When I had my factory Tikka 20” 6.5 barrel, shooting with an Omega, 42.4 grains of H4350 under a 140 ELD was my load. 2640 FPS.Anyone have a load for a tikka ctr 6.5cm 20" barrel with a 7in tbac can or any suppressed in that barrel length? Going to be loading soon with lapua brass, federal 210m, h4350 and either (130 eldms 143eldx also have some berger hybrid 144 i think).

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor

- Thread starter Sportin Wood

- Start date

I have a Tikka T3X with the 24” barrel and the best load for my rifle with Hornady brass, H4350, Federal 210m primers is 41.7 grains for shooting suppressed (Larue Tranquillio) and un-suppressed. Shoots about 1/2 MOA with SDs around 11-12. Velocity was around 2715 last summer but my latest load has velocity at 2660 but still shooting good to distance. I think my barrel is on the way out.

At 42.6 grains of H4350 with several attempts I have gotten SDs of around 2-3 but with groups around 1.5MOA. I am still pretty new to loading so trying to figure out if I can tighten up the groups (seating depth, ert) with the low SDs.

At 42.6 grains of H4350 with several attempts I have gotten SDs of around 2-3 but with groups around 1.5MOA. I am still pretty new to loading so trying to figure out if I can tighten up the groups (seating depth, ert) with the low SDs.

Had very good results with the 144 Berger Hybrid, it is a factory “tipped” bullet, good BC, but more importantly, it has very consistent BC, so vertical spread at distance is very good. I had a nice wide node around 2730 fps, but could drive naked bullets to 2810 before there were clear pressure signs. [Not relevant for this discussion, so just an aside: We managed to get them over 2900 fps with David Tubb’s blended HBN coating and Reloder-17. It is NOT a powder i would recommend, because it is very temperature sensitive, so on a hot day you drop out of the node and the groups open up, or you could even see bad pressure signs. Handle with care.]

However, I can’t find any Berger bullets anywhere. Where do you see 6.5 Berger bullets listed? I really need some!!

Barnes 145 Matchburner bullet: G7 BC appears to be significantly inflated. I guess Litz has tested them by now, because there is a Custom Drag Curve for it available in AB Ballistics app. If i true the BC in Strelok for 1000 yards, i get a G7 BC closer to 0.3 than 0.35. BC is speed dependent, so it might be slightly over 0.3 if fired at very high speed from a very big magnum.... but there seems to be some marketing hype here.

Weight range was 0.9 gn, which is 3x more than the typical batch from Berger. Base to ogive was pretty good for the small sample i checked. Not quite a premium bullet it seems, but way better than nothing! I will be shooting it as that is all i can get right now.

Have not had a chance to shoot this at 600, maybe tomorrow.

Last edited:

Barnes 145 Matchburner bullet: G7 BC appears to be significantly inflated. I guess Litz has tested them by now, because there is a Custom Drag Curve for it available in AB Ballistics app. If i true the BC in Strelok for 1000 yards, i get a G7 BC closer to 0.3 than 0.35. BC is speed dependent, so it might be slightly over 0.3 if fired at very high speed from a very big magnum.... but there seems to be some marketing hype here.

Weight range was 0.9 gn, which is 3x more than the typical batch from Berger. Base to ogive was pretty good for the small sample i checked. Not quite a premium bullet it seems, but way better than nothing! I will be shooting it as that is all i can get right now.

Have not had a chance to shoot this at 600, maybe tomorrow.

Have to modify my Base-to-Ogive comment: Have now measured around 100 with a good dial indicator, most (80-90%) are within -3 to +3 thou. I realize that the measurement technique can introduce errors of 2 to 3 thou. About 10% of the bullets were beyond 7 thou off. My ES was closer to 10 thou.

My best 600 yard estimate of the G7 BC is about 0.315 while pushing them to max from a long barrel using special powder (they are also HBN coated) at about 2900 fps. A 6.5 PRC might see a slight uptick in BC. I guess most 6.5 Creedmoor chambered rifles will see a 0.31 or less. The 0.35 published number did not work for me...

I guess at 32 cents per bullet (during a panic buying period) we should not expect Berger levels of consistency. Still far better than an empty shelf!

Shot them at 600 yards in a 5-9 mph wind, direction varied 0-30% from the berm so 6 pm to 8 pm on the clock. Good enough for practice at 400 and 600, but not recommending them for 1000 yard competitions.

Found a good node (flat spot in the speed graph) with SD around 6-7 fps, but have not optimized seating depth yet. Also not tuned for positive compensation, so very much an unfinished load! Could hit the 3-5” plates half the time. Once optimized i expect the hit percentage to go up, we shall see! But I first need to find more primers.

Last edited:

Was 2900fps what you settled into with them, or did you end up running / testing another velocity node? Also curious what you found as far as their tolerance to jump? They like to jump, or did you find they wanted to be snug in the lands?Barnes 145 Matchburner bullet: G7 BC appears to be significantly inflated. I guess Litz has tested them by now, because there is a Custom Drag Curve for it available in AB Ballistics app. If i true the BC in Strelok for 1000 yards, i get a G7 BC closer to 0.3 than 0.35. BC is speed dependent, so it might be slightly over 0.3 if fired at very high speed from a very big magnum.... but there seems to be some marketing hype here.

Weight range was 0.9 gn, which is 3x more than the typical batch from Berger. Base to ogive was pretty good for the small sample i checked. Not quite a premium bullet it seems, but way better than nothing! I will be shooting it as that is all i can get right now.

Have not had a chance to shoot this at 600, maybe tomorrow.

I've got a metric shitton of them and am running low on H 140g ELDM's so was figuring I'd pull a box of the Match Burners down and start tinkering with them.

Was 2900fps what you settled into with them, or did you end up running / testing another velocity node? Also curious what you found as far as their tolerance to jump? They like to jump, or did you find they wanted to be snug in the lands?

I've got a metric shitton of them and am running low on H 140g ELDM's so was figuring I'd pull a box of the Match Burners down and start tinkering with them.

I do think they show promise, so not giving up on them: It is all i have right now, so will find a way to make them work!

Have only tried a 20 thou jump. My rifle shoots ELDM and Sierra SMKs very well with either short jump (5-25 thou), or very long jump (mag length, 50-150 thou), but for some reason it does not like jammed bullets. No idea why.

Will report again once i have optimized the load. [It may not be required, and i hate doing it, but i have weight sorted the two 500 count boxes i have.]

Last edited:

Good to know. I may need to break into mine if I can't find any H140ELDM's for upcoming matches. They seem to have a true love or hate relationship online with guys and their did tests.I do think they show promise, so not giving on them: All i have right now so will find a way to make them work!

Have only tried a 20 thou jump. My rifle shoots ELDM and Sierra SMKs very well with either short jump (5-25 thou), or very long jump (mag length, 50-150 thou), but for some reason it does not like jammed bullets. No idea why.

Will report again once i have optimized the load. [It may not be required but i have weight sorted the two 500 count boxes i have.]

Coming into the game at the worst time, I managed to buy whatever I can.

Anyone have a special recipe for Sta-Ball 6.5 and CCI No. 34 primers? I’ll be using Berger .264 130gr AR Hybrid OTM and Berger 6.5mm 140gr Match Hybrid Target.

I have some Peterson and S&B brass.

Anyone have a special recipe for Sta-Ball 6.5 and CCI No. 34 primers? I’ll be using Berger .264 130gr AR Hybrid OTM and Berger 6.5mm 140gr Match Hybrid Target.

I have some Peterson and S&B brass.

Coming into the game at the worst time, I managed to buy whatever I can.

Anyone have a special recipe for Sta-Ball 6.5 and CCI No. 34 primers? I’ll be using Berger .264 130gr AR Hybrid OTM and Berger 6.5mm 140gr Match Hybrid Target.

I have some Peterson and S&B brass.

Those are all good components, and you will not be at a disadvantage. It is probably best to stick to one brand of brass, as the internal volume will almost certainly be quite different between Peterson and S&B. Maybe the 130’s should go into the S&B brass and the higher BC 140s should go into the premium Peterson brass. But your call!

IMO, it eats up too much barrel life if you have to develop four loads for the same rifle (2 bullets and 2 makes of brass), but just my opinion.

Have not used Staball yet, can’t get it anywhere... but heard good things about it. Where did you see Staball for sale?

Last edited:

Got it from Brownells a couple months back, it wasn’t the greatest deal.Those are all good components, and you will not be at a disadvantage. It is probably best to stick to one brand of brass, as the internal volume will almost certainly be quite different between Peterson and S&B. Maybe the 130’s should go into the S&B brass and the higher BC 140s should go into the premium Peterson brass. But your call!

IMO, it eats up too much barrel life if you have to develop four loads for the same rifle (2 bullets and 2 makes of brass), but just my opinion.

Have not used Staball yet, can’t get it anywhere... but heard good things about it. Where did you see Staball for sale?

im looking for some load info for staball with lapua SPR brass and hornady 129 interlock SP's.....hunting load.

I got 3lbs yesterday off brownells.

I got 3lbs yesterday off brownells.

In my CMs 41gr R16 seems to work well with any decent 140gr bullet In any decent rifle. Also, though the BC is unimpressive, I’ve not found a CM that won’t shoot the Hornady 140gr BTHP.

Here’s 41gr R16 behind the 140gr Hornady BTHP.

John

Here’s 41gr R16 behind the 140gr Hornady BTHP.

John

Yeah I'm quoting myself. Almost two years ago to the day I was buying the Hornady 140 BTHP for $22/100 and like $100/500. If only I knew then what I know nowLike the poster above said, Midsouth has them for $21.99 a box. Red River has then for $23.

Have to modify my Base-to-Ogive comment: Have now measured around 100 with a good dial indicator, most (80-90%) are within -3 to +3 thou. I realize that the measurement technique can introduce errors of 2 to 3 thou. About 10% of the bullets were beyond 7 thou off. My ES was closer to 10 thou.

My best 600 yard estimate of the G7 BC is about 0.315 while pushing them to max from a long barrel using special powder (they are also HBN coated) at about 2900 fps. A 6.5 PRC might see a slight uptick in BC. I guess most 6.5 Creedmoor chambered rifles will see a 0.31 or less. The 0.35 published number did not work for me...

I guess at 32 cents per bullet (during a panic buying period) we should not expect Berger levels of consistency. Still far better than an empty shelf!

Shot them at 600 yards in a 5-9 mph wind, direction varied 0-30% from the berm so 6 pm to 8 pm on the clock. Good enough for practice at 400 and 600, but not recommending them for 1000 yard competitions.

Found a good node (flat spot in the speed graph) with SD around 6-7 fps, but have not optimized seating depth yet. Also not tuned for positive compensation, so very much an unfinished load! Could hit the 3-5” plates half the time. Once optimized i expect the hit percentage to go up, we shall see! But I first need to find more primers.

145 Barnes Matchburners: Shot some groups today, bipod plus rear bag from a wooden bench, using an accurate MPA comp rifle. Loaded in full OCD mode: one kernel accuracy, weight sorted everything. Yeah i know. Overkill.

Group size varied between 0.4” and 0.8”, average around 0.5-0.6”. My Accutac bipod gave me trouble today, bench is too short, and i was probably not adequately loading the bipod, might well be the cause of (at least some) of the “fliers”. I did not call any fliers, trigger technique was mostly ok today.

Wind was gusting between 10 and 22 mph. NOT cherry picking the good groups only, so showing all of them, warts and all:

Tuner at 6:

Tuner at 8:

Tuner at 10:

Attachments

Last edited:

These bullets now shoot quit well, after optimizing with the Kinetic Solutions barrel tuner.

Results could have been better: Bipod gave me trouble, and wind was strong too, from the 4 o’cock position.

SD was 9.1 fps (measured via LabRadar over 30 rounds). I am slightly below the identified node/flat spot, it was a cooler day, powder is temp sensitive, switched from CCI 450s to GMM205s, and that combo dropped my MV by 25 fps.

I believe my results could be better if shot from a front sand bag, in calm conditions, and if i remained inside the node.

Results could have been better: Bipod gave me trouble, and wind was strong too, from the 4 o’cock position.

SD was 9.1 fps (measured via LabRadar over 30 rounds). I am slightly below the identified node/flat spot, it was a cooler day, powder is temp sensitive, switched from CCI 450s to GMM205s, and that combo dropped my MV by 25 fps.

I believe my results could be better if shot from a front sand bag, in calm conditions, and if i remained inside the node.

Last edited:

I may have missed it, but what was your jump distance?These bullets now shoot quit well, after optimizing with the Kinetic Solutions barrel tuner. SD was 9.1 fps.

I believe my results could be better if shot from a front sand bag.

Was this all the same load for all shots? Powder charge, CBTO, etc. or something else here?145 Barnes Matchburners: Shot some groups today, bipod plus rear bag from a wooden bench, using an accurate MPA comp rifle. Loaded in full OCD mode: one kernel accuracy, weight sorted everything. Yeah i know. Overkill.

Group size varied between 0.4” and 0.8”, average around 0.5-0.6”. My Accutac bipod gave me trouble today, bench is too short, and i was probably not adequately loading the bipod, might well be the cause of (at least some) of the “fliers”. I did not call any fliers, trigger technique was mostly ok today.

NOT cherry picking the good groups only, so showing all of them, warts and all:

View attachment 7610137

View attachment 7610138

View attachment 7610141

View attachment 7610142

View attachment 7610143

View attachment 7610144

View attachment 7610145

View attachment 7610148

View attachment 7610149

I'm down to my last few boxes of ELD-M's so will probably start into the Match Burners and work up a load for one of my 65's.

I may have missed it, but what was your jump distance?

Sorry, jump is 25 thou. These bullets are quite long. Trying to keep the pressure ring above the neck shoulder junction. Federal GMM205 primers in weight sorted Lapua brass.

They are HBN coated which allows for higher speed via RL-17 (2895 fps), but i don’t think that is relevant to how they perform at 100. But at 400 plus that extra speed will help to reduce wind drift. Others have seen similar speed with RL-26 and uncoated bullets. [RL-17 is not my favorite powder, too temp sensitive, but it is what i have available right now.]

COAL is way too long for mag feeding, also the lands have moved forward quite a lot after 2,000 plus rounds down the barrel.

This MPA rifle is accurate, but it does not like a jam for some reason. It shoots ELDMs, Atips and Berger Hybrids very well (0.35 MOA groups) with jump between 10 and 25, but also with very long jump (50-150 thou) suitable for mag feeding (0.45 MOA). Best groups ever were found with 135 gn weight sorted Atips and RL-16 (around 0.1”-0.2”) at 100. Several were below 0.1”, but lets call that “luck”!

Last edited:

Was this all the same load for all shots? Powder charge, CBTO, etc. or something else here?

I'm down to my last few boxes of ELD-M's so will probably start into the Match Burners and work up a load for one of my 65's.

Same load but slightly different barrel tuner settings (6, 8 and 10, but most/best groups were shot with the tuner at 10). Have not yet tried 9 or 11...

If you don’t have a tuner, then optimize via seating depth. The tuner is just a very convenient way for me to achieve the same result without having to reseat loaded rounds at the bench.

Last edited:

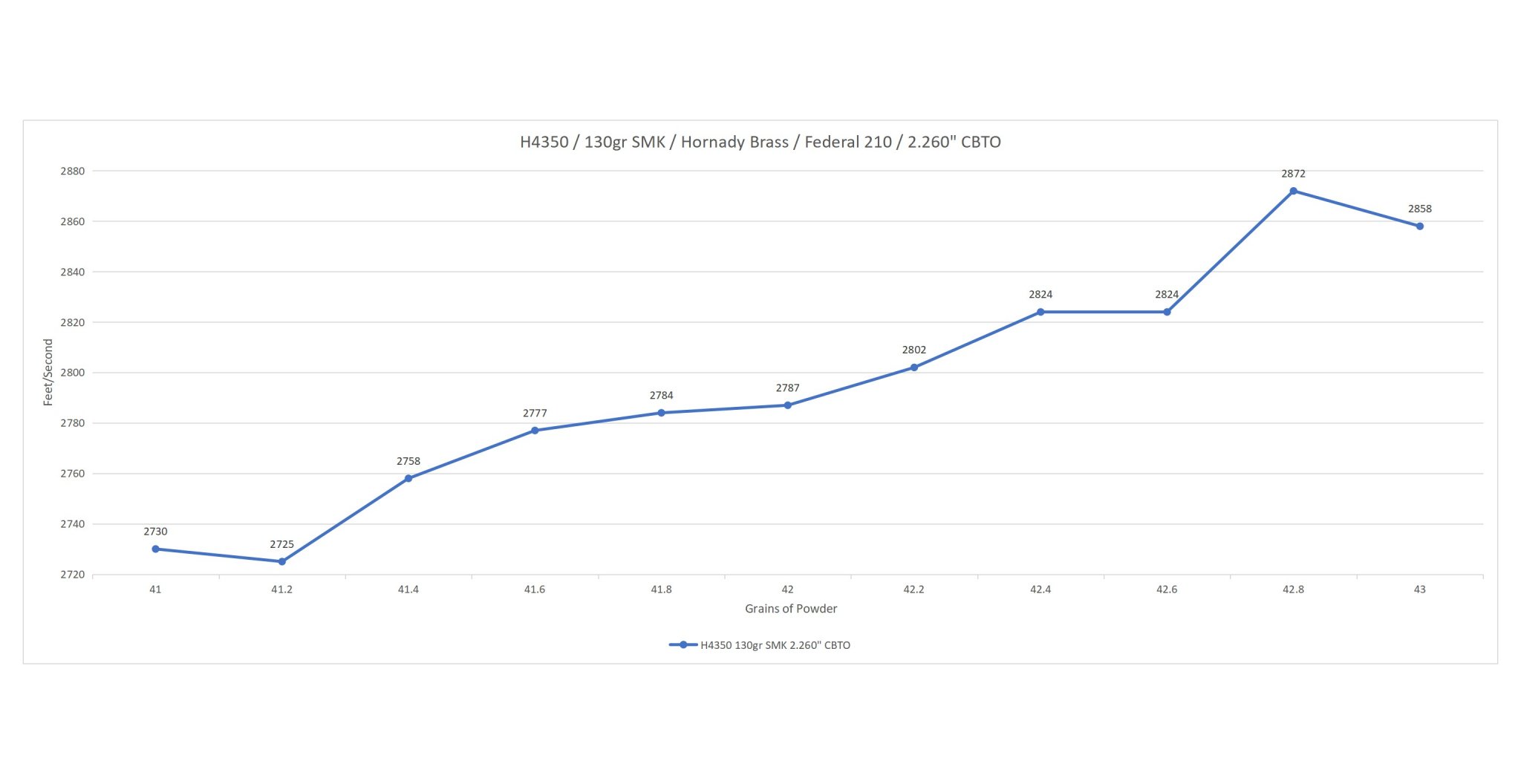

This is data I got today (60* F, 28.78") with the 130 SMK's in my Tikka Tac A1, 6.5 Creedmoor. There are a couple of areas that I'd like to explore more. With the H4350, I'd like to load up 5 shot groups for 41.8gr and 42.5gr. The 41.8gr node is a wider, but I'd be interested to see the ES and SD of 42.5.

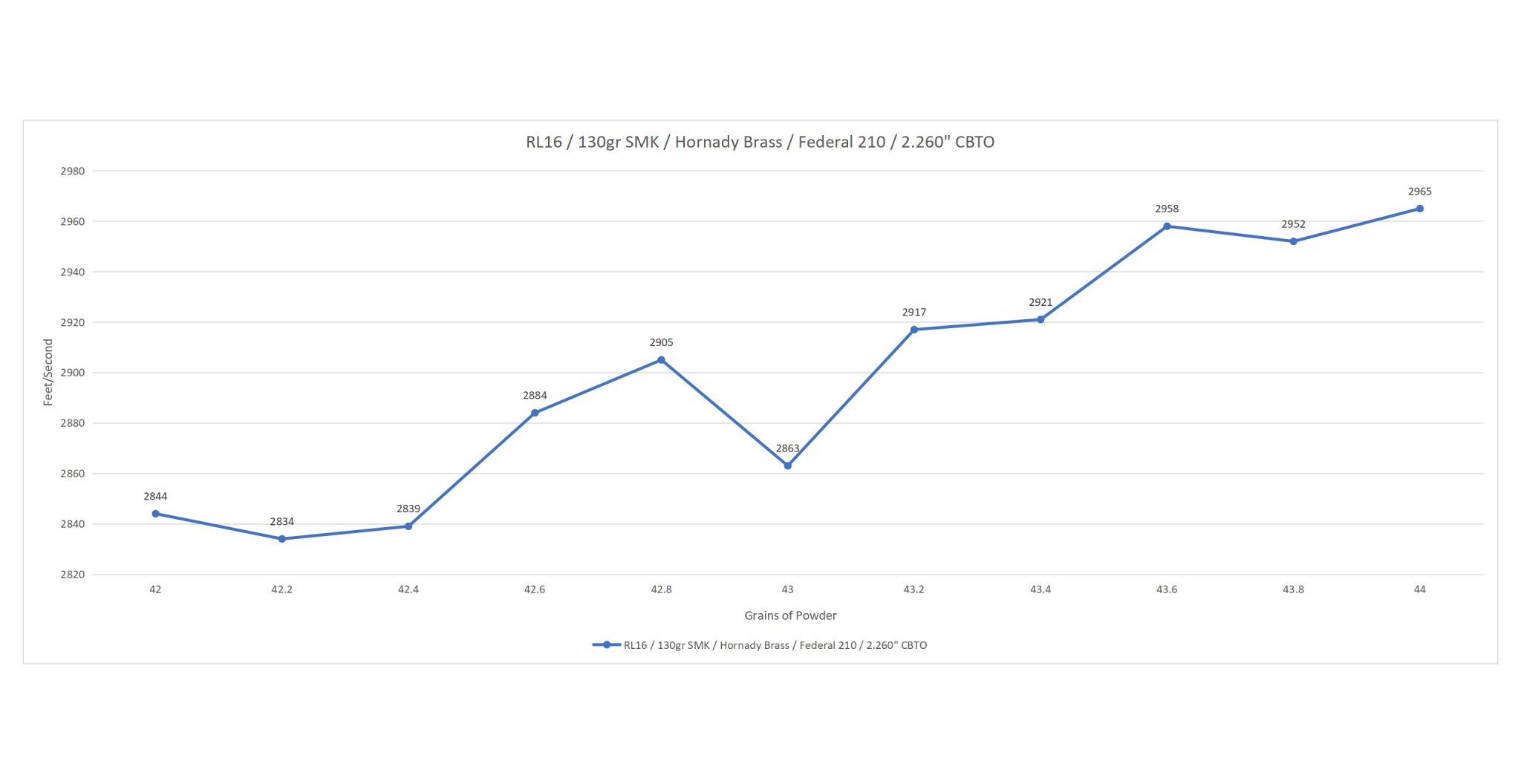

As far as the RL16 load goes, I'd like to do 3 shot groups from 42.8gr to 43.4gr. If that 43gr charge is an outlier (my mistake in loading, etc.), that makes that a very wide node. A difference of 16fps across 0.6 grains. I'd also like to do a 5 shot group at 43.8gr and look at the ES and SD there.

What do you all think?

Oh, and just for reference...the 140gr Hornady American Gunner ammo averages about 2640 out of my rifle in 70*F. But SDs in the high teens and ESs in the 50s and 60s. They shoot well out to about 600 or so. After about 800 it's a total crap shoot.

As far as the RL16 load goes, I'd like to do 3 shot groups from 42.8gr to 43.4gr. If that 43gr charge is an outlier (my mistake in loading, etc.), that makes that a very wide node. A difference of 16fps across 0.6 grains. I'd also like to do a 5 shot group at 43.8gr and look at the ES and SD there.

What do you all think?

Oh, and just for reference...the 140gr Hornady American Gunner ammo averages about 2640 out of my rifle in 70*F. But SDs in the high teens and ESs in the 50s and 60s. They shoot well out to about 600 or so. After about 800 it's a total crap shoot.

Your H4350 graphs shows promise. The wider flat spot around 41.8 looks like it could well be real. IMO if the flat spot is not at least 0.5 wide, it is not much use. I would reshoot it with 5 shot groups, from 41.5 to 42.1 in 0.2 gn increments... but your call.

Keep the barrel medium warm but not hot (and avoid using this load test ammo for the first 5 rounds, rather use your plinking ammo to put some moderate heat into the barrel, especially the cold bore shot could be way off). Avoid cleaning the barrel until load development is done.

For the RL-16 load: This graph is less convincing. Maybe reshoot the top end? Personally i would be sceptical of the very narrow flat spot around [Edit:] 43.2 to 43.4 gn. Probably just luck factor. Too narrow and too jagged right next to it. So maybe reshoot the higher flat spot from 43.3 to 44.1 gn using 5 shot groups. So start slightly below and go slightly above what appears flat in the graph, and go a little wider than before, and shoot the in-between values this time. If it is flat again, you can be sure it is real. Hope this helps!

And now for the unsolicited advice

: Your call, but I would first trim the Hornady brass to length (1.910”). Then weight sort the batch and use the middel of the weight range (close to the average for this batch) to do the load development. Cull out the really bad ones. If the batch is large enough (100 plus), divide the batch into two seperste batches of 50. Hornady brass has a rather wide weight range, and that leads to a wide internal volume range, which negatively affects your SD. Yes, volume sorting is better than weight sorting, but for well-made brass, weight sorting works well enough. I have tried both... the weight difference is mostly in the average thickness of the case wall, not variation in the web area.

: Your call, but I would first trim the Hornady brass to length (1.910”). Then weight sort the batch and use the middel of the weight range (close to the average for this batch) to do the load development. Cull out the really bad ones. If the batch is large enough (100 plus), divide the batch into two seperste batches of 50. Hornady brass has a rather wide weight range, and that leads to a wide internal volume range, which negatively affects your SD. Yes, volume sorting is better than weight sorting, but for well-made brass, weight sorting works well enough. I have tried both... the weight difference is mostly in the average thickness of the case wall, not variation in the web area.

Not meaning to insult folks who use Hornady brass: The biggest accuracy improvement i ever got was when i upgraded from Hornady and Winchester brass to Lapua brass... SD almost halved at that point. A $100 spent on two boxes of premium brass (Lapua, Peterson, Alpha, ADG) has a better bang-for-the buck than buying a milligram scale like an FX120 or an expensive annealer like the AMP machine... Then sort your 100 cases into two batches of 45 each, with no more than a 2 grain weight difference, cull out the worst 10... Just trying to help.

The only other ‘upgrade’ that will rival switching to top quality brass is replacing a shot-out factory barrel with a Bartlein or Krieger. Of course a premium barrel is closer to an $800 investment.

At 1000 yards, the long and heavy Berger Hybrids will have the edge over the Sierras because of their higher BC and better jacket consistency. But at 600 or less you will barely see a difference.

Hope you arrive at a superb load soon. Best of luck!

Keep the barrel medium warm but not hot (and avoid using this load test ammo for the first 5 rounds, rather use your plinking ammo to put some moderate heat into the barrel, especially the cold bore shot could be way off). Avoid cleaning the barrel until load development is done.

For the RL-16 load: This graph is less convincing. Maybe reshoot the top end? Personally i would be sceptical of the very narrow flat spot around [Edit:] 43.2 to 43.4 gn. Probably just luck factor. Too narrow and too jagged right next to it. So maybe reshoot the higher flat spot from 43.3 to 44.1 gn using 5 shot groups. So start slightly below and go slightly above what appears flat in the graph, and go a little wider than before, and shoot the in-between values this time. If it is flat again, you can be sure it is real. Hope this helps!

And now for the unsolicited advice

Not meaning to insult folks who use Hornady brass: The biggest accuracy improvement i ever got was when i upgraded from Hornady and Winchester brass to Lapua brass... SD almost halved at that point. A $100 spent on two boxes of premium brass (Lapua, Peterson, Alpha, ADG) has a better bang-for-the buck than buying a milligram scale like an FX120 or an expensive annealer like the AMP machine... Then sort your 100 cases into two batches of 45 each, with no more than a 2 grain weight difference, cull out the worst 10... Just trying to help.

The only other ‘upgrade’ that will rival switching to top quality brass is replacing a shot-out factory barrel with a Bartlein or Krieger. Of course a premium barrel is closer to an $800 investment.

At 1000 yards, the long and heavy Berger Hybrids will have the edge over the Sierras because of their higher BC and better jacket consistency. But at 600 or less you will barely see a difference.

Hope you arrive at a superb load soon. Best of luck!

Last edited:

Link explaining the effect of case volume on speed:

www.snipershide.com

www.snipershide.com

Effect of case volume on 6.5 Creedmoor velocity - some experimental data

OK, have been wanting to run this experiment for a while, and finally found the time 2 weeks ago. Have been collecting range brass over the past 4 years and just kept it in a plastic bucket, never shot it since it is unsorted, different manufacturer, different batch and different weight. Would...

I appreciate all of the info. Unfortunately, Hornady brass is all I have right now. BUT, I have about 300 pieces of it, about 280 of it being once-fired, with the rest being twice-fired. I was looking at Lapua but that seems to be all dried up, like most other components these days. Maybe I'll find the best 150 or so and use them.Your H4350 graphs shows promise. The wider flat spot around 41.8 looks like it could well be real. IMO if the flat spot is not at least 0.5 wide, it is not much use. I would reshoot it with 5 shot groups, from 41.5 to 42.1 in 0.2 gn increments... but your call.

Keep the barrel medium warm but not hot (and avoid using this load test ammo for the first 5 rounds, rather use your plinking ammo to put some moderate heat into the barrel, especially the cold bote shot could be way off). Avoid cleaning the barrel until load development is done.

For the RL-16 load: This graph is less convincing. Maybe reshoot the top end? Personally i would be sceptical of the very narrow flat spot around 42.4 to 42.6 gn. Probably just luck factor. Too narrow and too jagged right next to it. So maybe reshoot the higher flat spot from 43.3 to 44.1 gn using 5 shot groups. Go a little wider than before, and shoot the in-between values this time. Hope this helps!

And now for the unsolicited advice: Your call, but I would first trim the Hornady brass to length (1.910”). Then weight sort the batch and use the middel of the weight range (close to the average for this batch) to do the load development. Cull out the really bad ones, or if the batch is large enough (100 plus), divide the batch into two seperste batches of 50. Hornady brass has a rather wide weight range, and that leads to a wide internal volume range. Yes, volume sorting is better than weight sorting, but for well-made brass, weight sorting works well enough, I have tried both... the weight difference is mostly in the average thickness of the case, not variation in the web area.

Not meaning to insult folks who use Hornady brass: The biggest accuracy improvement i ever got was when i upgraded from Hornady and Winchester brass to Lapua brass... SD halved at that point. A $100 spent on two boxes of premium brass (Lapua, Peterson, Alpha, ADG) has a better bang-for-the buck than buying a milligram scale like an FX120 or an annealer like the AMP machine... Then sort your 100 cases into two batches of 45 each, with no more than a 2 grain weight difference, cull out the worst 10... Just trying to help.

The only other ‘upgrade’ that will rival switching to top quality brass is replacing a shot-out factory barrel with a Bartlein or Krieger. Of course a premium barrel is closer to an $800 investment.

At 1000 yards, the long and heavy Berger Hybrids will have the edge over the Sierras because of their higher BC and better jacket consistency. But at 600 or less you will barely see a difference.

Hope you get a superb load soon. Best of luck!

One other thing...when you said you were a bit suspicious of the 42.4-42.6 node, you meant on the 4350 graph, no? I know you were talking about the RL16 at that point but it seems you may have been looking at the H4350 by mistake.

I was going to go shoot again tomorrow and have already loaded 5 cartridges at 41.8 and 42.5 of H4350, along with 43.3 and 43.8 of RL16. I may pull these and go a different route, after sorting my brass.

Last edited:

I have 300 Alpha 6.5cm cases coming Tuesday. I haven't weight-sorted the Hornady yet because I had already primed some of the brass. Maybe I'll sort it tomorrow, or maybe I'll just sell it. The Hornady just seems to be all over the place. I know my primers are good (I've seen several tests where Federal 210's performed just as well as their "Match" counterparts), and I know my charge weights are accurate + or - a kernel of powder. I had several groups today that had ESs of middle to low single digits and then the ES up or down .2 were horrendous. It's always one that opens it up, and can be in either direction velocity-wise. Oh, and it's not even Match brass. It's American Gunner. Which, from what I've heard, is even more horrendous. I'm not going to load anything else in this brass as I feel I'm wasting time, and materials. Thank you for your wisdom. I'll be sure to report back Friday afternoon/evening with the results from the Alpha brass.Your H4350 graphs shows promise. The wider flat spot around 41.8 looks like it could well be real. IMO if the flat spot is not at least 0.5 wide, it is not much use. I would reshoot it with 5 shot groups, from 41.5 to 42.1 in 0.2 gn increments... but your call.

Keep the barrel medium warm but not hot (and avoid using this load test ammo for the first 5 rounds, rather use your plinking ammo to put some moderate heat into the barrel, especially the cold bote shot could be way off). Avoid cleaning the barrel until load development is done.

For the RL-16 load: This graph is less convincing. Maybe reshoot the top end? Personally i would be sceptical of the very narrow flat spot around 42.4 to 42.6 gn. Probably just luck factor. Too narrow and too jagged right next to it. So maybe reshoot the higher flat spot from 43.3 to 44.1 gn using 5 shot groups. Go a little wider than before, and shoot the in-between values this time. Hope this helps!

And now for the unsolicited advice: Your call, but I would first trim the Hornady brass to length (1.910”). Then weight sort the batch and use the middel of the weight range (close to the average for this batch) to do the load development. Cull out the really bad ones, or if the batch is large enough (100 plus), divide the batch into two seperste batches of 50. Hornady brass has a rather wide weight range, and that leads to a wide internal volume range. Yes, volume sorting is better than weight sorting, but for well-made brass, weight sorting works well enough, I have tried both... the weight difference is mostly in the average thickness of the case, not variation in the web area.

Not meaning to insult folks who use Hornady brass: The biggest accuracy improvement i ever got was when i upgraded from Hornady and Winchester brass to Lapua brass... SD halved at that point. A $100 spent on two boxes of premium brass (Lapua, Peterson, Alpha, ADG) has a better bang-for-the buck than buying a milligram scale like an FX120 or an annealer like the AMP machine... Then sort your 100 cases into two batches of 45 each, with no more than a 2 grain weight difference, cull out the worst 10... Just trying to help.

The only other ‘upgrade’ that will rival switching to top quality brass is replacing a shot-out factory barrel with a Bartlein or Krieger. Of course a premium barrel is closer to an $800 investment.

At 1000 yards, the long and heavy Berger Hybrids will have the edge over the Sierras because of their higher BC and better jacket consistency. But at 600 or less you will barely see a difference.

Hope you get a superb load soon. Best of luck!

Sorry, typo. I was actually looking at the RL-16 plot, corrected it in my post. Was trying to say that the flat spot below is way too narrow to be useful, and probably just luck.I appreciate all of the info. Unfortunately, Hornady brass is all I have right now. BUT, I have about 300 pieces of it, about 280 of it being once-fired, with the rest being twice-fired. I was looking at Lapua but that seems to be all dried up, like most other components these days. Maybe I'll find the best 150 or so and use them.

One other thing...when you said you were a bit suspicious of the 42.4-42.6 node, you meant on the 4350 graph, no? I know you were talking about the RL16 at that point but it seems you may have been looking at the H4350 by mistake.

I was going to go shoot again tomorrow and have already loaded 5 cartridges at 41.8 and 42.5 of H4350, along with 43.3 and 43.8 of RL16. I may pull these and go a different route, after sorting my brass.

Federal 210m and 41.5 H4350Think I asked this before, not sure where as I can't find it.

I want to duplicate factory hornady 140 eldm loads.

Anyone have the powder and primer to best match their loading.

You may need to adjust it slightly. My old Savage liked 41.1. But that 41.5 with a fed match primer was printed on old boxes of their match ammo as recommended reload. Which was funny at the time as the book max was 41 or very low 41 grains lol. But 41 to 41.5 should get it done.And I have both on hand, thanks!

I don't have Hornady's latest manual, but it appears 41.5 is max today.

You may need to adjust it slightly. My old Savage liked 41.1. But that 41.5 with a fed match primer was printed on old boxes of their match ammo as recommended reload. Which was funny at the time as the book max was 41 or very low 41 grains lol. But 41 to 41.5 should get it done.

That is one of my preferred loads, I don't however believe the powder in the 140g ELD-M factory ammo is H4350 from a side by side comparison of the powders. Extruded, but slightly different in color.Federal 210m and 41.5 H4350

41.5 is book max. (Vol 10 and 11). I found a velocity node that ran from 41.4 up to 41.6ish or so.

Pulled down a few of the Hornady American Gunner 140 HPBT's as well. Similar charge in the 41.4ish range although didn't look exactly like H4350.

That being said, H4350 is a very well proven powder in that cartridge/bullet/primer combo

YMMV.

Last edited:

They used to list the recipe right on the box.That is one of my preferred loads, I don't however believe the powder in the 140g ELD-M factory ammo is H4350 from a side my side comparison of the powders. Extruded, but slightly different in color.

41.5 is book max. (Vol 10 and 11). I found a velocity node that ran from 41.4 up to 41.6ish or so.

Pulled down a few of the Hornady American Gunner 140 HPBT's as well. Similar charge in the 41.4ish range although didn't look exactly like H4350.

That being said, H4350 is a very well proven powder in that cartridge/bullet/primer combo

YMMV.

They used to list the recipe right on the box.

I actually said that in my first reply. I also have a photo of the recipe on the box somewhere.

If you guys need it, here you go. They stopped listing the recommended load when they switched from AMAX to ELDM, if I remember correctly. Also, I thought I read that part of the list of "requirements" when they approached Hornady during the development of the Creedmoor was putting the recipe on the box and that they had to use off the shelf componentsI actually said that in my first reply. I also have a photo of the recipe on the box somewhere.

Hornady LRP Brass

FGMM Primers

ADI2209/H4350 - 41.8gn

140 ELD-M with COAL 2.820-2.850 (depending on chamber)

Recipe has given good results in last 3 6.5Creeds with MV of 2724-2740fps

Another charge that always seems work well with 140gn projectiles is 40.7gn +/- 0.1gn

FGMM Primers

ADI2209/H4350 - 41.8gn

140 ELD-M with COAL 2.820-2.850 (depending on chamber)

Recipe has given good results in last 3 6.5Creeds with MV of 2724-2740fps

Another charge that always seems work well with 140gn projectiles is 40.7gn +/- 0.1gn

They list a "recommended reload", which is not their exact recipe.They used to list the recipe right on the box.

Hornady LRP Brass

FGMM Primers

ADI2209/H4350 - 41.8gn

140 ELD-M with COAL 2.820-2.850 (depending on chamber)

Recipe has given good results in last 3 6.5Creeds with MV of 2724-2740fps

Another charge that always seems work well with 140gn projectiles is 40.7gn +/- 0.1gn

My 6.5CM worked awesome with 40.6 grains of H4350 and a 140 grain Hornady BTHP.

My Tikka barrel is just too slow. I need a heavier charge to achieve good velocities. But with 130's and 44.0 grains of RL16, I'm getting 2950+ fps.My 6.5CM worked awesome with 40.6 grains of H4350 and a 140 grain Hornady BTHP.

Last edited:

By the way, the Alpha brass arrived this morning. I ordered 300 pieces of brass. They arrived in a nice range case (100 per case). I selected 10 from each package. The lightest was 171.00gr and the heaviest was 171.78gr with the average right at 171.38gr. That's pretty ridiculous. The Hornady cases were all over the place. Like 6-8gr ES or more. Can't wait to load some up and try them out.

Ended up loading 41 grains of H4350 and CCI 200 primers, with the 140 ELDM. Used once fired American Gunner Factory brass. They were already primed with some old CCI 200's I had laying around, easier then prepping another batch of brass and using the Fed primers.

Used RCBS MatchMaster to seat the bullets (2.810), anyone change or modify the seating stem on these. I was getting a bit of marking on the bullets.

Used RCBS MatchMaster to seat the bullets (2.810), anyone change or modify the seating stem on these. I was getting a bit of marking on the bullets.

There are a couple ways to fix the bullet marking issue. 1. Reduce neck tension with a expander mandrel and/or larger bushing in your sizing die. 2. Use lapping compound on a bullet to polish the seating stem. In my personal experience reducing neck tension was more effective than polishing the seating stem.Ended up loading 41 grains of H4350 and CCI 200 primers, with the 140 ELDM. Used once fired American Gunner Factory brass. They were already primed with some old CCI 200's I had laying around, easier then prepping another batch of brass and using the Fed primers.

Used RCBS MatchMaster to seat the bullets (2.810), anyone change or modify the seating stem on these. I was getting a bit of marking on the bullets.

anyone have a recommendation for 6.5cm in lapua SRP with 205m, 6.5 staball, and 129gr hornady soft point and 140gr hornady ELDM?

Hodgdon has min and max loads for for the 140 Amax which is similar to to the 140 ELDM:anyone have a recommendation for 6.5cm in lapua SRP with 205m, 6.5 staball, and 129gr hornady soft point and 140gr hornady ELDM?

https://www.hodgdonreloading.com/reloading-data-center?rdc=true&type=54

anyone have a recommendation for 6.5cm in lapua SRP with 205m, 6.5 staball, and 129gr hornady soft point and 140gr hornady ELDM?

Have not been able to find Staball 6.5, so no experience with that. But i do know Lapua brass is a little thicker than Hornady, so less internal volume. Have a look at the load books. You might need to reduce powder charge by 0.3 to 0.5 gn if you use the Lapua brass. But that also depends greatly on your chamber.

By the way, the Alpha brass arrived this morning. I ordered 300 pieces of brass. They arrived in a nice range case (100 per case). I selected 10 from each package. The lightest was 171.00gr and the heaviest was 171.78gr with the average right at 171.38gr. That's pretty ridiculous. The Hornady cases were all over the place. Like 6-8gr ES or more. Can't wait to load some up and try them out.

Alpha brass is top quality, but slightly thicker than most. My necks were around 15 thou. Bullet would not drop freeling into the neck after firing, had to apply slight pressure, probably because my MPA rifle has close to a min spec chamber. They shot well, but i decided to neck turn them down anyway, down to 14.0 thou, out of an abundance of caution. [Just something to check. Might well be ok in a standard SAAMI chamber.]

Last edited:

Does anyone have a recommended load with H4350 and Lapua 136gr Scenar L?

Lapua: 39.0-43.1

Hodgdon: 38.4-43.2

I have a new barrel and brass so I figured I would load a known load that works well to season and fireform.

Lapua: 39.0-43.1

Hodgdon: 38.4-43.2

I have a new barrel and brass so I figured I would load a known load that works well to season and fireform.

Similar threads

- Replies

- 28

- Views

- 885

- Replies

- 11

- Views

- 568

- Replies

- 0

- Views

- 212

- Replies

- 3

- Views

- 431

- Replies

- 2

- Views

- 881