Re: A few more bedding tips (Pic Heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: craigp40</div><div class="ubbcode-body">I've done bedding jobs on several rifles and they all came out quite well. The hardest part that I find to get right is the trimming. What do you use to get the nice clean edges on the bedding just like when GAP or LSR do it? I usually end up chipping it, especially at the end closest to the forend. I know this is strictly cosmetic, but it sucks when you put the work into it and blemish it at the very end. </div></div>

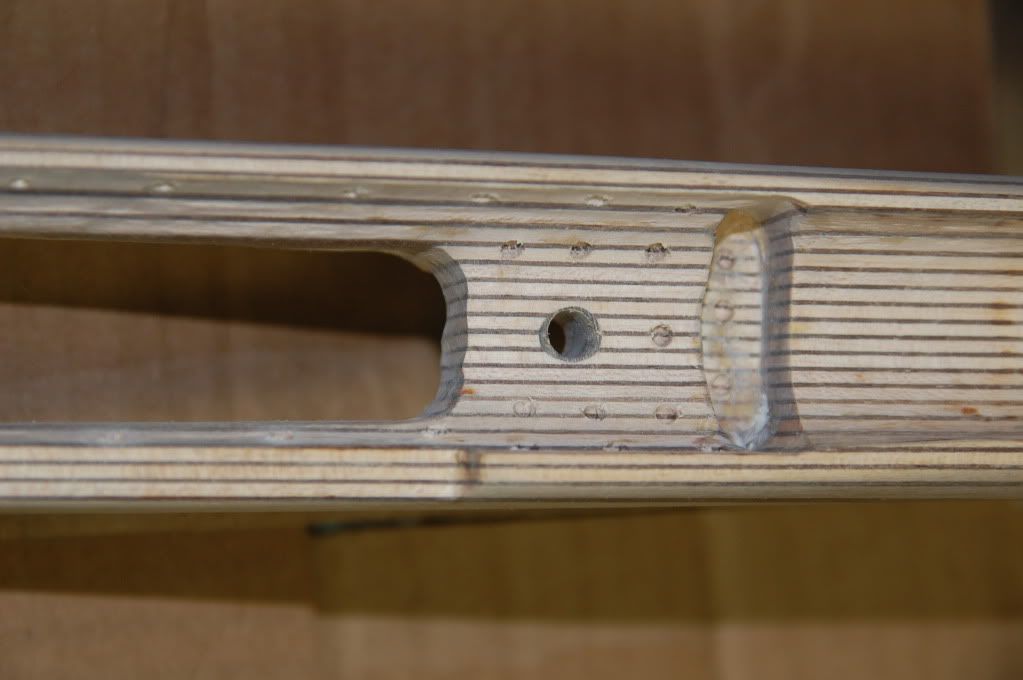

Try putting a layer of tape along the barrel channel. The bedding compound sticks to the tape witch can just be pulled off when done. You really do need to let the compound set up completely before removing the tape however. I started doing this to keep bedding compound off any finished parts of the stock. PITA to get off without damaging finish.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: craigp40</div><div class="ubbcode-body">I've done bedding jobs on several rifles and they all came out quite well. The hardest part that I find to get right is the trimming. What do you use to get the nice clean edges on the bedding just like when GAP or LSR do it? I usually end up chipping it, especially at the end closest to the forend. I know this is strictly cosmetic, but it sucks when you put the work into it and blemish it at the very end. </div></div>

Try putting a layer of tape along the barrel channel. The bedding compound sticks to the tape witch can just be pulled off when done. You really do need to let the compound set up completely before removing the tape however. I started doing this to keep bedding compound off any finished parts of the stock. PITA to get off without damaging finish.