Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do you prefer for mounting muzzle devices? Rocksett, Loctite, ?

- Thread starter pineoak

- Start date

272 breaks down around 500 degrees, rockset is 2000 degrees. Muzzle devices can hit 500 easily. I have no problem removing rockset it is high temp not high strength.

My one experience trying to remove a flash hider with Rockset was a COLLOSAL pain in the ass.

I can’t imagine why anyone would need anything beyond Loctite.

I can’t imagine why anyone would need anything beyond Loctite.

I've stopped using anything, and just torque down my ASR brakes tightly enough to hold my suppressors. If they loosen, I just crank them back down. I've realized that being able to remove and clean them, is more important than locking them down on the threads.

I too have stopped using a thread locker. The rifles recently set up for suppressors are not high volume of fire but they do heat up. Torqued at 21 ft. lbs. with clean threads and they have not come loose. On those that see FA, I use RockSett but I might reconsider those too after a little testing.

I am interested in hearing how to remove a device after using Rocksett.....

I am interested in hearing how to remove a device after using Rocksett.....

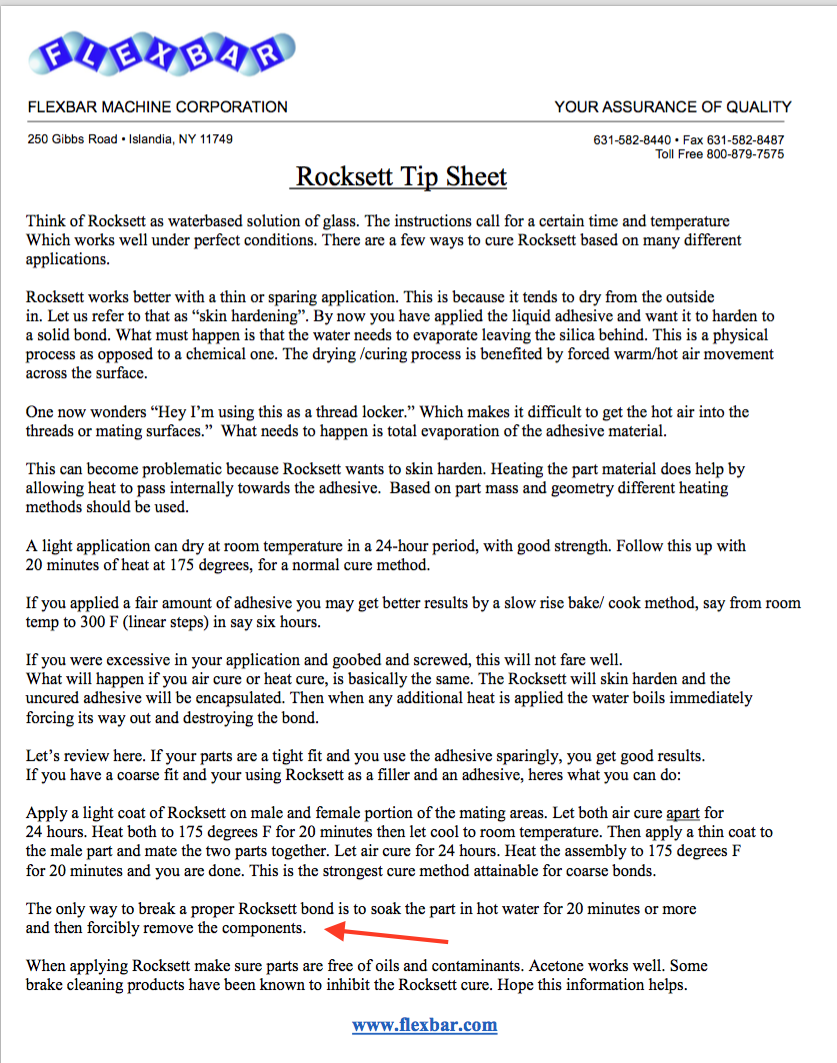

A tiny dot of rocksett keeps it from backing out due to heat but is not hard to break once you put a wrench on it like any torqued muzzle device should be.

A massive glob that drips out over everywhere when tightened will be really hard to break loose. Let it soak in water for awhile as it is soluble.

As with all things moderation is key for best results.

A massive glob that drips out over everywhere when tightened will be really hard to break loose. Let it soak in water for awhile as it is soluble.

As with all things moderation is key for best results.

Rockset is perfect for suppressor mounts and brakes. Wont let go under heat or use but cracks pretty easy if you need to remove it

I use anti seize and a torque wrench, brake hasn’t came loose and I’m not worried in the slightest about taking it off.

Exactly! That's why I only use Rocksett on firearms. Especially gas block set-screws, and muzzle devices.272 breaks down around 500 degrees, rockset is 2000 degrees. Muzzle devices can hit 500 easily. I have no problem removing rockset it is high temp not high strength.

Thunderbeast recommends red loctite for their muzzle devices. They are very thorough and diligent about doing their own testing (rather than just going with the standard quo), so they are a brand I trust and listen to when they make specific recommendations.

Probably should have gone with my gut rather than follow the instructions! Oh well, don't need to remove right now anyway!A tiny dot of rocksett keeps it from backing out

Thunderbeast recommends red loctite for their muzzle devices. They are very thorough and diligent about doing their own testing (rather than just going with the standard quo), so they are a brand I trust and listen to when they make specific recommendations.

They still rec Loctite 272.

Just hand tighten, maybe loctite blue, you use that crap you will have a hell of a time getting it off.

If barrels had tapers we wouldn’t be having this conversation lol

I over-applied Rockset to muzzle threads once. Someone posted here on SH it will dissolve in water. So I stood the barreled action up against a corner, muzzle-down in a jar of the dread Hydrogen Dioxide overnight, and in the morning the brake was easy to remove.

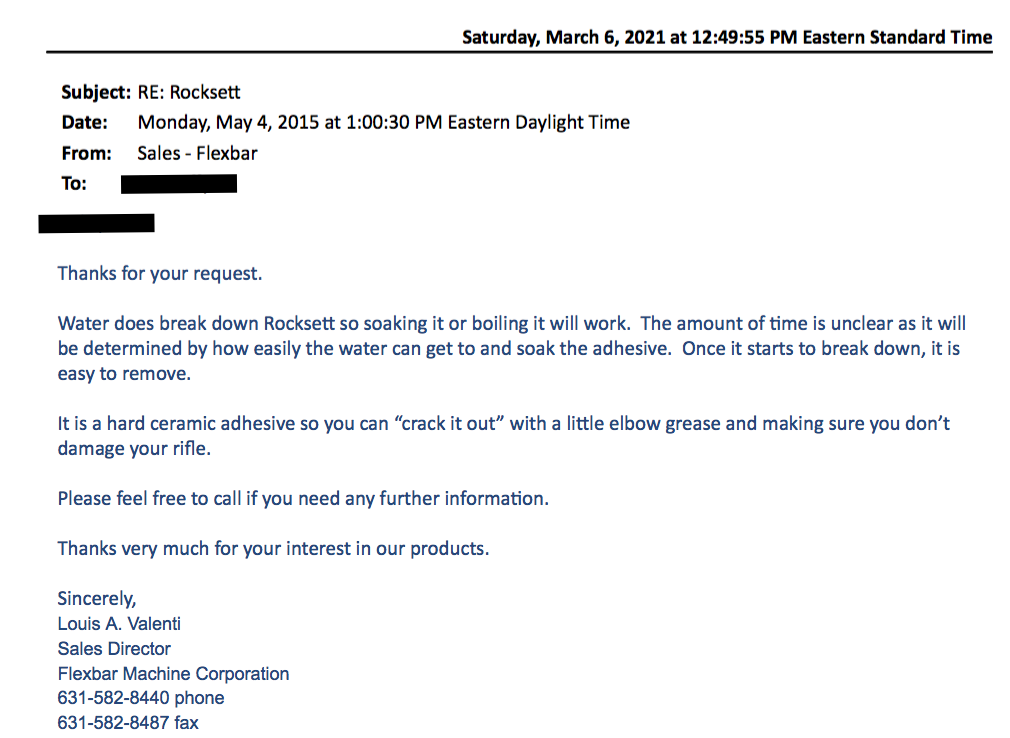

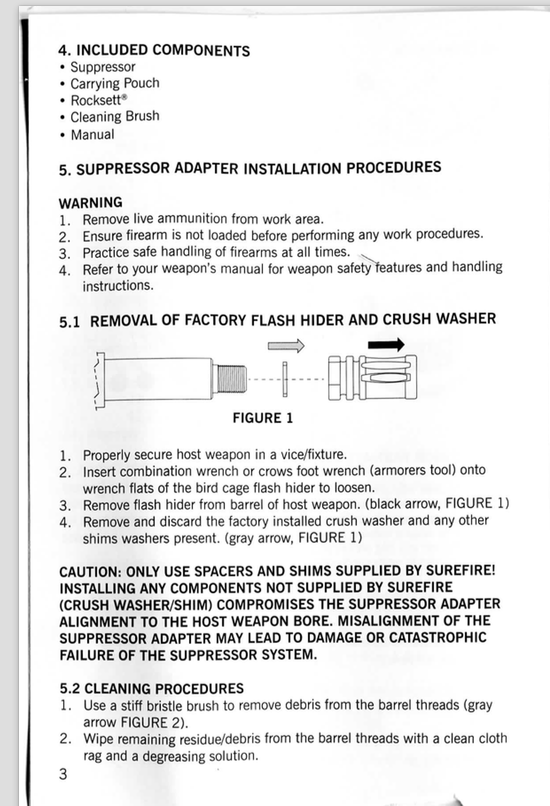

I inquired to FlexBar the mfg. of Rocksett in 2015 to learn the best method to release the ceramic based Rocksett adhesive that is stable to 2,000 Deg F. SureFire has always recommended Rocksett to secure their muzzle devices. Warm / hot water soaking is the method to release the ceramic adhesive. Application of heat of 2,000 deg F in an effort to release the ceramic adhesive would be nonsense.

I use the Permatex equivalent to Loctite 272. Degrease the threads with acetone, apply Loctite primer, then the threadlocker. Never hand one come loose with suppressor use.

Rockset can definitely be a real pain to remove sometimes, even after soaking overnight in water. (A tightly fitted threaded joint doesn't let much water in.) So I throw that crap away when it comes in the little tubes.

Some people love to quote temp numbers about this stuff, but I'd rather rely on experience. Common blue Loctite 242 or 243 (better than 242) works very well for muzzle devices, is removable much more easily than red 272, and withstands the heat of firing just fine. I switched to using blue 243 in 2008 for all sorts of suppressor mount brakes and flash hiders, and have never had one come loose or even close to coming loose. Loctite doesn't melt at 500 degrees (or whatever), the bond just starts to weaken, but it doesn't go away completely and the material is still there doing it's job.

While leaving the threads dry can work too, a big advantage in using 243 is that it seals the threads, preventing moisture from wicking in there and causing corrosion. It also lubricates the threads during assembly, like grease or oil. And with 243 you can use enough to actually seal the threads while still being able to remove the muzzle device, instead of just a drop like with red Loctite or Rockset.

Some people love to quote temp numbers about this stuff, but I'd rather rely on experience. Common blue Loctite 242 or 243 (better than 242) works very well for muzzle devices, is removable much more easily than red 272, and withstands the heat of firing just fine. I switched to using blue 243 in 2008 for all sorts of suppressor mount brakes and flash hiders, and have never had one come loose or even close to coming loose. Loctite doesn't melt at 500 degrees (or whatever), the bond just starts to weaken, but it doesn't go away completely and the material is still there doing it's job.

While leaving the threads dry can work too, a big advantage in using 243 is that it seals the threads, preventing moisture from wicking in there and causing corrosion. It also lubricates the threads during assembly, like grease or oil. And with 243 you can use enough to actually seal the threads while still being able to remove the muzzle device, instead of just a drop like with red Loctite or Rockset.

Rocksett has breakaway torque in about the same range as blue loctite. We have never had Loctite 272 come loose, ever, even in our extended full auto testing. Even when you melt it with a butane torch, it still takes alot of torque to remove it. I have, on the other hand, turned off Rocksett with a strap wrench before when trying to remove a can from a mount. I can see why cans that do not turn to remove might recommend Rocksett.

blue for me just tight enough , but still allows removing or loosening with just a little heat even boiling water can loosen it . red is just more hassle than I like .

And a spring washer.Uh just torque ......

I am amazed at the number of so called men that can't assemble things without them falling apart.

And a spring washer.

could that result in uneven pressure?And a spring washer.

Rockset for my gas guns that have a QD can muzzle device on them, I usually buy Knights shims and it always comes with a tube of Rockset.

That being said I did have a Knights CQB fh that was so stuck I had to take it to a certified armored to remove.

On my bolt guns I use blue loctite and torque to spec.

Both products work, but if you plan on swapping mounts out I would reach for the loctite and if you wanted it welded to your muzzle get Rocksett

That being said I did have a Knights CQB fh that was so stuck I had to take it to a certified armored to remove.

On my bolt guns I use blue loctite and torque to spec.

Both products work, but if you plan on swapping mounts out I would reach for the loctite and if you wanted it welded to your muzzle get Rocksett

How many problems arise not because of incorrect threadlocker, but rather due to lack of sufficient tightening torque?

If I crank on a muzzle device to 50-75 ft-lb, it's highly unlikely it's going to back off with hand torque during suppressor removal.

That being said, I use blue on bolt guns and red on semi-autos.

What I need to find is that yellow stuff that Magpul puts on its MLOK hardware. You may not want 35 ft-lb of prevailing torque on a 1/8" bolt, but that's what you need.

If I crank on a muzzle device to 50-75 ft-lb, it's highly unlikely it's going to back off with hand torque during suppressor removal.

That being said, I use blue on bolt guns and red on semi-autos.

What I need to find is that yellow stuff that Magpul puts on its MLOK hardware. You may not want 35 ft-lb of prevailing torque on a 1/8" bolt, but that's what you need.

And a spring washer.

I am amazed at the number of so called men that can't assemble things without them falling apart.

Ruger puts a simple wave washer behind the thread cap on Mark III/IV pistols. It works very well at preventing the cap from loosening, even when only finger-tight.

The only downside is that it takes me about 0.3 sec after removing the cap to lose one in the dirt.

I was told that yellow thread lock is 3M Scotch-Grip, tough to remove on small fasteners w/o heat

There are a number of different polymer "patches" applied to 180 deg of threaded fasteners, all variations of proprietary Nylok. They function not as adhesives but rather as hydraulic compression to the threaded engagement to resist loosening with vibratory impact, as such they are not heat-sensitive. Vibra-Tite is the working man's version of applying such a method to fasteners on the bench; I like to use a magnet to hold small gunsmith sized fasteners while it cures for installation. Magpul uses the yellow style, M&P uses the red style on their rear sight set screws etc. Not being an adhesive, its useful in applications such as rear sights that might require loosening / tightening as you adjust your windage at the range; usually good for 4-6 adjustments / per fastener. You can order fasteners with the adhesive applied from sources such as McMaster-Carr. As shown, sometimes the nylon is applied under the fastener head, not the threads proper.I was told that yellow thread lock is 3M Scotch-Grip, tough to remove on small fasteners w/o heat

Those nylon lock patches, as mentioned above, function as an interference fit, and do it by jamming the threads to one side, creating more metal/metal friction on the other side. Bad idea for a suppressor mount.

They also don't seal the threads from moisture like a liquid thread locking product can. And generally they're intended for a single use as well.

However there is a different type of pre-applied lock patch (also single use) that is applied 360° around the threads and is an adhesive-based product; those generally perform very similarly to a liquid thread locker other than the convenience of being pre-applied. I don't see much advantage for those in this application though, unless a muzzle device manufacturer wants to have it applied to their parts.

They also don't seal the threads from moisture like a liquid thread locking product can. And generally they're intended for a single use as well.

However there is a different type of pre-applied lock patch (also single use) that is applied 360° around the threads and is an adhesive-based product; those generally perform very similarly to a liquid thread locker other than the convenience of being pre-applied. I don't see much advantage for those in this application though, unless a muzzle device manufacturer wants to have it applied to their parts.

Those nylon lock patches, as mentioned above, function as an interference fit, and do it by jamming the threads to one side, creating more metal/metal friction on the other side

The plastic yields before steel does. It doesn't force anything anywhere. It just fills in gaps and the excess gets spread around/cut off by the mating threads.

If your threads are such a loose fit that a small dab of nylock/vc3/whatever is going to cause misalignment you have bigger problems to fix.

@strikeeagle1 has it right.

The plastic yields before steel does. It doesn't force anything anywhere. It just fills in gaps and the excess gets spread around/cut off by the mating threads.

If your threads are such a loose fit that a small dab of nylock/vc3/whatever is going to cause misalignment you have bigger problems to fix.

@strikeeagle1 has it right.

Typical reading comprehension fail for Thread Pirate. Great job proving you don’t know what you’re talking, or what anyone else is talking about.

Nobody said the steel yields, genius.

And yes, StrikeEagle is right. He never mentioned muzzle devices. That stuff is fine for the applications he described and what it’s commercially used for.

You're the one who doesn't have a clue, calling a joint with a plastic filler "interference fit".Typical reading comprehension fail for Thread Pirate. Great job proving you don’t know what you’re talking, or what anyone else is talking about.

Nobody said the steel yields, genius.

And yes, StrikeEagle is right. He never mentioned muzzle devices. That stuff is fine for the applications he described and what it’s commercially used for.

LOL, what a fucking ignoramus.

You're the one who doesn't have a clue, calling a joint with a plastic filler "interference fit".

LOL, what a fucking ignoramus.

Pretty much every time you post you prove yourself to be a clueless troll. Keep on winning!

You've reached the point where you don't even think about what your own words mean, let alone anyone else's. Are you drunk, or is it the meds? Or are you actually just that bad at critical thinking?

"Interference fit" doesn't mean steel has to yield, genius. It just means the sum of the male parts is slightly larger than the female parts, so something has to move - in this case it's obviously the thread locking patch. You have some major misconceptions about what things mean, and this is the second thread in the row where you tried to argue about something because your definition is wrong. Take a hint, and start looking up what things mean before you argue about them.

As I've said before - arrogance makes you stupid. That's 100% on you.

Last edited:

Pretty much every time you post you prove yourself to be a clueless troll. Keep on winning!

You've reached the point where you don't even think about what your own words mean, let alone anyone else's. Are you drunk, or is it the meds? Or are you actually just that bad at critical thinking?

"Interference fit" doesn't mean steel has to yield, genius. It just means the sum of the male parts is slightly larger than the female parts, so something has to move - in this case it's obviously the thread locking patch. You have some major misconceptions about what things mean, and this is the second thread in the row where you tried to argue about something because your definition is wrong. Take a hint, and start looking up what things mean before you argue about them.

As I've said before - arrogance makes you stupid. That's 100% on you.

Wrong answer dumbass. fillers/gaskets and other easily deformable materials aren't considered part of the fit.

Let's talk about your suppressor/muzzle device threads that are so loose that a dab of nylon on one side sets everything so off center.

I'm not an expert, but I'd start with a small tiny dab of blue loctite and start from there.

Not necessarily muzzle devices, but sometimes even a gob of blue loctite can bond 2 screwed items together pretty darn well.

Not necessarily muzzle devices, but sometimes even a gob of blue loctite can bond 2 screwed items together pretty darn well.

Last edited:

Wrong answer dumbass. fillers/gaskets and other easily deformable materials aren't considered part of the fit.

Let's talk about your suppressor/muzzle device threads that are so loose that a dab of nylon on one side sets everything so off center.

Might want to look up what an interference fit is in Machinists Handbook. Has a specific meaning.Those nylon lock patches, as mentioned above, function as an interference fit, and do it by jamming the threads to one side, creating more metal/metal friction on the other side. Bad idea for a suppressor mount.

They also don't seal the threads from moisture like a liquid thread locking product can. And generally they're intended for a single use as well.

However there is a different type of pre-applied lock patch (also single use) that is applied 360° around the threads and is an adhesive-based product; those generally perform very similarly to a liquid thread locker other than the convenience of being pre-applied. I don't see much advantage for those in this application though, unless a muzzle device manufacturer wants to have it applied to their parts.

Trust but verify.Might want to look up what an interference fit is in Machinists Handbook. Has a specific meaning.

I'll play. To entertain the viewing audience at large this is from my library.

In the original Machinery's Handbook 1914 Edition, the term interference fit was neither defined or referenced. The latest 31st Edition defines an interference fit. A lot has changed.

Last edited:

Threads are not cut to a class 5. They are recommended cut to a class 3. Reference TBAC thread page.Trust but verify.

I'll play. To entertain the viewing audience at large this is from my library.

In the original Machinery's Handbook 1914 Edition, the term interference fit was neither defined or referenced. The latest 31st Edition defines an interference fit. A lot has changed.

View attachment 7934882View attachment 7934883View attachment 7934884

View attachment 7934891

Adding something plastic to the thread does not change the tolerances of the thread. It just means the threads are dirty and fit tighter.

Yondering was saying that it becomes an interference fit. That is not so.

We don't have the need for interference fit at all for muzzle devices. Or else almost nobody would be able to install it at home without using an oven and a freezer. It is for Permanent installation of threads for extra strength in very specific uses. Or else you would almost have to cut off the muzzle device, throw it away, and rethread the barrel.

Pretty sure 308pirate was referencing the Machinery's Handbook definition. He just doesnt care/ have the patience enough to teach everyone the finer details of how things actually be.

Thanks for the supporting documentation. My Handbook is older than yours. My 27th edition is in my garage. Probably should get an new one to add. Didn't realize they've gone through so many editions.

Adding something plastic to the thread does not change the tolerances of the thread. It just means the threads are dirty and fit tighter.

Yondering was saying that it becomes an interference fit. That is not so.

Geez fella. You really can't see the critical thinking failure there?

If you want to get pedantic and technical, Machinery's handbook states "plastic movement of material", which is exactly what happens with the nylon lock patch. It does NOT say "plastic movement of steel", which seems to be your interpretation.

Beyond that, I said "function as an interference fit". Do you know what "function as" means, or do you need that defined for you? It's not the same as "is".

The nylon lock patch does not make the threads "dirty", and it does not just get wiped around the threads like Thread Pirate said; it deforms to fit the threads but stays put and forces the threads to one side, creating higher metal to metal friction on that side. If it were to get wiped off and spread around the threads (usually from excessive use), then it fails to do its job correctly at that point. The type of pre-applied patch that does wipe around the threads by design is a completely different type of material, and works through a completely different mechanism, being adhesive rather than just something wedged between the male and female threads.

I ran fastener testing for one of the largest truck manufacturers in the country for several years, and am intimately familiar with what the pre-applied nylon patches do and don't do. They aren't used on precision threads for good reason, which I hoped would be evident from my comments but apparently not to everyone.

What's even your point here? Just to defend the biggest dickhead on snipershide? Some of you turkeys that like to jump to Thread Pirate's defense could do better to pay attention to the stupid crap he actually says, and his method of crapping all over threads to derail them.

Similar threads

- Replies

- 48

- Views

- 4K

Suppressors

Anyone HUXWRX 762 TI direct thread?

- Replies

- 11

- Views

- 646