Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm SAW

- Thread starter Temper

- Start date

Quick update. Put 50 rounds through the new gun just at a break in load of 39gr of Reloader 16. Very short OAL at 2.845", still got an average of 2770fps and saw an average of 2818fps using 40.5gr. 26 inch barrel. Here's a group from the slapped together break in load.

Nice ! , what bullet brass primer combination did you use ?

I'm extremely interested in all aspects of this cartridge and rifle build factors involved .

I am in the process of building a 7SAW on a FN SA reciever and am considering barrels and gun smiths !

I'm extremely interested in all aspects of this cartridge and rifle build factors involved .

I am in the process of building a 7SAW on a FN SA reciever and am considering barrels and gun smiths !

Nice ! , what bullet brass primer combination did you use ?

I'm extremely interested in all aspects of this cartridge and rifle build factors involved .

I am in the process of building a 7SAW on a FN SA reciever and am considering barrels and gun smiths !

What length mags are you going to run mate?

I used:

Lapua .308 palma brass (neck turned to 0.310)

Hornady 162gr ELD-Ms seated at an OAL of 2.845" (short, but I have the short reamer).

39gr of Reloader 16.

Next step after I fireform another 150 or so cases is to move from 40 to around 45 grains of R16 and ladder test. My gun seems to like the R16 already, I was a little surprised at those velocities from such a low charge. Clayton recommended I start at 43.5gr.

I'm using FNH TBM & magazines , they max out at 2.885 so the short reamer is what I will use also .

I keep putting off a new build and the 7 SAW is my top choice. Keep the good news coming. So much potential.

I know this is now the Post Exchange so I will not post any pricing in this post. This is just a heads up for any of the SAW fans out there. I have 600+ pieces of Hornady 308 match brass that has been fired once as factory 308 and them formed/trimmed and fired once as a 7mm SAW that I am willing to part with. Just PM me and we can discuss further.

Happy new year to you too mate.Simia Dei , any updates ? , sorry for my impatience !

Happy New Year !

I'm off today to shoot. Have 100+ cases to fireform and finish shooting in the barrel. I have some base loads with charges up to 43.5gr of Reloader 16 to velocity test. Then I'll start ladder testing. I was going to wait to do the lot because I'm about to have another 7mmSAW built. If I don't get close to the velocities I am chasing then I'll have the freebore lengthened slightly.

Also, has anyone tried Reloader 26 in the SAW case?

Simia , you are way beyond where I'm at , I'm still in the infancy of my build , what new build are you doing for the next SAW ? , another Tikka ? , you should be able to acheive any coal you wish with that action magazine dependant ! as for me at the present time I'm limited to a coal of 2.885 for reliable feeding from my FNH SPR build . Even if I had all the stars aligned the weather here is horrid ! , three feet of snow and single digit temps for the foreseeable future . Please keep everyone infofmed of your progress .

Thanks again !, and all the best in 2019 !

Thanks again !, and all the best in 2019 !

So..quick question...it looks like i could seat this in an ar 308 mag. Max coal is usually 2.8-2.9 depending on manufacture. I just may not be able to chase the lands.

What is the barrel life anyway?

What is the barrel life anyway?

I can't say anything as to barrel life , maybe somewhat less than a 308 and somewhat more than a 6.5 whatever but at least with an AR platform barrels / pre-fits require no gunsmithing expense . I do not know much about chasing lands on an auto loader but I would suspect most will only be chambered to feed standard factory ammo .

Simia , you are way beyond where I'm at , I'm still in the infancy of my build , what new build are you doing for the next SAW ? , another Tikka ? , you should be able to acheive any coal you wish with that action magazine dependant ! as for me at the present time I'm limited to a coal of 2.885 for reliable feeding from my FNH SPR build . Even if I had all the stars aligned the weather here is horrid ! , three feet of snow and single digit temps for the foreseeable future . Please keep everyone infofmed of your progress .

Thanks again !, and all the best in 2019 !

Sorry mate, I forgot to reply to this. Pretty much the same again (another tempest) except with a carbon fibre barrel. The current tempest will get the PM2 put onto it and the build with the carbon barrel will get the 4-16x at this stage. Both rifles are going to get the freebore extended to 0.100” for the intent of seating the 162gr ELD-M at an OAL of 2.900”. I don’t have much to report from the range trip, 43 grains of Reloader 16 was a little slow but the barrel is still new. Those 162s are awesome in the wind though, absolute juggernauts. I’m looking forward to seeing what the 180s are like.

With the 0.45” freebore reamer, you’ll need to start your loads at around 2.840-2.845” for your break in I’d suspect. That’s where I started and was using the 162ge ELD-Ms. If you’re only going to use it as a hunting rifle, then the 150gr ELD-X projectiles might be an option due to their projectile BOL. If you want to use the 160gr class of projectiles, I’d suggest finding Berger 168gr VLD Hunting and target projectiles, which have projectile base to ogive lengths of approximately 0.705” and 0.707”, respectively. For comparison, the hornady 162gr ELD-M is at 0.730” and the ELD-X is even longer again. The Sierra 160gr TMK is approximately 0.762” for BOL. It may end up being insignificant but you might snatch a little more velocity using the bergers.

The Bergers are what I plan on going with as weight consistency is much better than the ELDs from my experience and they seem to be a better hunting bullet to begin with . My coal of 2.885 /2.900 MAX for mag length pretty much dictates the 0.45 FB Reamer , if only I were not a CRF FN devotee I could have should have gone with a TIKKA build ! . For the time being I plan on having LRI do a tier 1 action job with a bushed pin and WTO do the barrel/chambering .

Please post all your results with this cartridge ! .

Please post all your results with this cartridge ! .

I would be curious to see if the same could apply to regular 308 or regular 7mm-08... run them with lapua palma brass at higher pressures... I looked for on google about it and could not find anybody talking about the 308 Lapua Palma brass as an opportunity to run them with more pressure than regular 308 brass…?The key to the performance seems to lie in the Lapua Small Primer case, allowing it to run higher pressures. Eyeballing it looks very similar to what would be a 7mmSLR.

If this is the case, then I would give a try to lapua palma brass on regular 7mm-08 to see if it can keep up with the 7mm SAW. The results could be interesting! (no need for a new barrel and new dies, just new brass)

Palma would work for 7/08 REM , however it would have a shorter neck than the SAW and less powder capacity and possibly limit bullet weight. You would still be sizing and using powder to form brass on a minuscule scale.

Good info, I'm going to run a test with some R16 as soon as I get my rifle back from WTO I'm hoping its reported lower pressure with better speed in some chamberings over varget will get me the velocities im looking for. Was having awful pressure spikes with varget in my TAC30, piercing cci450s pretty bad even at 42gr. Also had real weird issues with my loads sometimes getting stuck in the chamber maybe a bad set of redding dies but it was hard to tell what's going on.

Good info, I'm going to run a test with some R16 as soon as I get my rifle back from WTO I'm hoping its reported lower pressure with better speed in some chamberings over varget will get me the velocities im looking for. Was having awful pressure spikes with varget in my TAC30, piercing cci450s pretty bad even at 42gr. Also had real weird issues with my loads sometimes getting stuck in the chamber maybe a bad set of redding dies but it was hard to tell what's going on.

I had some teething issues with mine. What's your headspace measuring on your die formed and once fired cases?

From the die using a Hornady .375 gauge I was getting ~1.618 IIRC fire formed they came out at 1.621. Most would resize and load just fine but 1 in every 4 or 5 would get super stuck in the chamber. Tried bumping back further, seating depth, no crazy out concentricity issues but all the ones that got stuck would have a bad rub mark on the bullet on one side, I'd have to resize it 2,3 even 4 times (resizing die with no expander to carbide neck mandrel) before I could seat the bullet have have it not get stuck in the chamber.

As for the Varget, I am running suppressed, not sure if maybe that's bumping up the pressure or what. Maybe my action just doesn't like varget at all, pierces even hard magnum primers like a mofo.

After a bunch of emails with Clayton, we couldn't figure out the issues so I sent it back with the dies so they could take a look at it. They're great folks I'm sure they'll get it sorted.

As for the Varget, I am running suppressed, not sure if maybe that's bumping up the pressure or what. Maybe my action just doesn't like varget at all, pierces even hard magnum primers like a mofo.

After a bunch of emails with Clayton, we couldn't figure out the issues so I sent it back with the dies so they could take a look at it. They're great folks I'm sure they'll get it sorted.

That's pretty nuts about the varget. Clayton told me to just give the R16 a crack first as he was getting some solid results from it.

My brass prep process is just: Size, chamfer, neck expansion, neck turn. I trim slightly into the shoulder.

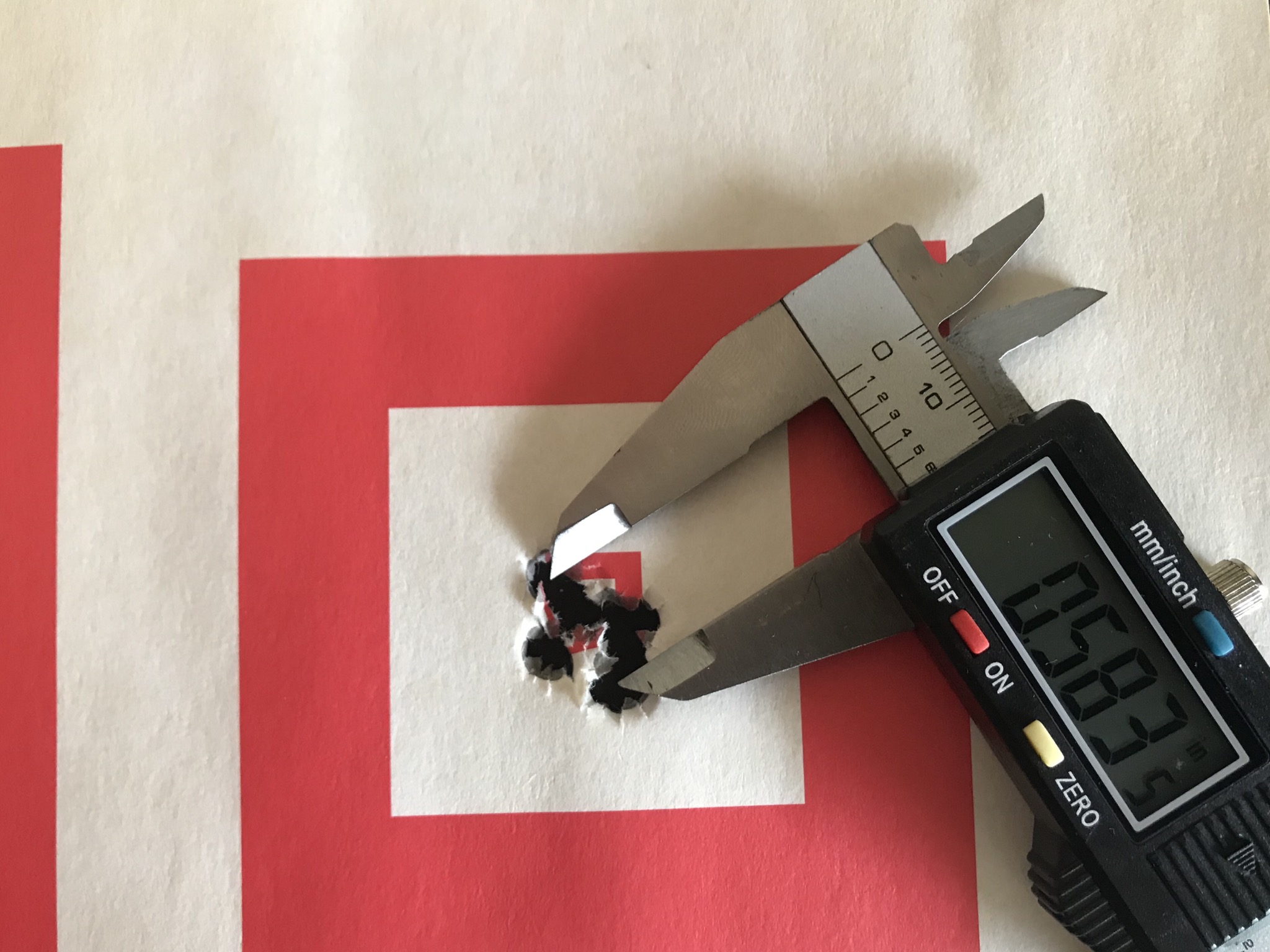

My headspacing measures at 1.597" (I used the .400 gauge thought) for a sized case through the die and comes at 1.611" for the fireformed brass. I had some rounds get "lost" in the chamber and not extract thanks to this length so now just size to 1.611-12" for the virgin cases. I also had a few soft struck cases thanks to the incorrect headspacing. I neck size as well, and this has reduced the stuck cases issue. Those results I posted yesterday were the best I've had through this rifle and I think I'm 90% there for working out the bugs. The group at 2865fps measured at 0.161" (yeah, only three rounds though...).

I hope it gets sorted mate, that would frustrate the hell out of me

My brass prep process is just: Size, chamfer, neck expansion, neck turn. I trim slightly into the shoulder.

My headspacing measures at 1.597" (I used the .400 gauge thought) for a sized case through the die and comes at 1.611" for the fireformed brass. I had some rounds get "lost" in the chamber and not extract thanks to this length so now just size to 1.611-12" for the virgin cases. I also had a few soft struck cases thanks to the incorrect headspacing. I neck size as well, and this has reduced the stuck cases issue. Those results I posted yesterday were the best I've had through this rifle and I think I'm 90% there for working out the bugs. The group at 2865fps measured at 0.161" (yeah, only three rounds though...).

I hope it gets sorted mate, that would frustrate the hell out of me

Simia, what dies are you using and how often do you anneal your brass?

I'm sending my bolt to Gre-Tan to be bushed & pin turned today and will most likely order a barrel from Bartlein soon, planning on a Marksman contour @26"s left gain twist possibly fluted but can't decide on going fluted or not!.

Happy Shooting!

I'm sending my bolt to Gre-Tan to be bushed & pin turned today and will most likely order a barrel from Bartlein soon, planning on a Marksman contour @26"s left gain twist possibly fluted but can't decide on going fluted or not!.

Happy Shooting!

I haven’t annealed the brass yet mate, I was going to get it done after 5 firings. I still have to form about 200 pieces of brass for a total of 500 pieces so annealing probably won’t happen for a while.

I’m secretly hoping the 7mmSAW alphamunitions brass makes it to our shores sooner than later and I’ll get that sorted from the first firing.

I’m secretly hoping the 7mmSAW alphamunitions brass makes it to our shores sooner than later and I’ll get that sorted from the first firing.

Really interested in how dependent this cartridge is on the small rifle primer. I could be interested in this if I could use the Lapua 7mm-08 brass and 4350 for powder. I'm also wondering if this would be any benefit to me as I would apply it to an 18" barrel.

have 100 each of 162eldm and 180eldm on the way. gonna see how they compare at distance as soon as everything arrives. just waiting on the headstamped brassDoes anyone plan to test 180 class bullets like the 175 ELD-X/180 ELD/183SMK? Would be interesting to see if these super low form factor bullets can reach 2700+ fps.

According to alphamunitions WTO will be getting brass very soon if not already!, shot them an e-mail and that was their reply.

My other SAW build is turning up next week. I’m wondering if I should just run the 150 grain hornadys in this one and not get the freebore extended as it’s primarily going to be used as a hunting gun. Has anyone been running the 150s?

Sweet looking rig, let us know how it shoots!. I almost went with a Proof Carbon on my build but went with a Bartlein #23 left gain twist 1n9-8.25, bummer is the barrel will not be ready till August.

Cheers mate, it'll have the freebore bumped to the same length as the other rifle and I'll find a load between them that shoots similar enough. This rifle balances bloody well with that barrel and optic, really easy to handle.Sweet looking rig, let us know how it shoots!. I almost went with a Proof Carbon on my build but went with a Bartlein #23 left gain twist 1n9-8.25, bummer is the barrel will not be ready till August.

How come you went the gain twist?

No reason in particular same as left vs right twist, I just wanted something different. Clayton and Brady @ Bartlein said it should work out great. I plan on 162-180 grain only and really hope the Berger 175 Hunter Elites work. WTO will do the work, to get 3.0"s I am having them remove the spacer plate on the magazine well for the hinged floor plate bottom metal. This will be a budget build hunting rifle.

FN PBR receiver in a McMillan A3G stock

FN PBR receiver in a McMillan A3G stock

Simia, forgot to ask, what bottom metal and magazine are you using and what coal can you get with it?,I would be happy if I could get close to 3.0. I may go to CDI and ARC magazine (2.970) further down the road when funds allow.

Ah fair enough mate. I'm interested to hear how you go with the 175s, I tried to grab a box to try but there's none available here at the moment.

CDI and ARC mags will definitely fit my handloads. Mine are measuring 2.900" OAL (noting that CBOL with the 162s can be a pain in the arse to use due to inconsistency - I had the throat lengthened to accommodate for this to allow for an approximately 0.02" jump). I'm getting good velocity with no pressure signs at that length with 46.4gr of Reloader 16. If you can seat longer though, that'll definitely help with those 175s.

CDI and ARC mags will definitely fit my handloads. Mine are measuring 2.900" OAL (noting that CBOL with the 162s can be a pain in the arse to use due to inconsistency - I had the throat lengthened to accommodate for this to allow for an approximately 0.02" jump). I'm getting good velocity with no pressure signs at that length with 46.4gr of Reloader 16. If you can seat longer though, that'll definitely help with those 175s.

Glad I stumbled across this thread...I was pretty set on building a 7 SAUM to be able to use 180 class bullets, but was worried about finding brass. Now you all have me looking real hard at a 7 SAW.

taking mine out this weekend to put some rounds through it before i start load development

27" benchmark. heavy varmint. 8 twist. 162 ELDMs. H4350

27" benchmark. heavy varmint. 8 twist. 162 ELDMs. H4350

taking mine out this weekend to put some rounds through it before i start load development

27" benchmark. heavy varmint. 8 twist. 162 ELDMs. H4350

liar

I’m keen to hear what velocities you hit with that barrel lengthtaking mine out this weekend to put some rounds through it before i start load development

27" benchmark. heavy varmint. 8 twist. 162 ELDMs. H4350

I’m keen to hear what velocities you hit with that barrel length

Stand by while I pop a couple out my window with his rifle ?? will start at 44.5 h4350 (Clayton rec) and see how it goes. New Alpha brass

Ha! Yeah nice. What projectile(s)? I’ve only tried reloader 16Stand by while I pop a couple out my window with his rifle ?? will start at 44.5 h4350 (Clayton rec) and see how it goes. New Alpha brass

Ha! Yeah nice. What projectile(s)? I’ve only tried reloader 16

It's B Graham's rifle, 162elds. I'll send a few tomorrow to get a baseline

Similar threads

- Replies

- 21

- Views

- 766

- Replies

- 8

- Views

- 429