Just got on the backorder list for end of January. Great customer service, and a lot cheaper than the Amp. See how it goes, but looks like will do the job.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quick Anneal any users out there with reviews?

- Thread starter Rover31

- Start date

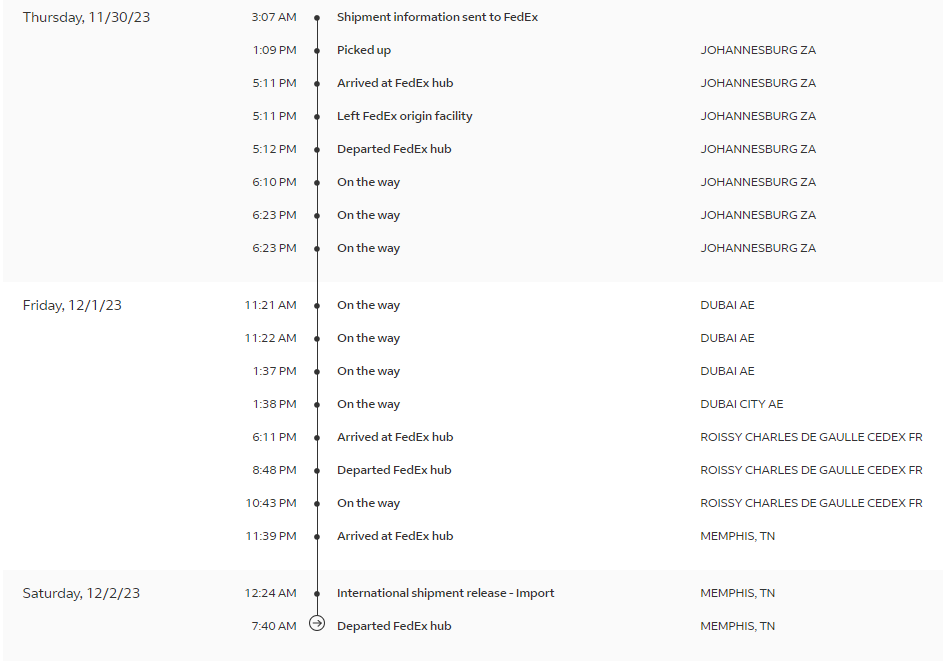

Interesting, never had an international shipment go through Memphis, TN before. Also, cleared customs in 45 minutes. I should have it by Monday.

Test 1 - headstamp detection with mixed 223 (small sample size). Going to set the machine to anneal based off the Lake City ⨁.

5 of each - Lake City, Lake City ⨁ (Lake City with NATO approval mark), PPU (Prvi Partizan), Federal, Remington, WCC (Western Cartridge Company), Wolf

1 or 2 cases of PSD, Hornady, Aguila.

Test 2- mixed 308win cases, Federal, PPU, and maybe one other. Don't have much random 308 brass around.

Test 3 - 223 Lake City, weight sorting (probably only going to do 5 cases).

Test 4 - 308 PPU, weight sorting (probably only going to do 5 cases)

Test 5 - 223 Lake City ⨁, neck turned brass at various increments.

Test 6 - 308 Federal, neck turned brass at various increments.

The first two tests are somewhat pointless but if the machine is capable of detecting a 1% difference between headstamps for a small rifle caliber case, it's likely to be able to detect a 1% difference for a larger case. This would leave me somewhat optimistic about it's capabilities in detecting neck wall thickness variance. I think that anyone who would spend the money and take the time to anneal brass cases would do the bare minimum of sorting their brass by headstamp visually to begin with. As a warning detection system, theoretically useful, if you shoot a lot of similar size cases (6cm and 6.5cm for example).

Weight sorting tests also seem kind of pointless as I don't know anyone who does it, but I do know that some people out in the world do it. Will be weighed in grains with FX120i.

Test 5 and 6 are probably going to be the toughest test to figure out how to structure. A 1% difference when it comes to neck wall thickness is not a lot. For example, 1% of a neck wall with thickness of 0.015" is only 0.00015". The K&M neck turner I have has index marks in 0.0002" increments (more than 1%), and while I can technically set the cutter in between index marks, I don't have a ball micrometer with that fine of a resolution. Unturned necks with neck wall thickness variation (high/low spots) would also be difficult to incorporate in this test I think.

Test 1 - headstamp detection with mixed 223 (small sample size). Going to set the machine to anneal based off the Lake City ⨁.

5 of each - Lake City, Lake City ⨁ (Lake City with NATO approval mark), PPU (Prvi Partizan), Federal, Remington, WCC (Western Cartridge Company), Wolf

1 or 2 cases of PSD, Hornady, Aguila.

Test 2- mixed 308win cases, Federal, PPU, and maybe one other. Don't have much random 308 brass around.

Test 3 - 223 Lake City, weight sorting (probably only going to do 5 cases).

Test 4 - 308 PPU, weight sorting (probably only going to do 5 cases)

Test 5 - 223 Lake City ⨁, neck turned brass at various increments.

Test 6 - 308 Federal, neck turned brass at various increments.

The first two tests are somewhat pointless but if the machine is capable of detecting a 1% difference between headstamps for a small rifle caliber case, it's likely to be able to detect a 1% difference for a larger case. This would leave me somewhat optimistic about it's capabilities in detecting neck wall thickness variance. I think that anyone who would spend the money and take the time to anneal brass cases would do the bare minimum of sorting their brass by headstamp visually to begin with. As a warning detection system, theoretically useful, if you shoot a lot of similar size cases (6cm and 6.5cm for example).

Weight sorting tests also seem kind of pointless as I don't know anyone who does it, but I do know that some people out in the world do it. Will be weighed in grains with FX120i.

Test 5 and 6 are probably going to be the toughest test to figure out how to structure. A 1% difference when it comes to neck wall thickness is not a lot. For example, 1% of a neck wall with thickness of 0.015" is only 0.00015". The K&M neck turner I have has index marks in 0.0002" increments (more than 1%), and while I can technically set the cutter in between index marks, I don't have a ball micrometer with that fine of a resolution. Unturned necks with neck wall thickness variation (high/low spots) would also be difficult to incorporate in this test I think.

But why do you want to put the machine to this task?

I think you might be setting yourself up for disappointment, and expecting the machine to do something it should never be tasked with doing, namely, sorting your brass for you

I think you might be setting yourself up for disappointment, and expecting the machine to do something it should never be tasked with doing, namely, sorting your brass for you

Interesting, never had an international shipment go through Memphis, TN before. Also, cleared customs in 45 minutes. I should have it by Monday.

View attachment 8286279

Test 1 - headstamp detection with mixed 223 (small sample size). Going to set the machine to anneal based off the Lake City ⨁.

5 of each - Lake City, Lake City ⨁ (Lake City with NATO approval mark), PPU (Prvi Partizan), Federal, Remington, WCC (Western Cartridge Company), Wolf

1 or 2 cases of PSD, Hornady, Aguila.

Test 2- mixed 308win cases, Federal, PPU, and maybe one other. Don't have much random 308 brass around.

Test 3 - 223 Lake City, weight sorting (probably only going to do 5 cases).

Test 4 - 308 PPU, weight sorting (probably only going to do 5 cases)

Test 5 - 223 Lake City ⨁, neck turned brass at various increments.

Test 6 - 308 Federal, neck turned brass at various increments.

The first two tests are somewhat pointless but if the machine is capable of detecting a 1% difference between headstamps for a small rifle caliber case, it's likely to be able to detect a 1% difference for a larger case. This would leave me somewhat optimistic about it's capabilities in detecting neck wall thickness variance. I think that anyone who would spend the money and take the time to anneal brass cases would do the bare minimum of sorting their brass by headstamp visually to begin with. As a warning detection system, theoretically useful, if you shoot a lot of similar size cases (6cm and 6.5cm for example).

Weight sorting tests also seem kind of pointless as I don't know anyone who does it, but I do know that some people out in the world do it. Will be weighed in grains with FX120i.

Test 5 and 6 are probably going to be the toughest test to figure out how to structure. A 1% difference when it comes to neck wall thickness is not a lot. For example, 1% of a neck wall with thickness of 0.015" is only 0.00015". The K&M neck turner I have has index marks in 0.0002" increments (more than 1%), and while I can technically set the cutter in between index marks, I don't have a ball micrometer with that fine of a resolution. Unturned necks with neck wall thickness variation (high/low spots) would also be difficult to incorporate in this test I think.

I would think the shoulder, and the part of the body that is annealed is also going to be included in the calculations, so neck turning may be less of a change than you are thinking?

I don't, or rather I have no expectations that the machine is capable of the task.But why do you want to put the machine to this task?

I think you might be setting yourself up for disappointment, and expecting the machine to do something it should never be tasked with doing, namely, sorting your brass for you

I bought the machine for 3 reasons, induction annealer with an adjustable time setting, usable for different calibers without pilots, and an eject system (so I don't have to manually remove a case after annealing). Auto case feeder potential was not a consideration for me, but knowing that it's possible is a nice bonus.

However, it's more about finding the limits of one features of the machine that they advertise on their website and letting potential consumers know whether or not it's a gimmick that they shouldn't expect any utility out of or something that has limited utility.

Very possible.I would think the shoulder, and the part of the body that is annealed is also going to be included in the calculations, so neck turning may be less of a change than you are thinking?

Just paid for mine so hope to have it in a week or so.

I bought it for the apparent ease of use with the case feeder. I have to babysit my ampmate. I anneal 500-1000 at a time and can’t walk away for too long.

I bought it for the apparent ease of use with the case feeder. I have to babysit my ampmate. I anneal 500-1000 at a time and can’t walk away for too long.

I did 100 cases by hand with my amp the other day, and well I don’t really mind it. I find it to be somewhat tedious, and would hate to do more than about 100 at a time.

Yes it can get tedious. Buy a second brass case gripper. Using two makes it go faster. While one is in the machine annealing, you are dumping the case out of the other gripper and then loading it with another caseI did 100 cases by hand with my amp the other day, and well I don’t really mind it. I find it to be somewhat tedious, and would hate to do more than about 100 at a time.

Comes with two 3d printed alignment plates, 1 quick instruction manual, 1 cover, 1 red cap (part of the case size adjustment process), 1 laser cut stamped sheet metal tray (that has a sticker film that needs to be removed) and 1 power cord. Machine looks nicely made, it sounds like there's liquid sloshing inside and MSDS states it's summer coolant. It's very simple to set up, remove tape, plug it in, flip the rocker switch.

Initial testing with the detection feature - In general, I would say it's not accurate enough to reliably sort the differences in 223 Remington or 308 Winchester cases by headstamp alone. I speculate that for the detection system to function there must be significant amount of difference in the neck/shoulder area either through material thickness or maybe dimensionally (as in same caliber case but fired from different chambers) .

Many of the different headstamp cases that I annealed fell within roughly +/- 1% of each other with only a few headstamps showing clear differences. I believe most if not all were fired through the same chamber which may be a factor in why many headstamps were so close.

I'm probably not going to upload the 223 rem test as the video is long and it was hard to see the headstamps. (I may redo this one but making sure the headstamps are clearly visible just to get it on video .)

Video of the 308 win headstamp test (edit - that low humming/buzzing noise is the annealer's fan running)

Test Case - FC results 59%, 5.5 sec

| FC | 56% | 57% | 56% | 57% | 55% |

| PPU | 53% | 56% | 56% | 55% | 54% |

| PMC | 55% | 53% | 53% | 52% | 53% |

Averages -

FC - 56.2%

PPU - 54.8%

PMC - 53.2%

There is, what I would call a clear difference between Federal and PMC, but between PPU and Federal, not so much. The cases were from PPU Match 168gr and FGMM 168gr and PMC 148gr.

Overall, it does what I need it to do and I'm satisfied.

Instructions below since there's no pdf online for the machine that I'm aware of.

Last edited:

View attachment 8288509View attachment 8288508View attachment 8288510View attachment 8288511

View attachment 8288534

Comes with two 3d printed alignment plates, 1 quick instruction manual, 1 cover, 1 red cap (part of the case size adjustment process), 1 laser cut stamped sheet metal tray that has a sticker film that needs to be removed and 1 power cord. Machine looks nicely made, it sounds like there's liquid sloshing inside and MSDS states it's summer coolant. It's very simple to set up, remove tape, plug it in, flip the rocker switch.

Initial testing with the detection feature - In general, I would say it's not accurate enough to reliably sort the differences in 223 Remington or 308 Winchester cases by headstamp alone. I speculate that for the detection system to function there must be significant amount of difference in the neck/shoulder area either through material thickness or maybe dimensionally (as in same caliber case but fired from different chambers) .

Many of the different headstamp cases that I annealed fell within roughly +/- 1% of each other with only a few headstamps showing clear differences. I believe most if not all were fired through the same chamber which may be a factor in why many headstamps were so close.

I'm probably not going to upload the 223 rem test as the video is long and it was hard to see the headstamps.

Video of the 308 win headstamp test

Test Case - FC results 59%, 5.5 sec

FC - 56%, 57%, 56%, 57%, 55%

PPU - 53%, 56%, 56%, 55%, 54%

PMC - 55%, 53%, 53%, 52%, 53%

There is, what I would call a clear difference between Federal and PMC, but between PPU and Federal, not so much. The cases were from PPU Match 168gr and FGMM 168gr and PMC 148gr.

Overall, it does what I need it to do and I'm satisfied.

Instructions below since there's no pdf online for the machine that I'm aware of.

View attachment 8288584View attachment 8288585View attachment 8288586View attachment 8288587View attachment 8288588

Can't wait for my order next month. Thanks for posting. Getting excited!

View attachment 8288509View attachment 8288508View attachment 8288510View attachment 8288511

View attachment 8288534

Comes with two 3d printed alignment plates, 1 quick instruction manual, 1 cover, 1 red cap (part of the case size adjustment process), 1 laser cut stamped sheet metal tray that has a sticker film that needs to be removed and 1 power cord. Machine looks nicely made, it sounds like there's liquid sloshing inside and MSDS states it's summer coolant. It's very simple to set up, remove tape, plug it in, flip the rocker switch.

Initial testing with the detection feature - In general, I would say it's not accurate enough to reliably sort the differences in 223 Remington or 308 Winchester cases by headstamp alone. I speculate that for the detection system to function there must be significant amount of difference in the neck/shoulder area either through material thickness or maybe dimensionally (as in same caliber case but fired from different chambers) .

Many of the different headstamp cases that I annealed fell within roughly +/- 1% of each other with only a few headstamps showing clear differences. I believe most if not all were fired through the same chamber which may be a factor in why many headstamps were so close.

I'm probably not going to upload the 223 rem test as the video is long and it was hard to see the headstamps.

Video of the 308 win headstamp test (edit - that low humming/buzzing noise is the annealer's fan running)

Test Case - FC results 59%, 5.5 sec

FC - 56%, 57%, 56%, 57%, 55%

PPU - 53%, 56%, 56%, 55%, 54%

PMC - 55%, 53%, 53%, 52%, 53%

There is, what I would call a clear difference between Federal and PMC, but between PPU and Federal, not so much. The cases were from PPU Match 168gr and FGMM 168gr and PMC 148gr.

Overall, it does what I need it to do and I'm satisfied.

Instructions below since there's no pdf online for the machine that I'm aware of.

View attachment 8288584View attachment 8288585View attachment 8288586View attachment 8288587View attachment 8288588

Sent you a PM sir.

$990 tydHow much is this one?

I actually got multiple PMs with similar questions, I figure I'd just post the response publicly.

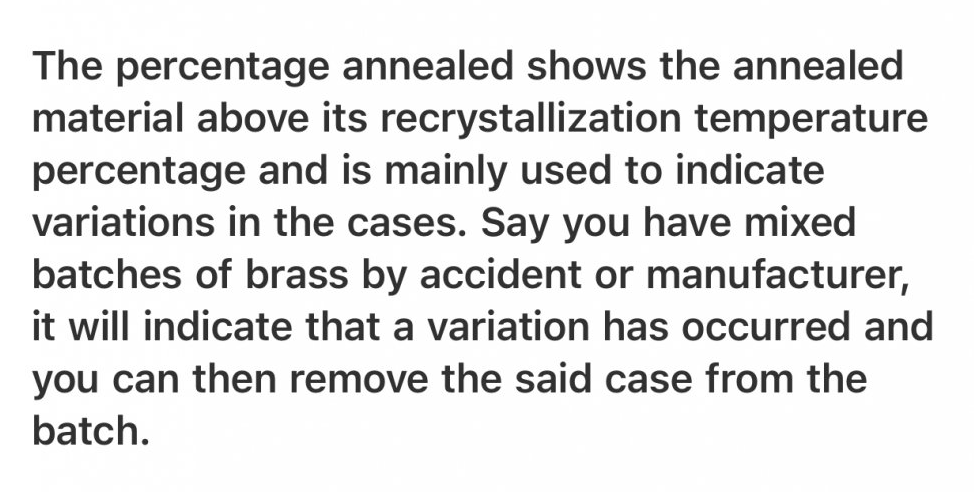

What does the percentages mean?

According to Quick Anneal the sensors measure the thickness around the neck/shoulder area. Quick Anneal's video, starting around 2 minute 8 seconds. So according to them, it's supposed to display differences between cases.

Edit 2 - screenshot from email

https://www.snipershide.com/shootin...-out-there-with-reviews.7196152/post-11264086

The machine after annealing and ejecting a case will give you a percentage at the top of the screen (the display goes away quick so if necessary, you can view the history by holding the Temp up button). The left most percentage is the most recent and the other 3 are the previous 3 annealed cases. Deviation is the percentage difference from the most recent case to the previous case. All the percentages I recorded is to see whether or not the sensors actually work and to what degree.

Annealing case color related questions -

When I did the test case, the glowing of dull orange (camera made it bright orange) is done with the lights that were directly above the annealer turned off. This is done to make sure that I don't overcook the brass case if I don't notice the color transition with the light on (with the naked eye, you barely notice it, and the camera certainly couldn't capture it well). The neck/shoulder of the case will be glowing dull orange in the dark before you even see it with lights on. I let go of the start button (to end test) after the case mouth edge turns dull orange. After the test is complete, it will display the percentage and time.

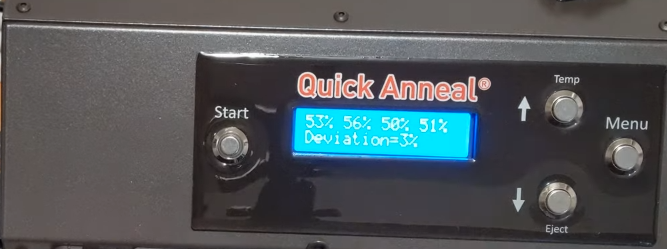

The time is more important. I subtracted 0.1 seconds from the test time to compensate for reaction time of letting go of the start button and adjusted my anneal times based off that. After running the test, you still have to manually change the anneal time by going into the "Set Heat Time" menu option. The test mode does not auto adjust the heat time, only displays what it was.

View attachment 8289011

I'll may be able to knock out a case detection/weight sort test today to see if there is any correlation between what the case anomaly detection senses and case weight in grains. The theory is heavier case = more material somewhere (not necessarily in the neck/shoulder).

The one I will for sure get to eventually is the neck wall thickness test. If the machine is capable, this would probably be more useful for people who don't want to neck turn but is willing to sort cases into various percentage groups.

What does the percentages mean?

According to Quick Anneal the sensors measure the thickness around the neck/shoulder area. Quick Anneal's video, starting around 2 minute 8 seconds. So according to them, it's supposed to display differences between cases.

Edit 2 - screenshot from email

https://www.snipershide.com/shootin...-out-there-with-reviews.7196152/post-11264086

The machine after annealing and ejecting a case will give you a percentage at the top of the screen (the display goes away quick so if necessary, you can view the history by holding the Temp up button). The left most percentage is the most recent and the other 3 are the previous 3 annealed cases. Deviation is the percentage difference from the most recent case to the previous case. All the percentages I recorded is to see whether or not the sensors actually work and to what degree.

Annealing case color related questions -

When I did the test case, the glowing of dull orange (camera made it bright orange) is done with the lights that were directly above the annealer turned off. This is done to make sure that I don't overcook the brass case if I don't notice the color transition with the light on (with the naked eye, you barely notice it, and the camera certainly couldn't capture it well). The neck/shoulder of the case will be glowing dull orange in the dark before you even see it with lights on. I let go of the start button (to end test) after the case mouth edge turns dull orange. After the test is complete, it will display the percentage and time.

The time is more important. I subtracted 0.1 seconds from the test time to compensate for reaction time of letting go of the start button and adjusted my anneal times based off that. After running the test, you still have to manually change the anneal time by going into the "Set Heat Time" menu option. The test mode does not auto adjust the heat time, only displays what it was.

View attachment 8289011

I'll may be able to knock out a case detection/weight sort test today to see if there is any correlation between what the case anomaly detection senses and case weight in grains. The theory is heavier case = more material somewhere (not necessarily in the neck/shoulder).

The one I will for sure get to eventually is the neck wall thickness test. If the machine is capable, this would probably be more useful for people who don't want to neck turn but is willing to sort cases into various percentage groups.

Last edited:

I actually got multiple PMs with similar questions, I figure I'd just post the response publicly.

What does the percentages mean?

According to Quick Anneal the sensors measure the thickness around the neck/shoulder area. Quick Anneal's video, starting around 2 minute 8 seconds. So according to them, it's supposed to display differences between cases.

Edit 2 - screenshot from email

https://www.snipershide.com/shootin...-out-there-with-reviews.7196152/post-11264086

View attachment 8289023

View attachment 8289024

The machine after annealing and ejecting a case will give you a percentage at the top of the screen (the display goes away quick so if necessary, you can view the history by holding the Temp up button). The left most percentage is the most recent and the other 3 are the previous 3 annealed cases. Deviation is the percentage difference from the most recent case to the previous case. All the percentages I recorded is to see whether or not the sensors actually work and to what degree.

Annealing case color related questions -

When I did the test case, the glowing of dull orange (camera made it bright orange) is done with the lights that were directly above the annealer turned off. This is done to make sure that I don't overcook the brass case if I don't notice the color transition with the light on (with the naked eye, you barely notice it, and the camera certainly couldn't capture it well). The neck/shoulder of the case will be glowing dull orange in the dark before you even see it with lights on. I let go of the start button (to end test) after the case mouth edge turns dull orange. After the test is complete, it will display the percentage and time.

The time is more important. I subtracted 0.1 seconds from the test time to compensate for reaction time of letting go of the start button and adjusted my anneal times based off that. After running the test, you still have to manually change the anneal time by going into the "Set Heat Time" menu option. The test mode does not auto adjust the heat time, only displays what it was.

View attachment 8289011

View attachment 8289013

I'll may be able to knock out a case detection/weight sort test today to see if there is any correlation between what the case anomaly detection senses and case weight in grains. The theory is heavier case = more material somewhere (not necessarily in the neck/shoulder).

The one I will for sure get to eventually is the neck wall thickness test. If the machine is capable, this would probably be more useful for people who don't want to neck turn but is willing to sort cases into various percentage groups.

Thanks a lot for sharing.

My big concern is with the Ackley Improved cases. I have shoved the shoulder out to where it does not chamber, or chambers hard. I can fix that, but sizing after the anneal makes me wonder is the steps need to be adjusted or I got the shoulder to soft,???

Thanks to @parshal for the idea for this test. Test is test anneal same case 3 times to see if there are any major changes or to find the average time for annealing. Sample size 5.

Federal brass 223 rem Results - Percentage (time)

Averages -

Case 1 - 53%, 3.7666666 seconds

Case 2 - 53.333%, 3.7 seconds

Case 3 - 53.333%, 3.433 seconds

Case 4 - 53%, 3.733 seconds

Case 5 - 53%, 3.8 seconds

Averages for all combined -

Percentage - 53.133333%

Time - 3.686666 seconds

Doesn't seem like the cases were ruined and likely are still usable but I cannot be certain. For safety reasons, you should probably discard the cases if you conduct a multiple "test anneal" function.

Test 3 -

Next test is a simple sample size 1 of PPU 223 Rem brass. Test anneal, size , test anneal, to see if any changes occur. I may do a repeat of this test but using a full length sizing die instead of a Lee collet die to see if any different changes occur.

Results -

Test Anneal - 49%, 4.7 seconds

Test Anneal after sizing with Lee collet die - 49% 5.1 seconds

Can't formulate a solid conclusion from a sample size of 1, but something to note is that if you're the type to anneal, size, anneal, that your anneal time will potentially require adjustments.

Test 4 - weight/percentage test (No video evidence for this one, I thought I had hit record)

Ended up doing the weight/annealer percentage correlation test on Remington (RP headstamp) brass and also tossed in 2 random Wolf cases that weighed in at 93.8gr and 94.3gr. The percentages the machine put out for those two cases were 49% and 50%. There is a possible correlation between heavier cases (in the same caliber) having lower percentage numbers and lighter cases having higher percentage numbers.

Anneal test case - Remington 223 - 91.08gr, 52% 3.5 seconds anneal time. Weight in grains.

Federal brass 223 rem Results - Percentage (time)

| Case 1 | 54% (3.7) | 53% (3.9) | 52% (3.7) |

| Case 2 | 54% (3.7) | 53% (3.7) | 53% (3.7) |

| Case 3 | 54% (3.5) | 53% (3.4) | 53% (3.4) |

| Case 4 | 54% (3.8) | 53% (3.8) | 52% (3.6) |

| Case 5 | 53% (3.8) | 53% (3.8) | 53% (3.8) |

Averages -

Case 1 - 53%, 3.7666666 seconds

Case 2 - 53.333%, 3.7 seconds

Case 3 - 53.333%, 3.433 seconds

Case 4 - 53%, 3.733 seconds

Case 5 - 53%, 3.8 seconds

Averages for all combined -

Percentage - 53.133333%

Time - 3.686666 seconds

Doesn't seem like the cases were ruined and likely are still usable but I cannot be certain. For safety reasons, you should probably discard the cases if you conduct a multiple "test anneal" function.

Test 3 -

Next test is a simple sample size 1 of PPU 223 Rem brass. Test anneal, size , test anneal, to see if any changes occur. I may do a repeat of this test but using a full length sizing die instead of a Lee collet die to see if any different changes occur.

Results -

Test Anneal - 49%, 4.7 seconds

Test Anneal after sizing with Lee collet die - 49% 5.1 seconds

Can't formulate a solid conclusion from a sample size of 1, but something to note is that if you're the type to anneal, size, anneal, that your anneal time will potentially require adjustments.

Test 4 - weight/percentage test (No video evidence for this one, I thought I had hit record)

Ended up doing the weight/annealer percentage correlation test on Remington (RP headstamp) brass and also tossed in 2 random Wolf cases that weighed in at 93.8gr and 94.3gr. The percentages the machine put out for those two cases were 49% and 50%. There is a possible correlation between heavier cases (in the same caliber) having lower percentage numbers and lighter cases having higher percentage numbers.

Anneal test case - Remington 223 - 91.08gr, 52% 3.5 seconds anneal time. Weight in grains.

| 90.3 | 53% |

| 90.36 | 53% |

| 90.5 | 52% |

| 90.5 | 52% |

| 90.66 | 52% |

| 90.72 | 52% |

| 91.02 | 52% |

| 91.06 | 52% |

| 91.16 | 52% |

| 91.2 | 52% |

| Wolf 93.8 | 50% |

| Wolf 94.3 | 49% |

Last edited:

This is the final test of the Quick Anneal case anomaly detection sensor - neck wall thickness variation. Short answer, it could not discern any meaningful differences (that I can see). Granted, none of these neck turned brass were completely uniformed, but it shows that even if the neck wall thickness averages are 5% thinner different than the unmolested cases, it will not change the percentage output.

There were no correlations that I could see between thicker neck averages and lower or higher percentages or thinner neck averages and lower or higher percentages. The Quick Anneal average output displayed were +/- 0.4% between groups.

Test anneal case was 52% at 5.2 seconds. Anneal time was set to 5.2 seconds

Summation of Anomaly detection capabilities -

Different headstamps (of same caliber) - somewhat to moderately capable of detection

Different average neck wall thickness (same headstamp) - not capable of detection of <6%

Different caliber cases - likely capable but I haven't tested it

Different weight cases - possibly capable (I don't weight sort, so I won't explore this further)

Test anneal capabilities -

Different headstamps - Gives different anneal times but percentage output are not consistently different

Different average neck wall thickness (same headstamp) - Gives different anneal times but percentages are not significantly different.

Different caliber cases - Gives different anneal times and but percentages are not always different (I've had 53% pop up for both 223rem and 308 win, but both had significantly different anneal times)

I did confirm with Quick Anneal that if the material thickness in the neck/shoulder area of the cases are similar or the same between two cases, even if they were different brands (different headstamps), that the percentages displayed will be the same.

Conclusions and initial impressions after all the testing -

This machine is great if you're looking for an induction annealer that has adjustable time settings, auto eject, easy adjust sizing for different cases without pilots, no sacrificial cases, and the potential of an easy add on case feeder. This is a solid machine for a fair price of around $990 USD shipped via Fedex to Midwest USA. If it wasn't for shipping costs from South Africa, I believe this would be around the same price as a Fluxeon Annie. Depending on where you live - conversion rates, inflation, deflation, shipping costs, taxes, etc. will all affect pricing.

In my opinion, the case anomaly detection is of very limited utility, or rather the percentage output displayed is of limited utility. Different weight cases (in the same caliber, same or different headstamp) is the only thing that I may have been able to find a correlation to with percentages.

I have not been able to figure out, in my limited testing, what exact factors increase or decrease the percentages displayed and how the percentages could be utilized in my reloading practices, so I'm just going to ignore unless it displays over 4% deviation.

There were no correlations that I could see between thicker neck averages and lower or higher percentages or thinner neck averages and lower or higher percentages. The Quick Anneal average output displayed were +/- 0.4% between groups.

Test anneal case was 52% at 5.2 seconds. Anneal time was set to 5.2 seconds

Summation of Anomaly detection capabilities -

Different headstamps (of same caliber) - somewhat to moderately capable of detection

Different average neck wall thickness (same headstamp) - not capable of detection of <6%

Different caliber cases - likely capable but I haven't tested it

Different weight cases - possibly capable (I don't weight sort, so I won't explore this further)

Test anneal capabilities -

Different headstamps - Gives different anneal times but percentage output are not consistently different

Different average neck wall thickness (same headstamp) - Gives different anneal times but percentages are not significantly different.

Different caliber cases - Gives different anneal times and but percentages are not always different (I've had 53% pop up for both 223rem and 308 win, but both had significantly different anneal times)

I did confirm with Quick Anneal that if the material thickness in the neck/shoulder area of the cases are similar or the same between two cases, even if they were different brands (different headstamps), that the percentages displayed will be the same.

Conclusions and initial impressions after all the testing -

This machine is great if you're looking for an induction annealer that has adjustable time settings, auto eject, easy adjust sizing for different cases without pilots, no sacrificial cases, and the potential of an easy add on case feeder. This is a solid machine for a fair price of around $990 USD shipped via Fedex to Midwest USA. If it wasn't for shipping costs from South Africa, I believe this would be around the same price as a Fluxeon Annie. Depending on where you live - conversion rates, inflation, deflation, shipping costs, taxes, etc. will all affect pricing.

In my opinion, the case anomaly detection is of very limited utility, or rather the percentage output displayed is of limited utility. Different weight cases (in the same caliber, same or different headstamp) is the only thing that I may have been able to find a correlation to with percentages.

I have not been able to figure out, in my limited testing, what exact factors increase or decrease the percentages displayed and how the percentages could be utilized in my reloading practices, so I'm just going to ignore unless it displays over 4% deviation.

Last edited:

I said before you were setting yourself up for disappointment. It was not designed for the use you intended

Not disappointed at all. Had no expectations of its anomaly detection capabilities and now (we all) have a clearer idea of what the limitations are as compared to the broad/vague/(mildly exaggerated?) marketing claims.I said before you were setting yourself up for disappointment. It was not designed for the use you intended

Last edited:

So what would be your overall conclusion on the working’s on this annealer? It seems to do his job just fine, like other induction ones? Or should one spend the extra $ for the amp? I surly like the operating procedures, like feed and dropping off the cases.Not disappointed at all. Had no expectations of its anomaly detection capabilities and now (we all) have a clearer idea of what the limitations are as compared to the broad/vague/(mildly exaggerated?) marketing claims.

Thank you again for sharing!

As much as I like the auto feature of the quick anneal. Not to mention it’s cheaper than the amp. If I’m spending time and money to anneal. I want it to be precise-annealed back to factory hardness. While consistency is important. I would rather pay a little more to know the machine is annealing back to the virgin brass hardness, every time consistently. I ended up using a $400 off amp certificate and buying the AMP for $1195. $1295 with 4 pilots and an extra brass case holder ( to speed up the feeding process). I figured what’s an extra $300. If I decide I don’t like it . Given what I paid I could sell it for what I have into it.

Would you pay regular price for the AMP with no certs?As much as I like the auto feature of the quick anneal. Not to mention it’s cheaper than the amp. If I’m spending time and money to anneal. I want it to be precise-annealed back to factory hardness. While consistency is important. I would rather pay a little more to know the machine is annealing back to the virgin brass hardness, every time consistently. I ended up using a $400 off amp certificate and buying the AMP for $1195. $1295 with 4 pilots and an extra brass case holder ( to speed up the feeding process). I figured what’s an extra $300. If I decide I don’t like it . Given what I paid I could sell it for what I have into it.

Just wondering.

I was on the fence. After speaking with quick anneal and reading up on both machines . I knew the AMP was a better machine. The quick anneals only real selling points were a quicker process. As well as a cheaper price. I figured if I spent the $1000 on the quick anneal . I would always wonder if I left anything on the table. The little bit of extra money was worth piece of mind. I’m using the AMP for short range Benchrest so I’m not annealing thousands of cases a week either. The $400 cert. certainly made it an easier pill to swallow.

Does it just fine like the other induction annealers. In my limited experience with both machines Quick Anneal > Amp.So what would be your overall conclusion on the working’s on this annealer? It seems to do his job just fine, like other induction ones? Or should one spend the extra $ for the amp? I surly like the operating procedures, like feed and dropping off the cases.

Thank you again for sharing!

I think if my ramblings below affect you mentally, you'd be better off paying the extra for the AMP. If it doesn't affect you, get the Quick Anneal for sure.

The adjustable height/no pilot feature pro is also a con for folks who need a hard stop repeatable height adjustment. You can make a mark to indicate where exactly the heights are for your cases on the Quick Anneal, but it would still depend on you lifting the tray to the mark and tightening the thumb wheel at that precise mark. Maybe a pro that outweighs the lack of hard stop con is probably that "infinite" height adjustability. So if your case shoulders are a little more far forward out of one chamber compared to another chamber of the same caliber, you can adjust relative to that.

The test anneal functionality to derive an anneal time of Quick Anneal's machine (even using the dark room glow method/human eye visual method), was very consistent (test #3) and the machine was able to determine time settings (within fractions) even at multiple anneals per case. The cases also at multiple anneals didn't seem like it displayed any changes at multiple anneals, whether it's time output or percentage output. My test results would be similar to AMP's own video titled "What happens if you anneal the same case twice?"

BUT

Sure, every brass will be annealed to the same time and theoretically same hardness (assuming you sort the brass, like you should, even AMP recommends it), but what is the exact hardness at that amber orange? No clue. It's not preprogrammed via software to set anneal times to achieve an average specific hardness. As far as I can tell, you can't discern that from the percentage displayed (on the Quick Anneal) as it doesn't correspond much to anything I am equipped to measure (except maybe weight).

This is probably why you would want the AMP. What you would be buying is not necessarily a better machine (my opinion) but access to preprogrammed/predefined data that has been collected to attempt to achieve an average specific range of hardness.

--------------------------------------------

I don't know if anyone has sacrificed enough random cases in testing the AMP to determine the limitations of the Aztec mode so I can't say if the sensors in the AMP are any more advanced than the Quick Anneal sensors but given the FAQ, I suspect it has the same limitations as the Quick Anneal and that minor variations would not produce a drastically different Aztec code (codes likely being within +/- 1), same as the percentage displayed by the Quick Anneal (+/- 1%).

I don't know if anyone has ever timed various Aztec codes to see how the increments relates to time (example - every 001 equals 0.025 seconds, so a code of 151 would equate to 3.775 seconds) and whether or not anyone has ever found the same code that applies to two or more different headstamp cases (same caliber). My suspicion is it would be something like time (from thermal sensors triggering the stop timer at melting temperature) minus a time interval to prevent melting, which is then converted into code at a certain ratio plus or minus the pilot number = final Aztec code.

The other thing about the AMP as it relates to neck wall thickness variation is the neck turning increments that AMP lists which is in 0.001" increments. Now granted, this is about standard mode, but is the Aztec sensor better? I'm doubtful.

https://www.ampannealing.com/faq/

https://www.ampannealing.com/settings/

---------------------------------

Some of links to where I got all of the ideas to do some of my tests. I couldn't find the link regarding the AMP code and what the neck turn thickness to code ratio was, but it's also on the accurateshooter forum.

https://forum.accurateshooter.com/threads/amp-aztec-mode-question.4097518/

https://forum.accurateshooter.com/threads/amp-aztec-codes-evolving-over-life-of-brass.4022293/

Attachments

Last edited:

I was hoping the quick anneal would be equivalent to the AMP. However after talking with quick anneal and reading the AMP website that wasn’t the case.The sensors in the machines would have to be totally different. The Amp is literally able to melt a case and then set a time / temp based on what it finds. The sensor in the quick anneal gives you a percentage that doesn’t really mean anything . They claimed through email with zero proof of anything to back up their claim. It gives you the percentage annealed past recrystalization. You’ll have to take them at their word. Im guessing if they had proof of any claims . They would publish them. As far as the test button on the quick anneal. It should simply say start/stop or timer. That’s all it actually does. There is no “testing” going on. You set the time in the quick anneal based on color / glow . This is no different than an Annie, handheld induction, or an annealeez. The only real difference is it’s ability to drop the case out of the bottom. I’m sure it will work ok for most people. I just couldn’t see spending $1000 on a machine and still have to set it up like a flame Annealer. With no idea what hardness you’re actually annealing to. I’ve read the amp website and I’m annealing Lapua brass. I’m not very concerned about variations. If I were annealing cheaper brass then maybe. But that’s not what I was buying it for.

I’ve sacrificed a dozen or so Lapua 65 PRC brass in Aztec in addition to other cases and cartridges. I’ve gotten a range of numbers sometimes near a 10 point range. It’s rare that I get the same number more than twice.

Here’s five PRC cases.

0191, 0195, 0194, 0196, 0198

Here’s five PRC cases.

0191, 0195, 0194, 0196, 0198

Last edited:

Is that good or bad in your opinion and why?I’ve sacrificed a dozen or Lapua 65 PRC brass in Aztec in addition to other cases and cartridges. I’ve gotten a range of numbers sometimes near a 10 point range. It’s rare that I get the same number more than twice.

Here’s five PRC cases.

0196, 0194, 0198, 195, 191

From a distance it doesn’t seem good.

I can’t say if it’s good or bad. It just shows the variability of what we're trying to achieve. There's no perfect number or setting with the variability of the brass. I think what it does show, though, is that, contrary to what some may believe, the AMP doesn't come up with a perfect setting. It has variability. To me, it's a black box. I have to trust that the number it gives me is what is best for that brass and I do trust it. I know they've put a lot of research into all this. But, it's not going to give you the same number every time.

I've got a Quick Anneal enroute. I'm most interested in using it with the case feeder. I do very large batches of annealing. I'm not keen on 'guessing' at the time based on color compared to the AMP telling me a number. But, if I 'test' a bunch of cases and come up with an average time to start with I don't think I'll be in bad shape.

I've got a Quick Anneal enroute. I'm most interested in using it with the case feeder. I do very large batches of annealing. I'm not keen on 'guessing' at the time based on color compared to the AMP telling me a number. But, if I 'test' a bunch of cases and come up with an average time to start with I don't think I'll be in bad shape.

“Perfect” every time….just different!I’ve sacrificed a dozen or so Lapua 65 PRC brass in Aztec in addition to other cases and cartridges. I’ve gotten a range of numbers sometimes near a 10 point range. It’s rare that I get the same number more than twice.

Here’s five PRC cases.

0191, 0195, 0194, 0196, 0198

I simply don't know what to think of people who WON'T READ a simple evaluation test that's repeatable and Verified . Just Try and COMPREHEND the Results .

He even made High resolution pictures for those whom are illiterate !. You're simply restoring ductility but NOT aligning or growing grain structure ,thus it's NOT annealing . Everyone just says it is , making Brass or other metal softer Isn't True Annealing . Atoms must slip between or atoms diffuse from the inside to the outside

Figure 9: The fully annealed specimen was cold reduced 50% in thickness. Then, CR specimens were annealed for 30 minutes at 500, 700, 800, 900 and 1300°F. Cross sections were prepared metallographically and 100 HV indents at 100 gf load were made in each. The plot shows the distribution of HV values for each specimen.

https://vacaero.com/information-res...rmation-and-annealing-of-cartridge-brass.html

Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of recrystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

Call it what you will ,I don't because it ISN'T . Factual info can't be dismissed .

He even made High resolution pictures for those whom are illiterate !. You're simply restoring ductility but NOT aligning or growing grain structure ,thus it's NOT annealing . Everyone just says it is , making Brass or other metal softer Isn't True Annealing . Atoms must slip between or atoms diffuse from the inside to the outside

Figure 9: The fully annealed specimen was cold reduced 50% in thickness. Then, CR specimens were annealed for 30 minutes at 500, 700, 800, 900 and 1300°F. Cross sections were prepared metallographically and 100 HV indents at 100 gf load were made in each. The plot shows the distribution of HV values for each specimen.

https://vacaero.com/information-res...rmation-and-annealing-of-cartridge-brass.html

Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of recrystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

Call it what you will ,I don't because it ISN'T . Factual info can't be dismissed .

How hot do you think an induction coil that will melt brass can get your brass? Hot enough to anneal it?I simply don't know what to think of people who WON'T READ a simple evaluation test that's repeatable and Verified . Just Try and COMPREHEND the Results .

He even made High resolution pictures for those whom are illiterate !. You're simply restoring ductility but NOT aligning or growing grain structure ,thus it's NOT annealing . Everyone just says it is , making Brass or other metal softer Isn't True Annealing . Atoms must slip between or atoms diffuse from the inside to the outside

Figure 9: The fully annealed specimen was cold reduced 50% in thickness. Then, CR specimens were annealed for 30 minutes at 500, 700, 800, 900 and 1300°F. Cross sections were prepared metallographically and 100 HV indents at 100 gf load were made in each. The plot shows the distribution of HV values for each specimen.

https://vacaero.com/information-res...rmation-and-annealing-of-cartridge-brass.html

Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of recrystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

Call it what you will ,I don't because it ISN'T . Factual info can't be dismissed .

How hot do you think an induction coil that will melt brass can get your brass? Hot enough to anneal it?

Plenty hot enough ,however TIME is required as well as Heat . Hence where in the problem lies . In order for Grain lattice or Re- crystallization to actually begin is FAR above any usable brass cartridge case temp .

The " Only " possible way would be wrapping the case body and circulating cold fluid around it ,to arrest the induction heating process .

NOT practical IMO .

It takes less than 10 seconds for my AMP to fully melt a case neck, and I can still pick it up by the case head.Plenty hot enough ,however TIME is required as well as Heat . Hence where in the problem lies . In order for Grain lattice or Re- crystallization to actually begin is FAR above any usable brass cartridge case temp .

The " Only " possible way would be wrapping the case body and circulating cold fluid around it ,to arrest the induction heating process .

NOT practical IMO .

Next.

Last edited:

https://ballisticrecreations.ca/sal...e-centre/annealing-study-effect-on-new-brass/

https://ballisticrecreations.ca/sal...eratures-for-reloading-brass-cartridge-cases/

https://www.diva-portal.org/smash/get/diva2:1237076/FULLTEXT02.pdf

My links has fancy pictures too. Might also wanna tell Norma they're not actually annealing and to stop using the term.

Might also wanna tell Norma they're not actually annealing and to stop using the term.

https://ballisticrecreations.ca/sal...eratures-for-reloading-brass-cartridge-cases/

https://www.diva-portal.org/smash/get/diva2:1237076/FULLTEXT02.pdf

My links has fancy pictures too.

It takes less than 10 seconds for my AMP to fully melt a case neck, and I can still pick it up by the case head.

Next.

Did YOU fail to read ? I'll highlight the emphasis ON TIME REQUIRED** . Making brass softer ISN'T true annealing ,it's simply restoring the metals ductility . Yet in order to truly anneal some if not all of the metal requires re-crystallization , this needs to occur and that DOESN'T happen in seconds !. I didn't invent or make the science up ,it's a KNOWN fact . People in the industry simply misuse the term ,as they misuse Boxer primer origin .

It's happens ,what is a thing a ma jig ?. Pull the doohickey ,slide the gizmo !. Now are those proper terms ,NO yet WE all except them in context of reference don't we .

Fyi : 2-3 seconds at proper temperature 756 Deg. F and above WILL soften brass and restore ductility but WON'T anneal it .

The simplest way I can PROVE this point is : Do what You consider cartridge annealing ,then send YOUR brass into an analytical lab and have them examine Your cartridge and see IF they say it's annealed !. I learned via the hard way working in Aerospace ,they cut you ZERO slack and slam home FACTS . As peoples lives depend upon it .

** Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of re-crystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

Did you fail to read? If it’s liquified, it’s gone totally past being annealed. If it liquifies in ten seconds, it anneals at less than ten seconds.Did YOU fail to read ? I'll highlight the emphasis ON TIME REQUIRED** . Making brass softer ISN'T true annealing ,it's simply restoring the metals ductility . Yet in order to truly anneal some if not all of the metal requires re-crystallization , this needs to occur and that DOESN'T happen in seconds !. I didn't invent or make the science up ,it's a KNOWN fact . People in the industry simply misuse the term ,as they misuse Boxer primer origin .

It's happens ,what is a thing a ma jig ?. Pull the doohickey ,slide the gizmo !. Now are those proper terms ,NO yet WE all except them in context of reference don't we .

Fyi : 2-3 seconds at proper temperature 756 Deg. F and above WILL soften brass and restore ductility but WON'T anneal it .

The simplest way I can PROVE this point is : Do what You consider cartridge annealing ,then send YOUR brass into an analytical lab and have them examine Your cartridge and see IF they say it's annealed !. I learned via the hard way working in Aerospace ,they cut you ZERO slack and slam home FACTS . As peoples lives depend upon it .

** Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of re-crystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

I ordered one 10 days ago. Arrived today. Better service then some companies here in the US. Looks good and packaged well. Thanks for your testing and report.I've got a Quick Anneal enroute. I'm most interested in using it with the case feeder. I do very large batches of annealing. I'm not keen on 'guessing' at the time based on color compared to the AMP telling me a number. But, if I 'test' a bunch of cases and come up with an average time to start with I don't think I'll be in bad shape.

Mine came today and I just set it up. I received the printed parts for use with the Dillon but no tube. I'll have to see if I can find some at the local hardware store.

Here it is next to an AMP.

And here are the test time results. Ones are left are Lapua SRP 6.5 Creed and ones on right are Lapua 6.5 PRC. 5.8 seems "about" right for both.

Here it is next to an AMP.

And here are the test time results. Ones are left are Lapua SRP 6.5 Creed and ones on right are Lapua 6.5 PRC. 5.8 seems "about" right for both.

It's slower than the AMP MATE with the case feeder. I'd say it's about 10s per case. You gotta be careful to ensure the next case doesn't come too quickly.

Here's a pic of a quick setup where I can use an akro bin to catch a whole lot more cases than the tray that came with it.

Here's a pic of a quick setup where I can use an akro bin to catch a whole lot more cases than the tray that came with it.

Attachments

So if we have an amp and amp mate, you'd say we should stick with what we have? Am I understanding this right? If you don't have an amp and a mate, then this would be a good option for you to feed cases and automate your annealing? Is that your opinion? Thanks for all the info, really appreciated!It's slower than the AMP MATE with the case feeder. I'd say it's about 10s per case. You gotta be careful to ensure the next case doesn't come too quickly.

Here's a pic of a quick setup where I can use an akro bin to catch a whole lot more cases than the tray that came with it.

I’ve only run 50 or so cases with the feeder on the QA. I think once it’s dialed in it has fewer hiccups. It’s less finicky in having to be perfectly set up.

With the setup pictured above, I had one case stick above the blue adapter at the upper end of the hose at the feeder. I chamfered the blue adapter a bit more and didn’t have another feed issue there.

I need to heat the tube to get it bent just right. It’s pretty stiff and has a bend I can bend out.

I did notice 3 or 4 of my Lapua Creed cases flashed showing a larger deviation from the others. Could be different lots, I guess. It’s nice to know but means nothing when the case falls in the box of other cases. No idea which one it was.

If you have the case feed moving too fast and it drops another cases before the annealer has dropped the last case it will drop both those case through the annealer with the last one not annealed. Again, you’ll not know which one that is other than the fact it won’t be scalding hot like the others.

<edit> I don’t know if there is a way to default to auto anneal. I’ll never run it without auto anneal and don’t want to flip through the menu to set it each time. I sent them an email requesting that be a feature in case I’m missing how that’s down now.

When I have time, I will run the QA with feeder and AMPMATE side by side and get a video.

With the setup pictured above, I had one case stick above the blue adapter at the upper end of the hose at the feeder. I chamfered the blue adapter a bit more and didn’t have another feed issue there.

I need to heat the tube to get it bent just right. It’s pretty stiff and has a bend I can bend out.

I did notice 3 or 4 of my Lapua Creed cases flashed showing a larger deviation from the others. Could be different lots, I guess. It’s nice to know but means nothing when the case falls in the box of other cases. No idea which one it was.

If you have the case feed moving too fast and it drops another cases before the annealer has dropped the last case it will drop both those case through the annealer with the last one not annealed. Again, you’ll not know which one that is other than the fact it won’t be scalding hot like the others.

<edit> I don’t know if there is a way to default to auto anneal. I’ll never run it without auto anneal and don’t want to flip through the menu to set it each time. I sent them an email requesting that be a feature in case I’m missing how that’s down now.

When I have time, I will run the QA with feeder and AMPMATE side by side and get a video.

Last edited:

Did you fail to read? If it’s liquified, it’s gone totally past being annealed. If it liquifies in ten seconds, it anneals at less than ten seconds.Did YOU fail to read ? I'll highlight the emphasis ON TIME REQUIRED** . Making brass softer ISN'T true annealing ,it's simply restoring the metals ductility . Yet in order to truly anneal some if not all of the metal requires re-crystallization , this needs to occur and that DOESN'T happen in seconds !. I didn't invent or make the science up ,it's a KNOWN fact . People in the industry simply misuse the term ,as they misuse Boxer primer origin .

It's happens ,what is a thing a ma jig ?. Pull the doohickey ,slide the gizmo !. Now are those proper terms ,NO yet WE all except them in context of reference don't we .

Fyi : 2-3 seconds at proper temperature 756 Deg. F and above WILL soften brass and restore ductility but WON'T anneal it .

The simplest way I can PROVE this point is : Do what You consider cartridge annealing ,then send YOUR brass into an analytical lab and have them examine Your cartridge and see IF they say it's annealed !. I learned via the hard way working in Aerospace ,they cut you ZERO slack and slam home FACTS . As peoples lives depend upon it .

** Figures 6 and b: Microstructure of wrought cartridge brass, Cu – 30% Zn, cold reduced 50%, annealed at 427°C (800°F): 4 minutes did not visibly affect the cold worked grain structure (note heavy slip lines); 8 minutes has produced the start of re-crystallization. Tint etched with Klemm’s I (Originals at 100X, crossed polarized light (off crossed) plus sensitive tint).

Do recrystallisation and grain grown not come before liquefaction all of a sudden?

If you wanted to go through the trouble of watching for the flash use 2 bins and make a catch tray/shelf on a pivot. Turn to drop in the pass or cull bins as needed. I suppose this is something QA could have automated but would add to the price.I’ve only run 50 or so cases with the feeder on the QA. I think once it’s dialed in it has fewer hiccups. It’s less finicky in having to be perfectly set up.

With the setup pictured above, I had one case stick above the blue adapter at the upper end of the hose at the feeder. I chamfered the blue adapter a bit more and didn’t have another feed issue there.

I need to heat the tube to get it bent just right. It’s pretty stiff and has a bend I can bend out.

I did notice 3 or 4 of my Lapua Creed cases flashed showing a larger deviation from the others. Could be different lots, I guess. It’s nice to know but means nothing when the case falls in the box of other cases. No idea which one it was.

If you have the case feed moving too fast and it drops another cases before the annealer has dropped the last case it will drop both those case through the annealer with the last one not annealed. Again, you’ll not know which one that is other than the fact it won’t be scalding hot like the others.

<edit> I don’t know if there is a way to default to auto anneal. I’ll never run it without auto anneal and don’t want to flip through the menu to set it each time. I sent them an email requesting that be a feature in case I’m missing how that’s down now.

When I have time, I will run the QA with feeder and AMPMATE side by side and get a video.

A cheaper but more of a hassle idea would be some sort of a raised landing zone in your bin. Would give you time to grab a bad one with large tweezers or gloved hand or flick a good one into the bin.

Similar threads

- Replies

- 0

- Views

- 505

- Replies

- 46

- Views

- 5K

- Replies

- 35

- Views

- 7K

- Replies

- 142

- Views

- 15K