Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quick Anneal any users out there with reviews?

- Thread starter Rover31

- Start date

Annealing is not always about the targets. Much of it is about case life, or maybe in some instances, it's wildcatting.

Why not both

What makes the difference is the OPERATOR behind the device ,as in KNOWING what they're doing . One is only softening the neck and minimally the shoulder . NO one , repeat NO one is rebuilding lattice or growing grain structure in cartridge brass .

Duration at temperature prohibits that from happening . It's NOT a matter of opinion it's a matter of PHYSICS .

I tend to agree and why I stick with flame annealing instead of investing in induction equipment. The one thing I feel induction does best is the timing for the amount of heat induced where its electronics can control that much better than what's done with flame annealing. But I don't think that difference really makes much difference if the flame annealer really knows what they're doing.Why not both. Partial annealing is simply just that and it makes NO F ing difference whether flame or induction does the deed .

What makes the difference is the OPERATOR behind the device ,as in KNOWING what they're doing . One is only softening the neck and minimally the shoulder . NO one , repeat NO one is rebuilding lattice or growing grain structure in cartridge brass .

Duration at temperature prohibits that from happening . It's NOT a matter of opinion it's a matter of PHYSICS .

BTW: I'm a big proponent of the induction technology, I think induction is great technology, as my wife can attest to having replaced her electric cook top with an induction cook top.

Really, "No one is rebuilding lattice or growing grain structure"? You've reviewed AMP's research?

You don't think flash annealing works?

Duration at temperature is defiantly key to that, like you said, it's a matter of physics. In my limited observations, very few people that are flame annealing their brass are doing all what they think they're doing. There's not been any real measurement for the results of one's process and just go by what the trend is. Even AMP didn't do the science for flame annealing and just looked and just looked at salt bath annealing. In my recent experiment, I found I wasn't getting my case necks as "soft" as I thought and now have doubled the time in the flame to get me to where I want to be. . . and that includes taking into account the effect of what sizing has after the annealing process.

Last edited:

I’ll try a 5 min timed warmup.just like 5 minutes, to heat up the brass torch head

Need a good regulator.

I bought a good one. Waited months for it to be in stock. They stopped making them for a while: EP-70G https://www.gossonline.com/air-propane-equipment/regulators/high-pressure-regulators

I don't know if a certain pressure range is more stable, but I use 20 PSI.

I'm using whatever torch head came with Giraud. Don't know if that matters either. It doesn't seem to be anything special.

You using a 20#/4.7 gallon tank?

I'm using whatever torch head came with Giraud. Don't know if that matters either. It doesn't seem to be anything special.

You using a 20#/4.7 gallon tank?

I tend to agree and why I stick with flame annealing instead of investing in induction equipment. The one thing I feel induction does best is the timing for the amount of heat induced where its electronics can control that much better than what's done with flame annealing. But I don't think that difference really makes much difference if the flame annealer really knows what they're doing.

BTW: I'm a big proponent of the induction technology, I think induction is great technology, as my wife can attest to having replaced her electric cook top with an induction cook top.

Really, "No one is rebuilding lattice or growing grain structure"? You've reviewed AMP's research?

You don't think flash annealing works?

Duration at temperature is defiantly key to that, like you said, it's a matter of physics. In my limited observations, very few people that are flame annealing their brass are doing all what they think they're doing. There's not been any real measurement for the results of one's process and just go by what the trend is. Even AMP didn't do the science for flame annealing and just looked and just looked at salt bath annealing. In my recent experiment, I found I wasn't getting my case necks as "soft" as I thought and now have doubled the time in the flame to get me to where I want to be. . . and that includes taking into account the effect of what sizing has after the annealing process.

No I read the IMI report in 1975 from Tel Aviv ,Israel , long before AMP was even d a dream . Report dealt primarily with grain structure of cartridge brass and it's inherent relationship to strength elongation and failure . Proper and Improper partial annealing benefits , case separation failure upon ejection . Primarily from M16 A1 and later 83 I believe M16 A2 ,also their Galil weapon .

IF people would simply read George Vander Vroot published brass annealing experiment/ Report , it tells anyone definitely WHAT brass cases due ,as to time verses temp. and annealing or lack of it . Basically we're simply restoring DUCTILITY . What matters is what TEMPERATURE the neck/shoulder achieve ,so as to become softened sufficiently to avoid embrittlement . Aka split neck blown shoulder . How that's achieved best is a matter of opinion flame or induction works .

I Like induction but it's too slow when setting up a semi auto repetitious home unit to do say hundreds or thousands of rounds .

AMP requires a person to insert and extract the cartridge ,every time . Other machines primarily flame can be set reliably to do hundreds hands off . Exactly WHY I chose flame machine over induction ,not because it's better but faster and far far less monies .

Now before anyone goes off on ME ,Faster means unless one has a commercial setup with 20-100 coil induction stations with mechanical auto feed capability . Cartridge case manufactures have those type setups . Having actually been inside Norma as well as Lapua cartridge manufacturing facility's ,I can attest to it .

https://vacaero.com/information-res...rmation-and-annealing-of-cartridge-brass.html

I had the GOOD fortune to have worked with George on a number of occasions decades ago , when I was employed as an R&D Chemist in the Aerospace industry . Below are two samples ( article shows colored photos for visual proof ) of Time & Temp of .338 cases .

Figures 6c and d: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 15 minutes has partially recrystallized the FCC grain structure with some remaining coarse cold worked grains; 30 minutes has increased the degree of recrystallization. Tint etched with Klemm’s I (originals at 100X, crossed polarized light (off crossed))

Figure 8a and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50% and annealed at 704°C (1300°F) – 30 min. producing a fully recrystallized, and grown, equiaxed FCC grain structure with annealing twins.

Clearly illustrating the point I've been trying to make on the hide for a year or more . Even at 1300 Deg. F. it took 30 minutes to produce full recrystallization aka , TRUE ANNEALING .

So everything we reloaders do is PARTIAL or IMPARTING DUCTILITY .

Try 10-12 psi. Propane is about double that of Natural gas 4-7 Psi . Torch is most efficient and quiet .I don't know if a certain pressure range is more stable, but I use 20 PSI.

I'm using whatever torch head came with Giraud. Don't know if that matters either. It doesn't seem to be anything special.

You using a 20#/4.7 gallon tank?

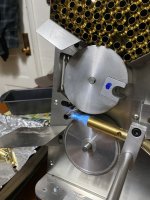

This setup works just dandy and budget minded . I match the witness marks of Lapua and haven't lost any cases do to split neck and all seem to seal in the chamber just fine . .222 , .223 , 5.56X45 ,7.62X51 , 7.62X63 ,6.5 CM , 7mm RM, .338 WM , .338 LM , 7.92×57mm and 9.3X72R .

I do em all and they come out just fine . I run each case after #3 firings ,Not every firing . I'm Not BR shooting either :

I do em all and they come out just fine . I run each case after #3 firings ,Not every firing . I'm Not BR shooting either :

Attachments

I use a very similar set up that's been working quite well for me. My Annealeez is one of the older models that I've had for years which I've upgraded a little:This setup works just dandy and budget minded . I match the witness marks of Lapua and haven't lost any cases do to split neck and all seem to seal in the chamber just fine . .222 , .223 , 5.56X45 ,7.62X51 , 7.62X63 ,6.5 CM , 7mm RM, .338 WM , .338 LM , 7.92×57mm and 9.3X72R .

I do em all and they come out just fine . I run each case after #3 firings ,Not every firing . I'm Not BR shooting either :

My flame cases never have that discoloration unless I bake the shit out of them red hot

Last edited:

No I’m using the 1lb bottles.I don't know if a certain pressure range is more stable, but I use 20 PSI.

I'm using whatever torch head came with Giraud. Don't know if that matters either. It doesn't seem to be anything special.

You using a 20#/4.7 gallon tank?

For some reason I am up at the 40+ pressure range using the ugly annealer torch. I end up having to increase a bit over time to maintain the same flame. I was hoping the regulator would eliminate the need for that. It does aid quick set up though.

Attachments

Is that because you clean them before you flame anneal? And if so, what method of cleaning?My file case is never have that discoloration unless I bake the shit out of them red hot

When I get brass very clean, like when wet tumbling, they too will not have much discoloration.

Otherwise, you many not be "annealing" as much as you think"??? Not that the discoloration really matters in any way about the state of the hardness from the annealing process.

Those cases in the pic above are right after my annealing process, which is my fist step after firing (other than depriming), then I take steel wool to the necks to remove the abrasive oxidation layer from the necks and shoulder in prep for sizing. After sizing and vibe tumbling to clean lube off, the finished cases will look like this:

If I happen to wet tumble, which I rarely do and do without any media (just hot water and Dawn), they'll look like this (note: pic under different lighting):

Last edited:

Yeah I go for the “glow” and drop. I never get discoloration …..My file case is never have that discoloration unless I bake the shit out of them red hot

If you monitor the temperature on the bottles you'll see they are getting colder when the pressure drops. The large tanks can go much longer before that is an issue.No I’m using the 1lb bottles.

For some reason I am up at the 40+ pressure range using the ugly annealer torch. I end up having to increase a bit over time to maintain the same flame. I was hoping the regulator would eliminate the need for that. It does aid quick set up though.

Yeah, dude, you definitely need to step up to a bulk tankNo I’m using the 1lb bottles.

For some reason I am up at the 40+ pressure range using the ugly annealer torch. I end up having to increase a bit over time to maintain the same flame. I was hoping the regulator would eliminate the need for that. It does aid quick set up though.

Yes I have noticed that. I suspected that was the culprit. So will larger tank fix that?If you monitor the temperature on the bottles you'll see they are getting colder when the pressure drops. The large tanks can go much longer before that is an issue.

Thx

What size is that one? Will the larger size be more consistent? ThxYeah, dude, you definitely need to step up to a bulk tank

View attachment 8574456

I have that one that is like a 1 gallon and it’s the smallest bulk tank you can get. I also have a 2 1/2 gallon. I used them for my camper van, but then realized the size is very convenient to sit on top of the bench for the annealer or underneath it or whatever.

They’re like $80 but it’s like a buy it one thing

They’re like $80 but it’s like a buy it one thing

Awesome the 1 gal seems like the ticket.I have that one that is like a 1 gallon and it’s the smallest bulk tank you can get. I also have a 2 1/2 gallon. I used them for my camper van, but then realized the size is very convenient to sit on top of the bench for the annealer or underneath it or whatever.

They’re like $80 but it’s like a buy it one thing

My flame cases never have that discoloration unless I bake the shit out of them red hot

The idea is 1200 Deg. F. at the neck tip about 950 Deg. F. at the shoulder and less than 225 Deg. F. down at the base . That's using the Annealeeze doing around #150 cases per load. Now 5.56X45 perhaps #225-250 ?

I just today completed # 50 firings on 1942-43 , 30.Cal M2 once fired cases . I lost #2 cases because I cut them so as to measure wall thickness at #45 firings . All loads were loaded within 1 grain Max. charge for M1 Rifles . Never split a neck or tore a rim and that in itself is damn remarkable ,as M1's aren't gentle on extraction . I will now single fire until failure ,as #50 firings is a shit load on 30/06 cases and don't want case separation auto load slam fire scenario .

Fyi: I've since fixed the stripped pinion on My beater Garand and am now able to move as in lower or elevate rear aperture . All #8 are right there at 165 yd. using original sights off sand bags on My bench . I don't fix what isn't broken .

Attachments

Last edited:

Yeah I go for the “glow” and drop. I never get discoloration …..

Hate to burst your bubble but if your brass isn't discoloring ,it's NOT HOT ENOUGH !. ALL brass even Lapua LC whom ever s brass discolors . I'll assume you DON'T have the means to check hardness ,as in a micro-Vickers gauge ,so You're only guessing .

I've been at this for over 58 years and worked in Aerospace Engineering ,more importantly had access to ALL necessary equipment to test near anything . One CAN'T soften cartridge cases without HEAT and High temp does it best . Temperature MUST exceed 850 Deg. F. and you would need to leave it at that for 3 minutes MINIMUM ,in order to soften the neck . So 1200-1300 Deg. F. works in seconds . You can polish 90% of discoloration out of brass if it bothers you . I could careless on mine ,it just needs to be clean .

In the photos you will see cases discolored from heat ductility restoration , one of those cases is Factory Lapua ,the rest are MY cases .

Note how MY witness halo matches Lapua near perfectly . It's Not by accident .

Attachments

Last edited:

As many of you prefer AMP for your partial annealing process ,simply Read what they post . Obviously they ruined cases by placing them in a furnace /oven . However clearly demonstrates the necessity for either TIME ( which we DON'T have ) or Higher Temperature which we must use ,if our case necks are to be made malleable .

https://www.ampannealing.com/articles/40/annealing-under-the-microscope/

The samples were placed in a controlled oven for one hour, one at 300°C (570°F), another at 350°C (660°F) and the third at 400°C (750°F). These were then sectioned as above for analysis. At temperatures of up to 350°C (660°F), very little happened in the neck regions. At 400°C (750°F) for one hour, the neck was annealed to an average of 117 HV mid wall and 83 – 89 HV at the edges of the neck wall. (Appendix (2) - 4.0 – 4.6). The case heads, however, were softened in each region measured as shown below. See appendix (2) 4.3 for explanation.

The basics of cartridge brass:

https://www.ampannealing.com/articles/40/annealing-under-the-microscope/

The samples were placed in a controlled oven for one hour, one at 300°C (570°F), another at 350°C (660°F) and the third at 400°C (750°F). These were then sectioned as above for analysis. At temperatures of up to 350°C (660°F), very little happened in the neck regions. At 400°C (750°F) for one hour, the neck was annealed to an average of 117 HV mid wall and 83 – 89 HV at the edges of the neck wall. (Appendix (2) - 4.0 – 4.6). The case heads, however, were softened in each region measured as shown below. See appendix (2) 4.3 for explanation.

The basics of cartridge brass:

- We submitted six representative cases from five manufacturers for chemical analysis. They were all consistent with UNS C26000 specifications for cartridge brass, within analytical margin of error. (see Appendix 1 - 1.1 and Appendix 4).

- Cartridge brass melts at 915°C (1679°F). Up to that temperature it remains homogeneous (Appendix 1 - 1.1).

- Dezincification of brass can occur because of chemical attack, but heating brass, even to high annealing temperatures cannot cause dezincification unless chemicals are present. The zinc content of the alloy cannot burn or melt out up until boiling point (Appendix 1 - 1.6).

- Brass becomes harder with cold work such as drawing, stamping, forming etc., and softer when heated to annealing temperatures.

- The hardness of thin wall brass sections should be measured using micro hardness Vickers or Knoop testers (Appendix 1 - 1.2). Conventional Rockwell and Brinell equipment is not best suited to this application. The Vickers hardness scale is expressed as HV, with lower numbers being softer and higher numbers harder i.e. 50 HV is softer than 100HV.

- From testing on cross sections, the neck hardness of virgin cases from the two major brands tested averaged 100 HV. The hardness half way to the case head averaged 190 HV and the heads were 185 – 218 HV. The head hardness is variable depending on the region of the head being measured. (Appendix 2 figures 6.3, 6.12 and 6.13.)

^disagree

AMP doesn’t discolor either

Brass oxidizes in atmosphere when heated ,so it does if one is doing it correctly .

https://www.lapua.com/what-is-the-discoloration-on-my-lapua-brass/

JFC.

Guys, heat it up till it barely glows (about 800 F) then drop it out of the flame and carry on for dozens of firings and no split neck and very consistent neck tension.

If you wanna split hairs, save it for your meeting with your accountant in a couple of months, when you prepare your taxes.

All of this hand waving and jerking off about a kneeling is tiresome, isn’t it? Fortunately, it’s also unnecessary.

Guys, heat it up till it barely glows (about 800 F) then drop it out of the flame and carry on for dozens of firings and no split neck and very consistent neck tension.

If you wanna split hairs, save it for your meeting with your accountant in a couple of months, when you prepare your taxes.

All of this hand waving and jerking off about a kneeling is tiresome, isn’t it? Fortunately, it’s also unnecessary.

JFC.

Guys, heat it up till it barely glows (about 800 F) then drop it out of the flame and carry on for dozens of firings and no split neck and very consistent neck tension.

If you wanna split hairs, save it for your meeting with your accountant in a couple of months, when you prepare your taxes.

All of this hand waving and jerking off about a kneeling is tiresome, isn’t it? Fortunately, it’s also unnecessary.

If you spent $1200 on a box that does something you can't measure or verify, you probably be in here too trying to convert others to your new secular religion.

Yeah. I use the expensive box bc I have it

I also use flame. For quick dirty and effective.

It all works. So well that I beat off to all of them when I’m lonely and cold

I also use flame. For quick dirty and effective.

It all works. So well that I beat off to all of them when I’m lonely and cold

Last edited:

Interesting. I love science.Hate to burst your bubble but if your brass isn't discoloring ,it's NOT HOT ENOUGH !. ALL brass even Lapua LC whom ever s brass discolors . I'll assume you DON'T have the means to check hardness ,as in a micro-Vickers gauge ,so You're only guessing .

I've been at this for over 58 years and worked in Aerospace Engineering ,more importantly had access to ALL necessary equipment to test near anything . One CAN'T soften cartridge cases without HEAT and High temp does it best . Temperature MUST exceed 850 Deg. F. and you would need to leave it at that for 3 minutes MINIMUM ,in order to soften the neck . So 1200-1300 Deg. F. works in seconds . You can polish 90% of discoloration out of brass if it bothers you . I could careless on mine ,it just needs to be clean .

In the photos you will see cases discolored from heat ductility restoration , one of those cases is Factory Lapua ,the rest are MY cases .

Note how MY witness halo matches Lapua near perfectly . It's Not by accident .

So why the change in seating pressure and the change in consistency of seating pressure?

I don’t run gauges but as my brass ages, I have to fiddle with the dial on the seater to get a consistent depth to Ogive. I usually will mark a range with pieces of blue tape and seat 2-4 times to get the desired cbto within that range. I have come to fear that this seating multiply varied times is causing a variance in neck tensions.

After annealing, for at least the next couple of loadings, the variance is gone. I set the seater and run 100 pcs without changing it. The pressure that needs to be used is also less as the bullets seat outside (before) the blue tape range, so they are discarded. Now just one piece of tape.

Fyi: I do not lube the necks as I have found with graphite, it does little to nothing and worrying about one of those little ceramic balls making into a case and taking out my can is not worth it. It also seems that my sinuses are pretty sensitive to breathing that stuff.

Since you've been at this for so long, then you also know that discoloration is a terrible indicator because it varies due to brass composition and surface condition, but please continue to stroke that ego and tell the world about it in BOOMER TEXT.Hate to burst your bubble but if your brass isn't discoloring ,it's NOT HOT ENOUGH !. ALL brass even Lapua LC whom ever s brass discolors . I'll assume you DON'T have the means to check hardness ,as in a micro-Vickers gauge ,so You're only guessing .

I've been at this for over 58 years and worked in Aerospace Engineering ,more importantly had access to ALL necessary equipment to test near anything . One CAN'T soften cartridge cases without HEAT and High temp does it best . Temperature MUST exceed 850 Deg. F. and you would need to leave it at that for 3 minutes MINIMUM ,in order to soften the neck . So 1200-1300 Deg. F. works in seconds . You can polish 90% of discoloration out of brass if it bothers you . I could careless on mine ,it just needs to be clean .

In the photos you will see cases discolored from heat ductility restoration , one of those cases is Factory Lapua ,the rest are MY cases .

Note how MY witness halo matches Lapua near perfectly . It's Not by accident .

I tried the carbon, but didn’t find it very effective.

I now use imperial wax because I am trying to seal the projectile in the neck to prevent changes in humidity within the cartridge

I think the vast majority of guys are switching to Neo lube

I now use imperial wax because I am trying to seal the projectile in the neck to prevent changes in humidity within the cartridge

I think the vast majority of guys are switching to Neo lube

This stuff ? https://a.co/d/4ozA2XoI tried the carbon, but didn’t find it very effective.

I now use imperial wax because I am trying to seal the projectile in the neck to prevent changes in humidity within the cartridge

I think the vast majority of guys are switching to Neo lube

Are you dipping the bullet or the case. Thx

Imperial Sizing Wax on the bullet when seating?I don’t use it yet. Others will have r to chime in

Thanks for the help man…..Yes. I do that on all of my large magnums. I just smear it right above the boattail on the shank of the bullet by hand.

I just did 50 rounds of 50 BMG like that last night

With .003” neck tension, they go into an AMP annealed RWS 4x fired case like butter

Since you've been at this for so long, then you also know that discoloration is a terrible indicator because it varies due to brass composition and surface condition, but please continue to stroke that ego and tell the world about it in BOOMER TEXT.

Composition is far closer in ALL cartridge brass than you can imagine . Heat discoloration will most certainly vary with Temp and duration will also vary as to witness length . Never had an ego problem ,so don't know where that's coming from . IF I'm wrong why does all the GOOD Brass cases have partial annealing marks on them ,right out of the box ?. Because manufacturers have spent umpteen bucks on metallurgy ,so laymen get GOOD quality ammunition right out of the box .

Interesting. I love science.

So why the change in seating pressure and the change in consistency of seating pressure?

I don’t run gauges but as my brass ages, I have to fiddle with the dial on the seater to get a consistent depth to Ogive. I usually will mark a range with pieces of blue tape and seat 2-4 times to get the desired cbto within that range. I have come to fear that this seating multiply varied times is causing a variance in neck tensions.

After annealing, for at least the next couple of loadings, the variance is gone. I set the seater and run 100 pcs without changing it. The pressure that needs to be used is also less as the bullets seat outside (before) the blue tape range, so they are discarded. Now just one piece of tape.

Fyi: I do not lube the necks as I have found with graphite, it does little to nothing and worrying about one of those little ceramic balls making into a case and taking out my can is not worth it. It also seems that my sinuses are pretty sensitive to breathing that stuff.

When one softens or restores ductility to the neck of a cartridge ,NECK TENSION CHANGES . There are proper procedures for cleaning partial annealing resizing and trimming and done in the correct order is important . Variation can be attributed to several explained circumstances . Ever measure shoulder set back ?. Does Your compartator gauge always read the same ?. Mine doesn't , after firing rounds out of MY Gas guns gauging measurements varies on several spent cases . Yet MY chamber is the same dimension .

IF I lube necks I use h-BN but generally don't bother . I'm not bench resting or using 18 lb. Rifles or a shooting rest .

When cases start out ( General rule of thumb ) they measure 100-120 HV in the Neck area ,as one moves down the case HV increases significantly until reaching the base , which again generally is over 200 HV . Firing a case increases HV in the neck primarily but also begins to increase in the shoulder as well . Hence the necessity to restore ductility .

Magnum cases along with Bore Burners , aka larger cases small projectile suffer the highest increase in HV . Powder charge and type also account for a % of increase as well . Hotter faster powders ,slower powder higher pressure all affect case measurements .

Hope that answers your questions .

Once fired Military 5.56X45mm and Brand New , OLD , F.N. 7.62X51mm cases and ammo respectfully .

Please NOTE discoloration on Brass ,even though they've obliviously been polished at the factory . Note WHERE the witness marks are as they travel down the case past the shoulder . All I can tell any of you is ; There's a reason it's done .

I clean MY Brass with an ultrasonic ,as it removes ALL debris oils carbon and leaves Brass naked . IF one spends enough time polishing their Brass , you can certainly diminish the witness mark but highly doubtful it will perform any better and will most certainly wear your Brass faster .

Ever polish a paint job ,until you've removed the pigment . Same principle one is removing oxidation and also some metal along with it .

Some people will try and dazzle you with BS ,while others simply present the FACTS as Science . I'll leave you to decide which is which .

Annealing experiments were conducted on a number of the cold worked specimens. Figures 5a and b show color etched images of the specimens cold reduced 50% and then annealed 30 minutes at 500 and 700°F. No difference in the microstructure is seen in the specimen held 30 minutes at 500°F while a very small amount of recrystallization is observed in the specimen held 30 minutes at 700°F. Figures 6a and b show color images of 50% cold reduced specimens held for 4 and 8 minutes at 800°F while Figures 6c and d show 50% cold reduced specimens held 15 and 30 minutes at 800°F. No change is observed after 4 minutes at 800°F, while a minor amount of recrystallization has occurred after 8 minutes. Holding specimens for 15 and 30 minutes at 800°F revealed partial recrystallization after 15 minutes and full recrystallization after 30 minutes. The grain structure is relatively fine but is not uniform in its distribution.

Please NOTE discoloration on Brass ,even though they've obliviously been polished at the factory . Note WHERE the witness marks are as they travel down the case past the shoulder . All I can tell any of you is ; There's a reason it's done .

I clean MY Brass with an ultrasonic ,as it removes ALL debris oils carbon and leaves Brass naked . IF one spends enough time polishing their Brass , you can certainly diminish the witness mark but highly doubtful it will perform any better and will most certainly wear your Brass faster .

Ever polish a paint job ,until you've removed the pigment . Same principle one is removing oxidation and also some metal along with it .

Some people will try and dazzle you with BS ,while others simply present the FACTS as Science . I'll leave you to decide which is which .

Annealing experiments were conducted on a number of the cold worked specimens. Figures 5a and b show color etched images of the specimens cold reduced 50% and then annealed 30 minutes at 500 and 700°F. No difference in the microstructure is seen in the specimen held 30 minutes at 500°F while a very small amount of recrystallization is observed in the specimen held 30 minutes at 700°F. Figures 6a and b show color images of 50% cold reduced specimens held for 4 and 8 minutes at 800°F while Figures 6c and d show 50% cold reduced specimens held 15 and 30 minutes at 800°F. No change is observed after 4 minutes at 800°F, while a minor amount of recrystallization has occurred after 8 minutes. Holding specimens for 15 and 30 minutes at 800°F revealed partial recrystallization after 15 minutes and full recrystallization after 30 minutes. The grain structure is relatively fine but is not uniform in its distribution.

Attachments

Last edited:

Yes every single time with a SAC comparator. They maintain .001 deviation. Usually it is something like .0025-.003”Ever measure shoulder set back ?. Does Your compartator gauge always read the same ?

Yeah, I don’t conflate brass from “gas gun” with bolt guns w/ match chambers. But that’s me…….after firing rounds out of MY Gas guns gauging measurements varies on several spent cases . Yet MY chamber is the same dimension .

I thought we were talking bolt guns here, so mea culpa…..

Yes every single time with a SAC comparator. They maintain .001 deviation. Usually it is something like .0025-.003”

Yeah, I don’t conflate brass from “gas gun” with bolt guns w/ match chambers. But that’s me…….

I thought we were talking bolt guns here, so mea culpa…..

As chamber warms dimensions can vary regardless of Bolt or gas operations . Bolts less variances that's for sure .

You've got this under control ,just be sure the necks are sufficiently softened so as to give consistent neck tension . After partial annealing sizing begins cold working once again ,which is a GOOD thing . I fire MY brass #3 times before partial annealing and have not seen any evidence presented which suggest ,it's more beneficial to do it every single firing . Yet admittedly I'm NOT BR shooting anymore ,so whatever works ,one should do it .

Quiet Torch is a HOT torch . IF any of you have ever used Oxygen / Acetylene torch ,you know Oxy is for clearing melt but Acetylene is low pressure compared to Oxygen and light mixture is HOT .

Same principle with partial annealing torch ,Fine pin point flame aimed properly saves a shit load of fuel and does the job faster .

Same principle with partial annealing torch ,Fine pin point flame aimed properly saves a shit load of fuel and does the job faster .

Without a hardness tester, you'd be hard pressed to tell a difference in the end result between any of them as long as the time to anneal is consistent, whether it's induction or flame. They're basically digitally controlled time cycle induction annealers, although AMP's time settings are predetermined and in the form of "codes."I started a thread on annealers mainly between QA and amp but haven't really got any feed back on the QA. How are you guys liking it and any info on them is appreciated

The predetermined time settings (AMP) vs the you have to find the time settings yourself (Quick Annealer, Annie Annealer, homemade induction annealer, flame based annealer, etc) and it's whatever you feel comfortable with in terms of operation, and price is really what you need to figure out whether the product is right for you.

I like my QA, but I use it like a flame based annealer and I make sure I sort my brass before using it, so I completely ignore the case anomaly feature (one of the features QA advertises). Work flow, the QA is still faster than an AMP since it's just drop case in, wait for case to auto-eject, then drop another case. For hands free operations, out of box, flame based annealers with case hoppers/case feeders will be cheaper, but QA and AMP have add ons for that.

The QA also has the feature to determine how long to anneal your case just like amp? I'm torn between the two. Flame like annealez seems faster but not sure want to deal with flame and setting up where the QA seems to be consistent time after time like ampWithout a hardness tester, you'd be hard pressed to tell a difference in the end result between any of them as long as the time to anneal is consistent, whether it's induction or flame. They're basically digitally controlled time cycle induction annealers, although AMP's time settings are predetermined and in the form of "codes."

The predetermined time settings (AMP) vs the you have to find the time settings yourself (Quick Annealer, Annie Annealer, homemade induction annealer, flame based annealer, etc) and it's whatever you feel comfortable with in terms of operation, and price is really what you need to figure out whether the product is right for you.

I like my QA, but I use it like a flame based annealer and I make sure I sort my brass before using it, so I completely ignore the case anomaly feature (one of the features QA advertises). Work flow, the QA is still faster than an AMP since it's just drop case in, wait for case to auto-eject, then drop another case. For hands free operations, out of box, flame based annealers with case hoppers/case feeders will be cheaper, but QA and AMP have add ons for that.

QA is manual time set method (watch neck glow) and then set time based off that, but the QA has a test/timer function on it so you don't need an external stopwatch to keep track of time. In test mode - first, turn off room light, then you hold the button down until case neck glows, then let go of the button (case auto ejects). Time will then be displayed.The QA also has the feature to determine how long to anneal your case just like amp? I'm torn between the two. Flame like annealez seems faster but not sure want to deal with flame and setting up where the QA seems to be consistent time after time like amp

Write that time down somewhere (I subtract 0.1 seconds to account for reaction time) so you know what time is for which brand/caliber case then manually set the time after that in the auto mode and off you go.

This is after you manually adjust anneal height. One of the features I like is the manual adjust height feature, so whether you bump shoulders 0.002" or 0.006" and your case is longer or shorter (fire formed vs almost fire formed), you can adjust the anneal zone so that it isn't lower than where you want it to be. Also beneficial because you don't need to buy pilots, so if you want to anneal a lot of different caliber cases, this QA is cheaper.

I appreciate the information thank youQA is manual time set method (watch neck glow) and then set time based off that, but the QA has a test/timer function on it so you don't need an external stopwatch to keep track of time. In test mode - first, turn off room light, then you hold the button down until case neck glows, then let go of the button (case auto ejects). Time will then be displayed.

Write that time down somewhere (I subtract 0.1 seconds to account for reaction time) so you know what time is for which brand/caliber case then manually set the time after that in the auto mode and off you go.

This is after you manually adjust anneal height. One of the features I like is the manual adjust height feature, so whether you bump shoulders 0.002" or 0.006" and your case is longer or shorter (fire formed vs almost fire formed), you can adjust the anneal zone so that it isn't lower than where you want it to be.

The QA also has the feature to determine how long to anneal your case just like amp? I'm torn between the two. Flame like annealez seems faster but not sure want to deal with flame and setting up where the QA seems to be consistent time after time like amp

Consistency is a factor of DWELL ,regardless of method used . As long as the case neck upper shoulder are heated above 1200-Better 1400 Deg. F. ALL methods work . Quicker temperature equates to less migration heating . Volumes of cases IMO benefit with flame induction ,as operations are near hands free . Providing setup is correct and timer drop out mechanism is functional .

No guess work or choking with my unit…QA is way too much guesswork and the case feed chokes so it’s the worst of all the choices if you ask me

None of that is really an issue if you know what you're doing.QA is way too much guesswork and the case feed chokes so it’s the worst of all the choices if you ask me

Flame annealing works quite well. . . again, if you know what you're doing. And it work works well for me matching hardness with virgin Lapua brass.

Last edited:

Similar threads

- Replies

- 31

- Views

- 4K

- Replies

- 36

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 106

- Views

- 4K

- Replies

- 9

- Views

- 2K