Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wet tumbling

- Thread starter Andrew07

- Start date

There have been reports that wet tumbling with the SS pins can cause the mouth of the case to get peened.

Wet tumbeling is more work but all my precision brass gets it.

Deprime with a universal deprimer

Wet tumble for 2-3 hours

Place brass in a dehydrator or oven to dry.

I don’t clean primer pockets and I have never had a problem with necks getting more beat up then getting shot and stepped all over during a stage.

I have the thumbler tumbler and do 100 rounds of rifle brass at a time.

They didn’t sell the larger one when I got in to it or I would have bought the larger one.

Deprime with a universal deprimer

Wet tumble for 2-3 hours

Place brass in a dehydrator or oven to dry.

I don’t clean primer pockets and I have never had a problem with necks getting more beat up then getting shot and stepped all over during a stage.

I have the thumbler tumbler and do 100 rounds of rifle brass at a time.

They didn’t sell the larger one when I got in to it or I would have bought the larger one.

I started wet tumbling to clean BPCR 45-90 brass and have just about migrated all of my brass cleaning to this because it cleans primer pockets so well. Havent noticed it accelerating brass hardness any quicker that shooting and sizing; however, i regularly anneal the aforementioned BPCR brass anyway, so I might not notice.

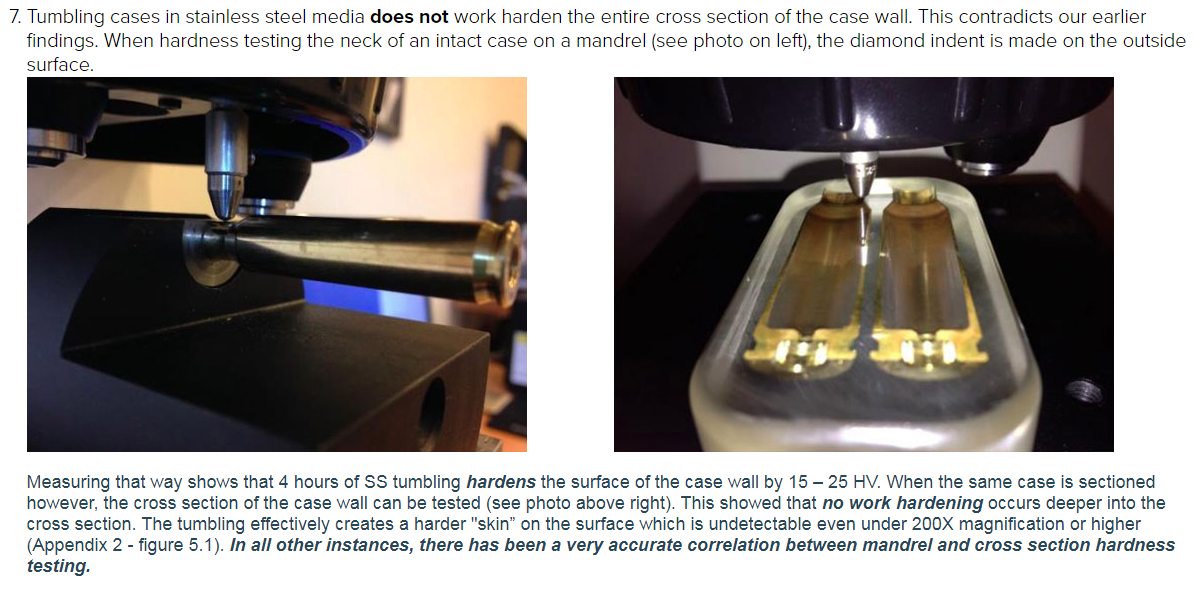

In regards to stainless tumbling and brass hardness changing

www.ampannealing.com

www.ampannealing.com

Induction Annealing Brass | Our Research | AMP

View the latest articles from AMP Annealing. Get tips and tricks from our R&D. Here we upload articles to provide your the best possible information on innovations in the annealing process.

IF the necks get dinged up at all your chamfering the inside and deburring the outside.

I don’t see where it’s a problem. I have been wet tumbling the same 200 pieces of Lapua 6.5 creed for 3 hours at a time for the past 1500 rounds or so.

I don’t see where it’s a problem. I have been wet tumbling the same 200 pieces of Lapua 6.5 creed for 3 hours at a time for the past 1500 rounds or so.

I'm with the Giver of Bad Advice, chamfering and deburring after sizing and trimming will get rid of any troublesome burrs.

So is wet tumbling the way to go for precision rifle brass? The dinged up necks aren’t gonna hurt consistenty and affect es and sd?

The peening of the case mouths typically happens when using steel pins. It's really not the pins that do the peening, but it the cases tumbling against each other. While I occasionally clean my brass by tumbling with SS pins to get ALL the carbon build up out, more often I use a vibrating tumbler with medium grain rice to clean the outside and leave some of carbon on the inside so that the carbon will act like a lubricant when holding onto the bullets. It doesn't matter how I clean my .308 brass as it always grows enough in length that I trim my brass as the very last step in my brass tuning process with a Tri-Way Trimmer to always keep my brass at the same length. So . . . since I trim my brass this way, I never have to worry about any peening as the trimming takes it all away. If not trimming like this, the peened case mouths can easily be cleaned up with a quick couple twists of a chamfering tool. None of this should effect your ES's or SD's . . . except a very clean inside neck that gives various resistance to seating (which can be handled by applying a lub to the inside of the neck).

Last edited:

I’ve been wet tumbling only. Air dry for 24 hrs. Those plastic FGMM rifle round holders come in handy for air drying. The Giraud takes care of the peening. 2 teaspoons of Dawn blue and cold water for 1 hour tumbling. I don’t clean the primer pockets or uniform the primer pockets. Most recent 5 round SD measurement on the magneto was 2.2. I wet tumble with the Lyman wet tumbler. This is what has worked for me so far, your experience may be different.

Wet tumbled for quite a while.

Complete waste of time other than when doing brass restoration/recovery.

Complete waste of time other than when doing brass restoration/recovery.

Play With Your Food: Clean Brass With Rice :: Primal Rights, Inc

Cleaning your brass is a necessity. Foreign material in or on our cases can cause all kinds of problems. Damage to expensive reloading dies, damage to rifles, and various other issues can arise if proper care is not taken.

www.primalrights.com

I wet tumble because I want clean cases. No amount of dry media tumbling will get the outside of the cases completely clean. That shit ends up in my hands and on the inside of my dies.

I don't use SS pins. I don't GAF about how clean the cases are inside and I rarely clean the primer pocket.

My brass comes out sparkling clean after tumbling by itself in dish soap, lemishine, and hot water.

It takes a shitload more of cold working than it slowly tumbling in a drum (with or without pins) to harden brass. Some of us have worked with metals our entire lives and don't need AMP to teach us about annealing, heat treatment, or metallurgy.

I don't use SS pins. I don't GAF about how clean the cases are inside and I rarely clean the primer pocket.

My brass comes out sparkling clean after tumbling by itself in dish soap, lemishine, and hot water.

It takes a shitload more of cold working than it slowly tumbling in a drum (with or without pins) to harden brass. Some of us have worked with metals our entire lives and don't need AMP to teach us about annealing, heat treatment, or metallurgy.

I switched to wet tumbling a couple of years ago and have been very happy with the results. Case mouth peening is not a factor if you limit the tumble time to about 1 and 1/2 hours and some Carbon remains inside the neck. I chamfer and dip the base of the bullet in some Graphite neck lube. I plan to start adding some liquid car polish to the wet solution since I've been told this will allow smooth bullet seating without the need for the Graphite.

It the only way to go but buy a dryer it will save tons of time. I’ve never noticed any dent ding etc. I do corn cob for 10 min to remove one shot platter sizing /expanding but before trim and chamfer

Case mouth peening is not a factor if you limit the tumble time to about 1 and 1/2 hours and some Carbon remains inside the neck.

Good point on the time. I'm experimenting when I wet tumble my pistol brass and have found that cycles as short as 30 min, using very hot water, will yield cases that are more than clean enough outside.

Overprocessing is just as dumb as underprocessing.

Kinda dumb question:

If the main (or only) point is to get the brass clean enough to not scratch dies/chamber.

What’s even the point of the stainless pins? I ran my brass last week with just soap and lemi shine and I can’t tell much if a difference. Maybe the primer pockets weren’t perfectly clean.

So, what am I missing as the point of pins that soap and water won’t do?

If the main (or only) point is to get the brass clean enough to not scratch dies/chamber.

What’s even the point of the stainless pins? I ran my brass last week with just soap and lemi shine and I can’t tell much if a difference. Maybe the primer pockets weren’t perfectly clean.

So, what am I missing as the point of pins that soap and water won’t do?

I wet tumble because I want clean cases. No amount of dry media tumbling will get the outside of the cases completely clean. That shit ends up in my hands and on the inside of my dies.

I don't use SS pins. I don't GAF about how clean the cases are inside and I rarely clean the primer pocket.

My brass comes out sparkling clean after tumbling by itself in dish soap, lemishine, and hot water.

It takes a shitload more of cold working than it slowly tumbling in a drum (with or without pins) to harden brass. Some of us have worked with metals our entire lives and don't need AMP to teach us about annealing, heat treatment, or metallurgy.

^^this...i quit using the pins in my wet tumbler over a year ago

30-45 min with soap and lemi shine...outsides are clean, insides i dont really care

giraud cleans up any small dings in the case mouths

Kinda dumb question:

If the main (or only) point is to get the brass clean enough to not scratch dies/chamber.

What’s even the point of the stainless pins? I ran my brass last week with just soap and lemi shine and I can’t tell much if a difference. Maybe the primer pockets weren’t perfectly clean.

So, what am I missing as the point of pins that soap and water won’t do?

It all boils down to people doing things because they heard/read about them without really understanding what the process really does and what their needs really are.

I don't even know who thought ss pins were a good idea to begin with. I have a feeling that pins were added because they're an analog to crushed walnut without understanding that in wet tumbling the soap and water do the cleaning by chemical action and you don't need anything to clean by mechanical action.

I also don't get why you would clean brass AFTER resizing it.

The whole point of cleaning is to not have foreign matter trapped between the case exterior and the interior surfaces of the die during a process that's an interference fit.

WTF

The whole point of cleaning is to not have foreign matter trapped between the case exterior and the interior surfaces of the die during a process that's an interference fit.

WTF

I also don't get why you would clean brass AFTER resizing it.

The whole point of cleaning is to not have foreign matter trapped between the case exterior and the interior surfaces of the die during a process that's an interference fit.

WTF

What am I missing?

To remove the Redding sizing wax off the sized brass rather than hand wiping 200 - 300 pieces.

What am I missing?

To remove the Redding sizing wax off the sized brass rather than hand wiping 200 - 300 pieces.

Well no shit. I also wet tumble after sizing to get rid of the lube.

But there are people here who don't start cleaning until after sizing, or at least it reads that way to me.

But there are people here who don't start cleaning until after sizing, or at least it reads that way to me.

Ah, I thought perhaps I was wasting my time recleaning as some people just leave the lube.

Uh, it's the only way to go with very dirty or large quantities of brass. I use a Harbor Freight cement mixer a friend gave me and I think I'm using 60lbs of pins but could probably use more. With the detergent and citrishine or whatever it's called, it does a good job. But you gotta use hot water for best results.

I should also mention that it's not exactly the best way to remove lanolin lubes, even with hot water. I make very high quality lanolin lubes (the best) and sell it only to Hide members in the PX at a little above cost. While it'll size BMG brass effortlessly (and everything else, saving dies and brass) it's a bitch to remove. One of the better options is to just wipe it off with a towel, maybe one with alcohol on it, but when loading on a progressive you don't really wanna take the time to do that. So I still have to retain a tumbler for this, though it can go through media faster than usual since it can't be "reclaimed". Just a heads up. Lanolin lube is by far the best, and the stuff I make I by far the best there is (not tooting my horn, it just can't be made stronger and still work in a sprayer, nor is necessary, and I only use the best stuff to begin with). However, water based wet tumbling solutions just won't remove the natural waxes in lanolin it ends up absorbing the dirt thus making the brass dirtier! So lanolin = dry tumbling, ultrasonic, hand wiping or in cases where it's thin enough and not problematic, just leaving it.

Now even though I do large quantities in the cement mixer, it still doesn't slow me down to do small dry tumbling batches after sizing as long as I keep it going. Or I can use the ultrasonic machine with very hot water and the very strong brass cleaner it uses. It'll handle a larger quantity too. Oh, dry tumbling gently in lots of corn cob is also about the only way to polish completed ammo (carefully of course, it's recommended to not do this in most manuals but obvious most all mfg.'s do it). If using a cement mixer for wet tumbling, removal of the vanes and pins and replacement with LOTS of corn cob can yield a high capacity and fairly safe way of polishing new loaded ammo.

Bottom line is different methods work better for different applications. I'm regularly using a few different methods, sometimes all at once. But for cleaning dirty brass the first time before sizing, wet tumbling is without a doubt the way to go.

I should also mention that it's not exactly the best way to remove lanolin lubes, even with hot water. I make very high quality lanolin lubes (the best) and sell it only to Hide members in the PX at a little above cost. While it'll size BMG brass effortlessly (and everything else, saving dies and brass) it's a bitch to remove. One of the better options is to just wipe it off with a towel, maybe one with alcohol on it, but when loading on a progressive you don't really wanna take the time to do that. So I still have to retain a tumbler for this, though it can go through media faster than usual since it can't be "reclaimed". Just a heads up. Lanolin lube is by far the best, and the stuff I make I by far the best there is (not tooting my horn, it just can't be made stronger and still work in a sprayer, nor is necessary, and I only use the best stuff to begin with). However, water based wet tumbling solutions just won't remove the natural waxes in lanolin it ends up absorbing the dirt thus making the brass dirtier! So lanolin = dry tumbling, ultrasonic, hand wiping or in cases where it's thin enough and not problematic, just leaving it.

Now even though I do large quantities in the cement mixer, it still doesn't slow me down to do small dry tumbling batches after sizing as long as I keep it going. Or I can use the ultrasonic machine with very hot water and the very strong brass cleaner it uses. It'll handle a larger quantity too. Oh, dry tumbling gently in lots of corn cob is also about the only way to polish completed ammo (carefully of course, it's recommended to not do this in most manuals but obvious most all mfg.'s do it). If using a cement mixer for wet tumbling, removal of the vanes and pins and replacement with LOTS of corn cob can yield a high capacity and fairly safe way of polishing new loaded ammo.

Bottom line is different methods work better for different applications. I'm regularly using a few different methods, sometimes all at once. But for cleaning dirty brass the first time before sizing, wet tumbling is without a doubt the way to go.

Similar threads

- Replies

- 35

- Views

- 1K

- Replies

- 7

- Views

- 301