Good morning all!

Was hoping I could get some ideas for help reloading for .223. I have been struggling getting good handloads. I seem to keep getting high es/sd (60-70 ES, usually high 20s to low 30 S/D) numbers when meticulously trying to work up a load I can get out past 650. The loads group about as good as factory, but the spreads seem high to me when i run them over the magneto speed. Every once in a while I get a good batch with an SD in the low teens, but then I cannot replicate.

I also load blackout and have loaded 30-06 with no issues getting good loads for these. I suspect it is in the brass/prep, but can't narrow it down. Any thoughts are appreciated.

Setup:

AR-15, 18" midlength, Hanson Profile BA, H2 buffer, SSA-E trigger

Dillon 550 press

Current load workup:

75 ELD-M, H4895, BR4 primer, LC brass, matching headstamp, sorted to nearest .5 grain

Process:

1) Tumble brass

2) Anneal using annealeez using tempilaq and flame color change as indicators

3) Deprime and FL size using Redding Type-S. Shoulder bumped back .003, using .247 bushing (intermediate size to attempt to reduce runout). Use dillon Case lube, WITH expander ball.

4) Clean primer picket using RCBS pocket preach in hand drill

5) Quick tumble

6) Resize again, same type s FL die, using smaller .245 bushing, WITHOUT expander ball, prime (this step is to get the desired .002 - .003 neck tension.

7) Trim

8) Fill powder using Lyman Gen 6 system, verify with dillon balance scale.

9) Seat bullet using Forster Ultra Micrometer Seater.

10) Verify using comparator.

I have tried a very light kiss with the a lee FCD. Doesn't seem to make a difference in accuracy or es/sd.

Have also tried CFE and H4895 wth 69 and 77 SMKs, and BLC-2 with 55 gr. Spreads always remain about the same - 60-80 ES with SD in the 20-30 range.

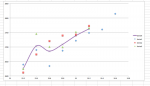

A typical example of my first go around with the 75 ELD-M, and H4895 method seating .010 off lands is below... Was also checking for pressure. Showed VERY light ejector mark at 24.4 and a bit more at 24.6. Didn't shoot any more of either of those.

Side notes: Bought some fiocchi 77gr SMK. Chrono'd that at over 150 fps ES. Was holding 6-8" @ 600 yards a few weeks ago. Don't have normal access to that range, have 300 to play with regularly.

Thanks for the help!

Was hoping I could get some ideas for help reloading for .223. I have been struggling getting good handloads. I seem to keep getting high es/sd (60-70 ES, usually high 20s to low 30 S/D) numbers when meticulously trying to work up a load I can get out past 650. The loads group about as good as factory, but the spreads seem high to me when i run them over the magneto speed. Every once in a while I get a good batch with an SD in the low teens, but then I cannot replicate.

I also load blackout and have loaded 30-06 with no issues getting good loads for these. I suspect it is in the brass/prep, but can't narrow it down. Any thoughts are appreciated.

Setup:

AR-15, 18" midlength, Hanson Profile BA, H2 buffer, SSA-E trigger

Dillon 550 press

Current load workup:

75 ELD-M, H4895, BR4 primer, LC brass, matching headstamp, sorted to nearest .5 grain

Process:

1) Tumble brass

2) Anneal using annealeez using tempilaq and flame color change as indicators

3) Deprime and FL size using Redding Type-S. Shoulder bumped back .003, using .247 bushing (intermediate size to attempt to reduce runout). Use dillon Case lube, WITH expander ball.

4) Clean primer picket using RCBS pocket preach in hand drill

5) Quick tumble

6) Resize again, same type s FL die, using smaller .245 bushing, WITHOUT expander ball, prime (this step is to get the desired .002 - .003 neck tension.

7) Trim

8) Fill powder using Lyman Gen 6 system, verify with dillon balance scale.

9) Seat bullet using Forster Ultra Micrometer Seater.

10) Verify using comparator.

I have tried a very light kiss with the a lee FCD. Doesn't seem to make a difference in accuracy or es/sd.

Have also tried CFE and H4895 wth 69 and 77 SMKs, and BLC-2 with 55 gr. Spreads always remain about the same - 60-80 ES with SD in the 20-30 range.

A typical example of my first go around with the 75 ELD-M, and H4895 method seating .010 off lands is below... Was also checking for pressure. Showed VERY light ejector mark at 24.4 and a bit more at 24.6. Didn't shoot any more of either of those.

Side notes: Bought some fiocchi 77gr SMK. Chrono'd that at over 150 fps ES. Was holding 6-8" @ 600 yards a few weeks ago. Don't have normal access to that range, have 300 to play with regularly.

Thanks for the help!