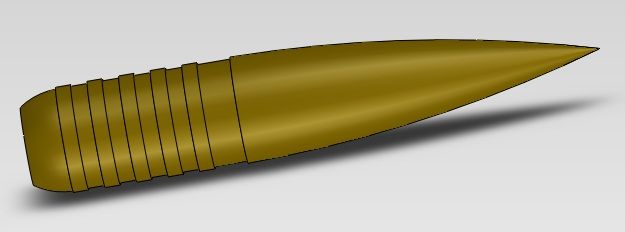

Id like to offer a free 1075grain .50cal VLD bullet design, you have my permission to use it however you wish. The design weight is accurate via 3D CAD calculation using copper as the material with a density of 8.95g/cm^3. Machined from Brass @ 8.47g/cm^3, it would be a bit lighter and the stability is also worse - i wouldnt recommend it.

So here it is...

The following BC and stability calculations were performed with the McDrag Projectile drag and static stability calculator as per Robert McCoy, former ballistics researcher, Aberdeen proving grounds.

Required twist is 1:11.3 @ 2791 fps for a stability factor of 1.5, however a 1:12 twist should be adequate, and still provides a stability factor of 1.3 in std atmosphere conditions at sea level.

G1 BC`s are calculated as follows;

1.793 @ 3349 fps

1.669 @ 2791 fps

1.615 @ 2232 fps

G7 BC`s as follows;

.846 @ 3349 fps

.834 @ 2791 fps

.811 @ 2232 fps

Assuming we shoot this projectile at a muzzle velocity of 2600fps, we can assume the velocity regime of this projectile over the course of a 1000yd flight to be between 2600fps and 2075 fps @ 1000yds, remembering that this is based purely of the calculated BCs.

By averaging the BC`s across this flight regime, we get an average G7 of .816 and this equates to an average G1 BC of 1.621. These would be the numbers youd be interested in to initially build a trajectory from in your initial testing, and revise it to a real world BC from there.

I have no idea whether the dynamic stability of this projectile is adequate, so proceed at your own risk and have fun whilst your doing it. If someone actually does get this machined up, please let us know how it goes... Enjoy.

So here it is...

The following BC and stability calculations were performed with the McDrag Projectile drag and static stability calculator as per Robert McCoy, former ballistics researcher, Aberdeen proving grounds.

Required twist is 1:11.3 @ 2791 fps for a stability factor of 1.5, however a 1:12 twist should be adequate, and still provides a stability factor of 1.3 in std atmosphere conditions at sea level.

G1 BC`s are calculated as follows;

1.793 @ 3349 fps

1.669 @ 2791 fps

1.615 @ 2232 fps

G7 BC`s as follows;

.846 @ 3349 fps

.834 @ 2791 fps

.811 @ 2232 fps

Assuming we shoot this projectile at a muzzle velocity of 2600fps, we can assume the velocity regime of this projectile over the course of a 1000yd flight to be between 2600fps and 2075 fps @ 1000yds, remembering that this is based purely of the calculated BCs.

By averaging the BC`s across this flight regime, we get an average G7 of .816 and this equates to an average G1 BC of 1.621. These would be the numbers youd be interested in to initially build a trajectory from in your initial testing, and revise it to a real world BC from there.

I have no idea whether the dynamic stability of this projectile is adequate, so proceed at your own risk and have fun whilst your doing it. If someone actually does get this machined up, please let us know how it goes... Enjoy.