. Difficult to machine with carbide.

For reduced stress cracking the thread may be required but idk. Existing un threads? No. Interference at the root. Check this out.

What's The “J” In UNJ Screw Threads?

Thread Check provides important information about UNJF threads, UNJ threads and UNJC threads.

Only for the Australian market...Left hand twist?

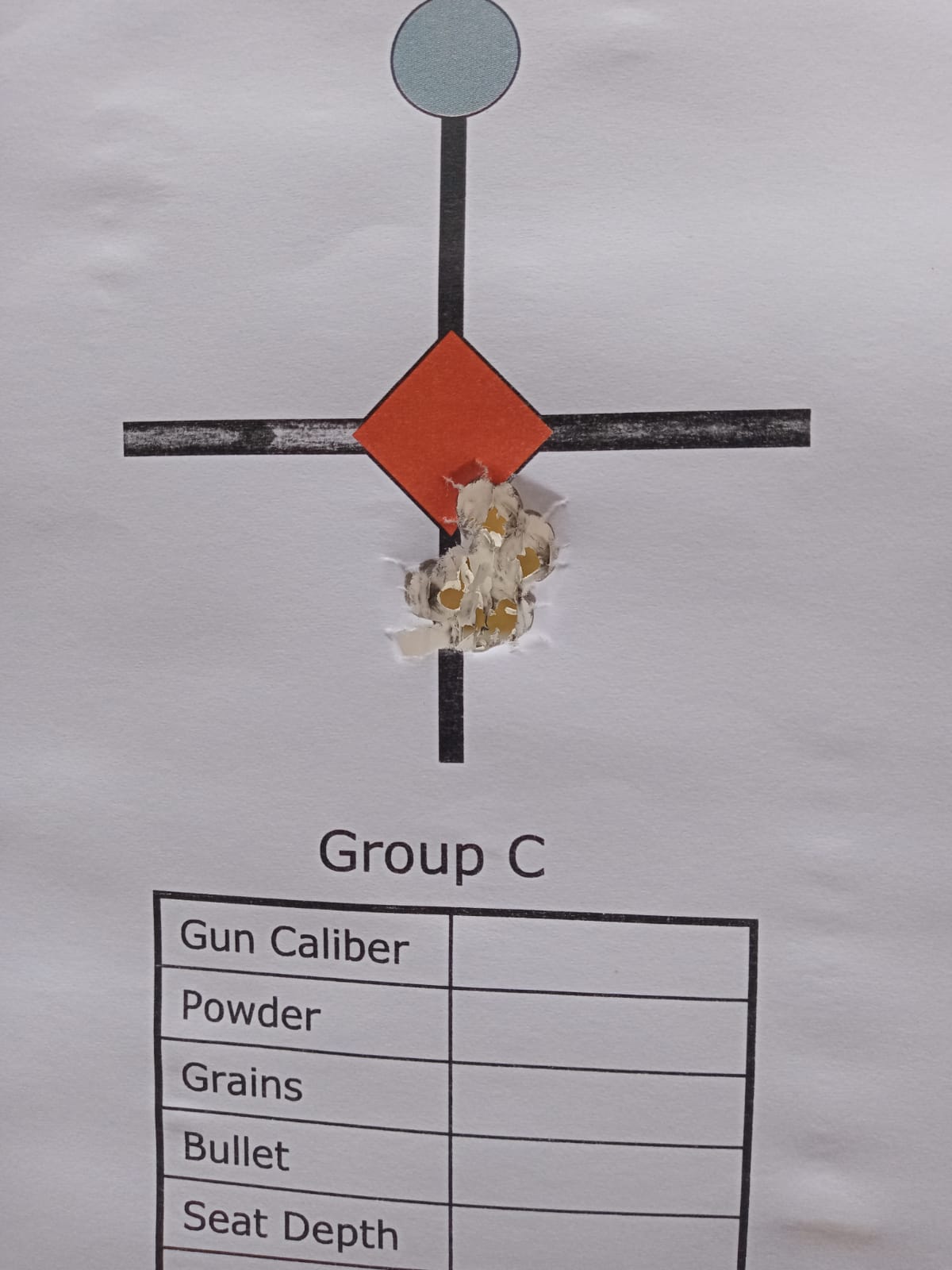

7" twist 6mm BR ECM Barrel test. Shot in less than ideal conditions with not the most ideal projectiles. Load was thrown together with 68gr Berger FBHPs - Ave: 3070, ES 41, SD 18.3. A really mild loading of old stock VV N135 - 28.9gr. Distance 100yds. Rain made the target wet and group looks bigger than it really is

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 34

- Views

- 3K

- Replies

- 212

- Views

- 14K