Okay. I wonder if AMP's findings were straight out of the annealer (no cleaning to change the brass surface).I clean, anneal, body size, collet neck size, graphite lube, mandrel neck expand.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help pls, Reloads went to hell after introducing an AMP Annealer in to the mix.

- Thread starter canuckistaninia

- Start date

Since I turn necks, I particularly like to us a collet die to neck size (rather than FL size) after I've bumped the shoulder back by .002. The collet die squeezes imperfection out of the neck (like any doughnut that might be forming).

When I FL size, I do it without a bushing or expander ball, so I then use a mandrel to get to the expected diameter.

If one is using a collet die after FL sizing, I don't see the point . . . unless the mandrel in the collet die isn't the proper size. It seems to me by doing both, it simply increases the propensity for getting more run out than desired . . . ???

When I FL size, I do it without a bushing or expander ball, so I then use a mandrel to get to the expected diameter.

If one is using a collet die after FL sizing, I don't see the point . . . unless the mandrel in the collet die isn't the proper size. It seems to me by doing both, it simply increases the propensity for getting more run out than desired . . . ???

Check your concentricity.SO things were going well, my rifle loved my recipe (43.4 grains of varget with a 178 ELD-M, lapua brass, BR2 primers getting me 2667 FPS) and was typically in the half to 3/4 MOA range at 100 yards. To be honest, when I was working up my initial recipe, the rifle shot all loads under 1.2 MOA. I decided to start annealing to bring down the SD and prolong brass life. Since introducing the AMP annealer in to the mix, the SD has dropped from 18 to 6, MV has stayed within 5 FPS but groups have opened up to 1 MOA being "good" and 1.5 being more the norm. The rifle is still performing with old/reference loads continue to shoot half MOA. Any assistance/confirmation of where you'd go next would be appreciated

I'm using a 2nd gen Amp annealer, in AZTEC mode, when I ran the test it spat out code 170 (so that's what I've been using in aztec mode to anneal)

My old process

20 min SS tumble w/soap

lube

decap/resize

trim

chamfer

debur

mandrel die

45 min SS tumble w/soap

prime

load

New process

20 min SS tumble w/soap

anneal

lube

decap/resize

trim

chamfer

debur

mandrel die

45 min SS tumble w/soap

prime

load

I've read that some people are using graphite to lube the inside of the necks before they load, I haven't gone down this road yet, it's the last thing I can think to try, but I'd appreciate some opinions if you guys are willing to share them.

Since I turn necks, I particularly like to us a collet die to neck size (rather than FL size) after I've bumped the shoulder back by .002. The collet die squeezes imperfection out of the neck (like any doughnut that might be forming).

When I FL size, I do it without a bushing or expander ball, so I then use a mandrel to get to the expected diameter.

If one is using a collet die after FL sizing, I don't see the point . . . unless the mandrel in the collet die isn't the proper size. It seems to me by doing both, it simply increases the propensity for getting more run out than desired . . . ???

Who's using a collet die after FL sizing?

Who's using a collet die after FL sizing?

That's what this sounds like ("body size = FL sizing???) :

I clean, anneal, body size, collet neck size, graphite lube, mandrel neck expand.

That's what this sounds like ("body size = FL sizing???) :

Body sizing is not FL sizing. FL dies size the whole case. Body dies size only the body. They leave the neck alone.

Body sizing is not FL sizing. FL dies size the whole case. Body dies size only the body. They leave the neck alone.

OK. Understood. My bad for thinking something else.

Why run an mandrel through the neck after sizing the neck with a collet die? Can't get a collet die mandrel of the right size?

OK. Understood. My bad for thinking something else.

Why run an mandrel through the neck after sizing the neck with a collet die? Can't get a collet die mandrel of the right size?

no you can get mandrels for the collet die in any size from lee...or just chuck them up in a drill and size them yourself...the idea behind the mandrels for final neck size is that they supposedly straighten out the necks and reduce run out,push any inconsistencies to the outside of the neck and all of this is supposed to reduce ESs...i just got the imperial dry lube and a full set of mandrels from 21st century yesterday so i can see for myself if all this is true...i hate to add a step to my process but if they do all of what ive read and heard then its worth it to me.

all that said im skeptical because ive full length sized for years with an expander ball and have never had ESs over 25ish with samples in the 50 plus range unless there was something else causing it....doughnuts..varying powder charges..bad primers ECT.

im shooting a 6BRX and was shooting a 6BR and recently started annealing every time and like the OP everything went south...i normally anneal every 4-5 firing and my ESs in both those guns was never much over 20FPS with 40plus round samples.

this time i annealed all my BRX brass and reduced my neck size from .002 to .001...ive shot 29 rounds this week and all the numbers are very good...the highest ES has been 26 and that was with a very compressed load of H4350...the others have been from about 7FPS to 16FPS.

i will finish my loads up this morning and verify at distance(as long as the wind dont start howling...calling for 40mph gusts)and then take a known load and load 5 like i normally do..5 using a mandrel to set final neck size and 5 using the mandrel and the imperial dry lube.

right now it looks like reducing my neck size has cured my issues.

IMHO the collet die is a great tool as long as you turn your necks...i ran a body die and a collet die for a few years when i turned necks...i got tired of spending so much time at the bench doing prep work and started looking for ways to cut time and one of the ways was to stop neck turning.

OK. Understood. My bad for thinking something else.

Why run an mandrel through the neck after sizing the neck with a collet die? Can't get a collet die mandrel of the right size?

The mandrel that came with the die was .3057” which produced .001” of neck tension with a direction of brass spring back AWAY from the bullet.

I then obtained .303”, .304”, and .305” mandrels to control neck tension. I found that if I used an undersized sizing mandrel with a .3065” expander mandrel I could get the desired neck tension with the direction of brass spring back TOWARD the bullet. Plus, the expander mandrel smears the graphite into the neck.

And I’m still sizing less than with a FL die.

The mandrel that came with the die was .3057” which produced .001” of neck tension with a direction of brass spring back AWAY from the bullet.

I then obtained .303”, .304”, and .305” mandrels to control neck tension. I found that if I used an undersized sizing mandrel with a .3065” expander mandrel I could get the desired neck tension with the direction of brass spring back TOWARD the bullet. Plus, the expander mandrel smears the graphite into the neck.

And I’m still sizing less than with a FL die.

no you can get mandrels for the collet die in any size from lee...

I thought so. I know lee had a mandrel that's supposed to be .306 (about .001 larger than their standard .305). I had gotten one, but it just didn't work out for me and so it just sit with a collection of other tried tools that I don't use.

the idea behind the mandrels for final neck size is that they supposedly straighten out the necks and reduce run out,push any inconsistencies to the outside of the neck and all of this is supposed to reduce ESs..

Hmmm??? I still a strong skeptic with regards to it "straightening out the necks" . . . if I understand how these mandrels are used where there's no support of the body. It seems to me to be more about not inducing any more run out than what's already there.

AND, am quite skeptical about any movement of "inconsistencies" to the outside of the neck. This issue is what I like about a collet die in that it's squeezes the "inconsistencies" away (not so much from one side to another) and why we see changes in the size (length) of the neck where the material expanded to. After using a collet die, I not only see an increase in the COAL, but also a slight decrease in head space, which is evidence of what I'm saying.

i just got the imperial dry lube and a full set of mandrels from 21st century yesterday so i can see for myself if all this is true...i hate to add a step to my process but if they do all of what ive read and heard then its worth it to me.

all that said im skeptical because ive full length sized for years with an expander ball and have never had ESs over 25ish with samples in the 50 plus range unless there was something else causing it....doughnuts..varying powder charges..bad primers ECT.

im shooting a 6BRX and was shooting a 6BR and recently started annealing every time and like the OP everything went south...i normally anneal every 4-5 firing and my ESs in both those guns was never much over 20FPS with 40plus round samples.

Expander balls weren't working for me (too much run out induced, like .006 or more . . . often). Am annealing after every firing as I'm convinced it's the thing to do given the expensive test results that Amp Annealing did:

Induction Annealing Brass | Our Research | AMP

View the latest articles from AMP Annealing. Get tips and tricks from our R&D. Here we upload articles to provide your the best possible information on innovations in the annealing process.

These days, am getting single digit SD's and ES's under 20 with a surprisingly good amount of ES's that are single digits. Was really blow away a couple months ago with a 5 round ES of 3 and SD of 1.1.

?IMHO the collet die is a great tool as long as you turn your necks...i ran a body die and a collet die for a few years when i turned necks...i got tired of spending so much time at the bench doing prep work and started looking for ways to cut time and one of the ways was to stop neck turning.

I too feel the collet die is a great tool . . . and very underrated if you ask me. I only wish the Lee collet die didn't leave little marks on the outside of my throats (apparently from the squeezing the throat takes). Hmmm??? Maybe I'll have to experiment and see if there's a way to exert less pressure to minimize this. Or . . . see if some kind of customization by Lee can be done.

i went out twice today and all the numbers look good...at this point i am pretty sure that just reducing the neck size is the fix for me.

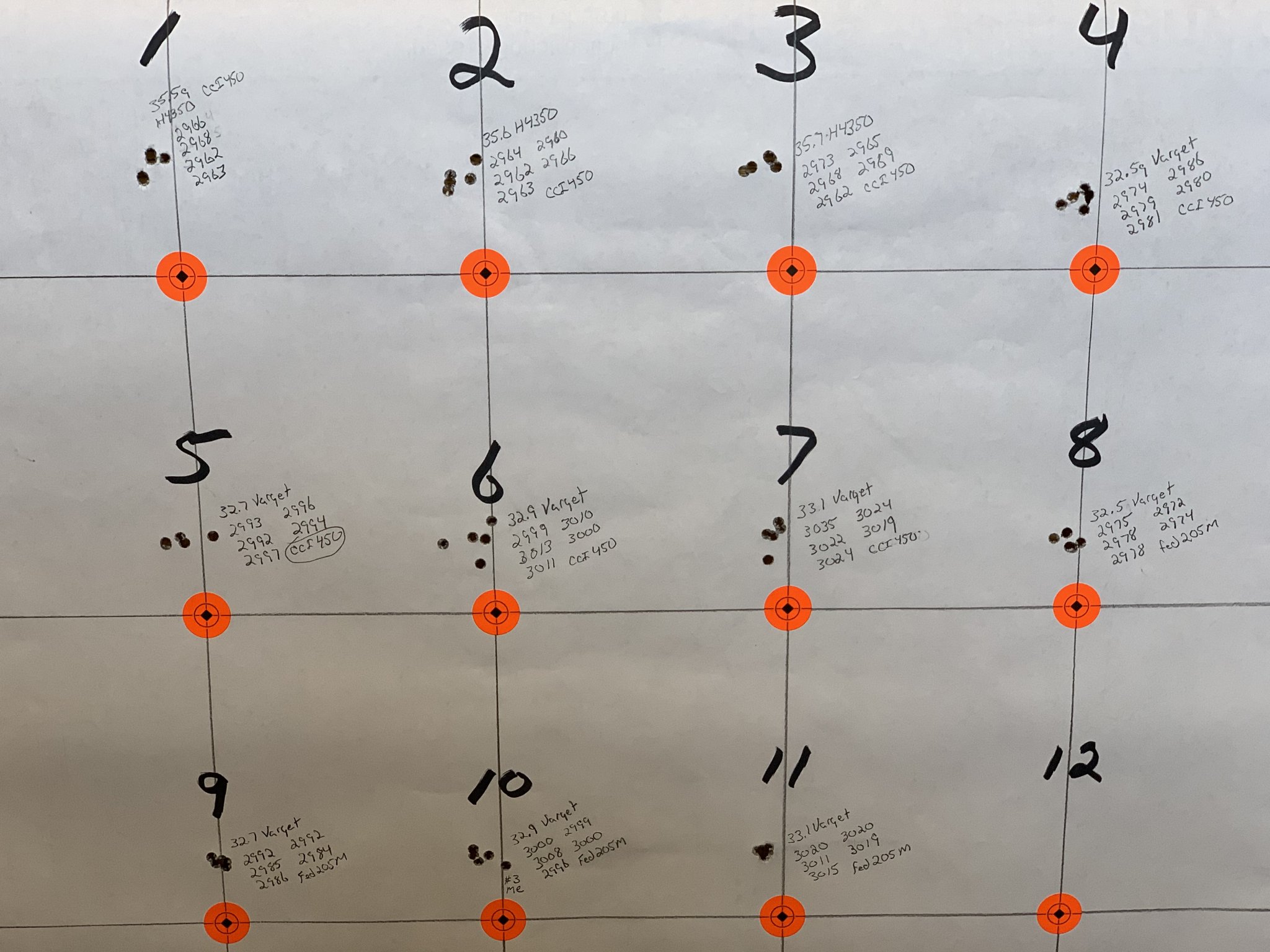

this is a 6BRX using Peterson 6BR brass and a 108g berger BTT...

1 thru 3 is H4350 CCI450 and were seated .015 off the lands

4 thru 7 is varget CCI450 and .015 off the lands

8 thru 11 is varget FED205M and seated .025 off the lands

i dont think the primer swap the second time out was the biggest factor in the tighter groups the seating change was....ive shot a lot of 108s and always end up .020-.025 off.

i have 10 rounds loaded for tomorrow with the 33.1g varget load that i sized to .0265 and used a mandrel to size back up to .267...i did not use the dry neck lube because the numbers are good at this point but did use my normal one shot on the inside necks...ive also got 30 loaded with 33.1g using just a .267 bushing...ill shoot all of these over the magneto speed tomorrow and see how the ESs and SDs go.

this is a 6BRX using Peterson 6BR brass and a 108g berger BTT...

1 thru 3 is H4350 CCI450 and were seated .015 off the lands

4 thru 7 is varget CCI450 and .015 off the lands

8 thru 11 is varget FED205M and seated .025 off the lands

i dont think the primer swap the second time out was the biggest factor in the tighter groups the seating change was....ive shot a lot of 108s and always end up .020-.025 off.

i have 10 rounds loaded for tomorrow with the 33.1g varget load that i sized to .0265 and used a mandrel to size back up to .267...i did not use the dry neck lube because the numbers are good at this point but did use my normal one shot on the inside necks...ive also got 30 loaded with 33.1g using just a .267 bushing...ill shoot all of these over the magneto speed tomorrow and see how the ESs and SDs go.

I thought so. I know lee had a mandrel that's supposed to be .306 (about .001 larger than their standard .305). I had gotten one, but it just didn't work out for me and so it just sit with a collection of other tried tools that I don't use.

i stopped using the LCD because i stopped turning necks and if not turning necks i found the LCD does not work so well

Hmmm??? I still a strong skeptic with regards to it "straightening out the necks" . . . if I understand how these mandrels are used where there's no support of the body. It seems to me to be more about not inducing any more run out than what's already there.

AND, am quite skeptical about any movement of "inconsistencies" to the outside of the neck. This issue is what I like about a collet die in that it's squeezes the "inconsistencies" away (not so much from one side to another) and why we see changes in the size (length) of the neck where the material expanded to. After using a collet die, I not only see an increase in the COAL, but also a slight decrease in head space, which is evidence of what I'm saying.

i to am skeptical but if you think about it the mandrel should produce the most consistent neck tension.

I hope you'll post a detailed update on what you find.

im lazy and dont like typing LOL...ill post up want i find but its not going to be a super detailed documentary.

Expander balls weren't working for me (too much run out induced, like .006 or more . . . often). Am annealing after every firing as I'm convinced it's the thing to do given the expensive test results that Amp Annealing did:

Induction Annealing Brass | Our Research | AMP

View the latest articles from AMP Annealing. Get tips and tricks from our R&D. Here we upload articles to provide your the best possible information on innovations in the annealing process.www.ampannealing.com

These days, am getting single digit SD's and ES's under 20 with a surprisingly good amount of ES's that are single digits. Was really blow away a couple months ago with a 5 round ES of 3 and SD of 1.1.Sure'd be nice if I could do that consistently.

i like to anneal every time because everything is just more consistent and now ive got the high ES issue figured out i will continue to anneal every time.

I too feel the collet die is a great tool . . . and very underrated if you ask me. I only wish the Lee collet die didn't leave little marks on the outside of my throats (apparently from the squeezing the throat takes). Hmmm??? Maybe I'll have to experiment and see if there's a way to exert less pressure to minimize this. Or . . . see if some kind of customization by Lee can be done.

if your leaving marks in your brass its because youve got the die screwed down to far and need a smaller mandrel...contact lee and they will make you what ever size mandrels you want.

if your leaving marks in your brass its because youve got the die screwed down to far and need a smaller mandrel...contact lee and they will make you what ever size mandrels you want.

It's not quite the mandrel that's the problem. It's the fingers of the collet that apparently don't come completely together leaving enough space for a slight ridge from some of the brass squeezing up into that space. This doesn't effect the interior surface against the mandrel.

So, I expect a smaller mandrel to allow the collet fingers to come almost completely closed leaving virtually no gap for the brass to move into, or . . . a better fitted collet to mandrel to get the right dimensions with no gaps that the brass can move into.

These ridges are really small and can be seen visually and even measured to some extent with a concentricity tool. Though, when you measure them, they've really small and don't seem to effect concentricity or the effectiveness of the loads.

It's not quite the mandrel that's the problem. It's the fingers of the collet that apparently don't come completely together leaving enough space for a slight ridge from some of the brass squeezing up into that space. This doesn't effect the interior surface against the mandrel.

So, I expect a smaller mandrel to allow the collet fingers to come almost completely closed leaving virtually no gap for the brass to move into, or . . . a better fitted collet to mandrel to get the right dimensions with no gaps that the brass can move into.

These ridges are really small and can be seen visually and even measured to some extent with a concentricity tool. Though, when you measure them, they've really small and don't seem to effect concentricity or the effectiveness of the loads.

yep I used a LCD for a long time I’m very familiar with them and how they work...are you or were you camming over when you used the die?

Rotate the case an 1/8 of a turn and collet it again and the fingers will get pressed down the previous ridges if it bugs ya.

bulletin.accurateshooter.com

bulletin.accurateshooter.com

Tips for Using LEE Collet Dies « Daily Bulletin

For those who prefer to neck-size their brass (rather than full-length-size), the LEE Collet Die is a popular, inexpensive option. It works by having collet tangs or fingers press the neck against a central mandrel. The benefit is that you get a very straight neck, which is sized consistently...

yep I used a LCD for a long time I’m very familiar with them and how they work...are you or were you camming over when you used the die?

Yup . . . camming over, just a little.

Yup . . . camming over, just a little.

im sure you know this but if your camming over and its noticeable or your ram kind of locks in any way at the bottom of the stroke then you really need a smaller mandrel...the collet can only size the brass to what the mandrel allows...camming over and or adding more pressure will not size the brass any more...trust me i had a stock pile of the aluminum caps for awhile.

Back off on the collet die a bit. If you are seeing ridges ironed into the necks and a shortened headspace after using the collet die, you are going down too far. Back up just a tad. There should be no headspace movement associated with the collet die....snip...

After using a collet die, I not only see an increase in the COAL, but also a slight decrease in head space, which is evidence of what I'm saying.

...snip....

Maybe I'll have to experiment and see if there's a way to exert less pressure to minimize this. Or . . . see if some kind of customization by Lee can be done.

I did some unscientific testing of brass yesterday with the induction annealer I made. I don't have access to a metallurgy lab so I decided to take a few fully prepped cases and used a small vise to witness the impact of various annealing temperatures. I used identically prepped cases to ensure consistency. The approach was to slowly close the vise until contact was made with the case neck. I then rotated the vice handle a bit more to the same exact spot each time. Pre-annealing tension would be applied to the case neck and upon release off the handle you would visually see the neck spring back and retain its shape. Post annealing it was evident that as I started to cross into over-temp territory the spring back was greatly reduced. Going to glowing red led to a case neck that lost all springback and would stay permanently deformed. The point here is that case neck tension is going to change as you get closer to a full anneal of the case neck. When using a more manual process (ie. NOT AMP with Aztec) you really have to stay consistent on temp and time for each lot. Getting to any sort of glow is getting too hot.

As for the mandrel topic... I was getting runout all over the map with my RCBS SB die and expander ball. Resizing without the expander ball was giving very low neck runout so I new the ball was the issue. I ended up going with a 21st Century mandrel (0.223) and it completely cleared up the runout issues. I do use Redding dry lube before seating as I SS tumble my brass. The devil is in the details and in my experience it pays to measure as much as you can to isolate issues.

Tim

Temper

As for the mandrel topic... I was getting runout all over the map with my RCBS SB die and expander ball. Resizing without the expander ball was giving very low neck runout so I new the ball was the issue. I ended up going with a 21st Century mandrel (0.223) and it completely cleared up the runout issues. I do use Redding dry lube before seating as I SS tumble my brass. The devil is in the details and in my experience it pays to measure as much as you can to isolate issues.

Tim

Also make sure you are not over annealing the necks. The settings are for specific lots of brass. Sometimes lots vary in neck thickness. If you over anneal the accuracy will go away too.

Temper

i stopped using the LCD because i stopped turning necks and if not turning necks i found the LCD does not work so well

i to am skeptical but if you think about it the mandrel should produce the most consistent neck tension.

im lazy and dont like typing LOL...ill post up want i find but its not going to be a super detailed documentary.

i like to anneal every time because everything is just more consistent and now ive got the high ES issue figured out i will continue to anneal every time.

if your leaving marks in your brass its because youve got the die screwed down to far and need a smaller mandrel...contact lee and they will make you what ever size mandrels you want.

I did some unscientific testing of brass yesterday with the induction annealer I made. I don't have access to a metallurgy lab so I decided to take a few fully prepped cases and used a small vise to witness the impact of various annealing temperatures. I used identically prepped cases to ensure consistency. The approach was to slowly close the vise until contact was made with the case neck. I then rotated the vice handle a bit more to the same exact spot each time. Pre-annealing tension would be applied to the case neck and upon release off the handle you would visually see the neck spring back and retain its shape. Post annealing it was evident that as I started to cross into over-temp territory the spring back was greatly reduced. Going to glowing red led to a case neck that lost all springback and would stay permanently deformed. The point here is that case neck tension is going to change as you get closer to a full anneal of the case neck. When using a more manual process (ie. NOT AMP with Aztec) you really have to stay consistent on temp and time for each lot. Getting to any sort of glow is getting too hot.

If you haven't read this yet and like real quantitative testing to compare your observations to, take a look:

Induction Annealing Brass | Our Research | AMP

View the latest articles from AMP Annealing. Get tips and tricks from our R&D. Here we upload articles to provide your the best possible information on innovations in the annealing process.

Back off on the collet die a bit. If you are seeing ridges ironed into the necks and a shortened headspace after using the collet die, you are going down too far. Back up just a tad. There should be no headspace movement associated with the collet die.

Will back off a bit and see if I can get the headspace to stay.

The shortening of the headspace amounted to .0005 to .00075). I haven't changed the setting in a long time as I've been getting such good results on the numbers (e.g. single digit SD's and ES's under 20) and the paper (e.g. .240 - .370 MOA groups and sometimes better and sometimes worse) and usually don't like to mess with a good thing. Am not sure how much better I can get out of a factory .308 rifle (RPR) with a Krieger barrel. . . and very old eyes.

If you haven't read this yet and like real quantitative testing to compare your observations to, take a look:

Induction Annealing Brass | Our Research | AMP

View the latest articles from AMP Annealing. Get tips and tricks from our R&D. Here we upload articles to provide your the best possible information on innovations in the annealing process.www.ampannealing.com

I’ve read that. I am definitely not opposed to sending some samples to a lab to see where things are falling from a metallurgy perspective if the costs are within reason. There is a lot of data out there but applying it to the hobby level isn’t a direct path.

For instance... in a general sense is the AMP unit getting to a higher than expected temp but because it does it so quickly the negatives are negated as they pertain to over annealing or extending too far down the body? If so mimicking that is trivial.

For their Aztec method to work they need feedback. I’m guessing they are monitoring temperature ramp rates to properly profile the brass. Their unit very likely also has power output limit control in real time. I think their unit is awesome but not practical for the average joe price wise.

I’ve read that. I am definitely not opposed to sending some samples to a lab to see where things are falling from a metallurgy perspective if the costs are within reason. There is a lot of data out there but applying it to the hobby level isn’t a direct path.

Maybe if you're lucky enough to have a nearby college with metallurgical testing equipment, a student might be willing to do some work for you???

For instance... in a general sense is the AMP unit getting to a higher than expected temp but because it does it so quickly the negatives are negated as they pertain to over annealing or extending too far down the body? If so mimicking that is trivial.

Seem to me the idea is to control just the area you really want annealed without affecting there other areas. Heating up the desired area as quickly as possible (within appropriate temps that don't have detrimental metallurgical effects) to keep the annealing within the area you want is most desirable. . . huh???

For their Aztec method to work they need feedback. I’m guessing they are monitoring temperature ramp rates to properly profile the brass. Their unit very likely also has power output limit control in real time. I think their unit is awesome but not practical for the average joe price wise.

It's a great machine and does a fine job . . . particularly in controlling the results. It's very appealing . . . except, as you point out, for the price. And it seems like flame annealing, when done correctly, doesn't present much of a disadvantage.

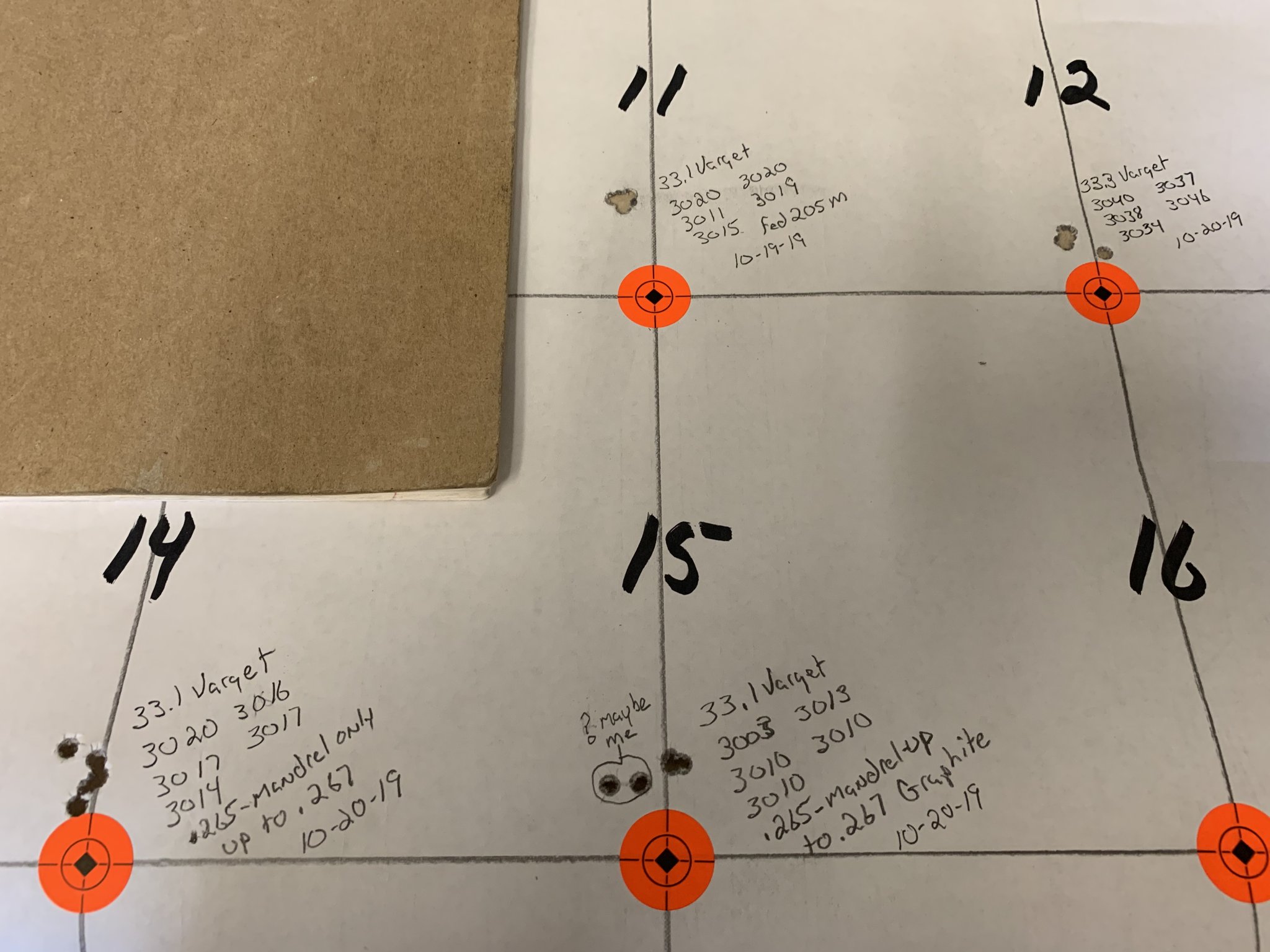

first let me apologize for jackin the OPs thread...we seemed to be having the same issue and i planed to figure it out and am 99% sure i have and hope it helps you out.

i went out this morning and shot the 33.3g load to make sure 33.1 was not right on the edge...it was loaded with .267 bushing only.

i also shot 33.1 that i size to .265 then back up to .267 with a mandrel only and 33.1 i sized to .265 then back up to .267 using a mandrel and the dry lube.

the 25 round pic is with a .267 bushing no mandrel or expander.

also when seating....

with just the bushing the bullets seat smooth with very little felt tension

with sizing down then back up with the mandrel even with the graphite there is slightly more felt tension...my thoughts are that the mandrel leaves the inside of the neck more even which in turn creates more of an even/concentric surface which seems like a good thing to me.

so my thoughts are that the dry lube does make a difference...its shows in the numbers..and im pretty sure the more you use it the better the results as it gets worked into the brass more...i also think that just reducing the neck size fixed my issue as it also shows in the numbers...i was getting ESs up to around 40FPS(and groups in the 1"ish range)with larger samples when annealing every time with a .002 neck size.

im going to play with the mandrel and dry lube more because my necks get dented and while they obviously shoot good it just bugs me and if i shoot a shitty group ill be blaming the outta round necks LOL!!

the one outta the group on #12 was the 5th shot and was me...i called it right as the trigger broke.

i went out this morning and shot the 33.3g load to make sure 33.1 was not right on the edge...it was loaded with .267 bushing only.

i also shot 33.1 that i size to .265 then back up to .267 with a mandrel only and 33.1 i sized to .265 then back up to .267 using a mandrel and the dry lube.

the 25 round pic is with a .267 bushing no mandrel or expander.

also when seating....

with just the bushing the bullets seat smooth with very little felt tension

with sizing down then back up with the mandrel even with the graphite there is slightly more felt tension...my thoughts are that the mandrel leaves the inside of the neck more even which in turn creates more of an even/concentric surface which seems like a good thing to me.

so my thoughts are that the dry lube does make a difference...its shows in the numbers..and im pretty sure the more you use it the better the results as it gets worked into the brass more...i also think that just reducing the neck size fixed my issue as it also shows in the numbers...i was getting ESs up to around 40FPS(and groups in the 1"ish range)with larger samples when annealing every time with a .002 neck size.

im going to play with the mandrel and dry lube more because my necks get dented and while they obviously shoot good it just bugs me and if i shoot a shitty group ill be blaming the outta round necks LOL!!

the one outta the group on #12 was the 5th shot and was me...i called it right as the trigger broke.

Last edited:

I’ve read that. I am definitely not opposed to sending some samples to a lab to see where things are falling from a metallurgy perspective if the costs are within reason. There is a lot of data out there but applying it to the hobby level isn’t a direct path.

For instance... in a general sense is the AMP unit getting to a higher than expected temp but because it does it so quickly the negatives are negated as they pertain to over annealing or extending too far down the body? If so mimicking that is trivial.

For their Aztec method to work they need feedback. I’m guessing they are monitoring temperature ramp rates to properly profile the brass. Their unit very likely also has power output limit control in real time. I think their unit is awesome but not practical for the average joe price wise.

That’s the advantage of induction annealing versus flame. You can ramp a localized area much faster and to a higher temperature than you ever could with a flame. Right now my 223 brass ramps to 750+ just below the shoulder in less than 3.5 seconds. Would it be better to increase the supply voltage, go higher in temp but get there in half the time? The body of the case wouldn’t have time to reach annealing temps.

Without the metallurgical data it’s just speculation. This is where AMP absolutely has credibility. The data fully backs their product and implementation. No other method has credible lab data to back up the implementation. The best you can do is verify changes by indirect methods.

you guys using a mandrel and dry lube are you brushing your necks after mandrel sizing with dry lube?

I didn't read all the responses to the OP so if I repeat something.....OOOPS ......I suggest you stop tumbling your brass, especially with SS media it digs up the neck something fierce. You want to leave the carbon in your necks for your bullet to seat over. Just nylon brush out the necks the same amount of strokes every time. If you want to clean up the outside of the cases try a ( As Seen On TV ) KRAZY KLOTH.......They work amazingly well and is an easy find through Amazon..................FWIW I sold my AMP and things are going well....

you guys using a mandrel and dry lube are you brushing your necks after mandrel sizing with dry lube?

I don’t.

I don’t.

I leave the graphite in place. Bullet on bare brass isn’t a good idea in my opinion.

Thanks guys.

so I’ve tried everything I can think of with annealing every time and it’s just not working so I’m going to go back to annealing when I see issues down range or spring back gets to bad.

so I’ve tried everything I can think of with annealing every time and it’s just not working so I’m going to go back to annealing when I see issues down range or spring back gets to bad.

Thanks guys.

so I’ve tried everything I can think of with annealing every time and it’s just not working so I’m going to go back to annealing when I see issues down range or spring back gets to bad.

Just out of curiosity, what setting are you using on your AMP? is it using AZTEC?

Just out of curiosity, what setting are you using on your AMP? is it using AZTEC?

yes aztec and ive ran several cases through to check codes with and without primers...my buddy has an AMP and the codes for lapua are the same from his machine.

straight 6BR

peterson 138

lapua 158

fire formed to 6BRX

peterson 129

lapua 147

Dumping the freshly, still hot , annealed brass into a citric acid/water bath removes all scaling. You will not see annealing marks after tumbling.

If you SS tumble, do that before doing all of your brass prep, especially to the neck and case mouths.

Tumbling in corn cob treated with NU-Funish will shine the brass up and provide adequate lube to the neck for seating. SS tumbling leaves the brass bare of any lube unless you put a capful of Armor-all wash and wax into the tumbler with the SS pins and brass.

If you SS tumble, do that before doing all of your brass prep, especially to the neck and case mouths.

Tumbling in corn cob treated with NU-Funish will shine the brass up and provide adequate lube to the neck for seating. SS tumbling leaves the brass bare of any lube unless you put a capful of Armor-all wash and wax into the tumbler with the SS pins and brass.

I have a batch of brass I loaded up for a match. Normally it takes about 30-35lbs of force to seat a bullet. I changed the annealing to “0142 +1” (6.5cm Peterson) on AZTEC and my brass hated that. Now it’s all over the place. 70-120lbs of force. I’m trying to figure out why such a thing would happen when nothing has changed in the prep process except the “+1” in Aztec.

I have a batch of brass I loaded up for a match. Normally it takes about 30-35lbs of force to seat a bullet. I changed the annealing to “0142 +1” (6.5cm Peterson) on AZTEC and my brass hated that. Now it’s all over the place. 70-120lbs of force. I’m trying to figure out why such a thing would happen when nothing has changed in the prep process except the “+1” in Aztec.

Apparently the change leaves more scaling on the brass which increases the friction during seating.

I have a batch of brass I loaded up for a match. Normally it takes about 30-35lbs of force to seat a bullet. I changed the annealing to “0142 +1” (6.5cm Peterson) on AZTEC and my brass hated that. Now it’s all over the place. 70-120lbs of force. I’m trying to figure out why such a thing would happen when nothing has changed in the prep process except the “+1” in Aztec.

like @Dthomas3523 said more scaling...more heat equals more scaling in the necks...im just wondering why you changed things if everything was working especially without running a small test sample.

like @Dthomas3523 said more scaling...more heat equals more scaling in the necks...im just wondering why you changed things if everything was working especially without running a small test sample.

I have reasons. I don’t feel like writing a novel nor sharing my research and testing at this time. I have a few more test to prove or disprove somethings.

I have reasons. I don’t feel like writing a novel nor sharing my research and testing at this time. I have a few more test to prove or disprove somethings.

curious to hear the outcome.

Similar threads

- Replies

- 55

- Views

- 2K

- Replies

- 7

- Views

- 306

- Replies

- 25

- Views

- 961