The AI manual does call for a break in and lists their procedure. What does it hurt?But why were you cleaning ? These are quality barrels. Not Remington copper catchers.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Accuracy International AT-X

- Thread starter Peter Laurvick

- Start date

Patched stuckThe AI manual does call for a break in and lists their procedure. What does it hurt?

Wear to rifling

Wear to crown

Wear to throat

Chance of solvent getting in action / trigger.

I’ve never broke in any Bartlien quality barrel and out of probably 20+ the only one that doesn’t shoot phenomenally is due to a terminus action issue

Let us know how the bore scoping turns out. Seriously...Took my scope off my .223 trainer and slapped it on my new AT-X for a few rounds of breaking in...which is mostly breaking me in to familiarize myself with the trigger and rifle.

I shot five to zero, and then (4) 5-round groups after a cleaning patch battle that cost me a new rod (mostly my fault).

I did chunk one low, but otherwise everything felt good.

View attachment 8182189

Please don't mind the POI shifts, I let the rifle cool for a long time between groups, and the shift is merely me not getting back behind the rifle consistently between groups (was screwing with buttpad placement).

Unfortunately, I had a cleaning patch sick itself inside the barrel. The rod wouldn't budge either way. I noticed what felt like a rough spot on my first patch, but it made it though, and I attributed it to fouling. #2 got stuck worse than I've ever had one stick before.

^ Light tapping with a mallet got the rod through, but the patch was still stuck, and I had to tap the rod backwards (and I boogered up the threads on the way back).

Cleaned the patch out. Grabbed a .243 jag and tried again...could feel a friction point, and then the rod stuck again. This time I was able to pull the rod back out. Ran a wet bronze brush (CLP) through about 30 times and it patched dry without issue. That was after shot #4.

I then shot the four groups above over the next 90 minutes.

I'm probably going to run my borescope through the barrel in the next day or two, just to see if I find anything...hopefully I got whatever it was shot out.

Lol, the barrel that came on my atx was great for about 30 rounds, then it became so copper fouled it wouldn't shoot 1 moa. Clean it and good for 30 more. The throat looked like it was cut with a chipped auger and the rifling pulled copper from end to end.But why were you cleaning ? These are quality barrels. Not Remington copper catchers.

I gave up on it quickly, it's a 25cm now.

Hmm. Who cuts these barrels now. ? Mile high ?Lol, the barrel that came on my atx was great for about 30 rounds, then it became so copper fouled it wouldn't shoot 1 moa. Clean it and good for 30 more. The throat looked like it was cut with a chipped auger and the rifling pulled copper from end to end.

I gave up on it quickly, it's a 25cm now.

I sold my atx barre cause I had piles from my AXSA. Ida figured the quality would be the same. Guess not

I only know it did not come from Mile High. I moved on pretty quick with the price of components.Hmm. Who cuts these barrels now. ? Mile high ?

I sold my atx barre cause I had piles from my AXSA. Ida figured the quality would be the same. Guess not

Domestically, Win Tac cuts all AI barrelsHmm. Who cuts these barrels now. ? Mile high ?

I sold my atx barre cause I had piles from my AXSA. Ida figured the quality would be the same. Guess not

But why were you cleaning ? These are quality barrels. Not Remington copper catchers.

Dude...I'm going to take some pictures.

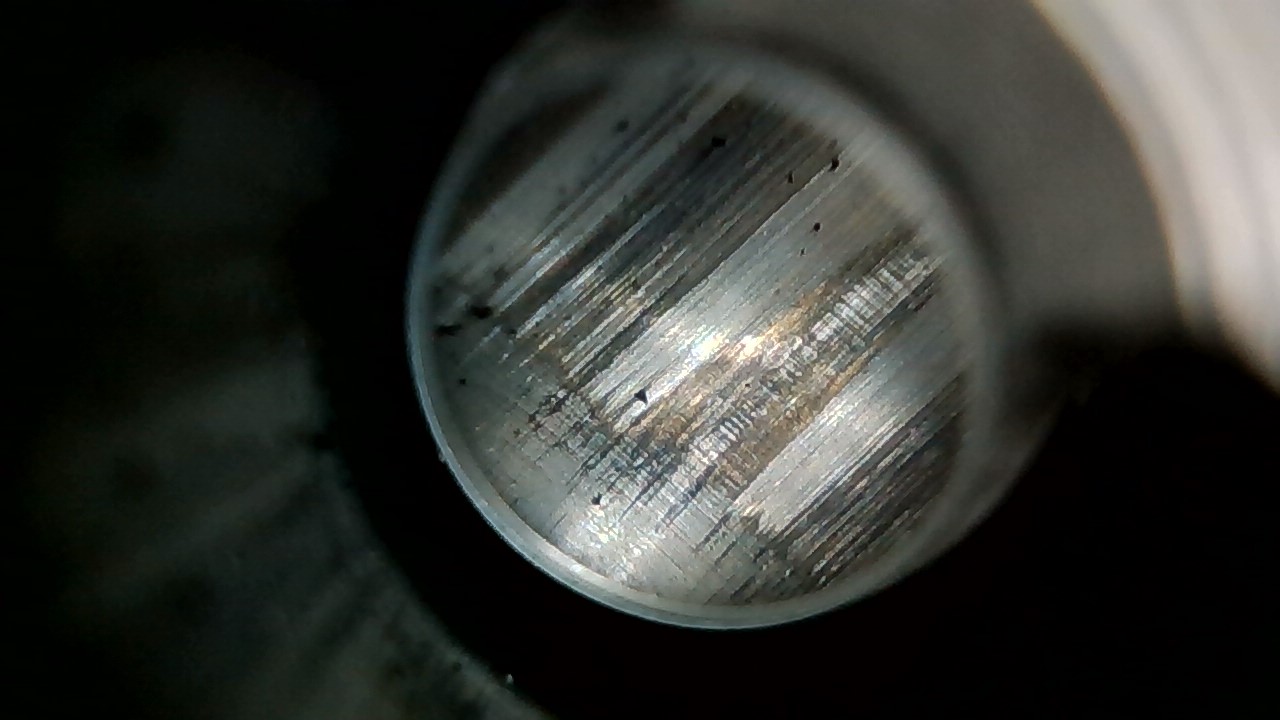

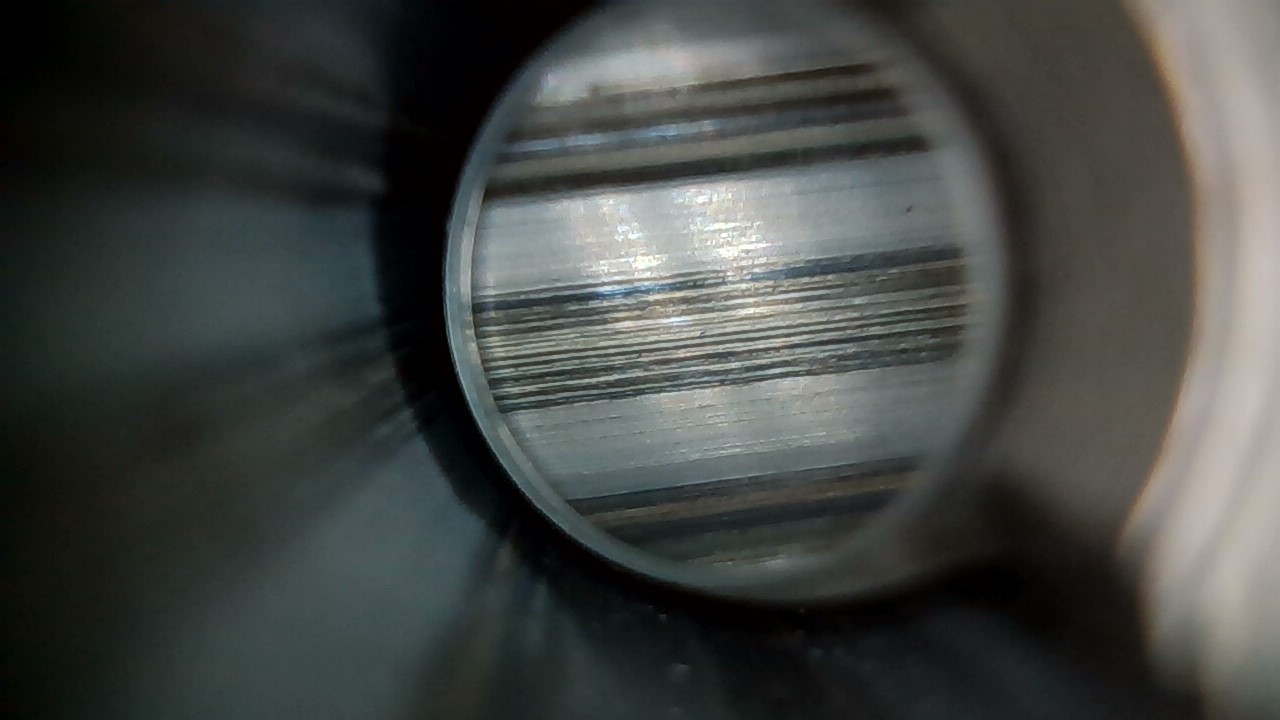

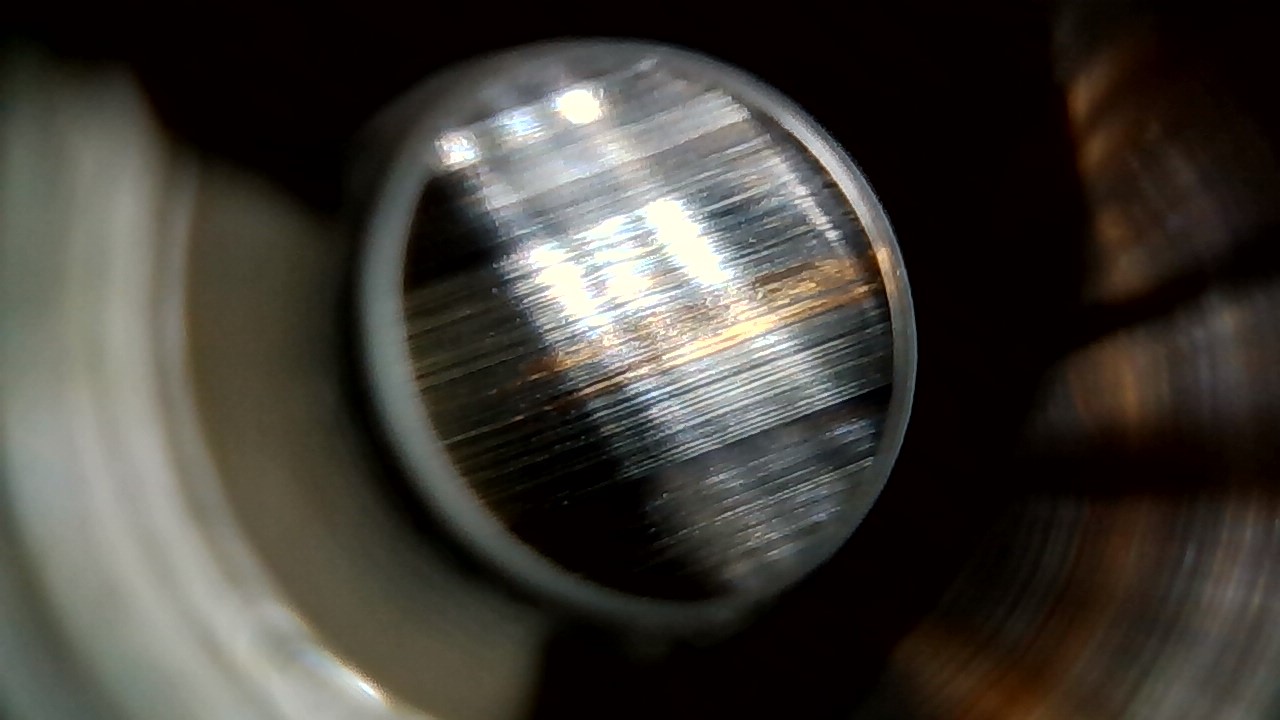

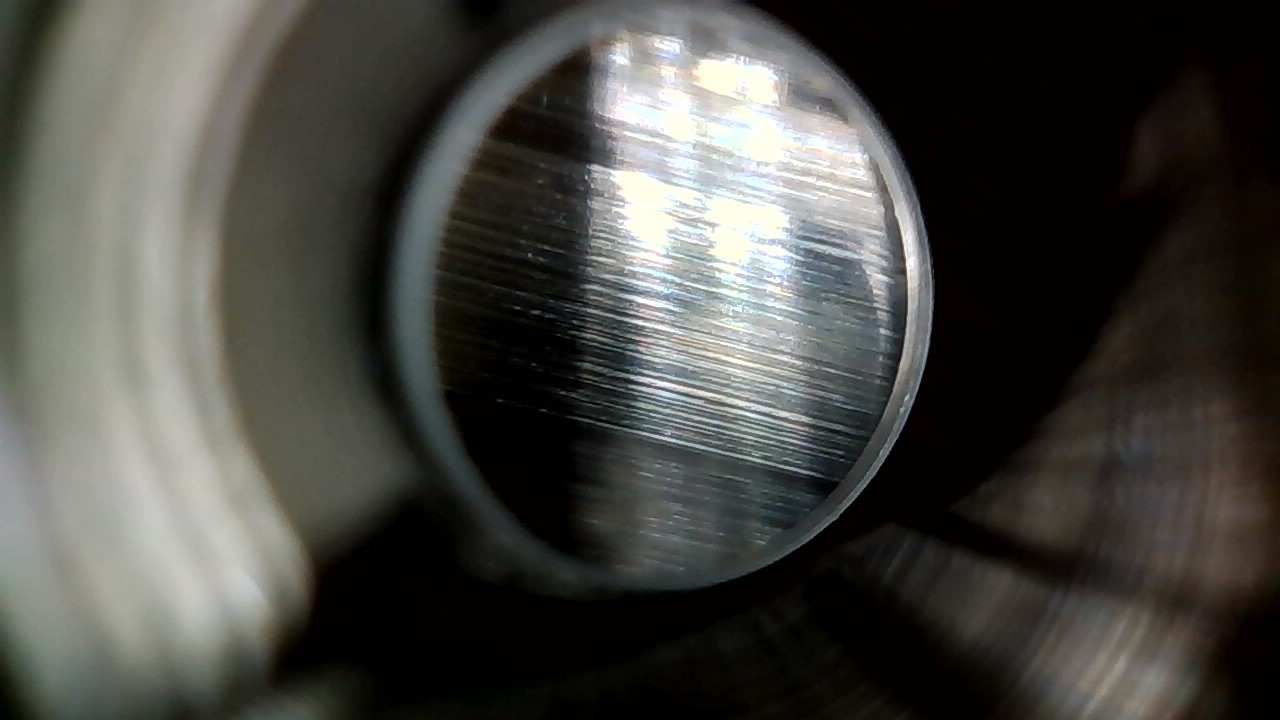

I took the borescope to the barrel last night to try to see if I had a deposit or something where the patches caught.

With 20 rounds since my last patching and 25 rounds total...frigging copper the whole length.

Because I don't want to shitpost and disappear for the day, I'll throw these two photos up for now...I'll document better before and after cleaning tonight.

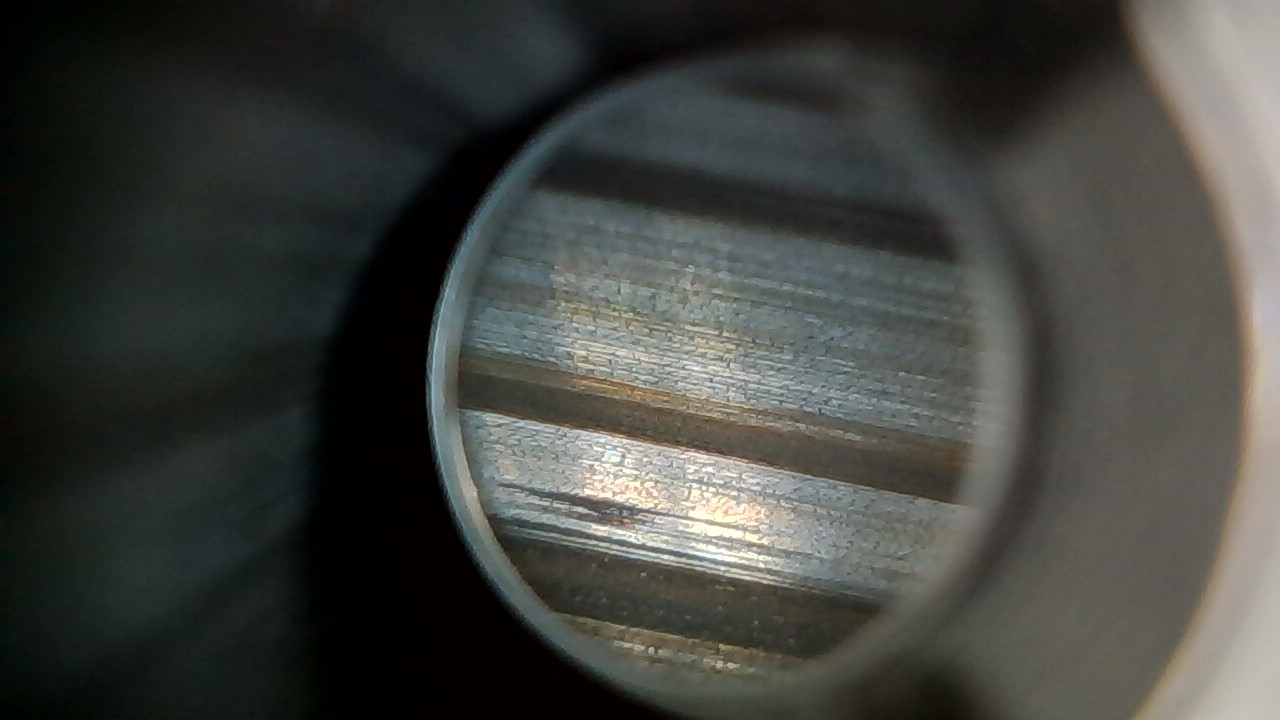

About like this from the whole way down:

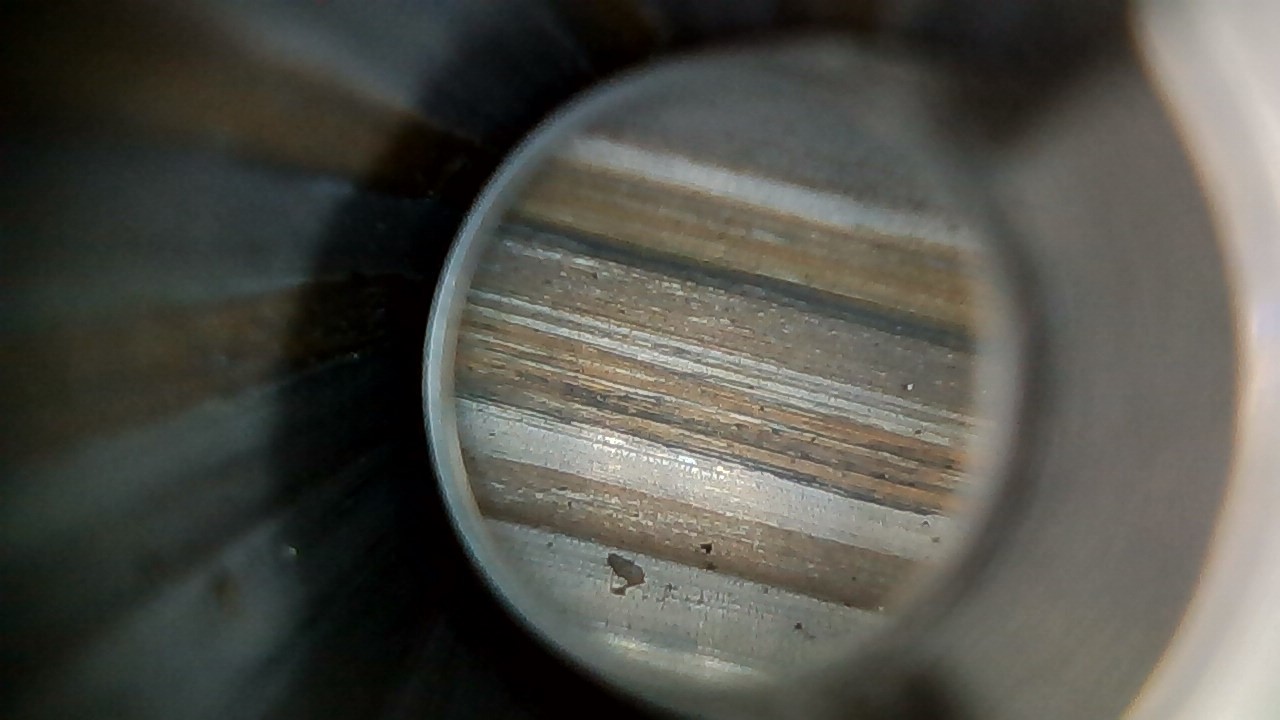

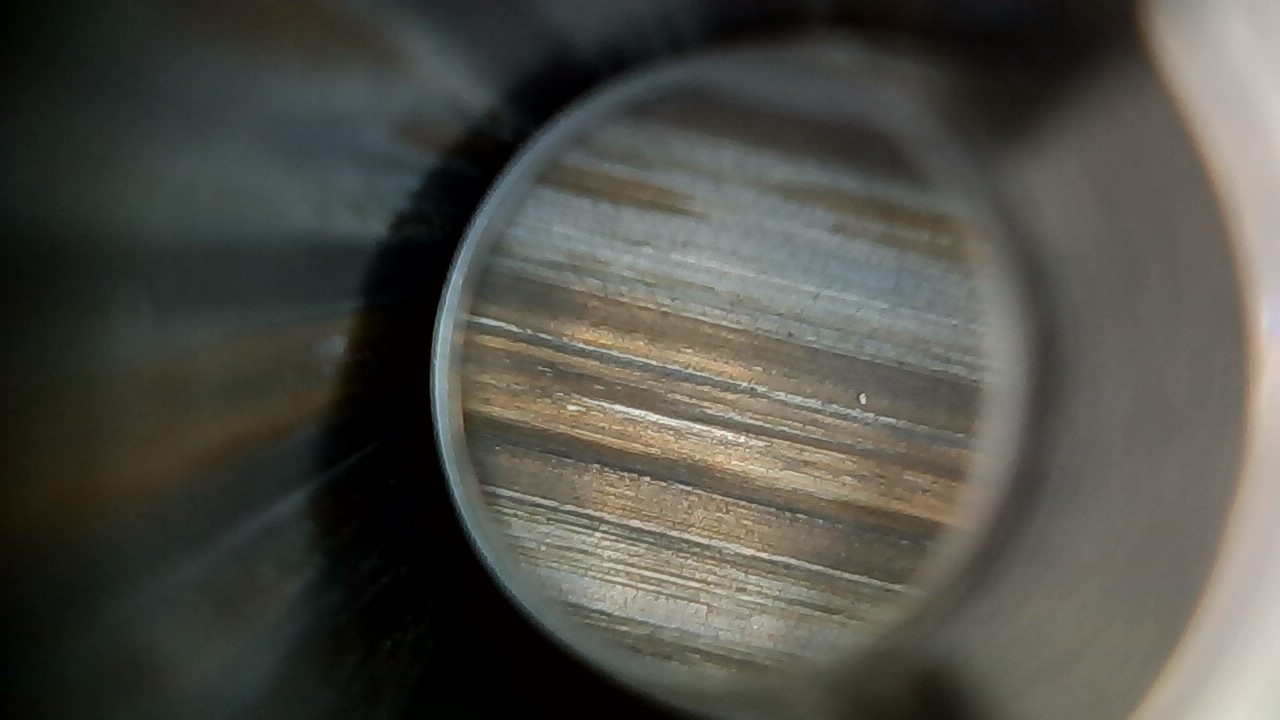

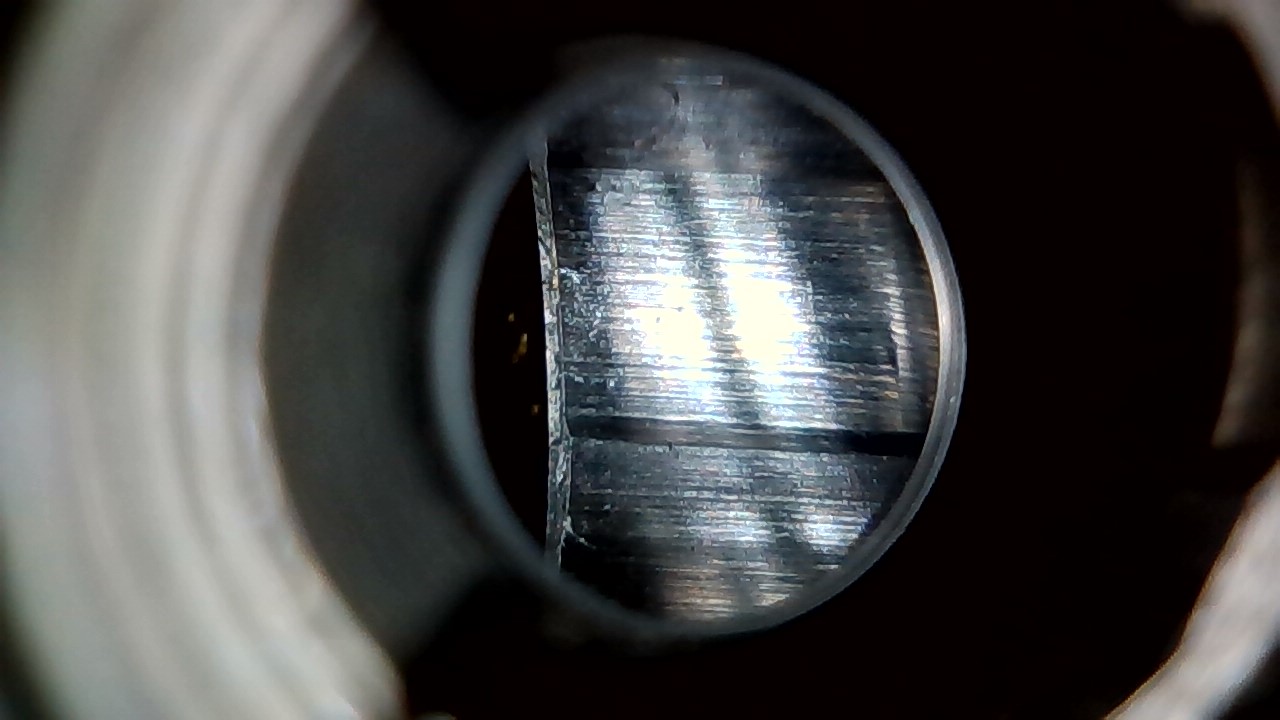

And from about 2 - 6" from the muzzle, it almost looks like fire cracking. I know it isn't...but this is unusual. For reference, I have 3 Kriegers and a Brux here at the house, and I've never seen this before during break-in.

* I'm not super concerned. The barrel shoots fine. Hopefully with another 100 rounds and probably some frequent cleaning it'll hopefully fix itself.

Last edited:

I believe AI started supplementing Bartleins with Hawk Hills (due to shortages) in the AT-X last year. Does anyone know from any markings etc how to tell them apart? Not saying yours is necessarily not a Bartlein, but your pics make me wonder....

Lol, the barrel that came on my atx was great for about 30 rounds, then it became so copper fouled it wouldn't shoot 1 moa. Clean it and good for 30 more. The throat looked like it was cut with a chipped auger and the rifling pulled copper from end to end.

I gave up on it quickly, it's a 25cm now.

My experience isn't far from yours at the moment. I'll take better photos tonight...but there are a lot of tooling marks going into the rifling on mine too.

I'll add here too that I obviously didn't follow AI's break-in, so the fault lies on me. My patch did get stuck after round #4 though.

Last edited:

I believe AI started supplementing Bartleins with Hawk Hills (due to shortages) in the AT-X last year. Does anyone know from any markings etc how to tell them apart? Not saying yours is necessarily not a Bartlein, but your pics make me wonder....

I have no clue on identication. I only know of what I've read on these forums, so I certainly don't want to accidentally trash a wrong manufacturer in my stupidity.

This one is a 5R. Does Hawk Hill make those?

Last edited:

I’d figure hawk hill is better than bartlienI believe AI started supplementing Bartleins with Hawk Hills (due to shortages) in the AT-X last year. Does anyone know from any markings etc how to tell them apart? Not saying yours is necessarily not a Bartlein, but your pics make me wonder....

Unless they cut corners to meet a price point or volume or something. Hope not.

Remind me not to talk about break in lol

Their site says 4 groove (so maybe that's the easy way of identifying) but I thought for sure I had a 5R Hawk Hill once upon a time (and I'm sure they'd be capable of producing 5R if that's what AI specified).I have no clue on identication. I only know of what I've read on these forums, so I certainly don't want to accidentally trash a wrong manufacturer in my stupidity.

This one is a 5R. Does Hawk Hill make those?

Has anyone seen a 4 groove factory AT-X barrel?

Last edited:

Here's what Tom Irwin said in Nov '21I do not think you will have any problem with time for load development and break in using Win Tac barrels.

All of the barrels on the AT-X so far have been chambered and threaded by WinTac and most of them are using Bartlein blanks, with the rest from Hawk Hill.

AINA have been using WinTac barrels on AXMC and AXSR rifles for six years and the performance is world class.

They can be ordered through Mile High and Euro Optic.

Tom Irwin

Accuracy International

That's what Tom Irwin said in Nov '21

I'm going to count my lands/grooves on the way out. If it's 4, maybe Hawk Hill?

Either way, I'm going to edit names out of my post, and just put the number of grooves in its place.

AT-X 6.5 CM here. My barrel looks like the one diggler has. Shoots 1-3 moa using FGMM, Hornady 140 ELDM, a couple of Berger factory loads, and Lapua 136 scenar L. Chamber, grooves, lands look really bad near the chamber. FGMM 140 SMK keep it about 1moa.

Very disappointed to say the least.

Very disappointed to say the least.

I put about 400 thru mine and called it quits, it never got better even after lapping.My experience isn't far from yours at the moment. I'll take better photos tonight...but there are a lot of tooling marks going into the rifling on mine too.

I'll add here too that I obviously didn't follow AI's break-in, so the fault lies on me. My patch did get stuck after round #4 though.

Ima start a new thread

www.snipershide.com

www.snipershide.com

AT-X accuracy ?

Let’s hear it How’s your AT-X with stock barrel shoot ? Please post approx group size and year your At-x is (it’s either by the serial number or part of it ) Hearing bad reports Also post number of grooves in barrel of possible. I sold my barrel unfired as I had plenty from my axsa but...

I did not get to my barrel before I had to go help my wife at her vet clinic.

I will post a lot of pictures tonight. I might even record it and put it on my YouTube channel if I get the weekend to do this.

My barrel is shooting acceptable at the moment, so I'm not stressed. I might not be a fan if I have to remove the copper after every 20 rounds. I'd bet that I could get better than .6s with handloads if I wanted to chase this.

Fortunately, I have a 6mm, 29" Krieger blank sitting at the house, and Matt Stewart is going to use my stuff to set up for doing AI AT/AX/AT-X prefits.

I will post a lot of pictures tonight. I might even record it and put it on my YouTube channel if I get the weekend to do this.

My barrel is shooting acceptable at the moment, so I'm not stressed. I might not be a fan if I have to remove the copper after every 20 rounds. I'd bet that I could get better than .6s with handloads if I wanted to chase this.

Fortunately, I have a 6mm, 29" Krieger blank sitting at the house, and Matt Stewart is going to use my stuff to set up for doing AI AT/AX/AT-X prefits.

This barrel definitely has 5 lands with the radius and grooves, and I have updated my previous posts accordingly. Barrel is marked "W7732" on the outside.

1) With the barrel shooting as well as it does, I'm not super concerned...unless it copper fouls again this badly.

2) Most of the issues seem to have come off with a decent cleaning. Time taken to get to the "after" photos was approx. 40 minutes and 30 patches. Right now ~97% of the copper is gone.

Here are some photos with 25 rounds total down the barrel by me. I'll try to list the photos with distance from chamber.

Rifling start at the lands and grooves:

6 Inches from chamber, nothing unusual to report really:

10 inches from chamber, turning into a copper factory:

14 inches from chamber, same:

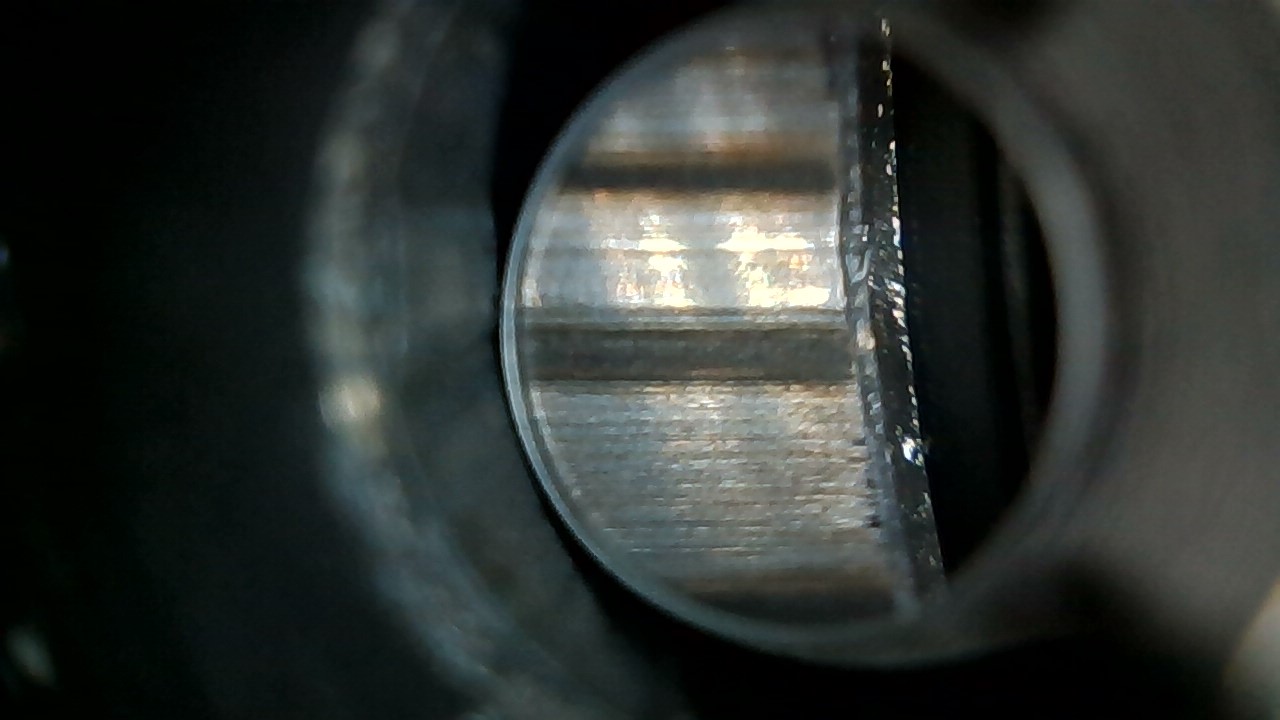

18 inches from chamber, and this is where I got the patch stuck. This is where that cracking appearance really starts:

22 inches from chamber, less copper but more of that weird appearance:

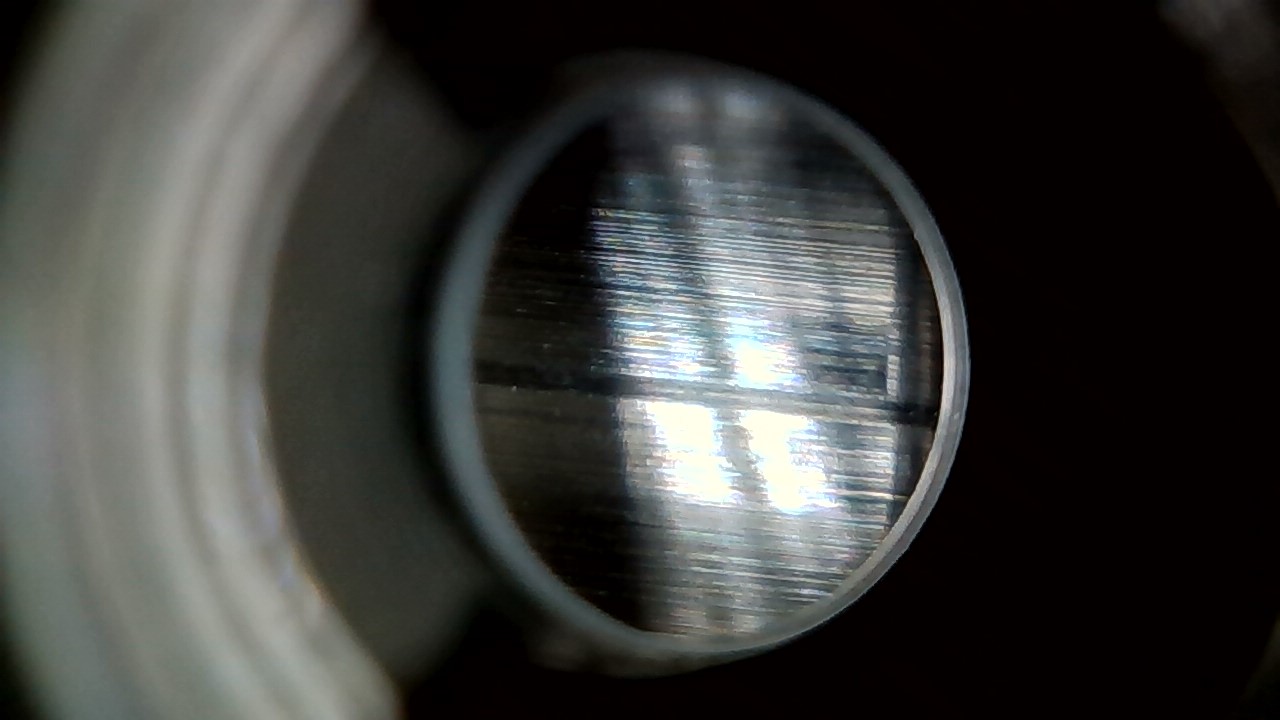

Crown:

1) With the barrel shooting as well as it does, I'm not super concerned...unless it copper fouls again this badly.

2) Most of the issues seem to have come off with a decent cleaning. Time taken to get to the "after" photos was approx. 40 minutes and 30 patches. Right now ~97% of the copper is gone.

Here are some photos with 25 rounds total down the barrel by me. I'll try to list the photos with distance from chamber.

Rifling start at the lands and grooves:

6 Inches from chamber, nothing unusual to report really:

10 inches from chamber, turning into a copper factory:

14 inches from chamber, same:

18 inches from chamber, and this is where I got the patch stuck. This is where that cracking appearance really starts:

22 inches from chamber, less copper but more of that weird appearance:

Crown:

Last edited:

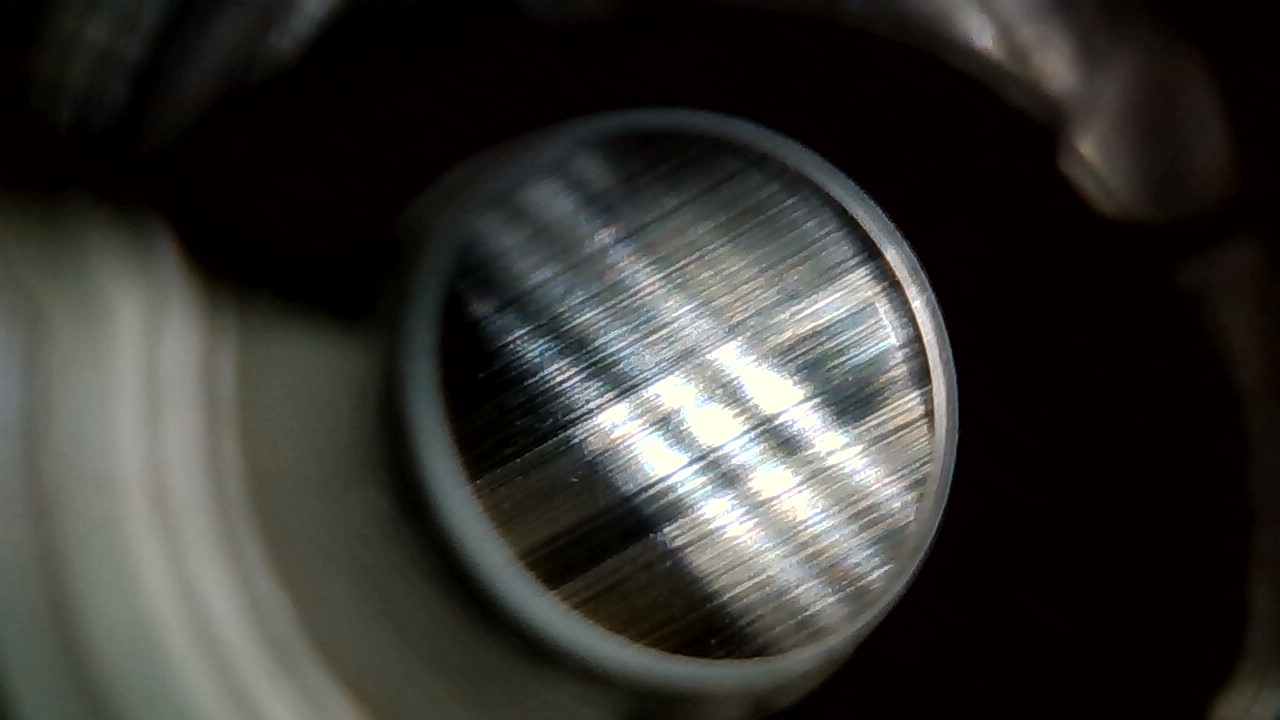

After a decent cleaning.

Rifling start at the lands and grooves. Keep in mind this barrel has 25 rounds on it (plus whatever from the factory):

6 inches in. Much happier camper to see this:

10 inches in:

16ish inches in is where I found the only remaining copper:

22ish inches in where the majority of that cracking looking copper was:

Crown:

Rifling start at the lands and grooves. Keep in mind this barrel has 25 rounds on it (plus whatever from the factory):

6 inches in. Much happier camper to see this:

10 inches in:

16ish inches in is where I found the only remaining copper:

22ish inches in where the majority of that cracking looking copper was:

Crown:

Vudoo V360 in an AT-X AICS Short upper chassis, not sure if these are available anymore. Shorter front end, have to use the compact bridge.

Is the bag rider available now? What can you tell me about the thumb rest?Vudoo V360 in an AT-X AICS Short upper chassis, not sure if these are available anymore. Shorter front end, have to use the compact bridge.

View attachment 8182906

Thanks!

Is the bag rider available now? What can you tell me about the thumb rest?

Thanks!

I'm not a financial sponsor of the site yet, so don't want to put a link up however if you visit lowvisgear.com you'll find it.

The thumb rest is 3D printed by a local Aussie here, we helped with the development of that also, it's excellent and weighs about nothing. It replaces folder hardware however so the stock will not clamp down when folded anymore which isn't a major issue.

Last edited:

I was talking with an AI rep several weeks ago; he told me that the 5 groove barrels are all Bartlein blanks finished by WinTac, and the 4 groove barrels are made by Hawk Hill.This barrel definitely has 4 lands with the radius and grooves, and I have updated my previous posts accordingly. Barrel is marked "W7732" on the outside.

1) With the barrel shooting as well as it does, I'm not super concerned...unless it copper fouls again this badly.

2) Most of the issues seem to have come off with a decent cleaning. Time taken to get to the "after" photos was approx. 40 minutes and 30 patches. Right now ~97% of the copper is gone.

Here are some photos with 25 rounds total down the barrel by me. I'll try to list the photos with distance from chamber.

Rifling start at the lands and grooves:

View attachment 8182840

6 Inches from chamber, nothing unusual to report really:

View attachment 8182842

10 inches from chamber, turning into a copper factory:

View attachment 8182843

14 inches from chamber, same:

View attachment 8182845

18 inches from chamber, and this is where I got the patch stuck. This is where that cracking appearance really starts:

View attachment 8182847

22 inches from chamber, less copper but more of that weird appearance:

View attachment 8182852

Crown:

View attachment 8182854

I'm almost positive mine is a 5 groove, but I'm going to double check.

15 more rounds down the tube today (40 total).

The first 10 inches have significantly less copper than last time (but round count is 15 and not 25). However from 12 - 23 inches it is still pretty heavy.

On the plus: including that almost new barrel CCB shot, my first 5 rounds went into .515". And my zero shifted all of .1 mil low with the barrel removal and cleaning...not shabby.

I'm still optimistic, but maybe a touch jealous of the guys who didn't have to go through this process .

.

The first 10 inches have significantly less copper than last time (but round count is 15 and not 25). However from 12 - 23 inches it is still pretty heavy.

On the plus: including that almost new barrel CCB shot, my first 5 rounds went into .515". And my zero shifted all of .1 mil low with the barrel removal and cleaning...not shabby.

I'm still optimistic, but maybe a touch jealous of the guys who didn't have to go through this process

So I couldn't figure out how I had the radiused lands with there only being 4.

Put my frigging readers on, pulled the barrel (had to clean copper again), then verified with my wife's 3x loupes. I then pulled my M24R out iof the safe and compared. Then I had my wife come and count to verify again.

This barrel is a 5R. I'm back and forth more than a middle-aged woman.

Sorry for the confusion. I'll go put myself in time-out now with the Savage shooters...

Put my frigging readers on, pulled the barrel (had to clean copper again), then verified with my wife's 3x loupes. I then pulled my M24R out iof the safe and compared. Then I had my wife come and count to verify again.

This barrel is a 5R. I'm back and forth more than a middle-aged woman.

Sorry for the confusion. I'll go put myself in time-out now with the Savage shooters...

Some info, a person can get the LOP way down on these if you're willing to get a lil creative. I removed the adj but pad by fully unscrewing the thumb wheel on the pad. Then removed the 2 screws holding the adj butt height capture block in place. Took a pacmeryer 0.5" pad I had laying around from and old project, and used the to ai mounting screws to put it in place. I now have a 12.25", LOP where prior the shortest I could get was over 13". I removed both the gen1 lock screws on cheek and butt, and installed single knurled screws to its tool-less adjustment. I'm average height but in positional shooting from barricades and props I've found a short LOP really helps get steady. Hope this may be helpful for some of you!

Some info, a person can get the LOP way down on these if you're willing to get a lil creative. I removed the adj but pad by fully unscrewing the thumb wheel on the pad. Then removed the 2 screws holding the adj butt height capture block in place. Took a pacmeryer 0.5" pad I had laying around from and old project, and used the to ai mounting screws to put it in place. I now have a 12.25", LOP where prior the shortest I could get was over 13". I removed both the gen1 lock screws on cheek and butt, and installed single knurled screws to its tool-less adjustment. I'm average height but in positional shooting from barricades and props I've found a short LOP really helps get steady. Hope this may be helpful for some of you!

View attachment 8183940View attachment 8183941View attachment 8183942

1. That will really help when I get the kids shooting mine. Thanks for sharing.

2. Man, I thought I did a hack job trimming my Hoplite cheek pad

Shooter side is the "Hollywood" side where everything lines up! Function over form for me. Honestly the cheek pads from anarchy fit better than the hoplite ones so far I think.2. Man, I thought I did a hack job trimming my Hoplite cheek pad

Had no luck searching how many internal weights does the AT-X chassis hold?

Thanks

Up to 3 of the brass bois in the forend.

8 sawtooth weights

3 wintac ATX chassis weights

Top bridge long

2.56kg = 5.6lbs

3 wintac ATX chassis weights

Top bridge long

2.56kg = 5.6lbs

Just picked up my first Ai atx. Couple things that I need some clarification on. First the over travel screw is not moving. I’ve tried heating it up without success. Do these come loctited in place?

The bolt that connects the qd socket towards the folder hinge arrived striped out. Is there a part number or what size is it for replacement.

Lastly the bolt lift seems overly heavy. Is that normal or does it just take time to smooth out?

The bolt that connects the qd socket towards the folder hinge arrived striped out. Is there a part number or what size is it for replacement.

Lastly the bolt lift seems overly heavy. Is that normal or does it just take time to smooth out?

Overly heavy is hard to quantify but they aren’t ever gonna be custom action smooth or light. The overtravel screw should adjust no problem. Contact mile high for questions they can help you.Just picked up my first Ai atx. Couple things that I need some clarification on. First the over travel screw is not moving. I’ve tried heating it up without success. Do these come loctited in place?

The bolt that connects the qd socket towards the folder hinge arrived striped out. Is there a part number or what size is it for replacement.

Lastly the bolt lift seems overly heavy. Is that normal or does it just take time to smooth out?

Overly heavy sounds normal. My action did smooth out a lot to the point of being heavy and smooth.

Contacting MH for the stripped bolt issue is a good approach. 2nd option would be AINA. Either will be able to take care of that.

My over travel screw was easy to turn and I don't believe it had loctite on it from the factory.

Contacting MH for the stripped bolt issue is a good approach. 2nd option would be AINA. Either will be able to take care of that.

My over travel screw was easy to turn and I don't believe it had loctite on it from the factory.

Call up AINA.that over travel grub screw is so tight to the point ever with heat I’m worried about stripping. Could that be something covered under warranty or something?

Had to move on from papa Smurf. Was fun while it lasted but needed something different. Just went to black for time being, but rest assured it will only be a base for rattlecan master race.

Also testing out a new fluting pattern on the new 6.5x47 tube. Really adds a level of eliteness to this gun IMO.

Also testing out a new fluting pattern on the new 6.5x47 tube. Really adds a level of eliteness to this gun IMO.

Last edited:

@just browsing interesting choice in fluting. More of a conversation starter than weight loss solution!

Had to move on from papa Smurf. Was fun while it lasted but needed something different. Just went to black for time being, but rest assured it will only be a base for rattlecan master race.

View attachment 8189860

Also testing out a new fluting pattern on the new 6.5x47 tube. Really adds a level of eliteness to this gun IMO.

View attachment 8189848

This little fella finally grew up & became a gunsmith.

and obviously prefers AI barrelwork

and obviously prefers AI barrelwork

Need to match the flutes to the scope mountHad to move on from papa Smurf. Was fun while it lasted but needed something different. Just went to black for time being, but rest assured it will only be a base for rattlecan master race.

View attachment 8189860

Also testing out a new fluting pattern on the new 6.5x47 tube. Really adds a level of eliteness to this gun IMO.

View attachment 8189848

Where did you get the knurled screws and what size. I've searched high and low and couldn't get the right ones, but I was always searching for thumb screws, not being familiar with all the termsSome info, a person can get the LOP way down on these if you're willing to get a lil creative. I removed the adj but pad by fully unscrewing the thumb wheel on the pad. Then removed the 2 screws holding the adj butt height capture block in place. Took a pacmeryer 0.5" pad I had laying around from and old project, and used the to ai mounting screws to put it in place. I now have a 12.25", LOP where prior the shortest I could get was over 13". I removed both the gen1 lock screws on cheek and butt, and installed single knurled screws to its tool-less adjustment. I'm average height but in positional shooting from barricades and props I've found a short LOP really helps get steady. Hope this may be helpful for some of you!

View attachment 8183940View attachment 8183941View attachment 8183942

Black Steel Knurl High Step Head Hand Tighten Thumb Screw M3 M4 M5 M6 M8 M10 Curtain Wall Glass Lock Thumbscrew Adjust (M4x20mm(10pcs)) https://a.co/d/7nGWTGcWhere did you get the knurled screws and what size. I've searched high and low and couldn't get the right ones, but I was always searching for thumb screws, not being familiar with all the terms

M4x20mm is the size you need.

Guys, I shot a PRS match this last weekend and the wind was howling. Lots of fine dust blowing around. I had 3 failure to fire out of the 120 rounds I fired. Just click and nothing. No marks on the primers so I am assuming the firing pin wasn't even released. I am guessing that the fine dust blowing around got inside the trigger pack? Looking back at page 99 should I flush the trigger pack with brake cleaner? Or try a different approach?

Flushing the trigger with brake clean is a good idea. I do it every time that I go out just to be safe. While spraying I pin the trigger back and slide my finger off the side allowing it to snap forward. Usually knocks some gunk out.Guys, I shot a PRS match this last weekend and the wind was howling. Lots of fine dust blowing around. I had 3 failure to fire out of the 120 rounds I fired. Just click and nothing. No marks on the primers so I am assuming the firing pin wasn't even released. I am guessing that the fine dust blowing around got inside the trigger pack? Looking back at page 99 should I flush the trigger pack with brake cleaner? Or try a different approach?

Any thoughts on selling one of those thumb rest?Vudoo V360 in an AT-X AICS Short upper chassis, not sure if these are available anymore. Shorter front end, have to use the compact bridge.

View attachment 8182906

Similar threads

- Replies

- 2

- Views

- 304

- Replies

- 8

- Views

- 1K

- Replies

- 8

- Views

- 555

- Replies

- 0

- Views

- 405