I switched from Norma with LRP pocket to Lapua SRP pocket. ES/SD did drop. The Lapua brass is very nice. Wish Lapua made 6GT brass too.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor

- Thread starter Sportin Wood

- Start date

I shot a few over 42 grs of Rl16, Peterson SRP brass, and CCI450s out of a 28" Bartlein. Was getting 2845 fps. Trying to decide between them and the 140 ELDM for a NRL Hunter match. I would need 2715 fps for the 140, 2815 fps for the 135, and 2924 fps for the 130 Norma to make power factor.Anyone shooting 135 A-Tips over 4350 or similar? Looking for approx. velocity.

I get SDs under 9 with about any load of Rl16 and Peterson SRP brass with CCI450s. I also have a jug of 4451 if I run out of RL16. Had good luck with 4451 in my 260 when H4350 was unobtainable 4 or 5 years ago.I am about to invest in some quality brass. I would like some input on large vs. Small primers for 6.5

I have a keg of rl16 and 100v, also 1k each of 147eldm and 140match burners.

24" barrel

Ranges 600 to 1200

Suggestions welcomed

I have the Hornady and alpha 6gt brass. I have finally fire formed all of it so I can compare. I am leaning towards the alpha for the GT.I switched from Norma with LRP pocket to Lapua SRP pocket. ES/SD did drop. The Lapua brass is very nice. Wish Lapua made 6GT brass too.

I burned through a couple of barrels on my 6.5cm using Hornady brass. I tried a nosler and Starline out of my 6.5cm and really didn't see a need to switch. I have lrp Hornady brass with 10 firings that are still usable.

All rounds fired out of a Bergara B14 HMR Wilderness 6.5cm, 24" 8 twist barrel with a EC tuner brake. Ive had a couple factory barrels on it and they shot well enough for what it is. I believe I settled jumping the 140gr Hornady BTHP around 0.050".

Hornady brass, 210M primers, 140gr Hornady BTHP with 41.7gr H4350. It ran around 2730-2740fps.

Hornady brass 210M primers,140gr Hornady BTHP with 45.0gr Superformance at 2720-2730fps

I wound up using Superformance for my backup hunting load.

Hornady brass, 210m primer, 127gr Barnes LRX, 45.2gr Superformance at 2895-2905fps.

To save my H4350 for my new 6GT I started using up my H4831sc with my 6.5cm.

Running Hornady brass, 210M lrp, 140gr bthp with 45.1gr H4831sc at 2735-2750fps.

The smaller case head is stronger. Less primer pocket stretch I believe. I have 200 cases on their 26th firing. Primers still snug.I've noticed many top shooters going with SRP but can anyone tell me why. I'm a math and physics guy. I like numbers.....

I just wanted to thank everyone for posting all of this data. It has really helped me a lot with developing a load of my own. I'll post results when I finish development.I'm in the process of building my 6.5 Creedmoor and I have a few boxes of their 120gr AMAX factory loads, but once those are gone it to the table. I've seen a few loads on here, but they are spread out all over the place. Figured we need a spot for all of them to go. Bullets I'm interested in using are: 130/140 Berger VLD, 120/140 AMAX, 123/139 Scenars, 142 SMK, and 142 Matrix. Haven't decided powder yet, but mostly will go wth H4831sc or H4350.

I didnt load or shoot any 135 A-Tips in 6.5cm...but I did load them up in my 6.5x47L and they shot lights out with Varget. Zero load development, zero seating depth testing. I loaded them up based off comparable weight bullets Ive done load development on in the past out of my x47L.

They shot lights out... I took this load to 1000yd in the snow and it shot 1/3moa. I was sent a few 100 to test... I wouldnt buy them. The new pointed 130smk (no not the 130TMK) shoot just as good as the 135 A-Tips out of my x47L so thats what I shoot. They are awesome to 1000yd and are way cheaper..

5 shot 1st time I tested them..

They shot lights out... I took this load to 1000yd in the snow and it shot 1/3moa. I was sent a few 100 to test... I wouldnt buy them. The new pointed 130smk (no not the 130TMK) shoot just as good as the 135 A-Tips out of my x47L so thats what I shoot. They are awesome to 1000yd and are way cheaper..

5 shot 1st time I tested them..

Im new here so im still finding my way around. Ive seen it before then couldnt find it i just have to play around on here and figure out all the threads or forums i guess thats what their called. Im actually new to this whole kind of platform where everyone can chime in on all the different topics.You might want to check out the 6.5 Creedmoor load data for ARs only thread

Im new here so im still finding my way around. Ive seen it before then couldnt find it i just have to play around on here and figure out all the threads or forums i guess thats what their called. Im actually new to this whole kind of platform where everyone can chime in on all the different topics.

Welcome.

Great place for info!

I had decent luck on Wednesday with a load I shot out of my RPR 6.5 Creedmoor.

140g Barnes Matchburner bullet

41.5g RL16

Federal GM # 210M Match primer

Hornady once fired brass

2.810" C.O.L.

I had a 15 mph wind gusting to 25 mph at 170 degrees relative, it was sunny and the temperature was 34 degrees. I was verifying zero shift after I replaced the Ruger stock with a modified Magpul PRS Gen 3 stock. I managed to shoot a pair of 5 shot groups that measured 3/8" wide x 9/16" high at 100 yards.

Has anyone else had good luck with the Barnes Matchburner bullet? What is your load recipe?

140g Barnes Matchburner bullet

41.5g RL16

Federal GM # 210M Match primer

Hornady once fired brass

2.810" C.O.L.

I had a 15 mph wind gusting to 25 mph at 170 degrees relative, it was sunny and the temperature was 34 degrees. I was verifying zero shift after I replaced the Ruger stock with a modified Magpul PRS Gen 3 stock. I managed to shoot a pair of 5 shot groups that measured 3/8" wide x 9/16" high at 100 yards.

Has anyone else had good luck with the Barnes Matchburner bullet? What is your load recipe?

Putting this up for posterity. I got into the 6.5C last April (Impact w a 26" Stuteville bbl /KRG Bravo). I didn't want to sell a kidney over components. I was able to get some Hornady 140bthp and Starline srp brass at "normal" msrp prices. I had CCI450s already. The powder wasn't there (was looking for H4350 or Staball) but I wanted to start shooting the new bangstick and fireforming brass. I had plenty 2000MR from when I owned a 308AR. I don't recall if I found or guessed a starting point. Shot an OCW and came out with a 0.31" load. Loaded all 250pcs of brass up (measured charges individually) . Shot some here and there at the shorter (100-200yds) with good results. No chronograph yet.

A couple months ago I got a Labradar.

Shot some the other day to get a velocity, which was a bit better than I expected, but oh man do the ES/SD suck. Don't plan on using 2000MR anymore for 6.5C as I have some Staball but it fulfilled it's purpose.

Hornady 140bthp, 37.3gr 2000MR, New Starline SRP brass, CCI450 primers.

COAL: 2.808"

Light crimp.

10 shots

2598fps

ES 90

SD 34

Let my 556 brass processing crew get in some trigger time as well.

A couple months ago I got a Labradar.

Shot some the other day to get a velocity, which was a bit better than I expected, but oh man do the ES/SD suck. Don't plan on using 2000MR anymore for 6.5C as I have some Staball but it fulfilled it's purpose.

Hornady 140bthp, 37.3gr 2000MR, New Starline SRP brass, CCI450 primers.

COAL: 2.808"

Light crimp.

10 shots

2598fps

ES 90

SD 34

Let my 556 brass processing crew get in some trigger time as well.

well i did a new load test on my ruger precision rifle yesterday, using h4350 powder hornady brass cci large rifle primer 147gr eld match hornady ball, 20thou off the lands. found my go to load now. as you can see 41.4 grains of h4350 works perfect, no pressure signs cycles well. and goes like snot. now to clean the gun clean brass and load some more.

Attachments

nice. tried to go more with mine but started getting pressure so stopped at 41.6. tried 30thou off the lands and got nothing working so will be staying at 20thou nowI throated out a 26" Proof so it would jump 147 ELDMs 85 thou from a 2.900" COAL. I was getting 2830fps from 45 grs of RL26 out of Alpha SRP brass. Switched to Alpha LRP brass and the same load shot up to 2900fps! Just backed it down to 44grs and 2820fps.

Anybody ever tried once fired brass that was shot out of a different rifle that even after FL resizing with .002" shoulder bump would not chamber in your new barrel?

I have like 1000 pieces of once fired hornady brass that was shot out of two factory 6.5 creedmoors along with a couple 100 pieces of Prime. The prime I could not get to chamber in my new barrel at all with anything less than .004" bump. The hornady will chamber like 90% of the time but is snug and 10% wont chamber at all with .002" bump.

Factory ammo runs smooth. Once fired brass that was shot in the new chamber runs smooth. I have checked it with headspace gauges and it passes. When I sharpie the old brass that was shot out of the old rifles it is clearly sticking around the base of the case. Just wondering if there is possibly a problem with this barrel or if it is just a tighter chamber when compared to the ones in my old rifles and I will just have to use new brass that was fired in the new chamber? Any insight is greatly appreciated.

Thanks!

I have like 1000 pieces of once fired hornady brass that was shot out of two factory 6.5 creedmoors along with a couple 100 pieces of Prime. The prime I could not get to chamber in my new barrel at all with anything less than .004" bump. The hornady will chamber like 90% of the time but is snug and 10% wont chamber at all with .002" bump.

Factory ammo runs smooth. Once fired brass that was shot in the new chamber runs smooth. I have checked it with headspace gauges and it passes. When I sharpie the old brass that was shot out of the old rifles it is clearly sticking around the base of the case. Just wondering if there is possibly a problem with this barrel or if it is just a tighter chamber when compared to the ones in my old rifles and I will just have to use new brass that was fired in the new chamber? Any insight is greatly appreciated.

Thanks!

Anybody ever tried once fired brass that was shot out of a different rifle that even after FL resizing with .002" shoulder bump would not chamber in your new barrel?

I have like 1000 pieces of once fired hornady brass that was shot out of two factory 6.5 creedmoors along with a couple 100 pieces of Prime. The prime I could not get to chamber in my new barrel at all with anything less than .004" bump. The hornady will chamber like 90% of the time but is snug and 10% wont chamber at all with .002" bump.

Factory ammo runs smooth. Once fired brass that was shot in the new chamber runs smooth. I have checked it with headspace gauges and it passes. When I sharpie the old brass that was shot out of the old rifles it is clearly sticking around the base of the case. Just wondering if there is possibly a problem with this barrel or if it is just a tighter chamber when compared to the ones in my old rifles and I will just have to use new brass that was fired in the new chamber? Any insight is greatly appreciated.

Thanks!

Yes I have...did you measure 1x brass that WAS fired in your rifle and compare measurements to brass in question to see where the problem lies? Might have to bump more...small base die....need trimmed....only you can answer those questions

Yea so 1x fired in my gun is 1.532" I dont remember exactly what it was 1x fired out of the old rifles but I know it was longer. But bumping them back to 1.530" I am still running into issues. I am trimming them all to the recommended length 1.910" I think. I have tried bumping some significantly more even down to 1.526" which is about all my die will do and still run in to the same issues with some of the cases. Sounds like a small base die would be my next step.Yes I have...did you measure 1x brass that WAS fired in your rifle and compare measurements to brass in question to see where the problem lies? Might have to bump more...small base die....need trimmed....only you can answer those questions

Yea so 1x fired in my gun is 1.532" I dont remember exactly what it was 1x fired out of the old rifles but I know it was longer. But bumping them back to 1.530" I am still running into issues. I am trimming them all to the recommended length 1.910" I think. I have tried bumping some significantly more even down to 1.526" which is about all my die will do and still run in to the same issues with some of the cases. Sounds like a small base die would be my next step.

Yep then that would leave larger base which you can just buy a small base die to fix...

Easy way is to sharpie the case and chamber...see where it's rubbing....you can wipe the case clean to remove sharpie with running alcohol

Yep I sharpied a couple of them and am getting about an 1/8" ring around the base of the case so Small base should fix me up. Will give it a try. Thanks!Yep then that would leave larger base which you can just buy a small base die to fix...

Easy way is to sharpie the case and chamber...see where it's rubbing....you can wipe the case clean to remove sharpie with running alcohol

Hornady brass... Probably the problem. Voice of experience.Anybody ever tried once fired brass that was shot out of a different rifle that even after FL resizing with .002" shoulder bump would not chamber in your new barrel?

I have like 1000 pieces of once fired hornady brass that was shot out of two factory 6.5 creedmoors along with a couple 100 pieces of Prime. The prime I could not get to chamber in my new barrel at all with anything less than .004" bump. The hornady will chamber like 90% of the time but is snug and 10% wont chamber at all with .002" bump.

Factory ammo runs smooth. Once fired brass that was shot in the new chamber runs smooth. I have checked it with headspace gauges and it passes. When I sharpie the old brass that was shot out of the old rifles it is clearly sticking around the base of the case. Just wondering if there is possibly a problem with this barrel or if it is just a tighter chamber when compared to the ones in my old rifles and I will just have to use new brass that was fired in the new chamber? Any insight is greatly appreciated.

Thanks!

Yea was considering buying some Lapua but I have so much of this stuff I hate not to use it.Hornady brass... Probably the problem. Voice of experience.

Hornady brass... Probably the problem. Voice of experience.

Funny I have a few thousand pieces of Hornady 6.5cm I bought when it was the only game in town for 6.5cm.. never had a single issue in shit 10-11 6.5cm barrels in both my custom gasser and bolt guns... still shooting it today...refuse to use any other 6.5cm brass till I shoot all this Hornady out..

Absolutely nothing wrong with it. The Indian or the chamber are the issue 99.999% of the time

Been there.... I had a 1000 new cases I finally sold.Funny I have a few thousand pieces of Hornady 6.5cm I bought when it was the only game in town for 6.5cm.. never had a single issue in shit 10-11 6.5cm barrels in both my custom gasser and bolt guns... still shooting it today...refuse to use any other 6.5cm brass till I shoot all this Hornady out..

Absolutely nothing wrong with it. The Indian or the chamber are the issue 99.999% of the time

Been there.... I had a 1000 new cases I finally sold.

You been where? Tell us these Hornady issues you had with 6.5cm brass that was directly attributed to the brass itself...

In the situation of a stockpile of brass that didn't workYou been where?

In the situation of a stockpile of brass that didn't work

You're still not answering the question... didn't work why? You said the OP problem was Hornady brass.. but have yet to say why. You fire brass in a looser chamber, I don't care what brand brass it is, then try and use it in another chamber that has a match or tighter chamber of course its not going to fit. That's not the brass fault

Last edited:

Yes sir!!You're still not answering the question... didn't work why? You said the OP problem was Hornady brass.. but have yet to say why. You fire brass in a looser chamber then try and use it in another chamber that has a match or tighter chamber of course its not going to fit. That's not the brass fault

I dont know about hornady brass. I was using federal small primer brass in a 6.5 creed gasser with no issues, S&B large

primer brass no issues. Went to hornady brass and started blowing primers. Reduced the load to 40.3gr of H4350 over a 140

and still 3 out of 10 primers popped due to the case head expanding.

primer brass no issues. Went to hornady brass and started blowing primers. Reduced the load to 40.3gr of H4350 over a 140

and still 3 out of 10 primers popped due to the case head expanding.

Disclaimer: I am new to reloading and I can only speak from my specific experience.Yea so 1x fired in my gun is 1.532" I dont remember exactly what it was 1x fired out of the old rifles but I know it was longer. But bumping them back to 1.530" I am still running into issues. I am trimming them all to the recommended length 1.910" I think. I have tried bumping some significantly more even down to 1.526" which is about all my die will do and still run in to the same issues with some of the cases. Sounds like a small base die would be my next step.

I had some similar issues with difficulty closing the bolt with my full length sized, 0.002” shoulder bumped cases.

Long story short, my Remington large rifle primer needed more oomph to fully seat than my CCI primers. It was sticking out ~0.002” past the base. Now I run my fingernail over the case/primer after every primer seating just to make sure that it’s fully seated.

I wish you the best in resolving your bolt closure issue.

YMMV, happy shooting

I just recently picked up some small primer brass ive always used large pocket brass. Can i keep my loads the same to start off and just do a little load tweaking as i go or do i need to start all over with the small brass. Question#2 i see alot of people switching and using mad. Primers wether it be 450s or 215s. How much of a difference does the mag. Primers make and pressures do the produce. I would like to try them out being that i have tons of them. Do i need to start a complete load ladder from start to max. Or do they not make a huge difference. I know i will have to work my way thru some components to get the particular load my rifle likes but ive been using all 210ms and BR. Does someone have any insight they would like to help out with or some data using mag primers large and small. Thanks

I just recently picked up some small primer brass ive always used large pocket brass. Can i keep my loads the same to start off and just do a little load tweaking as i go or do i need to start all over with the small brass. Question#2 i see alot of people switching and using mad. Primers wether it be 450s or 215s. How much of a difference does the mag. Primers make and pressures do the produce. I would like to try them out being that i have tons of them. Do i need to start a complete load ladder from start to max. Or do they not make a huge difference. I know i will have to work my way thru some components to get the particular load my rifle likes but ive been using all 210ms and BR. Does someone have any insight they would like to help out with or some data using mag primers large and small. Thanks

No. You should always drop down and work up changing any component. Small rifle primer brass is generally thicker, less case capacity so generally have to drop down your charge

Ok so i should just work up a completely new load with the small pocket brass and i figured if i switched to mag. Primers i would do the same i knew i couldn't or shouldn't start with my reg. Load i was thinking if i just went out of the hornady book and started in the middle of the feild and work my way up. I see so many people using the mag. Primers im guessing theres a good reason for it so wanted to give it a try.No. You should always drop down and work up changing any component. Small rifle primer brass is generally thicker, less case capacity so generally have to drop down your charge

Like with my blackout loads if i go out of the book it says SRP and a certain charge is max with reg. Primers then i look at hodgdons site and there charges are way up there and using mag. Primers on top of the heavy charges and my loads got so much better in every way possible so i was thinking this might be the same caseNo. You should always drop down and work up changing any component. Small rifle primer brass is generally thicker, less case capacity so generally have to drop down your charge

Question regarding 100fps change when barrel is cold.

Just worked up a load:

140 match burners

Lapua srp brass

RL16 42.9

2786fps es14 sd4

24" barrel

.5 groups at 100

Used Satterly ladder method to get here.

Went to range yesterday to confirm and also bang steel at long range.

My first 5 shots on cold barrel with this load

2672fps es17 sd 6

Loaded up another 5 and went back to normal

2785fps es15 sd 5

It struck me as very odd the first five would all be almost exactly 100fps slower.

What would cause this? I've found RL16 to be very temp stabile so this was a surprise. Could it has been the chrono? I also deep cleaned barrel previous with Iosso?

The rest of day was fine. Banged steel at 1200 no prob.

Just worked up a load:

140 match burners

Lapua srp brass

RL16 42.9

2786fps es14 sd4

24" barrel

.5 groups at 100

Used Satterly ladder method to get here.

Went to range yesterday to confirm and also bang steel at long range.

My first 5 shots on cold barrel with this load

2672fps es17 sd 6

Loaded up another 5 and went back to normal

2785fps es15 sd 5

It struck me as very odd the first five would all be almost exactly 100fps slower.

What would cause this? I've found RL16 to be very temp stabile so this was a surprise. Could it has been the chrono? I also deep cleaned barrel previous with Iosso?

The rest of day was fine. Banged steel at 1200 no prob.

sound's like something happened at the bench. I dont know your process reloading were those rounds loaded consecutively. Pretty odd to have those exact same numbers with the same 5 consecutive rounds

Anyone have some load data for 6.5CM, H4350, Berger 153.5gr?

This is what I got from Bob Blaine at Berger for the 153.5. Will try them out next week when I am home. I bought some loaded ones from Berger and they shoot very well at 100-200yds so far(new Sig Cross) so far. 2548fps. SD7

This is what I got from Bob Blaine at Berger for the 153.5. Will try them out next week when I am home. I bought some loaded ones from Berger and they shoot very well at 100-200yds so far(new Sig Cross) so far. 2548fps. SD7

Anyone have a good 153.3 Berger Load with lapua brass and H4350? Thinking of running this for NRL hunter.

Haven't tried them with 4350 but I'm getting 2833 with 43.8 of rl16. 22 inch Columbia River arms barrel. Barrel has always been a little slow but it shoots awesomeAnyone shooting 135 A-Tips over 4350 or similar? Looking for approx. velocity.

Just before Christmas, I had 100rd loaded up and went to sight in my rifle after a hunt for the new ammo. I shot a couple rounds and then started checking the brass. And there the signs were. I started getting pressure signs and hard lifts. I stopped after 12 rounds. Looks like I have to go back to a lower node and everyone was correct. A node I found was at 2,544fps at 41.6-41.9gr of H4350. I saw it initially but it just seems so slow. I really want more speed. I am going to try this range again to see if the velocity is correct and if my barrel is speeding up. It only has about 120rds through it.Here’s an update.

I went to the range today to find a for sure upper limit. I found it and I saw ejector marks. I didn’t get to the speed I was looking. I saw them at 45gr and around 2,730fps. I stopped.

I did load some ammo and adjusted the seating depth based on previous ladder test. It looks like I am going to shoot 43.9gr.

My powder and primers are about 2yrs old. They have been stored in my safe and in my air condition house. I know that can make a difference but I’m hoping it isn’t this time. I have almost a whole 8lb jug and 2k primers.

My barrel is a Terminus profit cut by Straight Jacket Armory and it’s their SAAMI chamber.

I am going to load my rounds and hopefully next trip sight in my rifle. Happy shooting.

Also is anyone running 140gr Berger Hybrids in a 20" barrel with Varget? If so, what speeds are you seeing at those loads?

Thanks in advance.

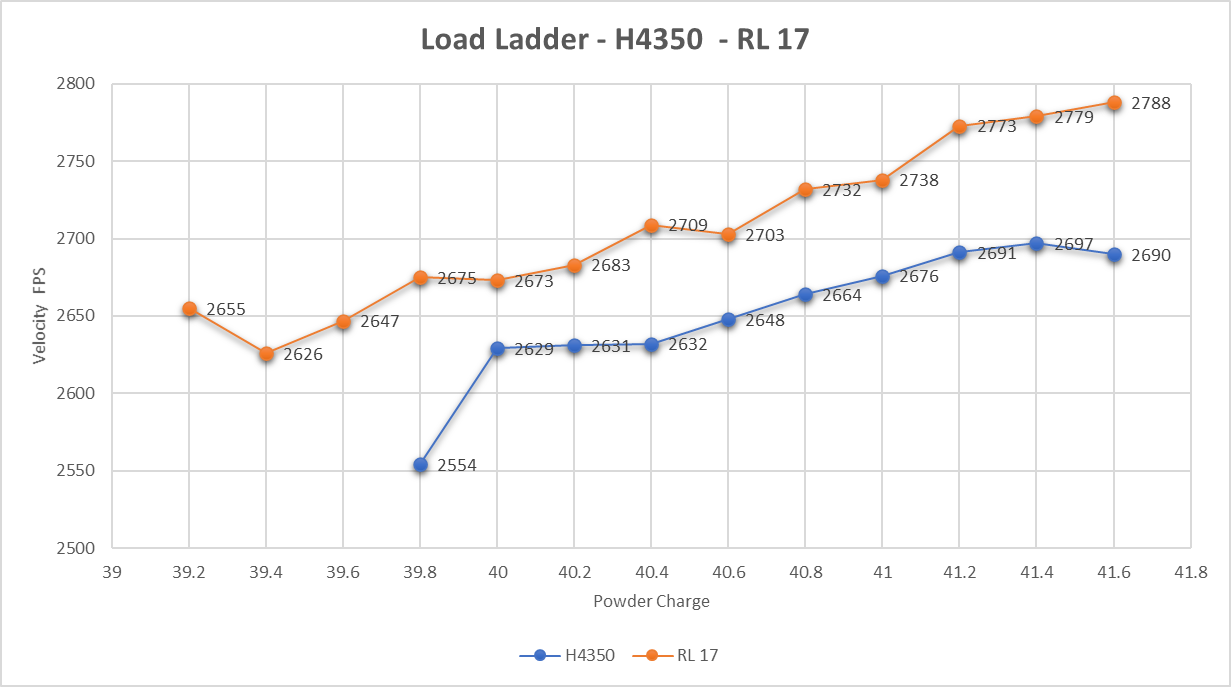

@shax2lex - no to your last question, but here's some data I just finished yesterday using 140gr ELD-M's with H4350 and RL17. I've settled on loads at the lower nodes shown on the attached graph. The 2554 value on the H4350 was the first shot - cold powder, barrel, about 30* F.

Attachments

Last edited:

Loaded up 5 rounds to test after running through a small base die and everything ran perfect... Thanks!Yes I have...did you measure 1x brass that WAS fired in your rifle and compare measurements to brass in question to see where the problem lies? Might have to bump more...small base die....need trimmed....only you can answer those questions

Is there any reasoning why a slower burning power would get my speed out of a short barrel? It seems like a slower burning powder would need a longer barrel to generate the speed. You are shooting a 20in barrel, correct?@shax2lex - no to your last question, but here's some data I just finished yesterday using 140gr ELD-M's with H4350 and RL17. I've settled on loads at the lower nodes shown on the attached graph. The 2554 value on the H4350 was the first shot - cold powder, barrel, about 30* F.View attachment 7781980

It’s the Bergara BMP with a 24” barrel and a Hellfire on- if that matters. That (barrel length) is likely the difference.Is there any reasoning why a slower burning power would get my speed out of a short barrel? It seems like a slower burning powder would need a longer barrel to generate the speed. You are shooting a 20in barrel, correct?

Last edited:

Got 8 pounds of superformance local today. Have cci 200 primers and 142 smk anyone else running this combo??

I had good luck a while ago around 44gn. I'd have to pull my notes but I think I was around standard length 2.825 or so.

Superformance builds pressure towards the top charges more progressively, but drops pretty good from a measure so worked for me for a bit.

I have been working up some loads for 6.5 using Hybrid 100V and RL16. Been using 140 match burners and 147 eldm. I started by using Lapua sm primer brass. My results with the 147 eldm were pretty average. Got some nice groups, Es, and Sd using RL16 but speeds were slow (2670ish with some really weird drop at 42.7 grains).

The 100V results with 147eldm were horrible. All groups over an inch and SD's above 20. The ladder range was 42.1 to 42.9 at .2 increments. Speeds slower than RL16. Very unimpressed

So I decided to try Hornady brass I had which is large primer.

I did two Ladder tests of 147 eldm using 100V and RL16 with hornady leg prime brass.

I included pics of notes but here are best results:

147eldm RL16 42.5grains 2740fps Es12 SD5

.5inch group horn lrg prime brass

147eldm H100V 43.1grains 2759fps Es16 Sd7 .7inch group horn lrg prime brass

From my earlier work using Lapua sm prime I got a fantastic load using RL16 and 140MB's

140MB RL16 42.9grains 2772fps Es15 Sd5 Lapua sm rifle primer brass. I have shot about 50 rounds using this load with consistent groups of .4inch and Sd's of 5.

I hit 10" steel at 950yards 7 of 10 with this load.

Rifle is Savage 110 24" heavy barrel

The 100V results with 147eldm were horrible. All groups over an inch and SD's above 20. The ladder range was 42.1 to 42.9 at .2 increments. Speeds slower than RL16. Very unimpressed

So I decided to try Hornady brass I had which is large primer.

I did two Ladder tests of 147 eldm using 100V and RL16 with hornady leg prime brass.

I included pics of notes but here are best results:

147eldm RL16 42.5grains 2740fps Es12 SD5

.5inch group horn lrg prime brass

147eldm H100V 43.1grains 2759fps Es16 Sd7 .7inch group horn lrg prime brass

From my earlier work using Lapua sm prime I got a fantastic load using RL16 and 140MB's

140MB RL16 42.9grains 2772fps Es15 Sd5 Lapua sm rifle primer brass. I have shot about 50 rounds using this load with consistent groups of .4inch and Sd's of 5.

I hit 10" steel at 950yards 7 of 10 with this load.

Rifle is Savage 110 24" heavy barrel

Attachments

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 28

- Views

- 1K

- Replies

- 20

- Views

- 921