Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing 10 years, but it finally happend.

- Thread starter LRI

- Start date

This is a really kickass thing, man... congrats!! I'm looking forward to seeing some of the creative solutions that this thing will enable.

I used to work with a computer coder who said that if you have to do something once, just get it done; but if you're going to have to do it more than once, automate it. Your approach seems very similar in concept... if it's a one-off, fine, whatever, just make it happen. But if there might be a market for it, develop and build the fixturing, determine the right tooling, write the CNC code, etc...

In the long run, the initial investment (in both time and money) can really pay off, as it allows for rapid throughput of whatever work you automated. Right on, man!

I used to work with a computer coder who said that if you have to do something once, just get it done; but if you're going to have to do it more than once, automate it. Your approach seems very similar in concept... if it's a one-off, fine, whatever, just make it happen. But if there might be a market for it, develop and build the fixturing, determine the right tooling, write the CNC code, etc...

In the long run, the initial investment (in both time and money) can really pay off, as it allows for rapid throughput of whatever work you automated. Right on, man!

D

Deleted member 10043

Guest

That will be a nice addition to your stable, we have an older Haas TL-1 cnc lathe with the manual handles and it's been a trooper. What coolant type do you intend to run in it? We use hangstefers S-500 and it worked ok until we did some plastic cutting jobs and that caused bio growth problems ever since. Looking at alternative coolants now.

How much does one of those cost?

Between machine, shipping, rigging, tool package, electricians, work holding, down time making room, and software upgrades:

Italian sports cars are cheaper.

@LongRifles Inc.

Did Kalli get a new last name?

I missed the news. Congrats!

That new machine looks awesome. always have loved the threads showing the work you and your crew do.

Did Kalli get a new last name?

I missed the news. Congrats!

That new machine looks awesome. always have loved the threads showing the work you and your crew do.

Between machine, shipping, rigging, tool package, electricians, work holding, down time making room, and software upgrades:

Italian sports cars are cheaper.

So somewhere in between Italian sports car and Swedish super car price brackets then I take it.

@LongRifles Inc.

Did Kalli get a new last name?

I missed the news. Congrats!

That new machine looks awesome. always have loved the threads showing the work you and your crew do.

She did!

Congratulations, man! Does that mean that the Kalli Reasor business cards that were sent with my orders are going to become collector's items? ;-)She did!After 15 years of "dating" we figured it was time to get legal I guess. lol.

Good timing. I saw that HAAS was raising prices some time this first quarter. Very nice addition.

Good thing the install wasn't like hardwood flooring where it has to sit a few days to acclimatize to the new environment before the install. I could only imagine the look on your face seeing it sitting there for a couple of days waiting to acclimatize before they could begin the install. For some reason I don't think you would have survived the wait.

Good thing the install wasn't like hardwood flooring where it has to sit a few days to acclimatize to the new environment before the install. I could only imagine the look on your face seeing it sitting there for a couple of days waiting to acclimatize before they could begin the install. For some reason I don't think you would have survived the wait.

A machine like that absolutely should acclimate, especially given the extreme and abrupt temperature changes. Hopefully it's still level and was allowed a few days to thaw before being put to work.

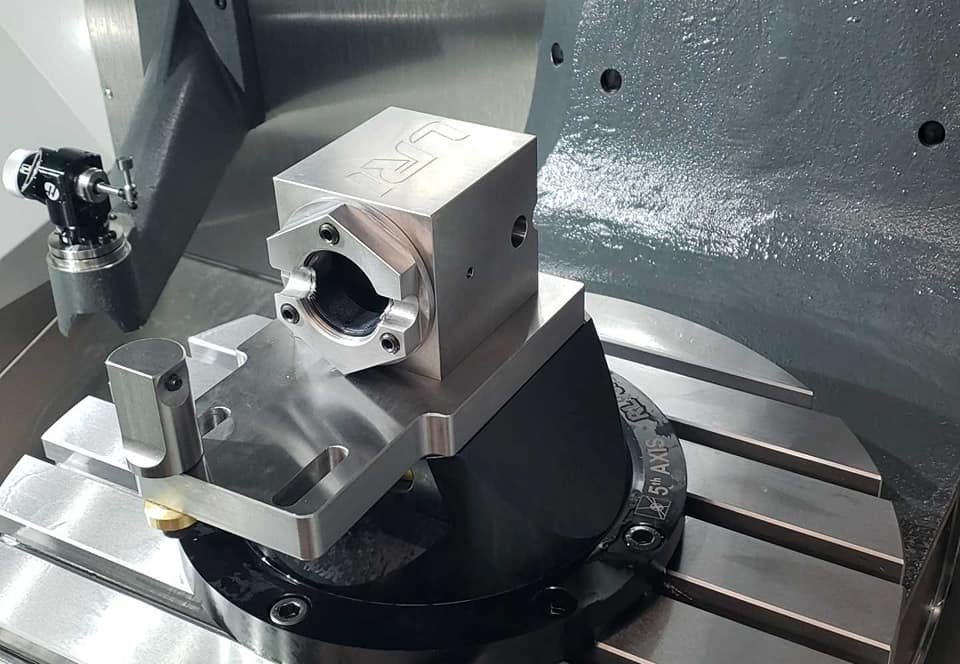

5 axis stuff. This shit is so cool to do. Sorry about the vid quality. The window on the machine gets a big ol bukkaka facial when the wet stuff comes on.

Freaking awesome! I can't wait to see the cool stuff you make with this!

Just curious, has shop work been delayed much due to the new equipment?

Just curious, has shop work been delayed much due to the new equipment?

I usually don't post stuff, but if anyone is deciding on which gunsmith to send their money to, I absolutely 100% recommend LRI. I needed someone to install a DBM for me in a pinch and messaged multiple gunsmiths on the weekend, Chad was the first to respond and literally responded at like 9pm SD time (i am in Hawaii) and told me to send my stuff on over. Once complete, spoke to him on the phone and he gave me a complete run down of how it went and he answered any questions I had. The stock hasn't even shipped from LRI back to the islands here, but just speaking with Chad over the phone and dealing with Quentin thru emails, these guys are a class act and have 100% confidence the stock will come back flawless. They will for sure be getting my hard earned money in the future. Wish these guys all the success in the world. Mahalo.

Can you please make something interesting on that thing?

Like an Annie Fortner on steroids, 223 size/m16 mags and 308 size with AIAW mags?

Should be room for a 5020 as well.

Congrats with the new tool!

I 2nd the Fortner idea!

Except build it for the 6mmBR family. Machine some nice mags that work 99.99%, which is the biggest hassle using the BR case. Also make the action "THE" chassis for everything else to bolt to, similar to AI but without being chemically bonded.

It'll become the sensation of the PRS/NRL world because it's a faster cycling system and you don't have to come off the rifle in awkward positions, saves a bunch of time on the long stages.

Above all, it's COOL!

...a big ol bukkaka facial when the wet stuff comes on.

Love it when you talk dirty!

Last edited:

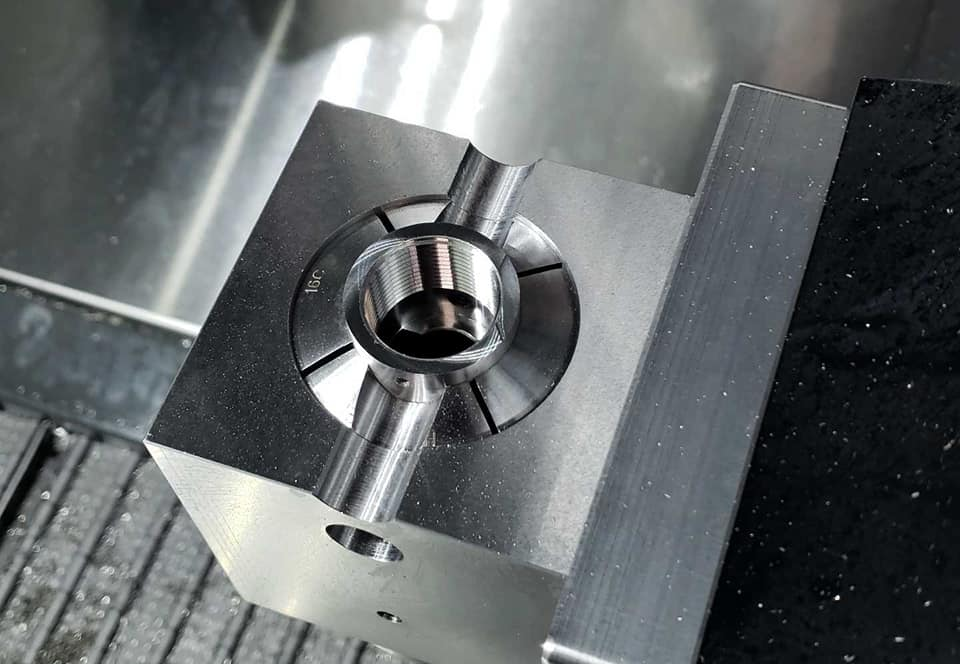

Man, does this make quick work at tuning up a receiver.

Thread milling scope base holes to 8-40. M700 LA.

Thread milling scope base holes to 8-40. M700 LA.

. A good stretch of Wyoming got shut down and the driver was stuck for a good part of yesterday. Took him forever to get his air brakes working this am.

Not sure how that even happens, never had issues with air brakes down to -40*

The new machine looks great, interested to see what it turns out in the future. Wish it was easier being a canadian and having access to a Smith like yourself.

If you drive a big truck long enough you’ll have air lines freeze up.

Badass matching Chad!! I’m looking forward to seeing all the tasks you use it for

Badass matching Chad!! I’m looking forward to seeing all the tasks you use it for

If you drive a big truck long enough you’ll have air lines freeze up.

Badass matching Chad!! I’m looking forward to seeing all the tasks you use it for

Drain down your air tanks every night, even then i rarely do that. Not uncommon to see temperatures hovering -20 to -40 here.

There is equipment in place to keep moisture out of the air system.

Either way doesnt matter. The machine is in place and pretty awesome to watch it do its thing

Parking warm brakes in freezing rain and snow can freeze the shoes to the drums so hard that you’ll crack a drum before you break them loose. There’s plenty of ways to freeze up brakes besides ice in the air lines.

Just gotta roll with the problems like they did. I happens and sometimes it’s out of your control

Just gotta roll with the problems like they did. I happens and sometimes it’s out of your control

Not sure how that even happens, never had issues with air brakes down to -40*

The new machine looks great, interested to see what it turns out in the future. Wish it was easier being a canadian and having access to a Smith like yourself.

Maybe move to Mexico?

Chad, am I seeing this right? One fixture in one machine to true a 700, enlarge scope base holes, and possibly even add a side bolt release all with a cycle run time of under 5 minutes?

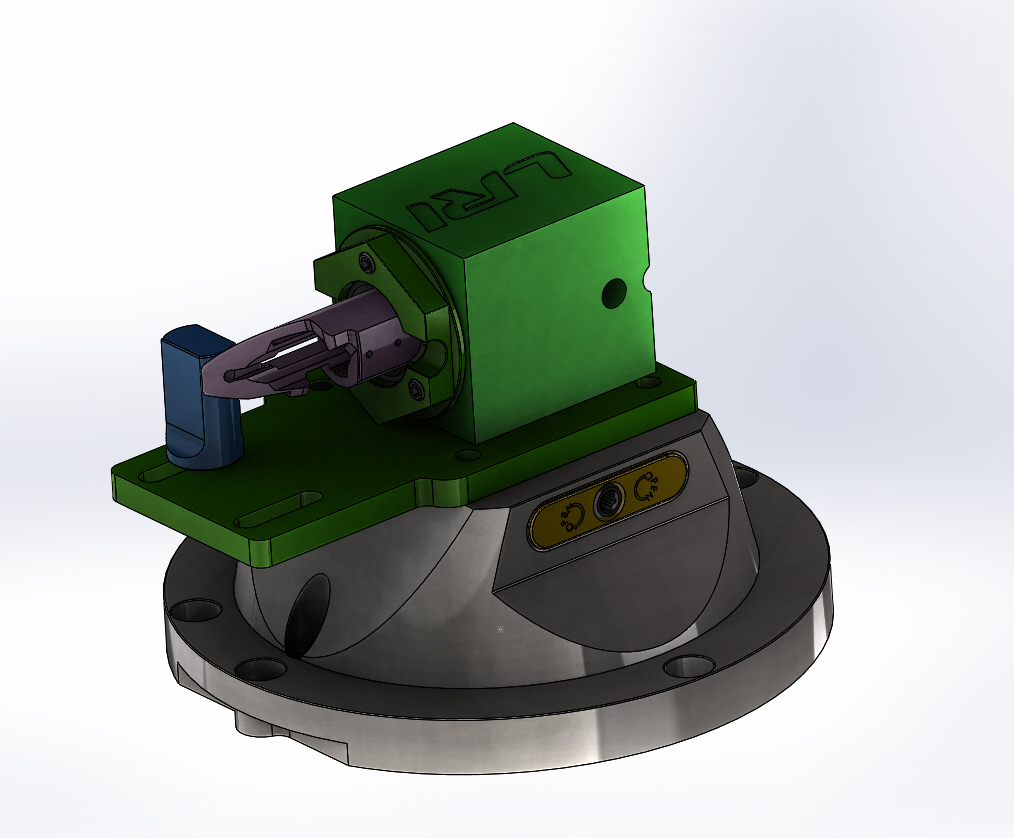

You would be correct and it adapts to the M7, SA, and LA. Both genders are covered as well. (LH/RH)

This is just one job for this machine. The crown jewel here is that the setup is COMPLETELY automated. Using a creative probe routine establishes all 5 axis vectors and positions. It was a bit of work to get it right, but now its water tight. I've vetted this back and forth with conventional setup prolly 50 times this weekend just to be sure. With the volume or work we have now, I had to go this route. There's just too much going on around here anymore to fiddle with the old way we did it.

Today will be a good indicator. I have close to 50 receivers to run. Hoping to have them wrapped up by day's end if they get here soon enough.

Off we go!

Chad, how many inches of X travel does this unit have?

Curiosity is killing me!

30"

Fixture assembly in SW and the real thing. Odd. They even look the same.  I do however need/should mate up the fixture to the riser block so that it sits the same way as it is in the machine. My model is 90* off.

I do however need/should mate up the fixture to the riser block so that it sits the same way as it is in the machine. My model is 90* off.

That's an impressive machine for a small shop. I've worked in aerospace for a lot of years and seen CNC machining grow big time. It still fascinates me what it's capable of. The only limit other than travel seems to be the skill and imagination of the programmer. I've been involved in tooling and tool design in my career and you're on the right track IMHO. Repeatability is king with repetitive, high accuracy tasks. Congrats on the machine and the "new" wife!

Is it possible to mill a chassie with this, what is the max size you could mill? Thanks

We've been able to do mill work on stocks since day one. This new machine is but one of a few here so doing the kind of work your inquiring about should not be an issue.

LRI's equipment assets:

2019 Haas UMC 750 5 axis

2017 Haas VF2 4 axis

2010 Haas Vf2 4 axis

2004 Kitamura Mycenter III 4 axis

1999 Kitamura Mycenter II 3 axis

2006 Doosan Turning center MecTec 280NII

1980's Bridgeport with Prototrak cnc control

1980's Brown and Sharp Surface Grinder

1980's Hardinge HLV tool room lathe

SW2019

MCX2019

2012 Mitutoyo Optical Comparator with QuadCheck DRO and "home grown" dxf generator

This is the "big stuff". Then there's all the little crap that goes with it, lol.

I would venture to guess that in the little corner of this industry we play at, we are equipped far better than most.

Happy to help.

C.

Wow Chad, you've really expanded! I got a tour several years ago around when you first offered the Rem 700 accurizing group buy. Congrats on your success!

I certainly dont claim to know the logistics this machine takes or the inner workings to remotely speak intelligently about it but i do enjoy seeing machines like this do work.

@LongRifles Inc. i hope you can get on an episode of How It's Made and have a special 2 hour show...Id watch it on repeat.

@LongRifles Inc. i hope you can get on an episode of How It's Made and have a special 2 hour show...Id watch it on repeat.

I certainly dont claim to know the logistics this machine takes or the inner workings to remotely speak intelligently about it . . .

-That makes two of us.

-That makes two of us.

Similar threads

- Replies

- 118

- Views

- 6K

- Replies

- 9

- Views

- 692

- Replies

- 19

- Views

- 2K

- Replies

- 5

- Views

- 1K