I decided to mine the 300 PRC thread in the ELR subforum for handload data ahead of starting to work up a load for my rifle, working backwards from recent posts. I think I fully mined that thread as of today (11/27/19) but if I missed any please plug them in or post your own load data. I know I could have added this to the earlier 300 PRC depot thread, but considering it withered on the vine and referenced the ELR thread, I decided to start anew.

------------------

Here's the load LakuNoc is testing (posts 1868 & 1894 on page 38 and post 1945 on page 39 and also look at post 1835 on page 37):

78.5Gr of H1000

230 A-Tip

RCC brass

I went to range today with RCC brass and 230gr A-Tip to see how will brass hold pressure.

This is my load and in my rifle, please be careful because it might be different in your rifle.

RCC Brass loaded with H1000, CCI BR-2 primers and 230gr A-TiP.

Like i said in part one i will do concentricity of rounds loaded and i did, not to write out all numbers but out of 10 rounds 8 rounds where with 1 thousands of an inch and 2 rounds were runout of 1.5 thousands of and inch. In my books that's very good.

My Weather 40 F, 28.6inHg, 64% Humidity My Altitude 1030ft

76.4 GN = 2869 FPS no pressure

76.7 GN = 2876 FPS no pressure

77.0 GN = 2896 FPS no pressure

77.3 GN = 2899 FPS no pressure

77.6 GN = 2890 FPS no pressure

77.9 GN = 2913 FPS no pressure

78.2 GN = 2940 FPS no pressure NODE

78.5 GN = 2938 FPS no pressure NODE

78.8 GN = 2945 FPS no pressure NODE

80.1 GN = 2966 FPS no pressure

Now some Comparison here with Hornady Brass.

HORNADY BRASS Same powder, bullet, primers everything same but HORNADY BRASS

77.9 GN = 2859 FPS

78.2 GN = 2863 FPS

78.5 GN = 2879 FPS

78.8 GN = 2899 FPS

80.1 GN = 2919 FPS PRESSURE Signs at 80.1GN, bolt lift started being slightly

heavy/injector mark this is on Hornady Brass just to be clear.

I run out of time today because i did lots of reloading on one case to test primer pocket on RCC brass, but i did get chance at the end to load 3 rounds of 78.5GN and numbers were amazing!

2941 FPS

2941 FPS

2939 FPS

I will load 10 rounds of 78.5GN and confirm this load. Will keep you guys posted how i do with 10 rounds.

As you can see difference from RCC brass to Hornady Brass 46FPS at 78.8GN of H1000.

RCC brass holds pressure much much better than Hornady Brass. At 80.1 GN with RCC brass no pressure of signs at all. I have been loading 80GN of H1000 and shooting of my back porch same round over and over and over. At 20 firings from same case and RCC primer pocket still tight! This is impressive and that's where i stop at 20 firings.

Big question is RCC brass worth $5.65? To me YES and i will explain why. I payed with shipping for 100 rounds right around $600. Comparing that to Hornady brass is big difference but Hornady brass primers were falling out after 4th firing and i could not get Extreme spread under 15FPS. Thats due to very inconsistent internal case volume that i my self measured and it was very inconsistent. h2o test on my scale was + or - 29 GN. I did turn necks on Hornady brass annealed it did primmer pockets flash hole i did everything i could to it and it was no where close to quality to RCC brass. I love long range/precision shooting and to engage small target consistently shoot after shoot past 1400 yards you want you extreme spread to be low as you can get. Many guys that compete in long range shooting they want to be under 10 FPS extreme spread.

And from post 1803 on page 37:

I think reason i can push 230 A-Tips faster and go up to 80.6 gr with H1000 untill i hit maximum pressure is because i coat them with Hex boron Nitride (hBN).

Post 1798 on page 36:

My neck thickness will be at .014 i will be using 230 A-Tip. Will tell you what happens later this week i will begin testing. Try different neck bushing put more pressure on it or try bumping powder up untill you reach max pressure. I find my node always right under max pressure. But again be careful, H1000 max is right about 80.6gr with 230 A tip and hornady brass and ES was under 10FPS. I’m at 1100 feet 40 F temp.

----------------

From jwknutson17 in post 1893, page 38:

I have been shooting 215 bergers. Hornady Brass. CCI250. 79.26 gr of H1000 (1gr over max) 2980 FPS. Haven't used RL26 on it yet as I'm shooting out this lot of H1k before I switch. I had a really good node at 3012 fps and will try to find it with RL26. Was too hot for H1k so I backed down a bit to save my primer pockets. Was only getting 4 loads on the brass when I was at 80 to 80.5grs and had pressure signs.

Edit. My COAL is 3.705. My lands are at 3.727. So puts me 22 thou off.

Post 1765, page 36:

26 inch tube here... 215 berger at 2980 with 79.26 gr of H1k without pressure even though 1gr over max. I would say you should get it without issue. Only one way to find out, right?

Post 1258, page 26:

Report on the Hornady brass..

Consensus is... it's terrible. I'm using a lot of 100 that was factory ammo once fired to start. After 2 loadings, and on a third, I have already thrown out 25 pieces of brass from loose primer pockets. A few of those were from my ladder test finding pressure before I backed down. I will most likely see over half of the brass has too loose of primer pockets to use after this loading. (4 times fired). Most of the loadings were 79.0-79.25 gr of H1k. I see zero pressure with these loads with the 215 berger in this rifle. Also, Neck thickness is not consistent at all. I first noticed this when sizing and my .305 mandrill would be tight on some and just barley scoot by on the inside on others. Using a 335 Redding bushing in a Redding type S custom die. I'm disappointed once again in Hornady brass. I may be just shooting other rifles in the meantime til some other brass comes along. I could drop it down another 75 FPS to 2900 and see if that helps with brass life. But at that point I'll just spin back on the 300 win mag barrel and get 2900 fps with the 215 Berger no problem with H1k and have all the quality brass I need. Lot of time spent and having this brass give way before/at the 4th firing is pretty terrible.

I'm going to shoot these 75 rounds and then most likely stick to factory ammo for the time being or spin back on my 300 win mag barrels and use quality brass for the time being.

I know there is great potential here in the 300 PRC. But the whole brass thing seems like I'm wasting my time right now for not really much gain.

ADG, Peterson, Lapua, if your listening, I need some brass. Please!

Post 1196:

I narrowed it down to the 2 best grouping loads of 79, 79.5. They we're just about the same FPS in a higher node I found. So I just split the two and shot with it. Higher then 79.5 I saw a larger increase in FPS and below 79 dropped off slightly. Splitting it gives me a little room on each end while maintaining the same velocity.

Post 1189 on page 24:

Range report with H1k and 215 Berger's. Hornady brass. Cci250 primers. 26 inch tube and TB Ultra 7. Setteled on the below load for now..

79.26 gr H1k shot pretty well. .46 inch 5 round group. Average 2975 FPS. SD was 2.6. ES was 6. 3.007 COAL

Going to shoot these again and see if I can duplicate results. Had a few loads group in the high .3s but SD and ES were not close to the above load.

Post 1182 on page 24:

For the Hornady 225s I am at 3.700 at the lands. 215 Berger's at 3.727

Post 1129 on page 23:

I would think with a 31 inch tube and 208s you should be in the 3100 range. I would keep going til you found pressure and back down.

Post 1094 on page 22:

I ordered the type S neck bushing full length sizing die. Had to go the custom route as they aren't making the type S for retail yet. 176 bucks for a die plus shipping... but it's worth it.. I've also found the 334 neck bushing is working the best with the Hornady brass.

Post 1072 on page 22:

So with the leftover sized and primed Hornady Brass I had before parting ways with the Hornady Dies, I just did some workup with 215 Bergers today with H1k in .5 gr increments. CCI 250 Primers. Loaded with an fx120i with 419 auto setup. (these things are awesome by the way). Brass was full length sized with a neck bushing with 2 thou tension. Used the Gurard trimmer on all the brass also. Loaded to 20 thou off the lands for testing with the Berger 215 Hybrids. COAL 3.700.

Rifle is a 26 inch proof Suppressor was a TB Ultra 7. Magnetospeed V3 Chrono. 85 degrees in the shade with no direct sun. 20% humidity. Allowing rifle to cool between 3 shots at a time roughly. Shot two foulers after a clean rifle. Let cool, and then began. Started low as I didn't know what to expect.

UPDATED with my sweet spot

H1000 ___ FPS

79.26 _____2975 SD of 2.6. 5 shot groups under .45

From post 537 on page 11:

Haven't had a chance to shoot anything but the factory stuff. Between what Dave posted for his lighter hunting load with h4831 and the 212s and what the factory stuff measured with H1k you should have a starting point with those two powders at least.

I have some loaded up with H1k starting at 74.5 gr through 76.5 gr to start. Guessing I'll be able to get higher even but starting on the lower end. With 225s, 215s and the 212s. Will be at least another week. This thing called work gets in the way.

Hopefully Hornady will come out with something more official soon.

Post 498 on page 10:

Factory 225 and also the 212 ammo both have 75.2 gr of H1000.

Post 436 on page 9:

I pulled a bullet on the Factory 225 eld and it had 75.2 gr of what looks like to be H1000. That's what I am starting at and working up with the 225.

------------------

From Cauld in post 1855, page 38:

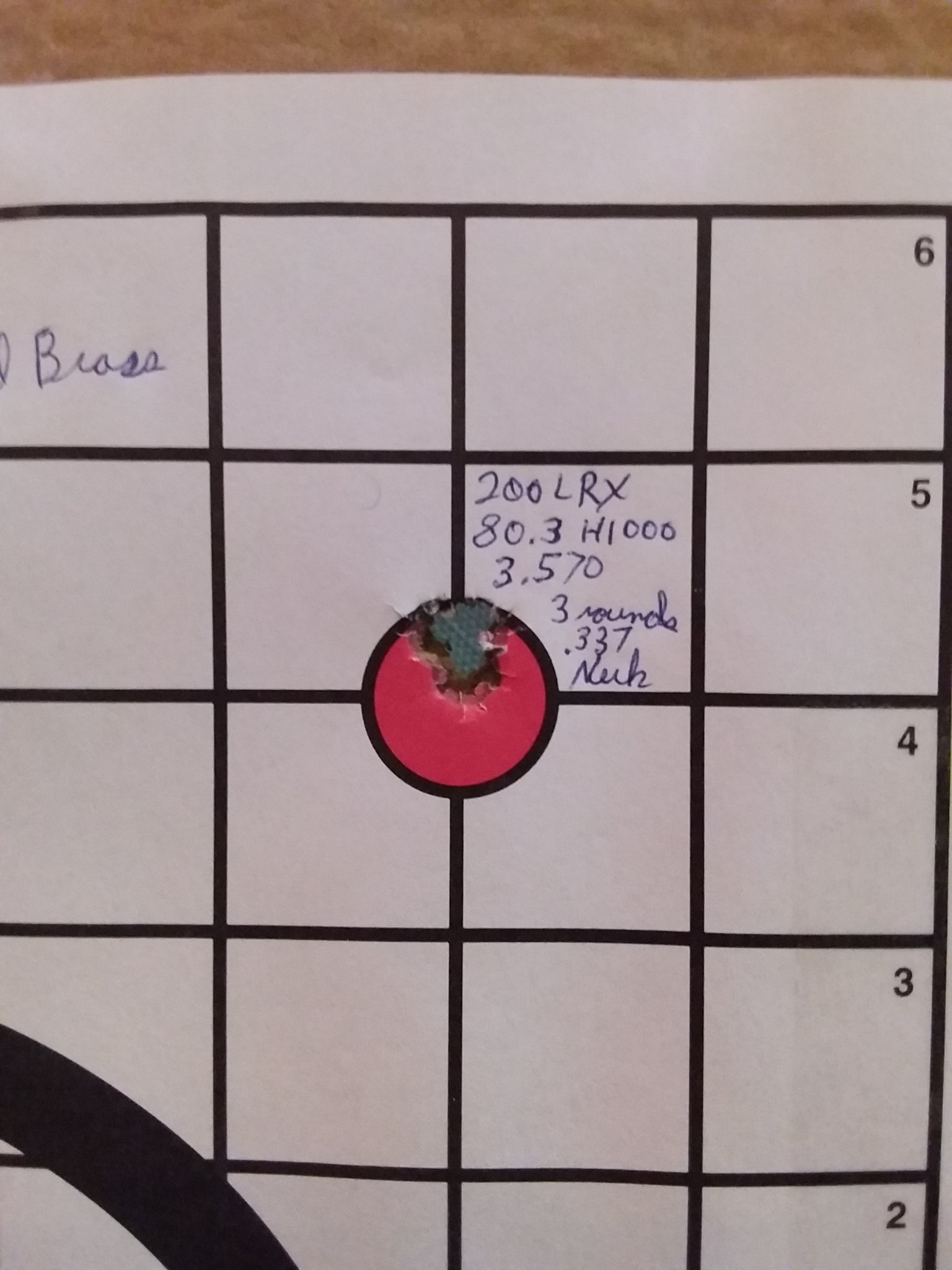

I put together a 300 prc in April but didn't draw any hunts. A friend used it for a hunt in Wolf point Montana this weekend. 26 inch Bartlein 10 twist is from Greg at SPR. We used a 200gr Barnes LRX, 80.3gr H1000 COAL 3.570 for .045" jump. 200 yard broadside hit on his left and the bullet was in the hide on his right with some shattered ribs. Lungs were liquefied.

Post 1245 on page 25:

Harleydog my fired case necks measure .341 I got the barrel from Greg at SPR, he used a JGS reamer. No interference on bullet shank to chamber wall. Haven't had a sticking bolt on factory or reloads.

Bullets hit lands at,

Barnes 200LRX 3.615

Hdy 212 ELDX 3.655

Hdy 225 ELDM 3.720

--------------

From Merovingian in post 1853, page 38:

For obvious reasons I may not be the best reference on this but mine were 2.577 out of the box, first round growth was .010-.013. Trimmed to 2.575 and bumped the shoulder .002 on 2x growth was .007-.009. Trimmed them back to 2.575 again for consistency and reduced bump to .001. Growth stabilized and after 4X all are 2.577 to 2.579. 2.580 is long for a 2.5874 chamber, you'd be trimming every time or risk crimping on the shoulder.

Post 1847, page 37:

Thx guys for any pics. Much appreciated. Forgot to add: Nailed down two loads. 230 BHT's / .030 off / 77.4 H1K / 2860 - 21 ES / .496 @ 200 +++ 215 BHT's / .020 off / 79.6 H1K / 2898 - 17 ES / .31 vertical + 1.3 right horizontal string @ 200 (got rushed because some instructor showed up wanting to start a class and I strung em...yeah yeah...excuses are like aholes….but the bullet width vertical at 200 made my day. Best vert spread of 4 pills and 40 + combos.

Post 1797, page 36:

What did you order your neck thickness at? Reason I ask is I'm having trouble keeping 230 BHT's below .75 but this happened after I turned the necks down to .014 (neck variance <.0005, neck runout <.001, concentricity <.001, ES 24). Thinking I maybe should have accepted the .003 variance but kept the lot closer to .016 / .340 OD. Oddly enough the 200 SMK's aren't exhibiting the same variance holding easily <.5 with a higher ES.

Post 1771, page 36:

Trimming to 2.57" - Starts right above 2750 regardless of 200g or 230g pills. Didn't split a case on 3X despite pushing fairly hard (H1000 - 200s @ 3020 / 230s @ 2870). Hoping it's as simple as the brass. Can't wait for ADG to get up an running so I can find out, RCC just isn't in the budget. We already spun a 2nd barrel trying to resolve. Base to datum first one was on the long side of specs (2.21), new one is on the short side (2.197). Same brass sign on both, cut with two different reamers. Interesting Notes : 230 BHT's are better above .080 than below .020. 200 SMK's as expected .010 to .020. 230 SMK's truly need a 1:8. Obviously your results may vary.

Post 1749, page 35:

1x fired - Not resized - Same result on 225 MATCH & reloads w/ virgin brass (except very bottom end of the ladders.) - **1st Pic - Bases are true, that's camera distortion** OEM/Virgin was -.003 to -.004 at the shoulder and 2X was bumping -.002. No material change to the wall thickness on 2X. Finally got to a point I have to start running 3X but I'd like to see what others are experiencing. I've got a lot of experience rolling my own (.308, .223, 300BLK, 6.5CM, 44Mag, 357 Mag) but this my first bottle neck mag. I'm not used to seeing this before resizing and it makes me twitch.

Post 1660, page 34:

230 Berger, 230 SMK. CBTO jam on both fall where I’d expect between 2.8368 - 3.005 (actually almost dead center) but once there, COL is beyond 3.70. Jump at 3.70 COL: 230 Berger .013, SMK 230 .140 (yeah 1-4-0). Disappointed to lose that much seating depth flexibility. Noticing short CBTO’s at max COL with any pills?

----------------

From b2lee in post 1818, page 37:

I wanted to post this little tidbit of information on my reloading. Yesterday I got around to reloading 21 pieces of brass I shot the other day on a load work up. 1 piece was a retail round, so this would be the first loading. I resized and trimmed to 2.565". I then resized the other 20 pieces and went to trim....and nothing. I mic'd and found that I had zero growth on these 5x fired brass. Primer pockets were still very snug as well.

Even the piece marked at 80gr of N565 had zero growth and the primer pocket had the same snug feel on seating a new Federal GMM #210. Originally I trimmed 50 pieces of new brass, loaded and shot....and on the first reload I had about 8-10 thou of growth....but nothing since then.

Also, after the next firing...I will most likely have to anneal them. However, they still seem to have consistent neck tension.

And another thing. Zero'd the rifle using 230gr A-Tips and Vihtavuori N565 on a 70F day. This morning it was 18F. My shots were within an error factor that could just be me and the cold. MV averaged with 20fps difference than the 70F day with and SD of 8.

From post 1784 on page 36:

I went to the range today to get the 308 ready for hunting season...and while I was there I decided to shoot some of my load developments for the 300PRC.

I decided to just do a 6 shot test looking for an accuracy node. I used the 225gr ELD-M's instead of the 230gr A-Tips because I have a few hundred ELD-M's that I'm not really going to use...but I can use them in these kinds of tests. I did NOT remember to take the chronograph since I more interested in simply getting the scope on the hunting rifle dialed in at 100yds and as a last minute thing decided to take the 300PRC for the load work up.

So, I did take a few retailed 225gr ELD-M's to see how much different in impact height it was from these work up loads...and to re-affirm Zero. First shot was within half a bullet of zero vertically..so it was good to go...wind was about 20mph right to left.

So fresh target....I shot in order of 75gr, 76gr, 77gr, 78gr, 79gr and 80 grains of Vihtavuori N565. My previous accuracy node using Retumbo on these 225gr ELD-M's was 75.5gr. As you will see...N565 and Retumbo...atleast in my rifle...acted very close to each other.

Looks like the VihtaVuori N565 is ready to play. That accuracy node at 75-77 grains looks really sweet. Probably load some up at 76 grains and work on some seating depths.......but I should be good to go with this load. Brass showed ZERO pressure signs. I'm wondering how far north of 80 grains I can go. Maybe another accuracy node up there with MORE speed...

One side note though.... The N565 was noticeably dirtier than ole Retumbo...which was surprising to me.

Post 1703, page 35:

230gr A-tip....I'm running them exclusively now. I will probably sell a few boxes of the 225ELD-M's because I don't intend to use them.

I'm currently running them with 80gr of Retumbo and getting great speeds and accuracy. HOWEVER...I'm loading them to magazine length...and not to what many of you would call a good jump to the lands length. Due to geometry difference between the 225 ELD-M and the 230gr A-Tip...there is a different jump to lands distance you can achieve....when loading to somewhere less than 3.75 COAL.

I won't argue with the accuracy though. I've read many times of some Bergers and others VLDs liking a 150 thou jump...that to me sounds wrong...real wrong...but you can't argue with what the bullet/chamber/barrel combo likes.

With the tight tight specs on the 300PRC at .3088"...I don't know if you will find much difference on most rifles with different seating depths.

Post 1634, page 33:

Bartlein 28" 1-9tw running 80.5 grains was averaging 3040fp/s across 2 different chornos. I should have my Labradar back soon....I...err....dropped it.

Post 1593, page 32:

My Bartlein 1-9tw at 28" finished....is stabilizing the 230gr A-Tips very well.....with 78.5gr of Retumbo...at 900+ ft of elevation...60% humidity...80F....while standing on my left leg only and holding my lip to the right.

Post 1526, page 31:

Continuing on from the above post. You'll most likely be asking about speeds.

1. Retail Hornady 225-ELD-M - 2909

Retumbo and 230gr A-Tips

2. 68.5gr - 2701

3. 70.0gr - 2817

4. 71.5gr - 2825

5. 73.0gr - 2849

6. 75.0gr - averaged 2884

7. 78.0gr - averaged 2925

8. 78.5gr - averaged 2947

9. 80.gr - said 3041...but only shot one.

As always....every chrono will measure differently...on different days....in different conditions....so take those speeds with a grain of salt I guess. Next week should be some H1000 load development with hopefully a new scope.

And...does anyone know where the hell I can get some RL-26?

Post 1525, page 31:

Ok...load development update...with a SERIOUS caveat. First, since I'm now poor after this purchase I don't actually have a scope that is valid for this setup....so....after the first monkey spank group I heard a metal on metal clanking and I broke the borrowed scope. So the other 2 5shot groups opened way up and you can't invalidate them as accurate...because the scope went to crap.

Details:

Cartridge: 300 PRC

Bullet: Hornady 230gr A-Tip

Brass: Hornady once fired....shot yesterday

Primer: Federal Gold Match Large

Powder: Hodgden Retumbo

Barrel: 28" Bartlein 1-9 Twist with a Lil'B brake, Heavy Varmint, spiral flute.

Action: Defiance Deviant Tactical, Fluted, 6mil rail

Trigger: TriggerTech Diamond - set to 6 ounces

Scope: (laugh) Vortex Crossfire (/stop laughing)

Distance: 100 yards

Temp: 80F

Wind: 10mph from 10o'clock - Steady

Mirage: Negligible

Elevation: 910ft

Shot angle: Even ground...very flat

Shooting position: Very steady benchtable with solid seat, front rest and rear small bag.

Reference following loads with pic of target below

Ammo:

1. Factory 225gr ELD-M - reference load

-----Start of 230gr A-Tips with Retumbo-----

2. 68.5gr - shot way low, audibly softer, recoil softer, felt like a wimp load

3. 70.0gr - came up near the factory load with similar audible and recoil.

4. 71.5gr - basically same damn hole. Audible and recoil weren't discernible from #3

5. 73.0gr - basically same dman hole. Audible and recoil weren't discernible from #3 or #4

These three different powder loads shot a 3 shot group under a 1/4MOA...to me..that is a nice node

Reloaded in blocks of 5 for the next groups

6-10. 75.0gr Group - Shift the windage to pull the group left of the other group. Measued .473 with a dial mic. Target is .018 thick cardboard and flaked around the holes...hard to measure. For a gun with less than 30 rounds to this point....this group made me think naughty thoughts.

11-15. 78.0gr group - Again, shifted windage to pull the group away from the previous.

First shot I heard a metal on metal clang...didn't know what it was.

Second shot went way low and then the adjuster ring for the parallax slid down the tube toward the elevation knob.

Third shot I noticed an artifact in the lens.

Fourth Shot I noticed something like extra scope shadow in the bottom left.

Fifth shot didn't seem to get any worse

This group can't be covered by a Quarter...It isn't the loads fault...I'll be able to buy the Razor GenII in a few weeks and revist this load again.

16-20. 78.5gr Group - Same issues with the previous group and about the same results. I shifted everything left again to pull the group out of the path of the other group. I'll revist this load when I get the new scope.

21. 80.0gr - OVER SPECS - Shift windage back to original wind zero and it shot high. Audible and recoil were very noticeable but brass appeared fine. When I de-prime I'll take notice of any primer pocket issues...and when I reprime, I'll see if it is loose or is noticeably easier to insert.

---------

From dukerugger25 in post 1804 on page 37:

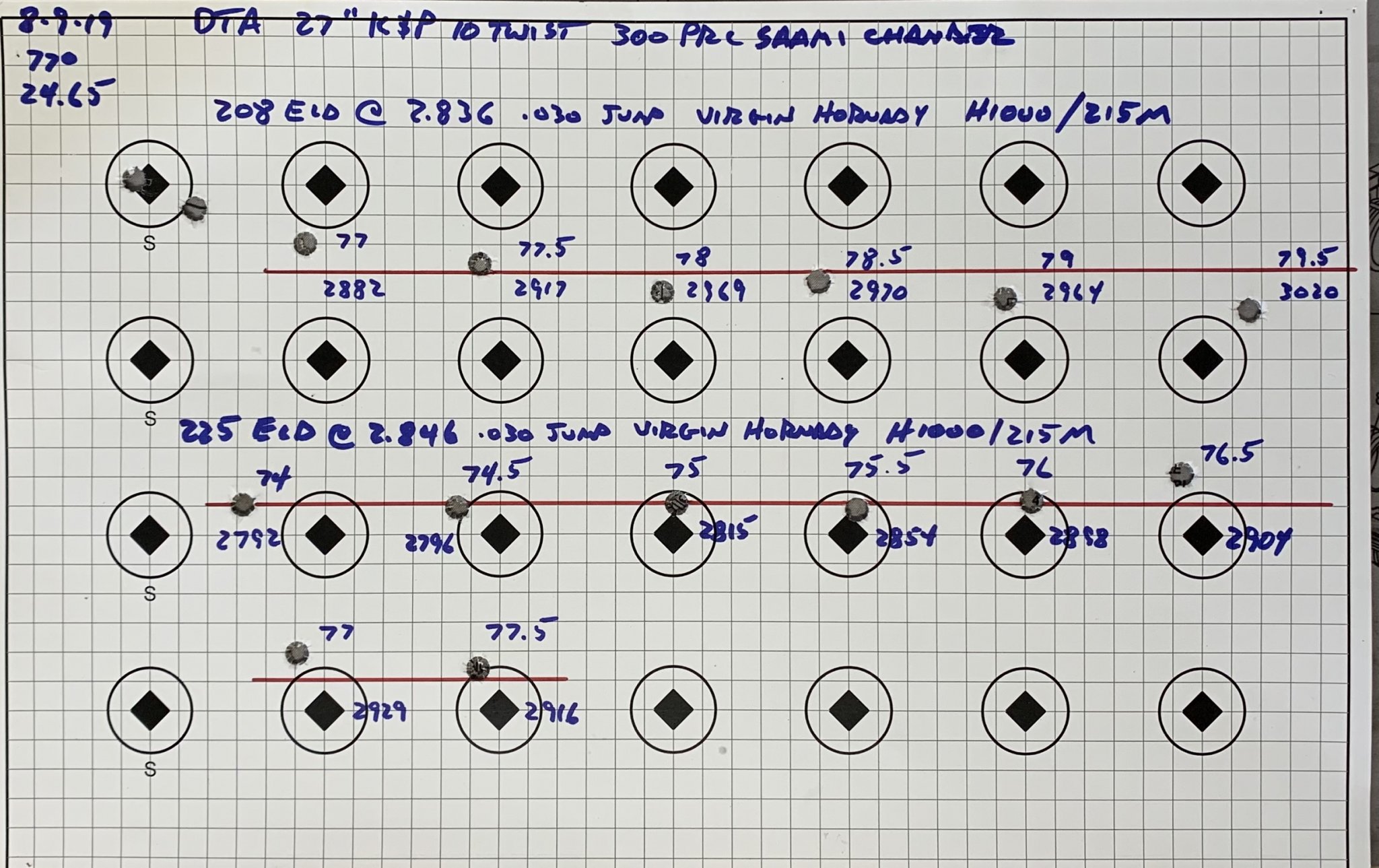

Got the 300PRC to the range finally for ladder testing. Used 225gr ELDM'S, RL-26 and 215m primers. Barrel is 26" and 9.5tw.

Found two nodes: 74.1gr - 2856fps, 76.0gr - 2937fps. Slight ejector swipe at 77gr (2974fps), primers were still round and no noticeable increase in bolt lift. Stopped there. I will load up some for seating at both nodes and test accuracy in a few weeks. Still have a late season archery tag to fill.

Factory 225 loads were shooting at 2880fps for comparison.

--------------

From pengilly in post 1736, page 35:

Testing 212s with RL26 28" Bartlien barrel 1:9 CCI BR primers basic case prep. Worked up tp 81 grns of 26 3200 had light ejector mark no stiff bolt. One ragged hole super low SD. Im going to do another ladder and look for a lower node in the 3100s.

---------------

From Dschapp in post 1617, page 33:

Just ran the 230 OTMs and 230 SMKs with H1000 and R26 thru the 300 Sherman mag. The summary is 3000 FPS with R26 and 2900 FPS with H1000. Both bullets ran within 30 FPS using identical loads.

Post 1594, page 32:

I went the 300 PRC improved by rich Sherman route. It’s been talked about earlier but just got time to do a ladder with the 215 Berger’s. No pressure at 3100fps using H1000

Post 911, page 19:

I’m using. 26 inch kreiger M24 countour and .020 off the lands. 76.5 grains of H1000. It was built by northwest action works and that was the load they recommended and they weren’t wrong.

Edit- just double checked my book. Velocity was 2970 after barrel break in. Coal is 3.552

--------------

From Rocketmandb in post 1598, page 32:

I bought the hydro die to form 8x68S (the die on the left with the water bottle) and the custom die because I'm having consistency issues with the Hornady die I've been using.

For the 8x68S, I use a .341 bushing to do the first sizing, then I ream out the inside of the neck to get rid of the extra brass that got forced in there from the sizing, then I use a .336 to get .002" of neck tension for the final. I've got two videos on YouTube showing how to do all this. Honestly, it's very easy to fire form 8x68S, and the RWS brass I use is much, much more consistent than Hornady and lasts a lot longer.

I actually have a full set of 30 cal bushings going from .329 to .341.

Post 1591, page 32:

Thought I'd give an update on my 8x68S brass adventure.

- I decided to try out Berger 230s. Me likee.

- I ran them at 10 off the lands and think I found my load with RL-26. Remember that the case has a little less volume than Hornady.

- 72 gr of RL-26 gave me 2849 fps average, an ES of 6 and an SD of 2.6 over 5 shots.

- Will be heading out this weekend to validate the load some more.

Post 1531, page 31:

Post 1527, page 31:

For anyone who is interested, I've redone my fire forming videos and reposted them on YouTube - I lengthened them, and added a disclaimer up front (lawyers... my wife is one). By slowing them down and adding some new commentary, I think they are easier to follow and better depict how easy fire forming 8x68S brass is for the 300 PRC.

Post 1483, page 30:

I've switched over to BR-2s for use with my RWS brass and RL 26 for my load development. I got better results with them on my 300 WM than I did with 215Ms. I lost a little velocity with them, but with RL 26, velocity is not a problem.

EDIT: I should note that I don't live in an area where I'll be doing cold-weather shooting.

From post 1451, page 30:

Another range report, this time with fire formed 8x68S:

The last time I went to the range to test out 8x68S brass that had been fire formed, it was a bit of a bust because, even though I lowered the powder load to accommodate for the thicker brass, it fired a lot hotter than I thought it would. I'm going to the private range on Saturday to run a ladder test, but I went to the local 100 yard range this evening to break in the barrel on my brand new 6mm BRA - so I figured I'd play around with 4 loads of RL 26 in 8x68S with my 300 while I was there.

I ran 4 groups at 72, 72.5, 73 and 73.5 grains of RL 26 with 225 pills.

The 72 grain group was poor, with a relatively large ES/SD and poor group. It averaged 2843 fps.

The 72.5 and 73 grain groups were both excellent. The ES on the 72.5 gr group was 7 and the SD 4.2. On the 73 it was 10/8.0. Both groups were essentially each one big hole. The 72.5 average was 2870 fps and the 73 was 2879 fps, which is closer than they should be on a linear comparison, leading me to believe that the sweet spot lies in this range. The ladder test will hopefully confirm.

Not coincidentally, this is the same fps range where my 76.2 gr of H1000 is performing best in Hornady brass.

Long story short: the 8x68S brass is performing well, and I haven't even dialed it in yet.

Post 1316, page 27:

I just added my two-part video to Youtube on fire forming 8x68S for the 300 PRC. The instructional parts total only about six minutes in total, then I add a minute or so of range footage.

I highly recommend going this route. Here are the key points:

- It doesn't take a ton more time to prep an 8x68S case for the 300 than it does a Hornady 300 PRC case. You have to do one extra sizing, more trimming, and the inside neck turning (reamer).

- I fire these fire forming loads for fun and they're accurate.

- RWS cases come in at about $42 per 20, so they're not cheap. However, they are far more consistent and (I hear) will last a lot longer. I got Norma brass on sale for half that.

- The Forster trimmer and reamer I use during prep will run under $200 with shipping

Post 1309, page 27:

I have both, primarily because I found a bunch of Norma on sale, but I'm saving the Norma for later. Right now I'm concentrating on the RWS.

I was hoping to do a ladder with it this weekend, but this week sucked, and I didn't have time to load. It has less volume than Hornady, so runs hotter. A few weeks ago when I was playing around the upper end of the scale with RL 26 with I was getting 3000+ fps with 75.2 gr (225 bullet).

I've decided that I don't want to play there any more, and I think my barrel has a sweet spot at 2850 fps-ish. That's the realm where my H1000 load of 76.2 gr lands. I'm going to start the ladder at like 73 gr of RL 26 and find 2850 with the RWS.

The long and the short of it is that I'm sold on 8x68S. I go through everything in the videos I'm working on (part 1 is done, part 2 in work - 2-video series), but the nice thing is that there's not a significant amount of additional prep. After I get the neck all set, I'm seeing less than a thousandth variation - and the primer pockets... I've said this before, and I know it's weird to get some kind of zen feeling over primers, but it feels so nice to have real brass to seat primers in again.

I think you guys will like the videos. I'm starting a channel and web site called Two Minutes to Target where I do videos and short posts on all things precision. A pet peave of mine in the shooting world (one of a number of them) is that so many of the videos are way too long. So every thing I do will be under three minutes - hence why I had to split this one into two. These two are the inaugural vids.

Post 1269, page 26:

Last weekend I ran my first fire formed 8x68S back through the barrel as 300 PRC. The only issue I had was that the pressure was higher (likely due to smaller volume - 75.2 gr of RL26 ran about the same as 75.6+ in Hornady cases. Otherwise, they were sweet, and they cleaned up nicely. I'm going to have to do another round of load development with these.

I also ran 8 more new rounds through to get more fire formed. I took down my Labradar before these rounds (I figured, why use it?), aimed at steel at 850, guess at the bullet drop. With 225 gr @ 2650 fps with 76.2 gr H1000, it was 15.5 MOA. These were 200gr ELDX and 68gr H1000, so I figured I'd try 18. Six o'clock low. Raised to 21 MOA... gong! Next 6 shots landed within an MOA at 850. Again, this was 8x68S, non-fire formed. I literally laughed at every hit.

Here is my process for prepping the brass:

- Size the brass in my 300 PRC die with a .339 bushing (I just ordered a .440 and .441 and will play with those next).

- At this point, all that brass from pushing down/in the shoulder is on the inside of the neck.

- Using my Lyman trimmer and power shank, I use a drill to trim the brass down to my 300 length and chamfer a bit to clean up the outside rim of the neck.

- Using my Forster trimmer and their .308 reamer, I ream out the neck (using my hand to turn, not a drill). If you don't do this, or alternately use an expander to push the neck back out and neck turn, you might have issues chambering the round - and you have to get rid of the extra brass at some point - I FAR prefer the reamer to neck turning, and it gets me very consistent neck thickness.

- I then do final chamfer and deburr and resize the neck using a .335 bushing - this gets me roughly 1 thousandth neck tension. .336 gives none. This is a similar drop when I do this to Hornady brass - initial size is .335, ream, final size is .331 for 1 thousandth NT.

- Finally, I load with 68 gr H1000, 200 gr bullet, and seat the bullet so it's touching the lands.

I'm very happy this is working out. I had to toss 10 Hornady cases during loading for this trip due to loose primer pockets. I've only got about 5 firings on them. I've never used Hornady brass to failure before, so I don't know if that's par for the course, but it's way short of what I'm used to with Norma. There was something oddly satisfying about priming the RWS cases - that extra little umph it takes to press the primer in, and no anxiety about whether it would stay.

EDIT: I might do a video of this.

Post 1184 on page 24:

Another range report.

Temp: 85

Wind: 15 mph and gusty @ ~30 degrees right of front

I ran primarily Reloder 26 @ 75.6 and H1000@ 76.2, both with 225s. The extra temp definitely made all rounds run a little hot. The RL 26 load showed minor pressure signs and was not very accurate. Luckily, I had loaded 7 rounds at 75.4 and these yielded similar velocities to the 75.6 load at 70 degrees.

I also fire formed 10 RWS 8x68S cases using some extra 200 ELDs I have on hand. Lastly, I tried out CCI BR-2 primers with both H1000 and RL26. All shot at 300 yards.

76.2gr H1000 w/215M Primers:

As with all loads today, this ran hot. I think the added temp took it out of the accuracy node. The ES and SD bore that out.

Shots: 5

Avg: 2889

ES: 32

SD: 14.1

Notes: This load is typically in the 2860-2870 range.

76.2gr H1000 w/BR2 Primers:

Avg: 2872

ES: 13

SD: 5.2

Notes: Much more in line with where my H1000 loads were shooting before. Wind was pushing it side to side, but vertical spread was .82" @ 300.

75.6gr RL 26 w/215M Primers:

Shots: 5

Avg: 2985.2

ES: 20

SD: 6.6

Notes: More in line with the 75.9gr load I did earlier. I got some minor pressure signs.

75.4gr RL 26 w/215M Primers:

Shots: 7

Avg: 2969

ES: 12

SD: 5.0

Notes: No pressure signs

75.6gr RL 26 w/BR2 Primers

Shots: 5

Avg: 2953

ES: 12

SD: 5.3

Notes: RL 26 has a much more substantial drop in velocity using these primers vs the H1000. Similar ES/SD to the 75.4 load.

Lastly, the fire forming. I used 72gr H1000 and a 200gr ELD. Below is a pic of a new 8x68S case (left), a fire formed case (middle), and a fired Hornady 300 PRC case.

Of note: I had to toss 5 out of 68 Hornady cases due to primer pockets this go. Those RWS cases have very tight pockets.

Post 1125 on page 23:

Brass update:

I just got 20 RWS 8x68S cases. Everything looks like this brass will work well. I was able to trim, neck it down easily enough (got neck thickness of .0145 - .0155), and test extraction from my action. It works fine. Next weekend I'll be fire forming 10-20 rounds using some extra 200 ELDs I've got laying around - I'm pretty sure I can get those to jam for forming.

I've never seen RWS before - the brass is very well done and consistent.

I'm confident enough from what I've seen (and read earlier on this thread) that I ordered a custom hydro-forming die (3-4 months out).

P.S. Speaking of brass (cleaning, it more appropriately), I just started using the Bore Tech case cleaner in my ultrasonic. Hands down the best I've ever bought or been able to concoct myself.

Post 1108, page 23:

Another range report - this time with RL 33.

I did groups at 82.5, 83. 83.5, 84, and 84.5 grains of RL 33. None were particularly impressive .

The best from a spread perspective was 83 gr, which had a 19 ES and 7.9 SD with an average of 2862 fps. I might play around a little more around this load, but I'm not going to do too much more with this powder.

For anyone interested, here are the average fps of each load:

82.5: 2837

83.0: 2862

83.5: 2875

84.0: 2897

84.5: 2917

EDIT: I started getting mild compression loading at 84.0, and a little more at 84.5, which is why I stopped there.

I also played a little more with RL 26.

Best loads came out at 75.4 and 75.6.

75.4: Avg - 2970, ES 15, SD 6.2 - 5 shots

75.6: Avg - 2971, ES 10, SD 5.5 - 5 shots

Groups were hard to come by as the mirage was fierce. The 75.6 load was also one of my better ones from the last trip, so I think I'm going with this as the "champion" load for this powder. I'll also be playing a little on the lower end - probably high 73s to low 74s.

Also, I did another neck tension test, this time with RL 26. Again, the lower neck tensions did better. I'll be loading at .001 neck tension in this rifle with both H1000 and RL 26 from here on out.

From post 1090, page 22:

Post 1078, page 22:

I just got back from the range where I did my big Reloder day (mostly RL-26). So, if you're thinking of trying RL-26, and can find it for sale somewhere, I wouldn't buy it. Instead, let me know where it is, and I'll do the precision shooting population a big favor by taking it out of circulation.

Two words: OH. MY.

Let's get to the meat of the day first: Reloder 26.

My first load was 74.1 gr. All groups today were at 300 yards and with the 225 gr ELDM (as always). I had expected this load to fall in the mid-2700 fps range. When I fired, I almost missed the target - as in the WHOLE target - because it fired high. The Labradar registered 2907 fps. The total group averaged 2913 with a 13 ES and 6.7 SD. Wow. Group size was 1.27" at 300 yards.

Here is all the data:

74.1 gr RL-26:

Average FPS: 2913

ES: 13

SD: 6.7

Group Size: 1.27"

74.4 gr RL-26:

Average FPS: 2926

ES: 21

SD: 8.8

Group Size: 2.42"

74.7 gr RL-26:

Average FPS: 2932

ES: 16

SD: 9.2

Group Size: 1.48"

75.0 gr RL-26:

Average FPS: 2950

ES: 29

SD: 13.9

Group Size: 1.82"

75.3 gr RL-26:

Average FPS: 2965

ES: 7

SD: 3.1

Group Size: 1.32"

75.6 gr RL-26:

Average FPS: 2979

ES: 5

SD: 2.3

Group Size: 1.52"

75.9 gr RL-26:

Average FPS: 2999

ES: 25

SD: 10.9

Group Size: 2.33"

76.2 gr RL-26:

Average FPS: 2994

ES: 12

SD: 5.6

Group Size: 1.28"

76.5 gr RL-26:

Average FPS: 3021

ES: 31

SD: 13.6

Group Size: 2.8"

Slight pressure signs

76.8 gr RL-26:

Average FPS: 3031

ES: 21

SD: 10.5

Group Size: 3.21"

Slight pressure signs

I am very surprised by the velocities I got with this powder - well above advertised. I am also happily surprised by the consistency of certain loads (75.3, 75.6, 76.2). Clearly this powder well outperforms either Retumbo or H1000 in my rifle.

Next, I did my neck tension test. I ran groups at .001, .002, .003, and .004 inches of neck tension. I'm not really a fan of .001, but it clearly won the spread contest. This test was with 76.2 gr of H1000.

.001 Neck Tension:

Average: 2856

ES: 8

SD: 3.6

.002 Neck Tension (what I ran all other tests at):

Average: 2874

ES: 16

SD: 8.6

.003 Neck Tension:

Average: 2871

ES: 25

SD: 11.1

.004 Neck Tension:

Average: 2875

ES: 44

SD: 19.8

Lastly, I ran a two rounds each at three different RL-33 loads to see what they'd do:

79gr RL-33

2690 fps

2699 fps

81gr RL-33

2770 fps

2776 fps

83 gr RL-33

2851 fps

2857 fps

Observations:

- Granted it was only two shots per "group" (I didn't have enough brass ready to do everything I wanted), but at each load, the velocities were close

- There didn't seem to be as much impulse from firing even the 83 gr round. It seemed "smoother" to fire.

- This powder warrants further attention. I'll be doing work up with this next, probably starting at 82.5 and going to like 85 (if the case capacity will allow)

Overall, another great day at the range.

From post 1022, page 22:

Update from the range:

I ran two sets of work ups today. One with a retry of Retumbo (see below as to why) and one with seating depth using my current "champion" load of 76.2 gr H1000. The second set was seating depth at 2.5, 5, 7.5, 10, 12.5 and 15 thousandths off the lands. I also sighted in and used my new Razor HD 4.5-27 for the first time - quite happy with it.

First the Retumbo: after returning from my last time out, I noticed that two of the screws on my rail were loose - think that had something to do with my accuracy issues? So I decided to retry Retumbo. This time I started at 76.1, and went up to 77.3 at .3 gr increments.

All groups were 4 shots at 200 yards using ELD 225

76.1:

Group: 1.07"

Average: 2846

ES: 12

SD: 5.6

76.4:

Group: .76"

Average: 2860

ES: 15

SD: 7.0

76.7:

Group: 2.01"

Average: 2863

ES: 21

SD: 8.6

77.0:

Group: 1.15"

Average: 2886

ES: 32

SD: 11.5

77.3:

Group: 1.22"

Average: 2892

ES: 21

SD: 9.5

I'm liking the 76.4 gr Retumbo load quite a bit. I'll probably pit it against the 76.2 gr H1000 load next time out and see which wins.

On the seating depth test, one group stood above. It had one flyer that took the group size out to 1.08" - but the other three were touching with a group size of .355" center to center. The average velocity as 2866 ft/s, ES of 5, SD of 3.6. This seating depth was 12.5 thousandths off the lands.

Post 948 on page 19:

PRC Update from the Range:

I went up to the 750 yard range today and a great time - again, 70 and bright blue skies. There was about a 10 mph coming in at about 30 degrees front right. My purpose(s) of the trip:

1) Load test Retumbo

2) Test my rifle's new trigger

3) Put my new attempt at a portable steel target holder to the test - one that can take being on a hill and absorb a 225 gr bullet hitting it at 2000 fps.

Load Test Retumbo

I started the ladder at 77.5 gr, which I thought would get me close to the equivalent of 76 or so of H1000. I was wrong. The muzzle velocity of the first load averaged 2891 fps, with an ES of 14 and a SD of 5.9 - nice! The group? Not so nice. It was all over the place. Okay, so not a good (or even decent) group, move up to the next load. It was worse than the first. The best group I got was 1.7" at 200 yards = ouch. It was so bad that I thought my scope might be loose, or that mucking with the trigger screwed up the joining of the action to the stock. I stopped my development and switched ammo over to my 76.2 gr H1000 load. I averaged 2853 fps and shot a .73" (.365 MOA) 5-shot group. I'm not ready to give up on Retumbo, but clearly the upper end of the spectrum isn't working for me.

Post 940, page 19:

Notes from call then my steps:

- The guy was perplexed as to why this was occurring.

- I use a turreted press (Redding T-7) and I used a Lee turreted before that. He said movement in the turret could be to blame. I told him I'd give them that on the Lee, but the Redding is rock solid and there is absolutely no play. I'm an ex-Space Shuttle engineer, and I know a little bit about structural mechanics and dynamics. The press isn't the issue, especially because I don't have this problem on other case types.

- He mentioned to try camming over the die more, and I told him I'd try that.

My steps:

- Adjusted the die to provide more cam-over, and used a varying-height holder set to adjust case length.

- The variation tightened up significantly, but still exists.

- Using the Hornady head spacer gauge to measure, my ideal case should measure out at 2.1925". I got 9 that ranged from 2.189" (just one, a few at 2.190") on the low side to 2.1935" on the high side. About 1/3 of the cases that were in the acceptable range measured 2.192", the remainder were 2.1925"

- Even re-pressing the high side cases, I could not force them into compliance. I even told them, "you have fifteen seconds to comply," but that did no good either.

I'm not too worried about 1/2 a thousandth (2.192 vs 2.1925), but I don't at all like spitting out a case that's 3 thousandths too short.

EDIT: Before I did the cam-over adjustment, I was getting as much as 6 thousandths short on the low side. Also, cleaned and recleaned the die to make sure there was no grease or debris inside.

Post 936, page 19:

I'm still having some small consistency issues on FL resizing. It can vary as much as a few thousandths for me - about 1 out of 6 falls outside +/- .0005. On the plus side, I found a couple pounds of Retumbo (bought them out of their last 2), so I'm heading out to the range tomorrow to run through 6 loads and see how it does.

From post 913, page 19:

I just got off the phone with Jeff at RCC Brass. This is related to my earlier cryptic post about doing something that by many standards would be considered somewhere up on the stupidity scale.

For those of you who don't know RCC, they machine brass in all sorts of wonky (and not so wonky) calibers - he told me they're making shells for the 75mm gun of a Sherman... This is not stamped brass, it's machined out of solid brass rod, and done so to very tight tolerances. Anyway, I asked Jeff if he could make 300 PRC brass, since it's not on their web site, and he said that since it's got a SAAMI spec, they can make it for $5.65 a case. That's a lot per case, but then the brass isn't worked much during forming, so it lasts longer. Even if it only lasts 50% longer, you're getting it for the equivalent of just over $3.75/case. Still a lot, but then you're also getting cases that measure out at +/- .1 gr of water per case, according to Jeff, so very consistent.

I ordered 100 cases. I'm going to run extensive tests after I receive them. Unfortunately they are a little backed up and I have to wait about 8 weeks. As always, I'll post the results. I'm looking forward to tinkering with them...

Post 889, page 18:

More data from another day at the range.

Temp: 68 F

Range: 200 yds

Bullet: Hornady 225 ELD

Powder: H1000

Loads tested: 76 - 77 gr, .2 gr increments

# of shots/group: 4

77gr - group size: 1.258" - ES: 17 fps

2883 fps

2887 fps

2893 fps

2876 fps

76.8 gr - group size: 1.073" - ES: 16 fps

2876 fps

2887 fps

2889 fps

2873 fps

76.6 gr - group size: 1.115" - ES: 26 fps

2875 fps

2863 fps

2879 fps

2853 fps

76.4 gr - group size: 1.008" - ES: 28 fps

2864 fps

2875 fps

2847 fps

2859 fps

76.2 gr - group size: 1.038" - ES: 15 fps

2866 fps

2867 fps

2869 fps

2881 fps

76 gr - group size: 1.481" - ES: 15 fps

2862 fps

2860 fps

2859 fps

2874 fps

Notes:

- Muzzle velocity is up over last visit.

- 76.2 gr looks like a good place to play, 76.8 is similar

- Not sure why my 76.2 gr loads have a higher average than 76.4...

- Still having some consistency issues on full length resizing. Called Hornady, they are at a loss too. Going to try a few things.

EDIT: Also dropped 3 out of 4 in about a 4" group on steel at 750 using 76.5 gr. 4th took group to about 7"

Also also, was shooting steel to test my new portable steel hanging setup - worked like a champ. Unfortunately I didn't take any pics. Will set it up in my yard and take a few. Boy do these 225s move the plate and sound the gong.

Post 863, page 18:

I went to a private range today for some load development. Good and bad on this front.

Bad:

I am having serious consistency issues on full length resizing. I've never had this before and am not sure what's causing it. Lengths are varying by as much as 6 thousandths. As such, I was only able to have 15 rounds that were consistent. I did 5 3-round groups at 75.5, 76, 76.5, 77 and 77.5 gr of H1000 with the 225 gr ELD.

Good:

It was 70 degrees today, not a cloud in the sky (ok, a few whispy ones), and I was in the hills by myself popping off rounds (after LD and also with my 6mm CM) at 600 and 850 yard steel targets. The operators also said there are places where they think I can get out to a mile after things dry out a bit.

Anyway... here's what data I could collect. All groups shot at 200 yards.

77.5 gr - Group Size: 1.32

2858 fps

2873 fps

2879 fps

77 gr - Group Size: 1.25

2873

2862

2871

76.5 gr - Group Size: 1.09

2834

2845

2835

76 gr - Group Size: See attached pic

2826

2807

2842

75.5 - Group Size: 1.41

2781

2814

2791

I'm loving the spread on 76.5 and 77 grain loads, and am surprised at the group on 76 with the spread it has. I'll probably do another load development day (hopefully I can get my consistency issue figured out) going from 76 to 77 at .2 gr increments. This range seems to yield the best spread, and groups were likely impacted by consistency, even after sorting.

Post 763, page 16:

Update from day 2 at the range:

Good news and bad news here - fortunately the bad news is more about data collection than anything going on with the build.

Bad news first:

My Lab Radar was failing to pick up a fair number of shots. I'm pretty sure the blast from the Little Bastard brake is knocking it around. I love the Lab Radar unit, but my biggest issue is that they have crappy solutions for mounting it, especially for use with larger caliber rifles with brakes that blow backward. I think I'm going to have to craft something that clamps it in and allows sand bags to weight it down (current thinking is just getting a drill press vise, and mounting it to piece of plywood).

The main issue with this is that of my nine neck-turned, annealed rounds, only three registered, so there's just not a big enough sample size to gauge the difference vs. other.

Here are the muzzle velocities I was able to capture (working backward):

2956

2928

2950

2933

2945

2935

2950

2943

2932

2934

2943

2945

2931

2924

2945

2954

2925

2932

2924

2930

The three neck-turned/annealed rounds I was able to capture

2936

2953

2930

There's still a big ES, but the numbers tightened up considerably. If I had already done load development and was getting the spread I'm getting here, I'd not be happy, but this isn't bad considering.

More notes:

Versus first set, average velocity ticked up slightly from 2935 to 2938 (roughly .1%), and standard deviation went down to 9.9.

Group size decreased. Best was .34 MOA, with most hovering near half MOA. I expect these to go down with load development. I will also probably

No signs of overpressure on any brass.

Load: 78.5 gr H1000, 225 gr ELD-X, Federal 215M primers.

Post 748, page 15:

I haven't begun load development yet as I want to get a good baseline of data. I'm using close to what the factory ammo load was purported to be. Mine is 78.5 gr of H1000 along with a 225 gr ELD-X. Primers are Federal 215M. My scale is an Ohaus that goes down to .02 gr accuracy, and I get all cases loaded with the scale showing 78.50 or 78.52, leaving me with a theoretical load ranging from 78.49 to 78.529 (or thereabouts).

As mentioned earlier, I REALLY want to try RL-26, but it is like a ghost at this point - I've heard stories, but can find no proof of its existence.

Post 745:

UPDATE:

I had been asked earlier whether I saw any signs of overpressure. I just found one casing where there is an extractor mark - I missed it when inspecting the casings pre-cleaning. I'm guessing it was one of those that jumped up ~40 fps. I found it because when I was priming, the primer didn't sit snug.

I've just cleaned, sized to 2 thousandths back, trimmed, and loaded 32 rounds. Why 32? Because I ran out of H1000, and my order to replenish is held up at the retailer for some reason. I found that Brownells has it, so I ordered a few pounds from them that will hopefully arrive this week. What is it with getting powder these days?

I also have 9 additional rounds that I also neck turned and annealed. I wanted 10, but one of those cases was the overpressure one - which of course I found after I'd neck turned and annealed.

I had planned to go to the range tomorrow to test better prepared brass vs my last numbers vs neck turned/annealed, but I might get rained out. As soon as I have more data, I'll post.

From post 699, page 14:

Just got back from my first day at the range with my newly rechambered 300 PRC. With 78.5 gr of H1000, 28" barrel, 225 gr ELD-X, I averaged 2935 ft/sec. Groups were sub-MOA, but not great - though with no load development, and minimal brass prep on first-fire Hornady brass, I'm not unhappy with the results.

Round by round:

2927

2932

2978 (ouch)

2934

2918

2926

2929

2920

2931

2926

2934

2935

2936

2940

2935

2932

2917

2928

2928

2934

2975 (there we go again)

2923

2932

2927

2935

2943

2936

2930

2936

2934

2938

2931

2933

2933

2935

2933

2946

---------------

From 8nbait in post 1540, page 31:

I’m finished with load development on my 300 PRC with 9 twist, 26” 3B bartlein

Two loads

78 H1000, 215 primer, 215 hybrid at .030 shoots 2900 FPS

79.8 H1000, 215 primer, 215 hybrid at .030 shoots 3000 FPS

Both loads are very accurate.

76 and 78 of RL26 were also accurate but I haven’t shot them enough to verify completely.

The Hornady data for a 200 eldx seem to mirror my results with a 215 hybrid.

----------------

From Coltonlrs in post 1508, page 31:

Well guys with n560 I started to see pressure at 73grs with 225gr eld m bullets but here’s a group with a load that I came up with with 72.2 grs the group that has a vertical string was shot at 200 yards

----------------

From Evolved Ballistics in post 1507, page 31:

So I wanted to add to the conversation here...I just got done with load development with my 300 PRC, I am shooting Warner Flatline 198's at 3123 with no pressure at all. I am using 85 grains of N570 and have an ES of 9...so far it is looking pretty good, group is about a 1/3 MOA which is fine...bullets won't feed, but this is for fun. I will probably develop another load with a jacketed that does. The Hornady brass only showed slight pressure signs at 86 grains, so far it is doing good. The bullets have an OAL of 4.018 and we had to use a 30 Nosler die to seat them because the ELDM seating die for the 300 prc was too short for the Flatline. I will take them out to distance soon and see what kind of results I get, on paper I should be supersonic to about 1800.

---------------------

From doctordoctor in post 1504, page 31:

I've settled on 74.4 gr RL 26. SD was 2.7. MV 2920 225amax

Post 1303, page 27:

Ok gang I finally found a morning to shoot. It was hot and the mirage was like the Sahara desert! But here is some load data with hornady new brass and RL26.

Gun is a DT

Barrel is 30" spun up by Dane @DMR rifles

Amax 225gr

Cci 250

3.66" COL

74gr = 2908

74.4 = 2920

74.8 = 2940

75.2 = 2960

75.6 = 2969

76 = 2992

From post 1031 on page 22:

I don't have a ton of time to post but I went out for round 2 with my 300 prc.... More or less frustrating. The used brass that was 1x fired in my gun last round still caused ejection issues. However the 10 pieces @Rocketmandb donated to the cause all worked flawlessly! So it must be a brass issue as suspected. So it wasn't a complete waste of a trip to the range. My velocity was around 2850 using 74.8 grains of H1000. 225eldm bullets. Cci250 primers. All 10 rounds fit into a quarter

So if my brass would show up and i could find powder and primers... I'd be more than happy.

Post 869, page 18:

So I got to try out my 300 PRC. It's always a joy to shoot but I had a sticky bolt no matter the charge weight.

I loaded 1x fired brass from D. Tubbs that I bought. FL resized with the hornady match diet set.

225 eld pills

COL = 3.66"

Cci 250 primers

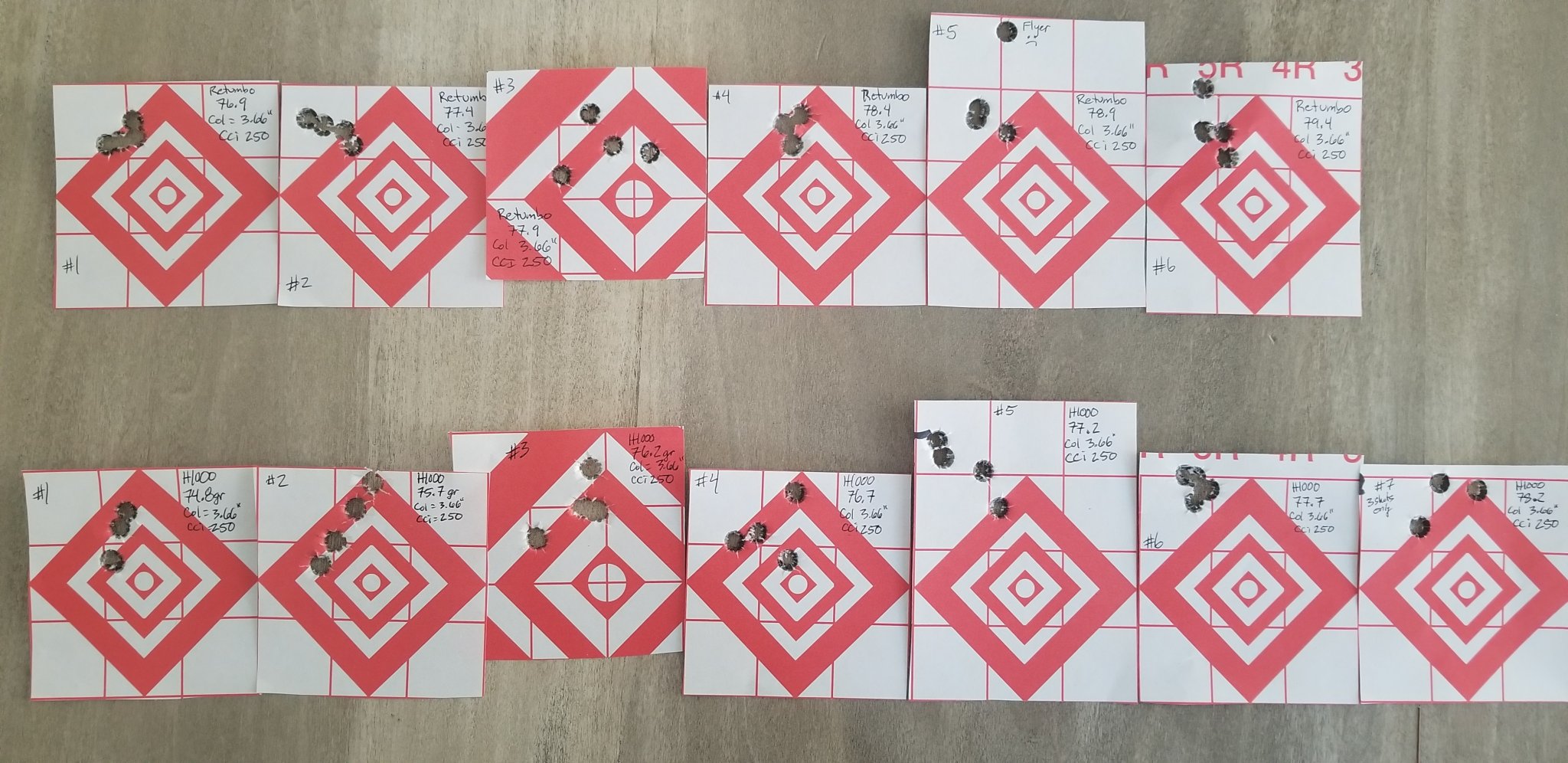

Top row is Retumbo bottom is H1000.

OCW ranged for Retumbo 76.9 to 79.4

H1000 74.8gr to 78.2gr

What say you? OCW charge and why the sticky bolts. I had to mallet every round out!

----------------------------

From Ledzep in post 1501, page 31:

74.0-74.5 gr of RL-26 at SAAMI COAL with a 225 has done very well in all of the 4-5 300 PRC's I've seen in the wild.

Post 1297, page 26:

Sorry in advance for the novel...

A year or two ago I got the chance to conduct some pressure and velocity testing with a legit pressure test barrel and it kind of opened my eyes as far as "seeing pressure". At the point you see pressure signs in a well-made custom action, you're probably in the 68,000-75,000psi range. SAAMI max for this cartridge is 65,000. So somewhere in between when you see a flat primer, or an ejector swipe or whatever it is, and the actual SAAMI max is 3,000-10,000psi unaccounted for. Max published loads tend to follow that SAAMI max avg. pressure pretty closely (this is where SAAMI chambers, the same brass, bullet, etc... plays a part-- deviation from what was tested causes deviation in pressures).

Anyway, there are a couple reasons I don't typically exceed those loads. The first is that things work better. I almost never get a stuck case, sticky bolt, etc.. Cases briskly extract and eject without issue. Cases last 10-30 firings-- in my last 6.5 barrel I averaged 22 firings on Hornady cases. Once you stretch the case out from too much juice, the primer pockets don't "heal" over time, they're toast. So my price per shot for brass goes to almost nothing. And finally there's the barrel. If you run the stress/strain equations for a thick-wall pressure vessel with a typical barrel contour for the first 4-5" of bore @ 60,000psi internal pressure you'll see that it's on the edge of yielding (plastic deformation) in the ID of the bore. Granted, a firing event isn't the same as static internal pressure loading, but the moral of the story is that the hotter you load, the higher the pressure, the more work is done to the bore. The wider the bore expands each shot before contracting back to original dimensions, the more work is done to the material, the sooner it will work harden and develop cracks (the last sentence purely theory on my part, but it does seem intuitive and appears to hold true if you look at guys loads vs. round count to burnout).

Long story short you get more case life, more barrel life, easier running, safer system, at the expense of 50-100fps. Run the numbers out to 2500yd and see how much 100fps at the muzzle helps you in wind variability. If I want that speed back (in this case I do), I get it through barrel length. If you read a few pages back here you'll see at least one poster that smoked primer pockets in 3-4 firings without seeing pressure. You see the same thing in 6.5 SAUM and 6.5 PRC cases-- Hornady makes their stuff to handle SAAMI pressure and not much more. You can get away with more with some other brands but it doesn't necessarily mean you're "safe" or that you're doing your equipment any favors. YMMV, to each his own, etc...

So with that said, I think shortening up the throat would increase pressure-- as a general rule that's what happens. I don't know if it would increase velocity, but it might, slightly.

I was around 3.715-3.720" COAL for 225's to touch the lands. Ran them at 3.700" COAL. They go 2940 fps with 74.6gr of RL26. Doing a linear interpolation for bullet weight vs. velocity, the 5gr of difference in bullet weight would make up about half of the ~35 fps change from 225 to 230 both with 74.6gr of powder (2905 vs. 2940)... So yeah, jumping an extra .080" probably has something to do with it, about 15-20 fps worth maybe.

This is really subject to individual barrels, but I did not find a satisfactory grouping load over 75.0gr. 75.0 was similar to the above picture, but SD was around 8 or 9 IIRC. Figure your ES is usually about 3x your SD so 1.5 up and 1.5 down-- past 1500 MV spreads start producing really significant POI changes.

Post 1295, page 26:

With RL-26, 2894 (74.3gr) to 2953 (75.9gr) with 230's is what I'm getting in a 31" barrel. Touch lands at 3.845 +/- a few thou (SAAMI spec reamer). Loaded to max mag length around 3.748" jumping almost .100, doesn't seem to care. SD of 5fps,

Post 1190 on page 24:

So in the indoor range with built-in optical chronographs I'm getting 2920fps avg with 74.6gr RL26 and a 225 ELDM. I got outdoors today to set/check zero and was averaging 2946fps with the same load from a Labradar. I tend to trust the Labradar more. 8-shot group plugged them all into .571" with 12 fps ES and 5.4 SD. Should be able to get on some steel this weekend. I think I'm just going to stick with this load for the time being until I can try out the A-tips.

Post 1179 on page 24:

In the vicinity of 3.715-3.720" COAL for 225's to touch the lands.

From post 1131 on page 23:

RL26 with 225 ELD-M @ 2.680" COAL

31" Bartlein 5r, 1:9.5-1:9 gain twist

Virgin Hornady brass, CCI 250

Rounds 26-50 on a new barrel:

-74.0gr SD 12 ~0.6" 4 shot group (fouler omitted for SD and group)

2860 <---fouler

2884

2881

2900

2910

-74.2gr SD 13 ~0.7" group

2866

2882

2894

2901

2898

-74.4gr SD 8 ~0.4" group

2905

2902

2888

2910

2893

-74.6gr SD 4 one big knot, 0.25"

2910

2914

2919

2913

2921

-74.8gr SD 6 ~0.35" group

2922

2935

2923

2924

2918

Got all of my cases fired, so I'll resize them, bump the shoulder as little as I can manage and test again around 74.4-74.8, then take it out to stretch its legs. Might be a week or three before I get around to it all.

Post 1130:

No doubt. I haven't really pushed the limits with anything yet. The first 10 rounds were 178's over 78gr of H1000. Shot 5, cleaned, shot 5 cleaned, then tested for accuracy today, just kind of playing around with odds and ends. Going to get serious about it in the coming week or two and see what it does with 225's. From published 24" data I'm consistently floating 100-125fps faster, and I suspect as the barrel breaks in that will increase a little.

Running the numbers on JBM it's kind of a wash between the 230 and 250 Atips. Wind is practically identical to beyond 2000yd, elevation is flatter with the 230's, supersonic range is very similar. I think I'm going to develop with and shoot the 225's for now and transfer over to 230's when I can get some.

Post 1128 on page 23:

Got mine on paper tonight at 100 yards. I tried 77.0, 77.5, and 78.0gr of H1000 behind some 208 ELD's. 1 of the 3 groups (5 rounds each) had 2 holes, the others all piled into 1 hole; 0.25-0.5" groups judging from the scope, I didn't go down and recover them. About 25fps ES and upper single digit SD's with 77.0 and 77.5, and a little worse with 78.0. I have 25 rounds through the barrel at this point so I imagine it will pick up a little speed as things progress, but the 78.0gr load gave an avg. of 2981fps in my 31" barrel. Cases/primers look fine, super easy extraction, and I think there's still room to boost it up if I wanted to.

Up next I'm going to try RL26 and 225's I think. At this point I'm just trying to get 50 fire-formed cases first before I start any serious load development. So far things are looking very promising, though.

Post 1048, page 22:

One thing people need to understand about Hornady brass is that you just can't hot rod it. It's perfectly fine if you stay under 65ksi (And I'm not going to say an especially soft lot never makes it through). If you're running on the upper end and something causes a spike (piece of carbon fell down the muzzle from your suppressor/brake and got in the neck area, for example, or carbon builds up in the throat or neck), then the cases exceed the yield strength and plastically deform. Primer pockets open up, sticky bolt, etc... I believe that's largely the problem with the GAP 4s brass they make/made. Some sort of interference between the brass, sizing die, and the chamber that makes pressure spike. I do believe the 1st lot of 4s brass got an over zealous annealing cycle, though.

The other thing could be a die sizing issue. That's as simple as doing a cerosafe mold of the die and micing it out to see if it's doing what it's supposed to. In that event, the BEST thing you can do is let whoever made it know so they are aware and can address it.

All teething problems that happen with anything. Don't buy the first year of production of any vehicle, motor, etc... etc... if you're not willing to accept the risk of some unforseen issues.

--------------------------

From Supersubes in post 1496, page 30:

Just an update, the .334 worked well. Shot a bunch of groups today testing seating depth, and all loads combined (same charge weight, different seating depths) had an SD of 10.

Edit: Not super duper by any means, but very consistent across a wide range.

I had a mix of rounds left over so I shot them into one group. .020 to .040 jump.

From post 1478:

Shot a narrow OCW test at 513 yards today. Probably should have gone wider on the charge range. It appears there’s a super wide velocity flat spot between 74 and 75 grains. On the last outing there was a 23fps spread between 74 and 75 grains(only single shots at each charge), and today it was 3 fps. Charges were double weighed, so not sure what happened, but that seems too close a spread. ES in the individual charges sucked for two of the three, which probably played into the low ES across the range. Since this was the first go round loading the fired cases, I learned that my neck bushing isnt small enough. The Hornady brass necks have a tapered wall thickness, and my .335 bushing doesn’t size them down enough to for a mandrel or expander ball to uniformly establish the ID. So the base of the neck is sized and gets kissed by my mandrel, but the top of the neck was oversized. So the necks are essentially funnel shaped on the ID. Neck tension was all over during seating. I have another bushing inbound.

(see images in post for details)

Post 1476, page 30:

There’s no expansion above the extractor groove until 78 gr with the 208, and 76 grains with the .225. The 208 load peaked at .0004 expansion, and the 225 load at .0006. Pretty soft loads by those measurements. Hodgdon considers max .0008. I’ll keep an eye on it though, and I dont plan on pushing past these charges I reached today.

Post 1471, page 30:

Went out again today to do 208 and 225 eld pressure test with H1000. For the 208’s no sight adjustment was made from the last outing, but the barrel had been removed and fully cleaned. I dialed .3 up for the 225 test. Interesting how the 208 trends down through the charge escalation. .8” total vertical through the whole range. The 225’s had almost exactly .36” of vertical through the whole range.

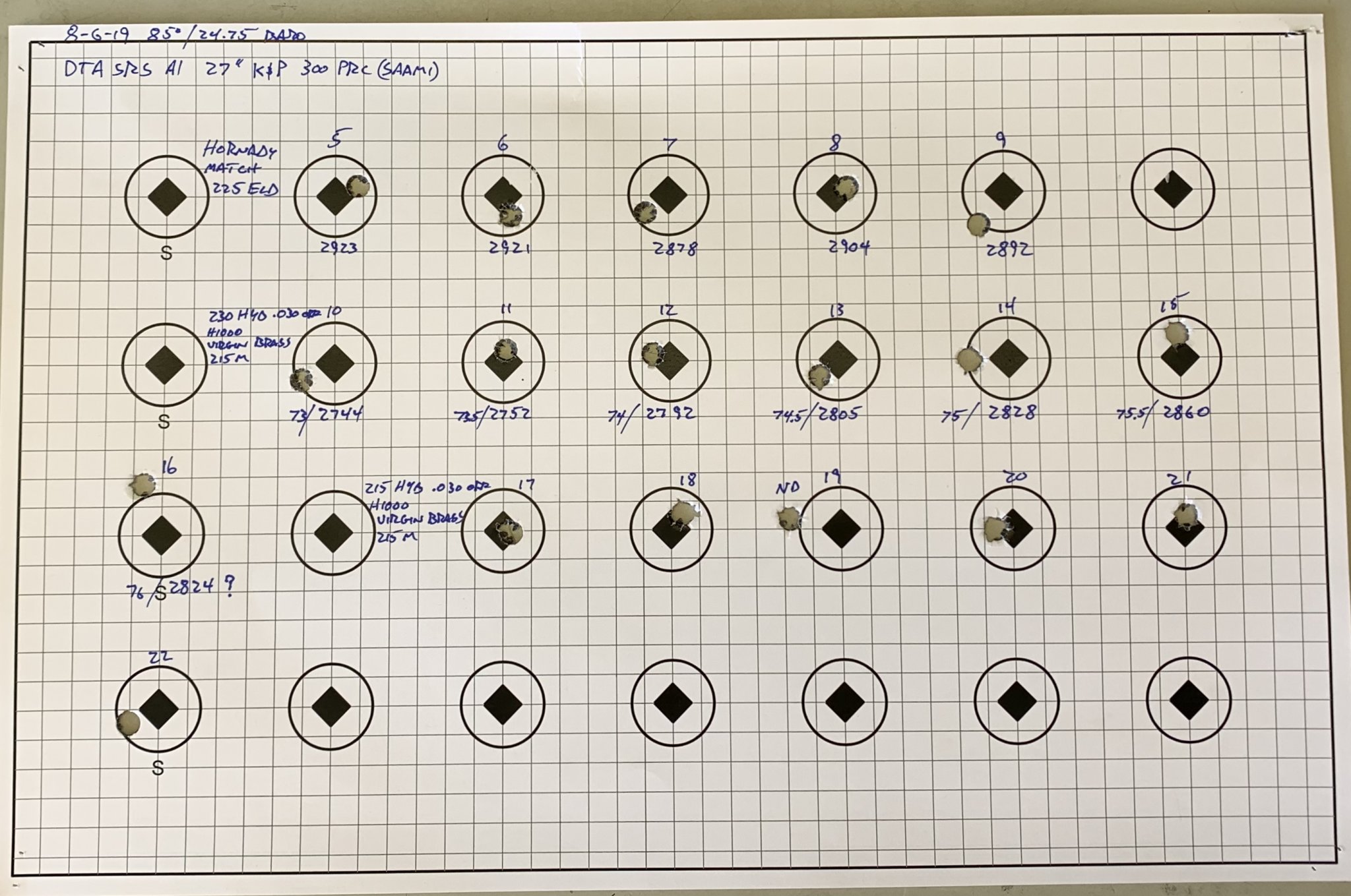

From post 1449, page 29:

Below that are two ladders with 230 and 215 hybrids in half grain increments of H1000. All virgin brass and bullets jumped .030. Charge weight and velocity is written under each dot. Not sure what happened to the last round of the 230 at 76 grains, but it was oddly slow. Shot 19 was a ND. I interrupted my trigger squeeze to do a breath cycle, and capped a round off. Doh!

Edit: Just realized that I didn’t write the 215 charges or velocities on the target. It was 75-77.5 grains, and topped out at 2947FPS.

I’m still a grain or two from max for both bullets with H1000. Primer pockets are like new. Case head expansion numbers for both bullets maxed at .0003-.0004, which indicates the pressures were pretty soft. Now that I’ve got a little Experience with the PRC, i’ll go out and do a 500 yd OCW. I also have some other bullets to test, as well as RL26.

------------------------------

From gnochi in post 1466, page 30:

Here’s the Flatline data (26in barrel, they also have a data sheet for 30in): https://www.warner-tool.com/wp-content/uploads/2019/04/300PRC_198Flatline_26inbbl.pdf

From post 1165 on page 24:

On a related note, is there a way to reliably mix multiple powders without it blowing up in your face?

From post 1146 on page 23:

---------------------

From high right in post 1411 on page 29:

Bought 200 230 gAy tips to try in mine along with 200gr Sierras, 215 Berger's.

All testing was done at 850 through a Chrony. Retumbo, Rel26, H-1000. Cycling through 50 pieces to see end of life. The 230s shot ok @2920 but never as good as the 225s, Bergers, or for that matter, the 200 grain Sierras.

Finally got the SD down to 4 and ran the gAy tips and 225s out to 1650. Easy button with the 225s @2900 with Retumbo. I have 150 230s left if someone wants to play with em.

PM me. I'll be out of town till mid August, then I'll list and ship.. I have several other Samplings of 30 Cal bullets I tried as well.

From post 1136 on page 23:

Not exactly, I'm running the 215 hybrids with 79 grains H-1000, CCI mag primers @2975. ES of 7. Virgin brass.

Very accurate out to 1350. That's as far as I've taken it. I'll have to figure a load for the fired brass after I get it all fired once. It will be different.

------------------

From Scrav223 in post 1270, page 26:

Range report:

Savage 110 rebarreled by Cresent Customs 26" barlien 1:8.5 M40

Manner T-4A

Load testing: 225ELDM

H-1000 77.2 Hornady Brass

Testing primers

10 loads each with GM215M and WLRM

Fired two (3) shot groups each and the GM215 had highest velocity at 2875/Ave and best groups but both primers shot well. Got first round hits at 553yards with 9.75moa Going to do some neck turning and will update.

From post 1163 on page 24:

Savage 110-Bartlien 26" 1-8.5

Hornady neck bushing .333 Range results with H1K and 225ELDM and 210VLD's:

Target 1: 225ELDM 77.2gr. H1K

T.L. 3.680

Ave. Velocity 2890

S.D. 7fps

Target 2: 210VLD 76.7gr H1K

No velocities taken

Target 3: 210VLD 78.2

Ave velocity 2945

S.D. 6.7

Looking promising

From post 1116 on page 23:

While patiently waiting for my Savage 110flp 300win to be rebarreled by Moon Roberts at crecent customs the 300prc was released, lucky me. I had him put a 26" M40 bartlien on it and I decided to switch it to 300PRC. I let him pick the twist rate and he talked to Frank at Bartlien who advised him go 1:8.5 twist. So I've broken it in with 225Hndy Match which shot about 3/4". Tested hand loads yesterday with 225ELDM H-1000 77.8gr max charge @2880fps

Best (3rnd) group was .300" at 20K off lands TL=2.680 but it showed pressure signs so I need to back it off.

My issue is I don't have CIP bottom metal so my best mag fed loads were 0.5" at a TL=3.630 and 77.8gr H-1000

More to follow soon?

----------------

From Harleydog in post 1235, page 25:

Post 1233:

Got a call from gunsmith. He says legnthening the throat he thinks will solve it. I’m wondering if it’s a length or diameter problem? He used a ptg reamer. All bullets have around 1/4” of scuffing when ejected. Ideas??!!

Post 1231:

Even with hornady seat depth gauge deal I can’t tap the bullet past the free bore to find the lands that tight would cause pressure correct?

Post 1229:

My local gunsmith did the work. I’ve been chasing pressure problem since new. Factory 225 match go in with a little effort. If you pull them they will have a scuffing all the way around the bullet. Been having sticky bolt pull for a while on all reloads. 74g-76g rl26. Betting this is the pressure issue?

Post 1226:

For the gunsmiths out there. Having pressure issues with sticking bolt since new. Free space area has always been very tight. Like solid marks around the whole bullet if pulled out. Today I was going to run some FACTORY 212 precision hunter rounds. First 2 were hard bolt close and pulled the bullet from case when tried to eject. VERY tight freebore area cause big case pressure?

Post 1207:

What was it doin? I’ve had same problem sometimes. New brass works great, full size after firing, fire again and sticks when I pull back. Barrel is broken in and speeding up tho. 74.0 grains of rl26 is giving me 2935fps! Might be pressure sign I’m thinking.

Post 1067, page 22:

Post 1053:

Got to shoot some rl26 and h1000 today. Didn’t get chrono but rl26 did good. Had decent groups on h1000 but need to work a bit on it. Here’s 2 groups of rl26 at 74g. 215m primers and eldm 225.

Post 1051:

I’ve had good luck with rl26 around 73.8. 26” 1:9 barrel. Got the sticking bolt taken care of today. There was the tiniest ridge in the chamber that needed polishing a bit. Tested 2 loads at the higher end and functions great. Have some h1000 and rl26 loaded up to test maybe tomorrow.

---------------

From senna.bra in post 983 on page 20:

I am a fan boy of the Berger 230gr OTM.

Loaded H1000 and 230grs 0,020 jump. Using regular rifle Federal primers.

75.9gr H1000 2849 FPS SD9.4

76.2gr H1000 2859 FPS SD 5 “some pressure”

76.5gr H1000 2875FPS SD 7.8 “pressure”

5 shot lots, all three were one big hole at 100 yards.

1.9 twist 28” barrel

I am here to tell you that the Hornady Factory loaf ain’t with H1000 for what I can tell.

I am getting 2930 FPS with Hornady 225gr ELD with NO pressure at all.

---------------------

From Dave Tooley in post 544 on page 11:

Hornady loads H1000 with 225's. I use 4831SC in my hunting rifle with 212's. Anything in between those will work. Personally I lean towards a fast to middle of the road burn rate.

Post 472 on page 10:

I'm not defending Hornady here. This nothing they don't know. There are a bunch of target shooters there using this round and it's nothing I haven't mentioned to them over the years.

When it comes to maximizing performance for the most part, we and I mean all of us are going to load to pressures that are just below or equal to the yield point of the brass. Every manufactures toughness differs and every lot can be different. So if you want primer pockets to last you make adjustments. I want reasonable longevity and precision. They are not exclusive. It's just that simple. If you want 300 Norma performance then build one. I'll agree the necks aren't as uniform as I would like. Norma and Lapua usually vary a .001". Sometimes less. I've measured PRC brass and it varies .0015" on some cases. Probably 35% are that way. That was with a very early lot. I neck turn it for my target rifles. I think a light skim cut on the necks would be the first thing I would do if I was concerned about uniformity. That would apply to any manufacturer. I shoot it as is in everything else. No one can convince me we can accurately measure internal capacity and then show me on the target that it matters. It gets lost in the noise.

Then let's talk price. 300 PRC is less than $1 ea and everything else mentioned is over $2.

Get 200 pcs and wear the barrel out.

In a perfect world RWS would make me PRC brass. That stuff lasts forever.

YMMV

Post 438 on page 9:

mild load but the 212's work.

Post 436:

Depends on which power. I use 4831 in my hunting rifle because I'm not trying to get all the velocity possible. For the sake of argument that's probably good in 24-26" barrels. My rifle has a 25" barrel. Slower powders need more barrel length to get maximum velocity but everything is a compromise. I wouldn't go longer than 27" for most applications but if all I was going to do is shoot ELR and velocity was important to me I would go 28-30" .

Complete powder burn probably never happens.

Post 360 on page 8:

I use a Hornady FL die and Wilson seater for my 1K BR rifle.

Post 359:

COAL with Flatline 198's

I can't touch the lands with the 198's. It would take a freebore length of .000" to have a chance of running through a mag. Not that I would with that bullet.

Post 350:

From post 301 on page 7:

COAL 3.730" with a 225 about .010" off.

One thing you do need to do with virgin brass. Expand necks and chamfer . Because of the way Hornady trims their brass there is a bit of ring on the case mouth. In some chambers it's enough to cause an interference fit.

From jascent in post 373 on page 8:

For those of you looking for better brass

I’m shooting a 338/375 ruger. I use 8x68s Norma or RWS brass and fire form it to my chamber. The head is a bit smaller so some actions may not be able to extract but with a sako/ m16 style extractor it works great! I hate the cow fire forming so I shoot cheap bullets to fire form. I neck up to 375 then down to 338 forming a false shoulder with a slight crush fit. It is much stronger than Hornady’s primer pockets. For the 300 prc you could prob just trim to 2.600 the neck down to 308. Left to right: Hornady 338/375, Norma 8x68 fireformed, 8x68 ready to fire form

From 110len in post 65 on page 2:

No, just a regular guy. No involvement with AI other than owning a few. 300PRC is nothing new, just a new name. 30-375 and, IIRC, 300AI. AI has had involvement with this cartridge for awhile as has Mr. Tooley. Thanks again Dave, - it's shooting extremely well btw.

Post 62 on page 2:

Hornady 225gr ELD-M OAL 3.630

Hornady brass

Fed 215M

RL 26 77grs

Bartlein 8 twist 26in

2923fps

*hot load, choose wisely

------------------

Here's the load LakuNoc is testing (posts 1868 & 1894 on page 38 and post 1945 on page 39 and also look at post 1835 on page 37):

78.5Gr of H1000

230 A-Tip

RCC brass

I went to range today with RCC brass and 230gr A-Tip to see how will brass hold pressure.

This is my load and in my rifle, please be careful because it might be different in your rifle.

RCC Brass loaded with H1000, CCI BR-2 primers and 230gr A-TiP.

Like i said in part one i will do concentricity of rounds loaded and i did, not to write out all numbers but out of 10 rounds 8 rounds where with 1 thousands of an inch and 2 rounds were runout of 1.5 thousands of and inch. In my books that's very good.

My Weather 40 F, 28.6inHg, 64% Humidity My Altitude 1030ft

76.4 GN = 2869 FPS no pressure

76.7 GN = 2876 FPS no pressure

77.0 GN = 2896 FPS no pressure

77.3 GN = 2899 FPS no pressure

77.6 GN = 2890 FPS no pressure

77.9 GN = 2913 FPS no pressure

78.2 GN = 2940 FPS no pressure NODE

78.5 GN = 2938 FPS no pressure NODE

78.8 GN = 2945 FPS no pressure NODE

80.1 GN = 2966 FPS no pressure

Now some Comparison here with Hornady Brass.

HORNADY BRASS Same powder, bullet, primers everything same but HORNADY BRASS

77.9 GN = 2859 FPS

78.2 GN = 2863 FPS

78.5 GN = 2879 FPS

78.8 GN = 2899 FPS

80.1 GN = 2919 FPS PRESSURE Signs at 80.1GN, bolt lift started being slightly

heavy/injector mark this is on Hornady Brass just to be clear.