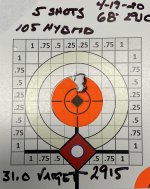

Awesome, thanks! Love the graph! Is it software or something you made? I can’t wait to get these rifles going!! I’m waiting on brakes before I thread the barrels. I might have to skip that for now, I can always spin them off later!View attachment 7526843

Yep. 6 BRA and 105 Hybrids from a 26" barrel, 1x fired Lapua brass, and 69 deg F. Using BR4 primers so again, work up slowly (and I may have missed pressure signs at the upper loads). I ended up at 31.5 gr for both.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6mm BRA

- Thread starter cjherrman

- Start date

Do the guys who’s loads favour CCI-450s find that BR-4s shoot just as well but cost more?

my smith swears by BR4s thats all he shoots....personally i have had better and more consistent numbers with FED205Ms but i always run the BR4s and 450s after i find my load just to be sure.

Thanks. I’m pulling a 6.5 Creed barrel in and tossing a straight 6BR on my gun soon. I’ve got 4000 BR-4, but only 1100 450s, so I’m curious why so many run the 450s over the BR-4.my smith swears by BR4s thats all he shoots....personally i have had better and more consistent numbers with FED205Ms but i always run the BR4s and 450s after i find my load just to be sure.

Half the priceThanks. I’m pulling a 6.5 Creed barrel in and tossing a straight 6BR on my gun soon. I’ve got 4000 BR-4, but only 1100 450s, so I’m curious why so many run the 450s over the BR-4.

Thank you. I was hoping that’s all it was.Half the price

When I starting seeing inventories diminish, I stocked up on whatever I could, and BR-4s were it.

There is an app called reloading all day, think of it as a digital log book. It’s amazing once you figure it out. I don’t even bring a notebook to the range anymore.Awesome, thanks! Love the graph! Is it software or something you made? I can’t wait to get these rifles going!! I’m waiting on brakes before I thread the barrels. I might have to skip that for now, I can always spin them off later!

Thanks. I’m pulling a 6.5 Creed barrel in and tossing a straight 6BR on my gun soon. I’ve got 4000 BR-4, but only 1100 450s, so I’m curious why so many run the 450s over the BR-4.

All I run in my BRA's are BR4 primers.

I haven't tried anything else, but I haven't seen a need to. Performance is excellent.

I a

Guess I’ll dive in further !

Guess I’ll dive in further !

i actually have that app!There is an app called reloading all day, think of it as a digital log book. It’s amazing once you figure it out. I don’t even bring a notebook to the range anymore.

GUNR - Shooting and Reloading

Are you tired of trying to keep track of all your shooting-related activities and data on paper or in separate documents? GUNR is here to help you streamline and organize everything in one place. Simply add your guns and start logging everything from weather conditions to shot velocities to...

What is H2O capacity of your BRA case?

39-ish grains depending on brass.

39-ish grains depending on brass.

thanks, do you mind weighing some and giving the details?

thanks, do you mind weighing some and giving the details?

what details are you looking for?

Water weight in grains for a sized or fired case all the way to the top, please

39 to 39.1g fired full length sized peterson brass.

Been fireforming brass, and breaking in a new barrel.

Used the last of my RL-15 for fireforming, so switching to Varget. Using 29.0-gr with both for my FF load.

Down to the last few of Hornady 105-gr BTHP bullets. Will be switching to 107-SMKs. My full load BRA bullet I use is the 110-SMK.

Over the Christmas holidays, went over to a friend's place, and poked at steel out to 1200-yards. Unbelievable accuracy with FF loads, and the cheapest bullets I could find. Wouldn't be afraid to shoot a match while fireforming brass.

Used the last of my RL-15 for fireforming, so switching to Varget. Using 29.0-gr with both for my FF load.

Down to the last few of Hornady 105-gr BTHP bullets. Will be switching to 107-SMKs. My full load BRA bullet I use is the 110-SMK.

Over the Christmas holidays, went over to a friend's place, and poked at steel out to 1200-yards. Unbelievable accuracy with FF loads, and the cheapest bullets I could find. Wouldn't be afraid to shoot a match while fireforming brass.

Water weight in grains for a sized or fired case all the way to the top, please

I was 39.1 in Lapua brass last time I measured, fired unsized case.

Can you share your data with the 110? I had horrible results with those Bullets, but I’m running low on 105hBeen fireforming brass, and breaking in a new barrel.

Used the last of my RL-15 for fireforming, so switching to Varget. Using 29.0-gr with both for my FF load.

Down to the last few of Hornady 105-gr BTHP bullets. Will be switching to 107-SMKs. My full load BRA bullet I use is the 110-SMK.

Over the Christmas holidays, went over to a friend's place, and poked at steel out to 1200-yards. Unbelievable accuracy with FF loads, and the cheapest bullets I could find. Wouldn't be afraid to shoot a match while fireforming brass.

Using 30.0-gr of Varget with BR4's, and with the old rifle I'm getting 2840-fps. It's a 26" barrel.

I have not had a chance to do any full BRA loads with the new build, as I'm only 150-rounds or so into it with fireforming and breaking in the barrel.

I have not had a chance to do any full BRA loads with the new build, as I'm only 150-rounds or so into it with fireforming and breaking in the barrel.

I think you are more realistic on your numbers than what a lot of the guys are throwing out there. I shoot two different BR rigs set up in 6BRA (one runs 103grain and the other 105g) with 30" barrels and find "safe" operating pressures and sweet spots at about 2970 fps. Anyone getting upper 2900's with a 26 " barrel are over-pressure, regardless of what they think their brass is telling them. Either that, or their chronographs are not calibrated properly.Still slower than some here. Your barrel kind of mirrors mine. I was at 2935 with the same charge of varget, but didn’t have the consistency.

Cheers

“America is all about speed, hot nasty bad ass speed” -Eleanor RooseveltI think you are more realistic on your numbers than what a lot of the guys are throwing out there. I shoot two different BR rigs set up in 6BRA (one runs 103grain and the other 105g) with 30" barrels and find "safe" operating pressures and sweet spots at about 2970 fps. Anyone getting upper 2900's with a 26 " barrel are over-pressure, regardless of what they think their brass is telling them. Either that, or their chronographs are not calibrated properly.

Cheers

Even if it is lying about it lol

I think you are more realistic on your numbers than what a lot of the guys are throwing out there. I shoot two different BR rigs set up in 6BRA (one runs 103grain and the other 105g) with 30" barrels and find "safe" operating pressures and sweet spots at about 2970 fps. Anyone getting upper 2900's with a 26 " barrel are over-pressure, regardless of what they think their brass is telling them. Either that, or their chronographs are not calibrated properly.

Cheers

not being a dick just asking...how do you know that a 24-26" barrel running a 105 at 2950-2970 is over pressure? are you...or have you...run pressure trace equipment on your rifles? and how do you know running 2970 out of a 30" barrel is safe or not over pressure?

What info I give is based on over 40 years of loading ammo for competition and hunting. That doesn't make me an expert, but I have been around a lot of them. Companies like Hornady spend a lot of time and money testing load data with specialized equipment to ensure information they put out is safe. They are usually cautious in their manuals, to protect themselves, so we get to decide how far to push pressures past that point. I have been at the underground range at Hornady and watched as loads were tested.not being a dick just asking...how do you know that a 24-26" barrel running a 105 at 2950-2970 is over pressure? are you...or have you...run pressure trace equipment on your rifles? and how do you know running 2970 out of a 30" barrel is safe or not over pressure?

In the case of the 6BRA, I have been using it for competition for over 5 years now. I have pushed several barrels past safe pressures and "good" harmonics to have a really good idea where safe stops. That includes most of the cut rifled barrel manufacturers with 5R and 4 groove. If we could get the velocities out of a 26" barrel, why would we shoot 30" barrels? In my testing of barrel lengths, there was an average of 75fps difference between a 26 and a 28 inch barrel from the same manufacturer in the 6BRA chambering.

The other part of the equation is twist rates in barrels. The faster your twist rate, the slower the velocity. I can run a 105 grain bullet faster in a 8 twist than a 7 twist barrel. I can't stabilize a 109-115 grain bullet in an 8 twist barrel, so now decisions have to be made on what will work best for LR accuracy. I want to push a bullet as hard as possible to cheat the wind and other factors as much as the next guy, but know that there are diminishing returns on what will happen if it is pushed too far.

Cheers

I'm a newer reloader (3 years) and admitted when I posted my velocity chart that I may have missed pressure signs. In the interest of getting more data out and in front of people to likely know more than me, here are the fired cases using 31.5 gr Varget (left two) and 31.7 gr N140 (right) that got 2920 and 2935 fps respectively in my 26" Tikka BRA. There is some cratering, and scratches there that might be extractor marks but I'm honestly not sure.

Attachments

When I hear of 26" BRA shooters running in excess of 2925fps... I think most are running in a very high node. (very)

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I'm sure a Dasher shooter running 105's at 3075 will be along to "correct" me soon.

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I'm sure a Dasher shooter running 105's at 3075 will be along to "correct" me soon.

Most of the guys running Dashers and BRX's are running high 2900 to maybe 3025 on really warm humid days. You are spot on...When I hear of 26" BRA shooters running in excess of 2925fps... I think most are running in a very high node. (very)

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I'm sure a Dasher shooter running 105's at 3075 will be along to "correct" me soon.

What primers are you running? Standard primers would show cratering in my Tikka with SRP Creedmoor brass, switching to magnum primers fixed that. Might be the same with your BR brass, although, good luck finding primers.I'm a newer reloader (3 years) and admitted when I posted my velocity chart that I may have missed pressure signs. In the interest of getting more data out and in front of people to likely know more than me, here are the fired cases using 31.5 gr Varget (left two) and 31.7 gr N140 (right) that got 2920 and 2935 fps respectively in my 26" Tikka BRA. There is some cratering, and scratches there that might be extractor marks but I'm honestly not sure.

These are BR4s, so I believe that it's a warm load just not sure how bad. I have 400's, 450's, and 205Ms to try too.What primers are you running? Standard primers would show cratering in my Tikka with SRP Creedmoor brass, switching to magnum primers fixed that. Might be the same with your BR brass, although, good luck finding primers.

I’d run that, I’m 90% sure 300 pieces of brass treated like that would out last 2 barrels. Some folks treat brass like it’s a forever thing. It also might be your action. I had a trued remmy that would give an ejector mark on factory Hornady 6.5cmI'm a newer reloader (3 years) and admitted when I posted my velocity chart that I may have missed pressure signs. In the interest of getting more data out and in front of people to likely know more than me, here are the fired cases using 31.5 gr Varget (left two) and 31.7 gr N140 (right) that got 2920 and 2935 fps respectively in my 26" Tikka BRA. There is some cratering, and scratches there that might be extractor marks but I'm honestly not sure.

Last edited:

I'm running my BRA at 30.6 gr H4895. This gets me ~2950, which is right on the cusp of where I start to get a sticky bolt. Still, it gets me the best groups, so that's where I play. I have seen no quicker brass degradation as a result of loading there.When I hear of 26" BRA shooters running in excess of 2925fps... I think most are running in a very high node. (very)

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I would stay with the BR4's. They have a harder/thicker cup than the 205M or 400's have. You don't want to start piercing primers and have your action go down. It never hurts to test other primers, but I have found BR4's and 450's hold up better to high pressure loads than some of the others. I do like Remington 7.5's as well for SRPs., since they are considered a magnum primer with a thicker cup. I get better SD and ES with the 7.5 Remmys, but on target performance usually favors the BR4.These are BR4s, so I believe that it's a warm load just not sure how bad. I have 400's, 450's, and 205Ms to try too.

Cheers

so to answer my question im going to take this as a no you have not run pressure trace equipment to verify your claim.What info I give is based on over 40 years of loading ammo for competition and hunting. That doesn't make me an expert, but I have been around a lot of them. Companies like Hornady spend a lot of time and money testing load data with specialized equipment to ensure information they put out is safe. They are usually cautious in their manuals, to protect themselves, so we get to decide how far to push pressures past that point. I have been at the underground range at Hornady and watched as loads were tested.

In the case of the 6BRA, I have been using it for competition for over 5 years now. I have pushed several barrels past safe pressures and "good" harmonics to have a really good idea where safe stops. That includes most of the cut rifled barrel manufacturers with 5R and 4 groove. If we could get the velocities out of a 26" barrel, why would we shoot 30" barrels? In my testing of barrel lengths, there was an average of 75fps difference between a 26 and a 28 inch barrel from the same manufacturer in the 6BRA chambering.

The other part of the equation is twist rates in barrels. The faster your twist rate, the slower the velocity. I can run a 105 grain bullet faster in a 8 twist than a 7 twist barrel. I can't stabilize a 109-115 grain bullet in an 8 twist barrel, so now decisions have to be made on what will work best for LR accuracy. I want to push a bullet as hard as possible to cheat the wind and other factors as much as the next guy, but know that there are diminishing returns on what will happen if it is pushed too far.

Cheers

now i am not arguing the fact that running these speeds are "probably" over pressure...as a matter of fact i agree with you...to a point.

what is your load for 2970 in your 30" barrel?

when you say "in a very high node" (very). do you mean in dangerous territory like near blowing a gun up?When I hear of 26" BRA shooters running in excess of 2925fps... I think most are running in a very high node. (very)

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I'm sure a Dasher shooter running 105's at 3075 will be along to "correct" me soon.

I don't think that would be the case with most actions. Someone could basically dunk these BR-based cases in the jug and top the neck off with powder and crush a neck full of kernels when seating a 105 and it likely still wouldn't be enough to fracture most modern actions. Doesn't mean it's any good for your brass or your nodes, however.when you say "in a very high node" (very). do you mean in dangerous territory like near blowing a gun up?

I think the loads being mentioned would be 5 firings on brass... maybe 10. Where as running in the lower node you can see 60-80 firings pretty easy. This is all very relative depending on by what definition you define "brass is done."

However, the high nodes are also quite finicky in relation to their lower counterparts. I don't tend to consider the rightest possible combinations to need the justification of safety, but its certainly an added benefit.

So y’all think brass shouldn’t deprime itself when it’s fired? I thought I was on to somethingI don't think that would be the case with most actions. Someone could basically dunk these BR-based cases in the jug and top the neck off with powder and crush a neck full of kernels when seating a 105 and it likely still wouldn't be enough to fracture most modern actions. Doesn't mean it's any good for your brass or your nodes, however.

I think the loads being mentioned would be 5 firings on brass... maybe 10. Where as running in the lower node you can see 60-80 firings pretty easy. This is all very relative depending on by what definition you define "brass is done."

However, the high nodes are also quite finicky in relation to their lower counterparts. I don't tend to consider the rightest possible combinations to need the justification of safety, but its certainly an added benefit.

To put things in perspective, I advocate 6 DASHER users stay around 2900-2925. So a BRA is well outside of its intended range when at those velocities I think. Though I can get dozens of firings on my brass usually. Some guys are fine only getting 3 firings.

I respectfully disagree. I’ve been shooting 105s at 2920 with a 26” Bartlein, 31.0 gr. Varget with CCI 450s and Lapua brass. 8 firings now and the brass is fine and zero pressure issues. I also found a wider seating node further out than many use -> -065 to -080 off the lands.

I’d say 2920 is the *optimal* node. (slower and faster were not nearly as consistent)

Last edited:

I disagree. I’ve been shooting 105s at 2920 with a 26” Bartlein, 31.0 gr. Varget with CCI 450s and Lapua brass. 6 reloads now and the brass is fine and zero pressure issues. I also found a wider seating node further out than many use -> -065 to -080 off the lands.

I’d say 2920 is the *optimal* node.

View attachment 7528980

Well I disagree with your disagreement.

Though I often wonder if I'm the only one on the planet that loads a single case until failure as part of my load proofing methodology.

The number of folks I've talked to that were running almost that exact same load that had "mysterious" pressure spikes halfway through a string... may surprise you. "Oh man... why am I having heavy bolt lift all of a sudden..." lol Could be you've got a fast barrel there. 120fps difference between fast barrels and slow barrels, easy. So its possible.

What I see is a group that's 2 bullets tall, and if you were running in the 2850fps range... could be 1 bullet tall. If you want to prove me wrong, just put 20 rounds on a 1/2" dot drill at 100yds and we'll see how many come out high/low as opposed to horizontal dispersion.

That’s the same node and width Mark Gordon found to be least sensitive with the 105s as well.I respectfully disagree. I’ve been shooting 105s at 2920 with a 26” Bartlein, 31.0 gr. Varget with CCI 450s and Lapua brass. 8 firings now and the brass is fine and zero pressure issues. I also found a wider seating node further out than many use -> -065 to -080 off the lands.

I’d say 2920 is the *optimal* node. (slower and faster were not nearly as consistent)

View attachment 7528980

What I see is a group that's 2 bullets tall, and if you were running in the 2850fps range... could be 1 bullet tall. If you want to prove me wrong, just put 20 rounds on a 1/2" dot drill at 100yds and we'll see how many come out high/low as opposed to horizontal dispersion.Seeing the rest of the targets from that workup of yours would tell me some things too.

That group was from a 35 round OCW shot round robin - it was the center of the chosen node and remarkably the smallest group. I was using H4895 initially and it too shot the best at 2920 (about a grain less), but found Varget held tighter groups.

I don't think 2920 with both powders is a coincidence.

Thanks for your suggestion, I’ll try the 20 round dot drill.

31.4 grains of Vargetso to answer my question im going to take this as a no you have not run pressure trace equipment to verify your claim.

now i am not arguing the fact that running these speeds are "probably" over pressure...as a matter of fact i agree with you...to a point.

what is your load for 2970 in your 30" barrel?

Couple questions on the barrel:I respectfully disagree. I’ve been shooting 105s at 2920 with a 26” Bartlein, 31.0 gr. Varget with CCI 450s and Lapua brass. 8 firings now and the brass is fine and zero pressure issues. I also found a wider seating node further out than many use -> -065 to -080 off the lands.

I’d say 2920 is the *optimal* node. (slower and faster were not nearly as consistent)

View attachment 7528980

What is the lands, 236 or 237?

5R or 4 groove, and what is the twist rate?

31.4 grains of Varget

funny that 31.4g of varget in your 30" barrel making 2970 is safe but 31.3g of varget a 105g hybrid .015-.020 off the lands in peterson brass with a FED205M in my 26" barrel going 2975 is way over pressure and from what you have seen i should be 75fps slower than your 30" barrel.

you asked @DellaDog about his barrel lands a groves...he is shooting a 26" bartlin barrel...its in his post...most likely a 5R and .237...same barrel and length as my first 2 BRA barrels mine are heavy palmas....only barrels i shoot anymore.

Last edited:

The only comment I will make in regards to the above, is the you have the fastest most slippery barrels that Bartlein has ever put out if you are getting those velocities with that powder charge. I've used 7 different barrels from all the big boys that make cut rifled barrels chambered in 6BRA, and shoot against some of the best BR and F-class guys in the US, and we don't get those velocities with 26" barrels. Good on ya...funny that 31.4g of varget in your 30" barrel making 2970 is safe but 31.3g of varget a 105g hybrid .015-.020 off the lands in peterson brass with a FED205M in my 26" barrel going 2975 is way over pressure and from what you have seen i should be 75fps slower than your 30" barrel.

you asked @DellaDog about his barrel lands a groves...he is shooting a 26" bartlin barrel...its in his post...most likely a 5R and .237...same barrel and length as my first 2 BRA barrels mine are heavy palmas....only barrels i shoot anymore.

Cheers

The only comment I will make in regards to the above, is the you have the fastest most slippery barrels that Bartlein has ever put out if you are getting those velocities with that powder charge. I've used 7 different barrels from all the big boys that make cut rifled barrels chambered in 6BRA, and shoot against some of the best BR and F-class guys in the US, and we don't get those velocities with 26" barrels. Good on ya...

Cheers

how much freebore are you running?

ive got no reason to lie or make stuff up im telling you what load and velocities i was running and before you say my chrony is off my dopes lined up consistently out to 1200yds.

i just text a buddy thats down in veagas shooting a match that shoots a BRA...27" bartlin at 2200ish rounds 31.2g varget BR4 105 hybrid .075 off the lands 2947fps....we have 5-6 BRAs in our club all run similar velocities.

Last edited:

how much freebore are you running?

ive got no reason to lie or make stuff up im telling you what load and velocities i was running and before you say my chrony is off my dopes lined up consistently out to 1200yds.

I can believe it. My 28" Krieger easily pushes 105 hybrids over 3,000 fps with 30.6 grains of H4895, no pressure signs. Supposedly the BR based cartridges hide pressure well though.

I don't shoot it that fast anymore though, I'm now shooting around 2970 fps with 30.3 grains H4895.

I can believe it. My 28" Krieger easily pushes 105 hybrids over 3,000 fps with 30.6 grains of H4895, no pressure signs. Supposedly the BR based cartridges hide pressure well though.

I don't shoot it that fast anymore though, I'm now shooting around 2970 fps with 30.3 grains H4895.

agree the BRs hide pressure and im not disputing the fact that we are over pressure im just trying to figure out why/how @Joel Danielson running a 30" barrel is only 2970 with a similar load....powder lot? brass? freebore? maybe his barrel is to long?

@orkan is spot on.Most of the guys running Dashers and BRX's are running high 2900 to maybe 3025 on really warm humid days. You are spot on...

Multiple 6BRX running 105s at 2920fps from 26" Bartleins and Proofs.

FWIW, my fireforming loads using 108ELD-Ms jammed, Lapua brass and 30.0gn 2208/Varget are 2800fps and produce tiny groups(smallest I've ever shot actually)

If you're getting 2980-3025fps in a 26" 6BRX, cool, just let me know so I can walk away before you pull the trigger

Similar threads

- Replies

- 0

- Views

- 149

- Replies

- 7

- Views

- 412