What barrel length is this out of, 24"?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6GT current loads and progress

- Thread starter MachoMan

- Start date

What twist?

It’s a Hawk Hill 26” 1:7.5 twist

Out of stock but more should be coming.

www.gaprecision.net

www.gaprecision.net

Alpha Munitions 6mm "Gay Tiger" GT Brass

6mm Gay Tiger(GT) Brass, Now in Stock with the New Packaging!

Does anyone know what all is needed to load for the 6mm GT on a Dillon 650? I have several other calibers and may be able to piece the parts together.

I’ve searched here and google with no success. Even left 3 messages and an email with Dillon and haven’t heard back.

Thanks

Jim

I’ve searched here and google with no success. Even left 3 messages and an email with Dillon and haven’t heard back.

Thanks

Jim

Man, thanks a lot Reubenski!

Snipers Hide members again come through for each other!

Snipers Hide members again come through for each other!

I’m set up for 308 so that will help a lot. I need to look into the Mr Bulletfeeder conversion. Only load pistol bullets with mine and it makes loading so much nicer!

Thanks for the offer of the Dillon numbers but it looks like I have all those parts and I have a powder funnel and die for 243 so maybe that’ll work too.

Jim

I’m set up for 308 so that will help a lot. I need to look into the Mr Bulletfeeder conversion. Only load pistol bullets with mine and it makes loading so much nicer!

Thanks for the offer of the Dillon numbers but it looks like I have all those parts and I have a powder funnel and die for 243 so maybe that’ll work too.

Jim

What powder are you using? actually will you share all your load data? This is pretty interesting. I load some mean 223 precision loads but haven’t had the balls to try one of my 6mm’s on my progressive yet. I’m also assuming you’re doing all your brass prep separately right? I already seat decap and mandrel on mine, so getting the primer and powder is all that’s setting me back.No problem. Ive really enjoyed automating my 650 as much as I can(without an autosrive) so it's an enjoyable task for me. The powder die insert(little slide'y funnel) is the same for GT and 243.

For the bullet dropper, I used two 6.5mm bearings in the top row of detents and a .223 bearing in the bottom row. This is the only way I was able to get it to work. The 6.5mm hopper plate comes with two sections. Basically a two-layered cake type of deal. You'll need both for the long .243 bullets to work. Getting the hopper to fees was the most frustrating part.

What kind of consistency are you getting through your powder drop? .1gr? With staball specifically. I’ve got my hornady drop to do cfe black/223/pistol to do a es of .06gr I’m very very pleased with that. Also do you have crono numbers? For your gt with staball. I have 8lbs of this stuff and didn’t have any luck in my wife’s old creed.Sure.

.223, 75gr Hornady BTHP, 23.5gr 8208, mag length, Rem 6 1/2 primers, Dillon powder measure

Brass prepped separately. Ready to load.

6mmBR, 107 SMK 10 thou off, 29.4gr 8208, 10 thou jump, CCI BR4

Brass prepped separately. Ready to load. But I can just swap out the sizing die and reload the cases dirty. Using a Redding BR30 to throw powder. And a 6mm mandrel in pos 1 to set neck tension and ensure all necks are round when I prep brass/ on a different toolhead.

6GT, 107SMK 10 thou off, 38.2gr StaBall, CCI BR4, Hornady Brass, Redding BR30 manually operated.

Brass prepped separately. Ready to load. But again, Every once in a while I'll just lube dirty brass, put my sizing die in pos 1, and run it dirty.

308W, Hornady 178gr BTHP, 44gr BLC2, LC brass, Win LR primers, RCBS case activated drop.

Brass prepped on a case prep toolhead in the thousands.

300BO, 190gr Nosler CC @ 2.185", 6.8gr Hornady Longshot, CCI small pistol primers

Prepped, ready to load on a seperate toolhead. Using a Dillon powder measure

Case prep.

6br/ GT: i run it through the machine with just a Universal decapping die, wash, dry, anneal, lube and run through again with a sizing die, wash, and dry again.

.223 and 300BO: decapping die, press mounted swage it, RT1500 trimmer/ sizing trim die, Lyman M die to wear down the trimming burs and bell the mouths slightly. Wash, dry, ready to load.

I trim PR cartridges by exception, when necessary in large batches, on a Henderson motor powered trimmer.

Also this 8208 stuff I keep hearing folks talk about it like it’s the new unicorn powder. Did you ever load varget in your br, is it comparable? What are the numbers in powder drop es and crono? I’d love to load this without trickling everything. (I switched my wife to a 6br this year because she can burn a barrel out better than anyone I’ve ever met, lol)

Unfortunately, i am not getting ES of .1 powder charges. In anything besides an Autotrickler. I get SDs of around 15 in just about everything I mentioned above.

The whole 6mm/ progressive thing for me started when I did load development for a buddy. I helped him get into a Tikka CTR, 24" 6.5 Creedmoor. KRG Bravo, etc. I bought all his reloading components cheap. Hornady bulk pack 140 ELDMs at $.28 each and bulk pack Hornady brass at $.35 ea. $35 die set. I was loading on my 550 at the time. I tried RL17(bc I have a bunch I wanted to get rid of) and RL23. Then he saw I had an 8lb'r of StaBall and he'd heard the myth about it and insisted I try it. I did a powder ladder at 300yds and it was amazing. Huge flat node from 44gr to 45.5g. 1.2" groups. 2800fps out of a slow Tikka barrel. I chrono'd a couple of confirmation groups 4 days in a row, dialing in a Lee Perfect Powder Measure on a powder die on the 550. Comparing trickled and thrown charges to see if I could get away with just throwing bc I was about to load 500rds for him when I got everything confirmed and dialed in. It held, day after day. Finally, I took him out to shoot it before I committed to loading the 500rds for him. He shot 5rds trickled and 5rds thrown at 100yds. Both were a ragged hole. The SD on the trickled loads was 3. On the thrown charges it was....2.3! The charge weights weren't under .1 ES. I think the node was so flat that the error just hid in the white noise of the SDs. So I loaded 500rds for him on the 550 in an evening. Every other month for the last year, he has messaged me to tell me what a hammer the rifle is.

So this became my goal with 6mm BR. I figured it was the 6mm cartridge most likely to provide a wide node. Unfortunately I never found one with Varget, 8208, and H4895. I also played with StaBall in the BR and got some pretty amazing velocities and only a small flat node. So I decided at the time to try 8208 because it throws so well in a Dillon powder measure. I use it in my .223, get mid-teens SDs and really great accuracy. Worked out pretty similar in 6BR. Decent, but not amazing. 29.4gr gives me 2880 in a 28" barrel. By comparison I was getting 2900 with 30.5gr Varget. It is on the high end of pressure. I should probably try a much lower charge weight and see if it nodes.

So my goal was to find nodes to hide charge weight inconsistencies. Just didn't work out like it did for the 6.5 Creed. But I found SDs in the mid teens to be tolerable. The last club match I loaded 100rds of 6GT using StaBall in about 20 minutes and tied for first. We had 3 stages out to 1100 and one out to 1200. I had no elevational misses the entire day. SDs in the low teens. Worked like gangbusters.

So that's my long story, lol

Have you tried mix/matching powders with different primers? Or just using same primer? Obviously the current market you use what you can find.

Unfortunately, i am not getting ES of .1 powder charges. In anything besides an Autotrickler. I get SDs of around 15 in just about everything I mentioned above.

The whole 6mm/ progressive thing for me started when I did load development for a buddy. I helped him get into a Tikka CTR, 24" 6.5 Creedmoor. KRG Bravo, etc. I bought all his reloading components cheap. Hornady bulk pack 140 ELDMs at $.28 each and bulk pack Hornady brass at $.35 ea. $35 die set. I was loading on my 550 at the time. I tried RL17(bc I have a bunch I wanted to get rid of) and RL23. Then he saw I had an 8lb'r of StaBall and he'd heard the myth about it and insisted I try it. I did a powder ladder at 300yds and it was amazing. Huge flat node from 44gr to 45.5g. 1.2" groups. 2800fps out of a slow Tikka barrel. I chrono'd a couple of confirmation groups 4 days in a row, dialing in a Lee Perfect Powder Measure on a powder die on the 550. Comparing trickled and thrown charges to see if I could get away with just throwing bc I was about to load 500rds for him when I got everything confirmed and dialed in. It held, day after day. Finally, I took him out to shoot it before I committed to loading the 500rds for him. He shot 5rds trickled and 5rds thrown at 100yds. Both were a ragged hole. The SD on the trickled loads was 3. On the thrown charges it was....2.3! The charge weights weren't under .1 ES. I think the node was so flat that the error just hid in the white noise of the SDs. So I loaded 500rds for him on the 550 in an evening. Every other month for the last year, he has messaged me to tell me what a hammer the rifle is.

So this became my goal with 6mm BR. I figured it was the 6mm cartridge most likely to provide a wide node. Unfortunately I never found one with Varget, 8208, and H4895. I also played with StaBall in the BR and got some pretty amazing velocities and only a small flat node. So I decided at the time to try 8208 because it throws so well in a Dillon powder measure. I use it in my .223, get mid-teens SDs and really great accuracy. Worked out pretty similar in 6BR. Decent, but not amazing. 29.4gr gives me 2880 in a 28" barrel. By comparison I was getting 2900 with 30.5gr Varget. It is on the high end of pressure. I should probably try a much lower charge weight and see if it nodes.

So my goal was to find nodes to hide charge weight inconsistencies. Just didn't work out like it did for the 6.5 Creed. But I found SDs in the mid teens to be tolerable. The last club match I loaded 100rds of 6GT using StaBall in about 20 minutes and tied for first. We had 3 stages out to 1100 and one out to 1200. I had no elevational misses the entire day. SDs in the low teens. Worked like gangbusters.

So that's my long story, lol

I’ve gotta be the worst reloader on here but have you tried N150 ? I just loaded a nice round 30.0gr into my 28” BR and get 2830 FPS and an SD of 7 over a 10 round string using a Chargesmaster. It meters very well but I get the occasional over throw but don’t bother throwing those again so I’m sure better results are achievable.

You want a ball powder for 6 BR, try CFE223.Unfortunately, i am not getting ES of .1 powder charges. In anything besides an Autotrickler. I get SDs of around 15 in just about everything I mentioned above.

The whole 6mm/ progressive thing for me started when I did load development for a buddy. I helped him get into a Tikka CTR, 24" 6.5 Creedmoor. KRG Bravo, etc. I bought all his reloading components cheap. Hornady bulk pack 140 ELDMs at $.28 each and bulk pack Hornady brass at $.35 ea. $35 die set. I was loading on my 550 at the time. I tried RL17(bc I have a bunch I wanted to get rid of) and RL23. Then he saw I had an 8lb'r of StaBall and he'd heard the myth about it and insisted I try it. I did a powder ladder at 300yds and it was amazing. Huge flat node from 44gr to 45.5g. 1.2" groups. 2800fps out of a slow Tikka barrel. I chrono'd a couple of confirmation groups 4 days in a row, dialing in a Lee Perfect Powder Measure on a powder die on the 550. Comparing trickled and thrown charges to see if I could get away with just throwing bc I was about to load 500rds for him when I got everything confirmed and dialed in. It held, day after day. Finally, I took him out to shoot it before I committed to loading the 500rds for him. He shot 5rds trickled and 5rds thrown at 100yds. Both were a ragged hole. The SD on the trickled loads was 3. On the thrown charges it was....2.3! The charge weights weren't under .1 ES. I think the node was so flat that the error just hid in the white noise of the SDs. So I loaded 500rds for him on the 550 in an evening. Every other month for the last year, he has messaged me to tell me what a hammer the rifle is.

So this became my goal with 6mm BR. I figured it was the 6mm cartridge most likely to provide a wide node. Unfortunately I never found one with Varget, 8208, and H4895. I also played with StaBall in the BR and got some pretty amazing velocities and only a small flat node. So I decided at the time to try 8208 because it throws so well in a Dillon powder measure. I use it in my .223, get mid-teens SDs and really great accuracy. Worked out pretty similar in 6BR. Decent, but not amazing. 29.4gr gives me 2880 in a 28" barrel. By comparison I was getting 2900 with 30.5gr Varget. It is on the high end of pressure. I should probably try a much lower charge weight and see if it nodes.

So my goal was to find nodes to hide charge weight inconsistencies. Just didn't work out like it did for the 6.5 Creed. But I found SDs in the mid teens to be tolerable. The last club match I loaded 100rds of 6GT using StaBall in about 20 minutes and tied for first. We had 3 stages out to 1100 and one out to 1200. I had no elevational misses the entire day. SDs in the low teens. Worked like gangbusters.

So that's my long story, lol

Like I said before in the very least it might stay in a tighter node, it meters amazingly for me. In my Hornady measures. Which are rotary like your Redding. It doesn’t have the temp stability of most though. In Dallas we shoot in 40-105 degree temps. I found that out the hard way, I developed in January and was blowing primers in July lolWhy? Do you think it will node or provide better SD's? I'd agree, it's burn rate is probably about right. TAC probably is too.

Yeah, mostly the burn rate is good, some people have had good results with it. I’ve only used it for fireforming with crappy bullets so I’m not sure I have a strong opinion one way or another. But it’s probably worth trying.Why? Do you think it will node or provide better SD's? I'd agree, it's burn rate is probably about right. TAC probably is too.

My experience with StaBALL in the GT has been tiny groups and moderate SDs.

I worked up loads for both the 112 Match Burner using Varget and the 115 DTAC using H4350 based on what others had done. Both shoot very well, under .5 MOA. Now I'm doing a round of seating depth tests with a lower powder charge (33.5 instead of the 34.1 I did my initial test with) on the 112's from 0.020 to 0.110 off the lands to see if what I heard about larger jumps is true. Just something to do...

@todd How did your 115 DTAC load work out?

Jamming or jumping those 109's. New gt this year still trying to decide what bullets , have a long neck long throat for 115 DTAC's . Some H-4350, some 6.5 Staball , but 37.2 is best so far with 115vld . Still trying to decide where to go with limited supplies. Probably just shoot BR this year at 300.Running 37.6 gr of H4350 with Berger 109

Jumped. They are hybrids, I realized they don't care what you do with them.Jamming or jumping those 109's. New gt this year still trying to decide what bullets , have a long neck long throat for 115 DTAC's . Some H-4350, some 6.5 Staball , but 37.2 is best so far with 115vld . Still trying to decide where to go with limited supplies. Probably just shoot BR this year at 300.

I am a benchrest shooter mostly 300yrd. Light neck tension so we tend to jam. I thank you for posting your data . I have been very limited on supplies so hard to decide where to go with what components. Only have about one pound H-4350 . Tried staball but small node and quick pressures. Around 36.8 with 115 Dtac was pretty good , just looking for bug hole load. Then hopefully get components. Thanks and good shooting.from N.Y.Jumped. They are hybrids, I realized they don't care what you do with them.

37.0 H-4350 109hybrid LR at three hundred five shots.

Sorry to bring this thread back to life.I've tried CCI 450's, BR, and 400's. I don't have anything else. I honestly haven't seen a difference between BR and 450's. Ever. I can't shoot the 400's in my GT bc its ona LFP AI. Pierces 400's pretty regularly.

I built my 6 GT from a Savage Model 12 with a Criterion MTU barrel. I placed it in an MDT XRS chassis, with a gen 1 PST scope on it.

Day 1: I was able to shoot my newly built 6GT with Copper Creek's Hornady (GAP) brass and 108 ELD-M's. They really grouped well. So, the build proved it worked with the Copper Creek's Ammo. Time to put on my EC Tuner Brake and reload some! Woop!

Day 2: Did some reloads with Varget, Hornady (GAP) brass, and CCI 400 primers. I fired 2 sighters with Varget 33.5 and 1 with Varget 33.2... And saw that it was piercing the primers from the reloads. So, I retired the handloads and resumed shooting the rest of my Cooper Creek ammo (ELD-M 108's and Lapua Scenar 105's) with no issues. Man, this thing can shoot... just not my loads.

Day 3: I shortened the length as according to the Hornady OAL (I was just .007 off). So, I shortened the seating by an additional .015 (.022 off) with the 33.2g's. Plus, I brought a chrono to see what the velocity was. First shot didn't get picked up by the chrono and it pierced the primer. DANG IT!! I adjusted the chrono to being 1 number more sensitive and shot the 2nd one. Of course, it pierced the primer, but I did get the velocity of 2862.

I was scratching my head and came across Reubenski's post in this thread about his GT piercing the 400's regularly. Thank you for posting this Reubenski!! You may have saved me several more trips to the range, and I have some hope and know to try a different primer for the next round. haha

Again, my apologies for bring this back from the dead, but wanted to say my thanks and share that I may have the same issue with 400's. We will see.

Thanks,

-Dave

Thanks NiteQwill and Reubenski!

I have the following small rifle primers:

CCI BR-4

Federal GM205M

CCI 41

CCI 400 (as mentioned before)

But no 450's.... I will keep my eyes out for them, but these days I try to buy whatever I can find.

Glad that I have something that is known to work well with the 6GT. Bummer that the BR-4's were by far the most expensive in my inventory. While breaking in the barrel, I was cheaping out with the 400's. Given this issue, I was about to try the 41's or the GMM's. If I need to use my BR-4's, I certainly will. That's why I got them. haha

I'm pretty new to reloading... just finished my first year. Is this normal for the CCI 400's to be an issue, or is this a 6GT thing?

Thanks again!

-Dave

I have the following small rifle primers:

CCI BR-4

Federal GM205M

CCI 41

CCI 400 (as mentioned before)

But no 450's.... I will keep my eyes out for them, but these days I try to buy whatever I can find.

Glad that I have something that is known to work well with the 6GT. Bummer that the BR-4's were by far the most expensive in my inventory. While breaking in the barrel, I was cheaping out with the 400's. Given this issue, I was about to try the 41's or the GMM's. If I need to use my BR-4's, I certainly will. That's why I got them. haha

I'm pretty new to reloading... just finished my first year. Is this normal for the CCI 400's to be an issue, or is this a 6GT thing?

Thanks again!

-Dave

That makes sense as the 400's work like a champ with my 223 loads.

Thanks again for sharing your info and experience! I really was scratching my head, esp. after I made the pullet jump at least .022 and still saw the pierced primers with what appears to be a couple of common charge weights of Varget.

I look forward to doing my reloads with the right primers the next time, and learning more from you guys!

-Dave

Thanks again for sharing your info and experience! I really was scratching my head, esp. after I made the pullet jump at least .022 and still saw the pierced primers with what appears to be a couple of common charge weights of Varget.

I look forward to doing my reloads with the right primers the next time, and learning more from you guys!

-Dave

Last edited:

Okay... as I am trying to source CCI 450's for my 6GT to address my pierced primer issue, I was researching what I have in inventory that may work instead.

According to this post as the source from Ultraman550:

It looks like CCI 41's are a very close alternative to the 450's, and I have some of that. Any thoughts on using the 41's instead? If for some reason the 41's don't work, I'll use my BR4's... But, if I can get enough shots through this barrel to get it where it's up to speed with the 41's, that would be great... or better yet, just use the 41's.

Thanks,

-Dave

According to this post as the source from Ultraman550:

CCI 450 - same thicker .025" cup as the BR4 and #41.

CCI #41 - commercial version of the fully-qualified DOD primer for use in U.S. military ammo. With this primer there is more 'distance' between the tip of the anvil and the bottom of the cup than with other CCI SR primers. .025" thick cup. Same primer mix as CCI 450.

It looks like CCI 41's are a very close alternative to the 450's, and I have some of that. Any thoughts on using the 41's instead? If for some reason the 41's don't work, I'll use my BR4's... But, if I can get enough shots through this barrel to get it where it's up to speed with the 41's, that would be great... or better yet, just use the 41's.

Thanks,

-Dave

The 41's will work for you. My understanding is the anvil is slightly different and requires more impact before ignition on the 41's compared to the 450. I have used 41's in my bolt rifle loads in the past with no problems encountered.

Awesome! I’ve did a few loads with 41’s, 450’s, and BR-4’s. I made the start weight a little lower this time around as well, but I have a good feeling about going with the thicker cupped primers this time. I hope to get this tried out before the weekend.The 41's will work for you. My understanding is the anvil is slightly different and requires more impact before ignition on the 41's compared to the 450. I have used 41's in my bolt rifle loads in the past with no problems encountered.

Hope you all have a great turkey day!

Just closing the loop with my fork in this thread. I tested the 450's, 41's, and BR-4's and all three worked with my 6GT. We can mark this up with another one that is unable to use the CCI 400's with their 6GT. I may try the 400's again in the future, once my barrel settles down on the speed. Would be good to know if this is an issue with new/tighter barrels.

Thanks!

Thanks!

400s are a low pressure primer. Made for 22 hornet etc. it’s no surprise they pop when you should be using a thicker cup.

I used to say that as well… used to.cci400 primers are the only primers I have ever used on two different 6GT barrels and not a single issue with well over 4,000 of them.

Once it starts popping them it will only get worse from there.

If it’s working great. Don’t expect it to the rest of time.

I've been using some old batches of 400s without issue as well. They are harder to seat so probably thicker from 1979/80/81, still no issues. Only a few hundred remain of this old stuff. I'll have to try my newer stock and compare.

cci400 primers are the only primers I have ever used on two different 6GT barrels and not a single issue with well over 4,000 of them.

How old are we talking? Like the ones on the left? I use the ones on the left in my 223 loads and also find they are harder to seat. My SDs have never been so low when using the older ones so I might keep them around for the 6GT especially if the cups are thicker/harder.I've been using some old batches of 400s without issue as well. They are harder to seat so probably thicker from 1979/80/81, still no issues. Only a few hundred remain of this old stuff. I'll have to try my newer stock and compare.

Late 70's, early 80's old...

All brought from gun stores, before you could mail order components.

All brought from gun stores, before you could mail order components.

How old are we talking? Like the ones on the left? I use the ones on the left in my 223 loads and also find they are harder to seat. My SDs have never been so low when using the older ones so I might keep them around for the 6GT especially if the cups are thicker/harder. View attachment 7749708

Think of all the room a guy could save if they still packaged them this way. Federal could take some notes.Late 70's, early 80's old...

All brought from gun stores, before you could mail order components.

View attachment 7749711

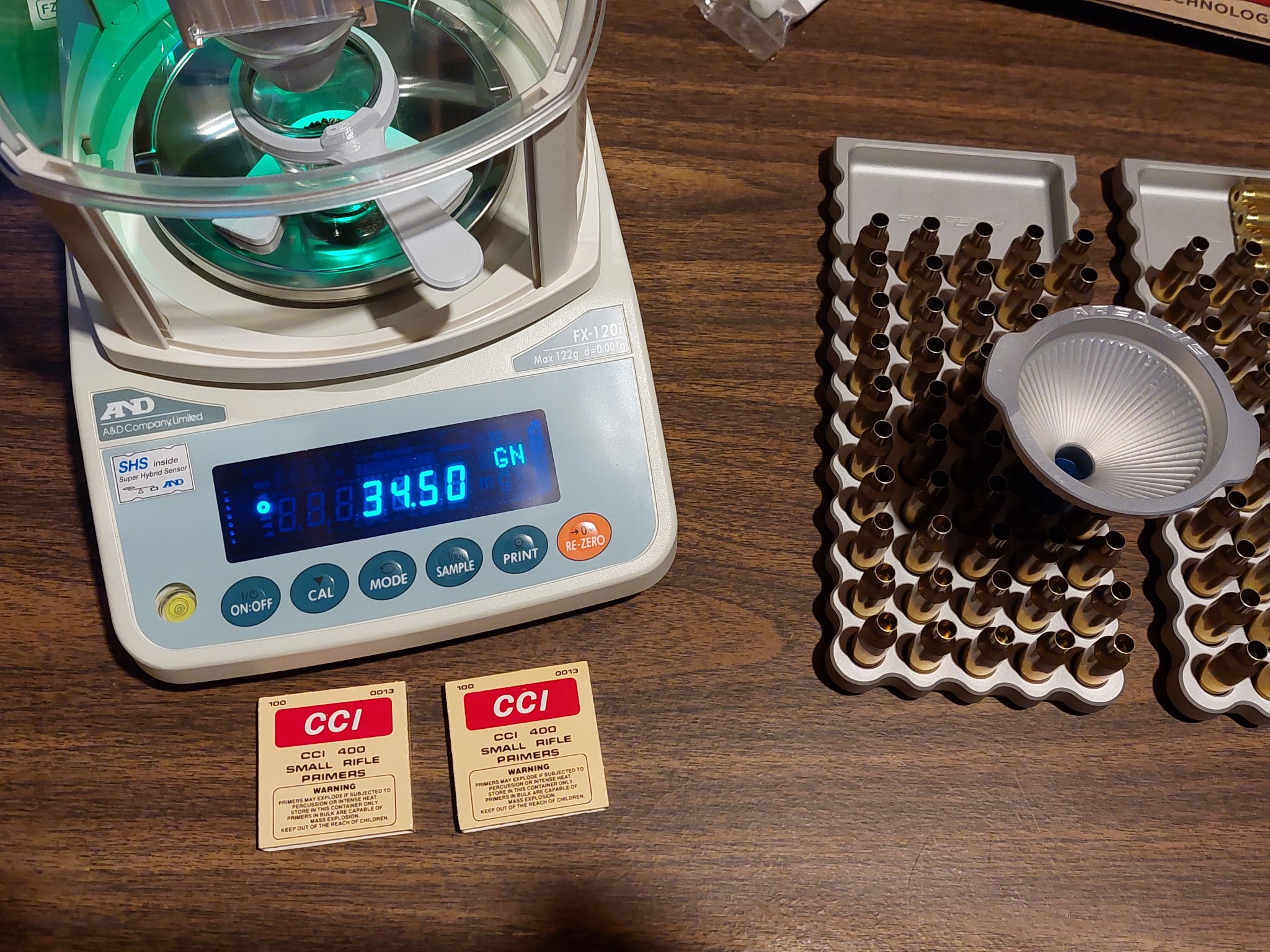

Okay... two rounds of shooting 3 different charges with CCI 450, 41, and BR-4's, and no pierced primers. I think I can say it's pretty conclusive that the newer CCI 400's were the cause.

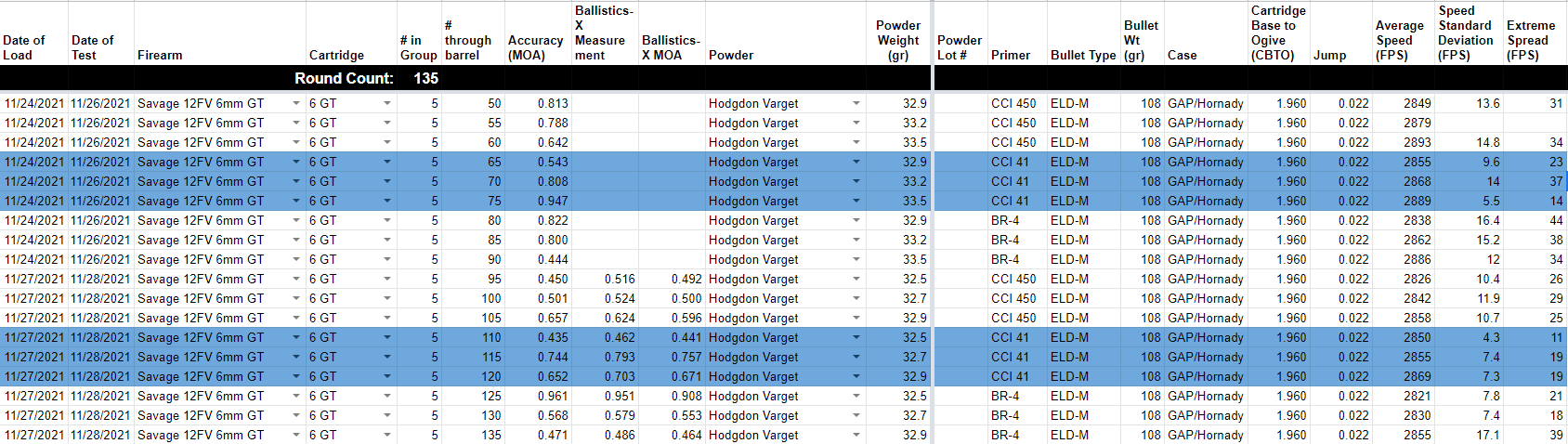

The first round (11/26/21) my chrono was complaining about the battery, so I don't fully trust the numbers... and it was missing shots. However, I'll put the data here anyway.

The second round (11/28/21) my chrono was happy with new batteries and seemed to be fully operational. Yes, I understand that the charge is on the low side, but I figured I'd play it safe with the young barrel. The velocities were very similar between the 450's and BR-4's, but the SD's were similar between the 41's and BR-4's. I have more BR-4's than 41's, but the 41's are cheaper and have given me a little better SD's and velocities.

Anyways... I've ~135 form fired Hornady brass, and I've deprimed, cleaned, and annealed them. So, I think I'm ready to start my load development. The only thing that I'm iffy on is if I have enough rounds through the new barrel. I've heard 100 and 150, so this is close to splitting the difference. haha

This will be the first time that I'm trying to do it based on velocity, instead of OCW. Since I have lots of StaBALL 6.5, I think I will play with it. Time to search the threads to see if anyone has done with that and the Hornady ELD-M 108's.

Thanks again for the help on figuring out the pierced primer issue that I was experiencing. It really saved me a lot of time and headaches!

The first round (11/26/21) my chrono was complaining about the battery, so I don't fully trust the numbers... and it was missing shots. However, I'll put the data here anyway.

The second round (11/28/21) my chrono was happy with new batteries and seemed to be fully operational. Yes, I understand that the charge is on the low side, but I figured I'd play it safe with the young barrel. The velocities were very similar between the 450's and BR-4's, but the SD's were similar between the 41's and BR-4's. I have more BR-4's than 41's, but the 41's are cheaper and have given me a little better SD's and velocities.

Anyways... I've ~135 form fired Hornady brass, and I've deprimed, cleaned, and annealed them. So, I think I'm ready to start my load development. The only thing that I'm iffy on is if I have enough rounds through the new barrel. I've heard 100 and 150, so this is close to splitting the difference. haha

This will be the first time that I'm trying to do it based on velocity, instead of OCW. Since I have lots of StaBALL 6.5, I think I will play with it. Time to search the threads to see if anyone has done with that and the Hornady ELD-M 108's.

Thanks again for the help on figuring out the pierced primer issue that I was experiencing. It really saved me a lot of time and headaches!

Hello,

Just took delivery of my new GAP 6GT. Lots of great information here on loading for the cartridge wanted to take the opportunity to say thanks for the information in advance. I have also seen questions regarding color choices on the forun so thought I would include a couple pics for reference. GAP did a fantastic job on this rifle and I am very excited to shoot this beauty for the first time. Paint is Scorched Earth and looks fantastic in person, much nicer than I expected. So far I have Varget, Alpha brass, two types of projectiles (105gr Nosler RDF and 110 Hornady A-Tip's). Time to break this bad boy in.

Happy new year everyone

Just took delivery of my new GAP 6GT. Lots of great information here on loading for the cartridge wanted to take the opportunity to say thanks for the information in advance. I have also seen questions regarding color choices on the forun so thought I would include a couple pics for reference. GAP did a fantastic job on this rifle and I am very excited to shoot this beauty for the first time. Paint is Scorched Earth and looks fantastic in person, much nicer than I expected. So far I have Varget, Alpha brass, two types of projectiles (105gr Nosler RDF and 110 Hornady A-Tip's). Time to break this bad boy in.

Happy new year everyone

Attachments

I've been a little slow posting up my load developments. Unfortunately, I'm just not able to find the Berger Hybrids, so I'm going down the path of the ELD-M 108's and SMK 107's, as those are semi-obtainable at the moment.This will be the first time that I'm trying to do it based on velocity, instead of OCW. Since I have lots of StaBALL 6.5, I think I will play with it. Time to search the threads to see if anyone has done with that and the Hornady ELD-M 108's.

For my quick throwable load:

Hornady ELD-M 108 @ 76K jump

StaBALL 6.5 @ 38.4g

CCI 41's

SD's in the high single digits

ES in the mid-teens to 20

I've seen as low as .215" MOA, but that was just a 3 shot group... on another day with new brass I got .403" MOA. Hoping that it will tighten up with fired brass and tuner brake tweaks.

I consider this 95% done as I just need to confirm my tuner brake setting @ 4, 5, or 6.... Then, load up ~20-25 to validate.

Currently developing what I hope to be my low SD/ES load with SMK 107, H4350, CCI 450:

Here are the results from my velocity test to find a workable node...

I didn't really get a strong node with the quick throwable load, but it looks like I have a few to choose from with this one. The green boxes are my first choices, and leading off with the higher velocity one. So far, with the seating depth test of 3 rounds, it's delivering the goal of a low/mid-single digit SD and low double-digit ES. Of course, this is just 3 shot groups, so I'm anticipating it to climb up.

I now have the 5-round groups loaded to get a better view in the SD/ES and group size. I'm just waiting for warmer weather.

Sorry for the long post, but thought I would share my findings as I learn how to do this loading process.

Happy 2022!!

-Dave

Sorry I forgot this on my original post. I loaded up a couple dummy rounds for seating depth on the K&M Arbor press and the neck tension was about 35 to 40lbs on this new brass. I used a mandrel to ensure consistency of the necks in the new alpha brass. Does anyone have any insight if this is about normal or what value we should be aiming for for neck tension when seating?Hello,

Just took delivery of my new GAP 6GT. Lots of great information here on loading for the cartridge wanted to take the opportunity to say thanks for the information in advance. I have also seen questions regarding color choices on the forun so thought I would include a couple pics for reference. GAP did a fantastic job on this rifle and I am very excited to shoot this beauty for the first time. Paint is Scorched Earth and looks fantastic in person, much nicer than I expected. So far I have Varget, Alpha brass, two types of projectiles (105gr Nosler RDF and 110 Hornady A-Tip's). Time to break this bad boy in.

Happy new year everyone

Thanks everyone.

On bolt gun I try to stay in the 1.5-2 range, and on semi's 3-4 range. I don't even chamfer the new alpha brass, it just works out of the boxSorry I forgot this on my original post. I loaded up a couple dummy rounds for seating depth on the K&M Arbor press and the neck tension was about 35 to 40lbs on this new brass. I used a mandrel to ensure consistency of the necks in the new alpha brass. Does anyone have any insight if this is about normal or what value we should be aiming for for neck tension when seating?

Thanks everyone.

I get excess resistance when seating new brass fro the first time on different batches and calibers of brass for whatever reason. Even if I size it and mandrel it. The next time you seat bullets into that same brass after firing I guarantee you that it will be much less.Sorry I forgot this on my original post. I loaded up a couple dummy rounds for seating depth on the K&M Arbor press and the neck tension was about 35 to 40lbs on this new brass. I used a mandrel to ensure consistency of the necks in the new alpha brass. Does anyone have any insight if this is about normal or what value we should be aiming for for neck tension when seating?

Thanks everyone.

You might want to try annealing it, then sizing/expanding to spec...I get excess resistance when seating new brass fro the first time on different batches and calibers of brass for whatever reason. Even if I size it and mandrel it. The next time you seat bullets into that same brass after firing I guarantee you that it will be much less.

Sorry I forgot this on my original post. I loaded up a couple dummy rounds for seating depth on the K&M Arbor press and the neck tension was about 35 to 40lbs on this new brass. I used a mandrel to ensure consistency of the necks in the new alpha brass. Does anyone have any insight if this is about normal or what value we should be aiming for for neck tension when seating?

Thanks everyone.

Keep in mind, force gauges and such are still just comparator tools.

Thus far, no one has been able to produce any data that says “40lb is best.”

This is because (generally speaking) there are so many things that contribute to seating force, you can’t just assign a value to the end result.

Used properly, you will find a process that works/shoots best for you. And then use the gauge to make sure the seating resistance is consistent.

Even when it’s not consistent (say you get 60lbs when everything else was 40lbs), just based on the seating force/resistance, you will have no idea why it did that. It could be one or several things. And sometimes if you shoot that round over the chrono/on paper, it won’t deviate, and other times it will.

Point being, force gauges and such are comparator tools to assist you in making consistent ammunition. You will have to decide what the process is and target weights are for you.

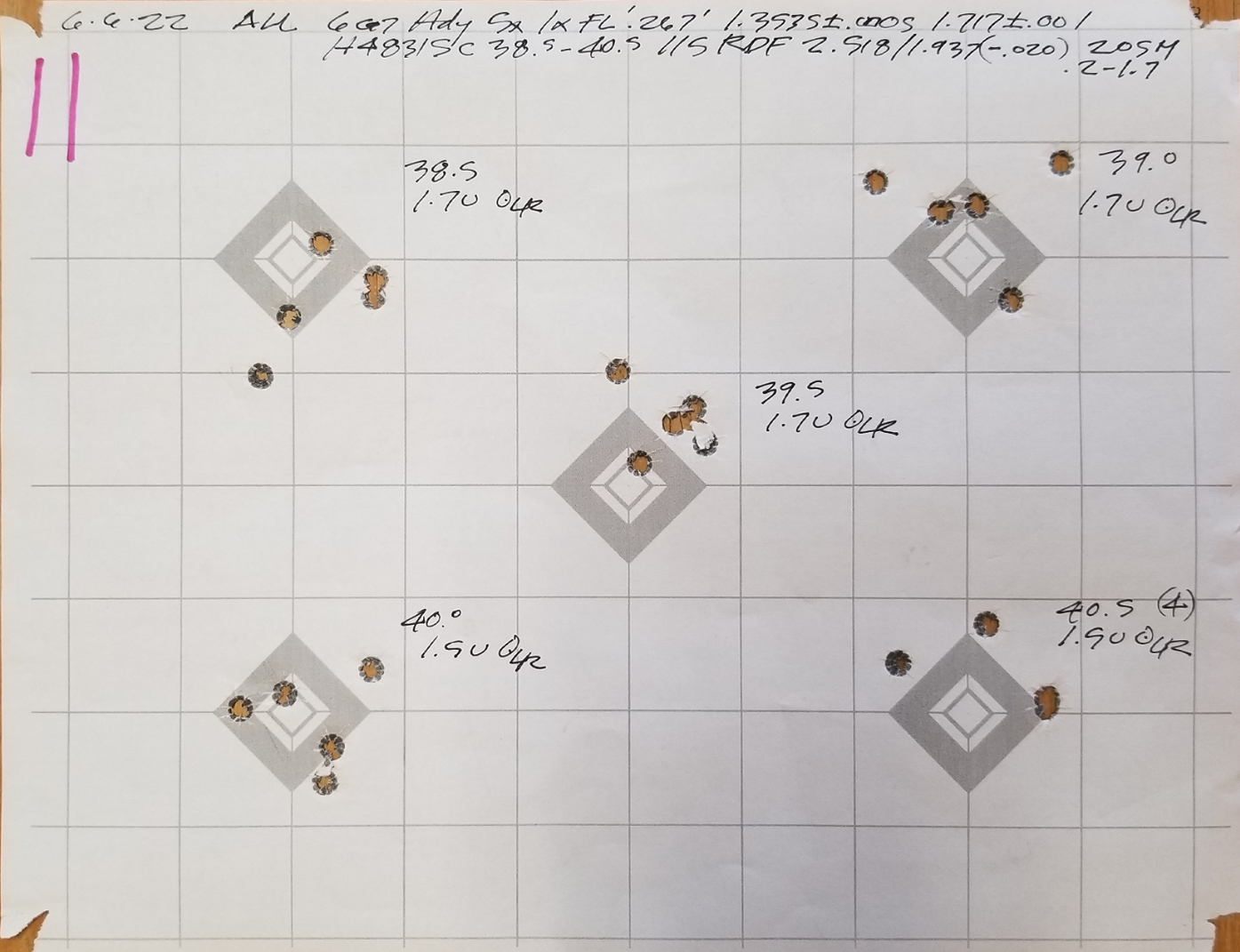

If anyone is interested in using H4831SC in the GT, here are some of my results with 115 RDFs (I have more of the 4831 powders than anything else, so I thought I would try it).

.020" jump

26" 7.5 twist Bartlein 5R HV (~850 rounds so far)

Hornady brass

Fed 205M

Rear bag and bipod off a bench. 3 mph 7 o'clock wind. 86 degrees F.

Did a 200 yard test of 38.5-40.5 grains if H4831SC (basing the loads on Hodgdon's 41.3 max. of Superformance for 110 grain A-Tip).

38.5, 39.0, and 39.5 were slightly crunchy; 40.0 and 40.5 were crunchy, but no pressure signs on any of these.

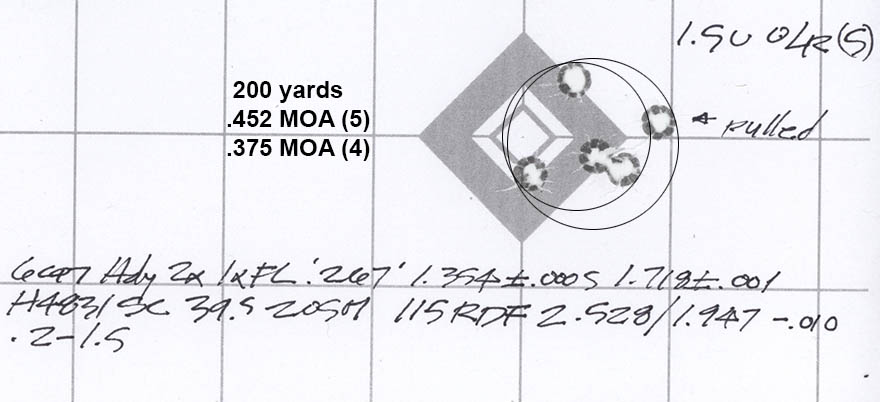

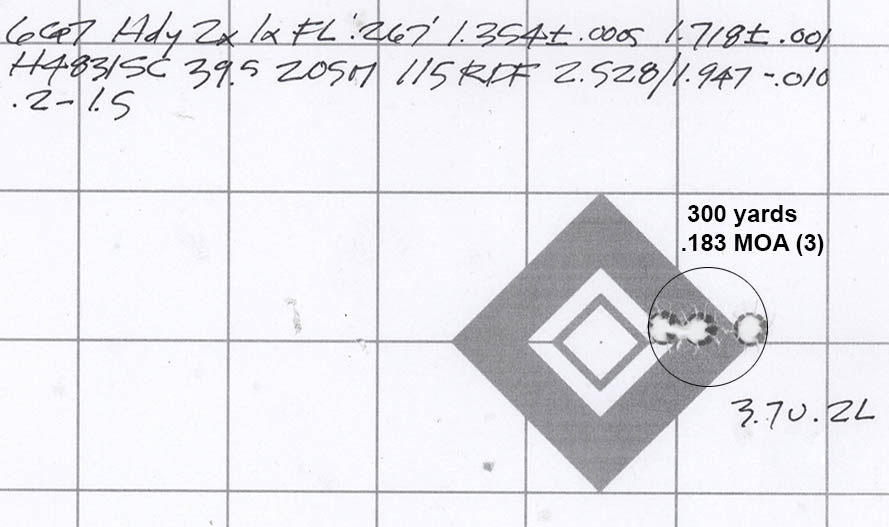

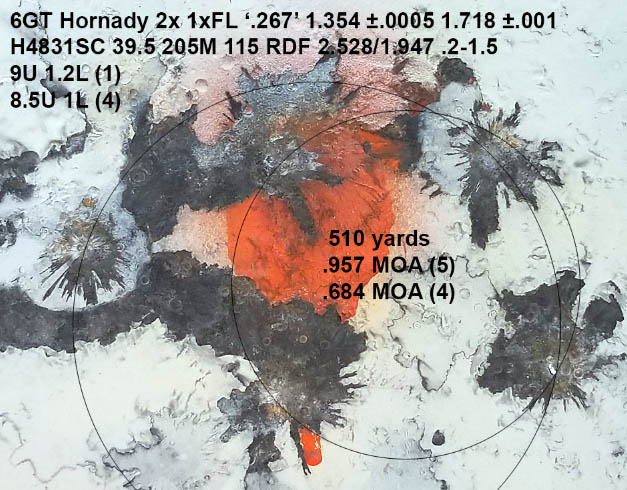

39.5 looked good, so I loaded more of that and tried it at 200, 300, and 510 yards.

200 still looking good, 300 was so awesome I stopped after 3 shots (knowing the Random Damn Flyers were coming , and it opened up a bit at 510. I didn't chrono it, but based on the come-ups the velocity looks to be 2875-ish.

, and it opened up a bit at 510. I didn't chrono it, but based on the come-ups the velocity looks to be 2875-ish.

.020" jump

26" 7.5 twist Bartlein 5R HV (~850 rounds so far)

Hornady brass

Fed 205M

Rear bag and bipod off a bench. 3 mph 7 o'clock wind. 86 degrees F.

Did a 200 yard test of 38.5-40.5 grains if H4831SC (basing the loads on Hodgdon's 41.3 max. of Superformance for 110 grain A-Tip).

38.5, 39.0, and 39.5 were slightly crunchy; 40.0 and 40.5 were crunchy, but no pressure signs on any of these.

39.5 looked good, so I loaded more of that and tried it at 200, 300, and 510 yards.

200 still looking good, 300 was so awesome I stopped after 3 shots (knowing the Random Damn Flyers were coming

Similar threads

- Replies

- 32

- Views

- 2K

- Replies

- 0

- Views

- 178