Tactical Operations: When you care enough to send your very best...

Soft, smooth-radius edge on Tac Ops Recoil Lug. Mike was kind enough to radius the edge of my Receiver too (thanks Mike!):

Soft radiuses on 303 Stainless Tac Ops Bottom Metal. Mike doesn't bitch about 303 being a PITA to machine and a bitch on tooling:

Here are a couple of photos showing the radiuses on leading edge of the bolt as well as the bolt lugs:

Tac Ops "times" the screws that fasten the Anschutz Rail to the underside of the stock. A 10" Anschutz Rail has four screws:

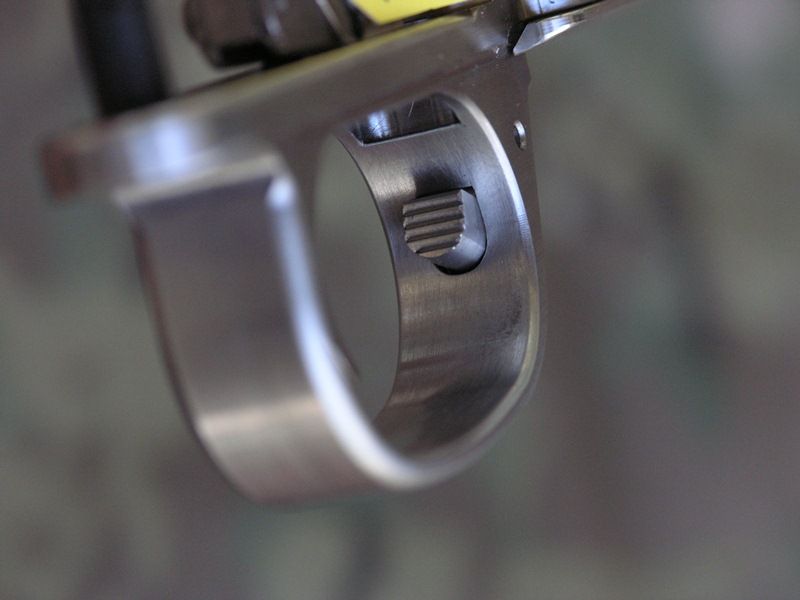

Unlike most "tactical" bolt knobs, when properly-installed, the TOBKC strengthens the handle shank, and can increase clearance between the scope and stock:

Those are just a few touches that are visible on the outside - when you move beyond the surface there are about 20 other things that Tac Ops does differently to their rifles. Some of these things are proprietary while others are step-based. Together as a system, they are why Tac Ops rifles are so smooth, reliable, and consistently-accurate. For instance, the POI of Tac Ops rifles doesn’t change from Cold Bore to Warm Bore. Aside from the extremely precise machining to square-up the receiver face, threads, bolt face, lugs, and chamber - two other things directly related to Tac Ops rifle’s CB to DB zero POI shift that I can mention is that Tac Ops uses a special receiver-to-barrel fit. What?

The barrel torque used by most gunsmiths’ ranges between 50-60 ft./lbs. - sometimes 100 ft./lbs and the torque is only borne by the first three (3) threads (standard barrel-to-receiver fit). The problem here is that the barrel and receiver heat-up and expand during firing at different rates. This causes the receiver-to-barrel fit to loosen, resulting in POI change.

The special receiver-to-barrel fit on Tac Ops rifles provides load-bearing on 100% of the mating threads, allowing Tac Ops barrels to be torqued much, much higher (between 220-280 ft./lbs. depending upon the rifle and caliber). The perfectly-machined receiver-to-barrel thread fit combined with very high torque do not allow any slop to develop between the receiver and barrel as the two heat-up, resulting in consistent POI from CB to WB/HB.

Furthermore, no matter how dependable, consistently accurate, or how finely crafted and obsessively finished Tac Ops rifles are there are people who are less discerning and/or who place less importance on refinements, or just don’t know enough to realize that there really are differences and to appreciate those differences. But it’s impossible to see, feel, and experience those differences when you haven’t handled and fired one. Me, I’m into it.

As Lowlight said “It’s a long term investment, it’s a collector’s piece, and it’s a shooter”.

Keith

I'll preface this reply by stating that what Lowlight posted really nailed all points, and that what I'm about to say is truly said without malice and absolutely devoid of emotional and monetary investment. I speak from very long experience. That said, it's fair to say that since you haven't handled or shot a Tac Ops rifle that you can't comment on whether the price is worth it or not. The reality is that anyone who hasn't personally handled and/or shot a Tac Ops rifle has no basis for comparison with other rifles. There are lots of little refinements on Tac Ops rifles that most people never notice until those details are pointed-out to them. These include, but are not limited to the smoothly-radiused edges on the Tac Ops Bottom Metal, Tac Ops Recoil Lug, leading edges on the bolt and bolt lugs, the “timing” the screws of Anschutz Rails, and the extra thought and execution of the Tac Ops Bolt Knob Conversion.I will preface this statement with the fact that I have not handled one of these rifles, so cannot comment on whether the price is worth it or not.

Soft, smooth-radius edge on Tac Ops Recoil Lug. Mike was kind enough to radius the edge of my Receiver too (thanks Mike!):

Soft radiuses on 303 Stainless Tac Ops Bottom Metal. Mike doesn't bitch about 303 being a PITA to machine and a bitch on tooling:

Here are a couple of photos showing the radiuses on leading edge of the bolt as well as the bolt lugs:

Tac Ops "times" the screws that fasten the Anschutz Rail to the underside of the stock. A 10" Anschutz Rail has four screws:

Unlike most "tactical" bolt knobs, when properly-installed, the TOBKC strengthens the handle shank, and can increase clearance between the scope and stock:

Those are just a few touches that are visible on the outside - when you move beyond the surface there are about 20 other things that Tac Ops does differently to their rifles. Some of these things are proprietary while others are step-based. Together as a system, they are why Tac Ops rifles are so smooth, reliable, and consistently-accurate. For instance, the POI of Tac Ops rifles doesn’t change from Cold Bore to Warm Bore. Aside from the extremely precise machining to square-up the receiver face, threads, bolt face, lugs, and chamber - two other things directly related to Tac Ops rifle’s CB to DB zero POI shift that I can mention is that Tac Ops uses a special receiver-to-barrel fit. What?

The barrel torque used by most gunsmiths’ ranges between 50-60 ft./lbs. - sometimes 100 ft./lbs and the torque is only borne by the first three (3) threads (standard barrel-to-receiver fit). The problem here is that the barrel and receiver heat-up and expand during firing at different rates. This causes the receiver-to-barrel fit to loosen, resulting in POI change.

The special receiver-to-barrel fit on Tac Ops rifles provides load-bearing on 100% of the mating threads, allowing Tac Ops barrels to be torqued much, much higher (between 220-280 ft./lbs. depending upon the rifle and caliber). The perfectly-machined receiver-to-barrel thread fit combined with very high torque do not allow any slop to develop between the receiver and barrel as the two heat-up, resulting in consistent POI from CB to WB/HB.

In terms “of getting the best bang for the buck for your intended purpose” the OP (nightwolf0215)’s question would be a legitimate one IF it was innocuous. However, like 18Echo and Lowlight I recognize trolling. A loaded, beaten-to-death question asked by a low post count “member” who just slunk quietly away after posting.That being said, I think the OP's question is a legitimate one from the context of getting the best bang for the buck for your intended purpose.

Again, Lowlight nailed the OP’s question, as well as your and other questions in this thread. I like the fact that Lowlight said these things, since his words tend to carry much greater weight than what most others - including myself, say. Once again, custom actions aren’t necessarily better (and don't not magically make a rifle more accurate) than a rifle built on a trued Remington action. That’s a function of picking the right gunsmith. Sure, out-of-the-box a custom action is typically machined to much tighter tolerances, but it’s not like they’re all perfect. Off the top of my head I can think of custom actions from four (4) manufacturers’ held in very high esteem that I’ve personally seen that had been finished poorly, had insufficient lug contact, incorrect timing, and a few other issues. Buying a custom receiver does not guarantee everything is perfectly square, well-finished, or that a rifle built off of it will be more accurate and more dependable than a rifle built off of the lowly Remington 700. I’d go with a “polished turd” Remington 700 built by Tac Ops over a custom action screwed-together by Joe Bob gunsmith any day of the week.Thru the years, I have had over 8 custom rifles built by such gunsmiths as R Bros, SSG, Montour County Rifles, Centershot Rifles. All were different calipers, and all were tack drivers. All were 1/2 MOA rifles out to 800 yards, and some, like my 7 Rogue and 338 built by R Bros were shot out to 1300 yards, and were still 3/4 or less MOA rifles.

All of these rifles were built for $3500 or less with custom actions and top notch components.

Depending upon the model of Tac Ops rifle and the features that one is looking at said Tac Ops rifles might be in the $4,500.00 range. You may not have found it “necessary” to spend what you perceive as an additional $1,000.00-$1,500.00 for your needs. And as far as the OP’s question of what is to be gained with “the extra money” on Tac Ops rifles over “custom builds” (besides the extreme near bench rest accuracy out of a tactical rifle, fit and finish of a Holland & Holland Custom, the confidence that you’ll make the shot if you do your part, and the satisfaction of knowing you own the best I really can’t quantify it.Correct me if I am wrong, but aren't these TacOp rifles in the $4500 range?

My point of this post is that I have not found it necessary to spent an additional $1-1,500 for my needs.

I think the jist of the OP's question was what is to be gained with the extra money on these rifles over other custom builds.

No disrespect intended to those that own these rifles, as I can appreciate quality work based on the fact that I have gone the custom route on many occasions.

Furthermore, no matter how dependable, consistently accurate, or how finely crafted and obsessively finished Tac Ops rifles are there are people who are less discerning and/or who place less importance on refinements, or just don’t know enough to realize that there really are differences and to appreciate those differences. But it’s impossible to see, feel, and experience those differences when you haven’t handled and fired one. Me, I’m into it.

As Lowlight said “It’s a long term investment, it’s a collector’s piece, and it’s a shooter”.

Keith