Had a few more rifles to bed so I figured that I'd take the time to get a few pics and share.

There were a few things different about each job and hopefully this may help a few DIY guys.

Enjoy.

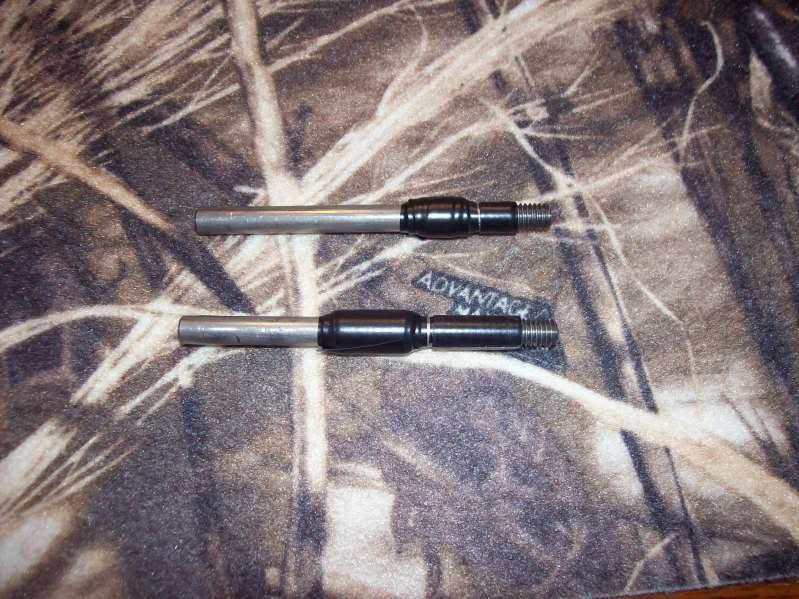

First one was a Savage FTR single shot. It has a 30 inch heavy barrel so we wanted a pad in

front of locknut to help support barrel. Also, one thing that I am sure several others have

done before, and will again, is to forget the lugs in the barrel nut when you bed. I have.

Had to beat the action out with a hammer on the inletting screws and break up the mechanical

lock I had just created

The tip is to fill those with modeling clay like any other crevice

The tip is to fill those with modeling clay like any other crevice

you don't want epoxy in. Then I wrap tape around my inletting screw to center it in the

pillar hole. Also tape the front/bottom/sides of the recoil lug. Then I dug out recesses all

along the bedding area for compound to lock into. I taped the barrel in two places to center

action/barrel in the stock. Also ran tape across stock under where barrel should be for where

I want bedding to end. Finish it off with some more modeling clay and that's about it. Coated

with acra release agent and bed. Some use the srews to pull action into stock/pillars. I don't

anymore. Some factory actions have a littel warp from heat treating. You can put quite a bit

of tension on an action with the screws. I prefer to bed it in the with the action "relaxed"

if that's the way to put it. I hold it in place with black tape or surgical tubing.

I used Devcon steel putty in these applications.

Came out looking OK. Just need to trim up a bit.

After trimming

There were a few things different about each job and hopefully this may help a few DIY guys.

Enjoy.

First one was a Savage FTR single shot. It has a 30 inch heavy barrel so we wanted a pad in

front of locknut to help support barrel. Also, one thing that I am sure several others have

done before, and will again, is to forget the lugs in the barrel nut when you bed. I have.

Had to beat the action out with a hammer on the inletting screws and break up the mechanical

lock I had just created

you don't want epoxy in. Then I wrap tape around my inletting screw to center it in the

pillar hole. Also tape the front/bottom/sides of the recoil lug. Then I dug out recesses all

along the bedding area for compound to lock into. I taped the barrel in two places to center

action/barrel in the stock. Also ran tape across stock under where barrel should be for where

I want bedding to end. Finish it off with some more modeling clay and that's about it. Coated

with acra release agent and bed. Some use the srews to pull action into stock/pillars. I don't

anymore. Some factory actions have a littel warp from heat treating. You can put quite a bit

of tension on an action with the screws. I prefer to bed it in the with the action "relaxed"

if that's the way to put it. I hold it in place with black tape or surgical tubing.

I used Devcon steel putty in these applications.

Came out looking OK. Just need to trim up a bit.

After trimming