I hate that heavy webbing too. Nothing a little sandpaper and a fresh shot of krylon can fix though.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yeah kinda.If I am being a whiny bitch let me know.

Google parkerized sling swivels. The webbing looks a little heavy compared to what I remember but honestly I think I would've liked that on my issued one, the plain finish could get slick. It looks like a nice rig, shoot it, enjoy it, don't get wrapped up in the minutiae too much.

Yeah kinda.

Roger that lol. I'll get over it

Uncle Mike's put out some boron-nitride swivels, which I think these are (I have a set as well). Nothing wrong with them.... the sling swivels are not parked. Other than the butt pad is there a major difference between the actual m24 stock and the civilian version that HS sells? Is there a place to get the parked swivels? Does the stock look finished right? I don't remember that much webbing on the original.

The webbing is probably just the way the last finisher sprayed it. If you use textured krylon you won't even notice.

Nice rifle combo. I'll bet it shoots straight. It looks damn good (if you were a cherry straight out of school with a new rifle). It'll look better painted -- just sayin' (everybody starts somewhere).

I need a new phone with a better camera, but anyways.... Correct rings are on the way, and now for that pesky trigger

How many PSI are you you tightening the screws too? When I pulled the stock is around 60. When I put the new one on, anymore than 50 PSI and the bolt binds.

in/lbs bud, it's inch pounds. PSI is what you use for your tires. The issued Seekonk torque wrench was 65 in/lbs for the action screws and cross bolt on the scope rings.

what would cause the bolt to bind with the 15 lbs difference? ETA see signature for future reference lol.

I checked the bolt, there aren't any marks on it. I'm using the original screws from the original stock. I guess I will try to use the news ones.

Just for clarification, you're saying that when you tighten your action screws the bolt binds in the raceways of the action?

Check your torque wrench as well -- inch-pounds, NOT foot-pounds.Bind when trying to lift the bolt? Screw may be too long

Just for clarification, you're saying that when you tighten your action screws the bolt binds in the raceways of the action?

Bolt is ok in the raceways, but is binding when opening and closing. I re-greased the rear of the lugs and they still bind. It snaps into place now if that makes sense. Lemme try the replacement screws that came with the stock.

It is inch-pounds

Sorry to keep bumping the thread. The new screws are shorter. Right are the original m24 screws left are the New screws. ETA used new front screw. New rear screw would barely engage threads so stuck with the original screw there.

Last edited:

Without physically seeing and feeling what's going on with those screws it's tough to pin down what could cause the binding. From what you're describing it seems like the top of the front action screw is just impinging on the bolt, maybe. I'd put a dab of paint on the end of the screw and run it up in the action to see if it's actually touching the bolt.Sorry to keep bumping the thread. The new screws are shorter. Right are the original m24 screws left are the New screws. ETA used new front screw. New rear screw would barely engage threads so stuck with the original screw there.

View attachment 7715747

I'd also clean the threads in the action and the screw and make sure they go together smooth while outside of the stock. Then look down the pillar holes with the action in the stock and make sure they are in alignment and the action screws aren't touching the sides.

I trimmed the front screw enough to work this evening. Also the bolt handle was rubbing the top of the inlet for the handle.Without physically seeing and feeling what's going on with those screws it's tough to pin down what could cause the binding. From what you're describing it seems like the top of the front action screw is just impinging on the bolt, maybe. I'd put a dab of paint on the end of the screw and run it up in the action to see if it's actually touching the bolt.

I'd also clean the threads in the action and the screw and make sure they go together smooth while outside of the stock. Then look down the pillar holes with the action in the stock and make sure they are in alignment and the action screws aren't touching the sides.

Has anyone opened up the inletting on a BDL version stock to fit the beefier M24 bottom metal? Looks like the front and back tang areas and the 2 trigger end magazine well corners would need to be opened up a bit. That's easy enough, but is the bottom metal thickness difference big enough to cause feeding issues from the magazine not sitting high enough?

I have a PST013 I got cheap that I'm thinking of trying it on if the thickness isn't an issue.

I have a PST013 I got cheap that I'm thinking of trying it on if the thickness isn't an issue.

My paint flaked badly so I spent some time looking at return rifle camo schemes, I liked this one so I emulated it.

Copied the original camo with this:

Copied the original camo with this:

Nice rifles!!!My paint flaked badly so I spent some time looking at return rifle camo schemes, I liked this one so I emulated it.

View attachment 7719245View attachment 7719246

Copied the original camo with this:

View attachment 7719249View attachment 7719250

I converted a PST 026 stock to handle the M24 floor metal. The dimensions were the same around the edges, it's the aluminum pillars and the stock material around those pillars that have to be milled down. It was rather simple with an end mill but without that, it would be difficult. A machinist could make that work for you pretty quickly.Has anyone opened up the inletting on a BDL version stock to fit the beefier M24 bottom metal? Looks like the front and back tang areas and the 2 trigger end magazine well corners would need to be opened up a bit. That's easy enough, but is the bottom metal thickness difference big enough to cause feeding issues from the magazine not sitting high enough?

I have a PST013 I got cheap that I'm thinking of trying it on if the thickness isn't an issue.

Finished product. I guess I will hunt up a correct scope, swivel studs and back up sights. Kinda miss the original black paint but it’s growing on me

I have the gear to mill the pillar areas down if need be, but I don't think I will need to. Thickness from the bottom of the pillar to the bedding block trough is the same for the pst013 and m24 takeoff I have. I already opened it up a bit so the bottom metal sits flush on the pillars, and it looks like the mag sits the same in both. I'm going to put a complete action in it this weekend to see if it will pick up the rounds reliably.I converted a PST 026 stock to handle the M24 floor metal. The dimensions were the same around the edges, it's the aluminum pillars and the stock material around those pillars that have to be milled down. It was rather simple with an end mill but without that, it would be difficult. A machinist could make that work for you pretty quickly.

m24 takeoff

pst013

down the action with the mag pressed up into the bottom metal

m24 takeoff

pst013

Looks like a good fit from this pics. There was one interesting unintended consequence with my PST026 modification. The AI magazine follower allowed the bolt to lock to the rear on ejecting last round like a semi auto bolt catch. The BDL version of the Badger DBM floor metal that is in my PST013/M24A2 does not do that. Good/Bad? A matter of opinion.

Did you mill down to get the bottom metal flush with the belly of of the stock or were those thicknesses from pillar base to block trough different for you?Looks like a good fit from this pics. There was one interesting unintended consequence with my PST026 modification. The AI magazine follower allowed the bolt to lock to the rear on ejecting last round like a semi auto bolt catch. The BDL version of the Badger DBM floor metal that is in my PST013/M24A2 does not do that. Good/Bad? A matter of opinion.

Mine you can see the thicker bottom metal isn't flush because the 013 isn't as deep (not sure of the proper term) in that area in order for the commercial bottom metals to sit flush. I already started building up the area with a CaCO3 filled epoxy to re-profile it. I'll post some pics next week when it's done.

I have a 700 Varmint, originally in an H-S Varmint stock. Ray Federico at Night Owls Gunsmithing in Salt Lake City milled out the magazine pocket and the ends of the aluminum pillars to fit a Tactical Rifles AI magazine conversion bottom, then bedded the new metal.

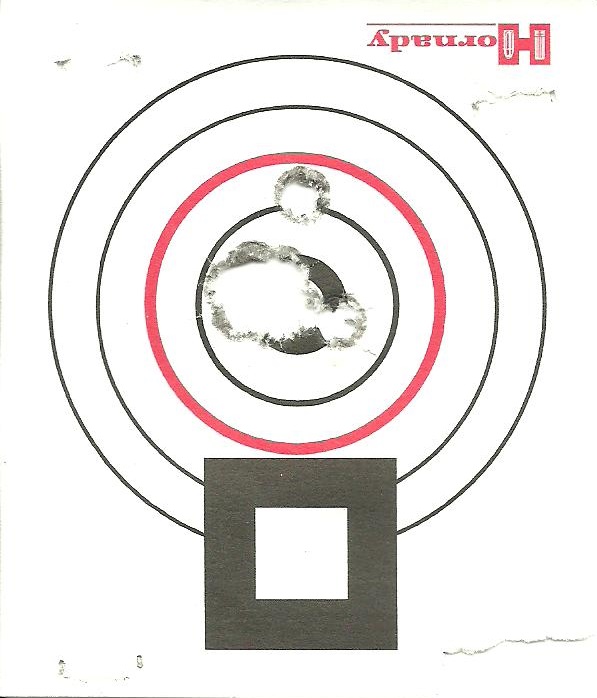

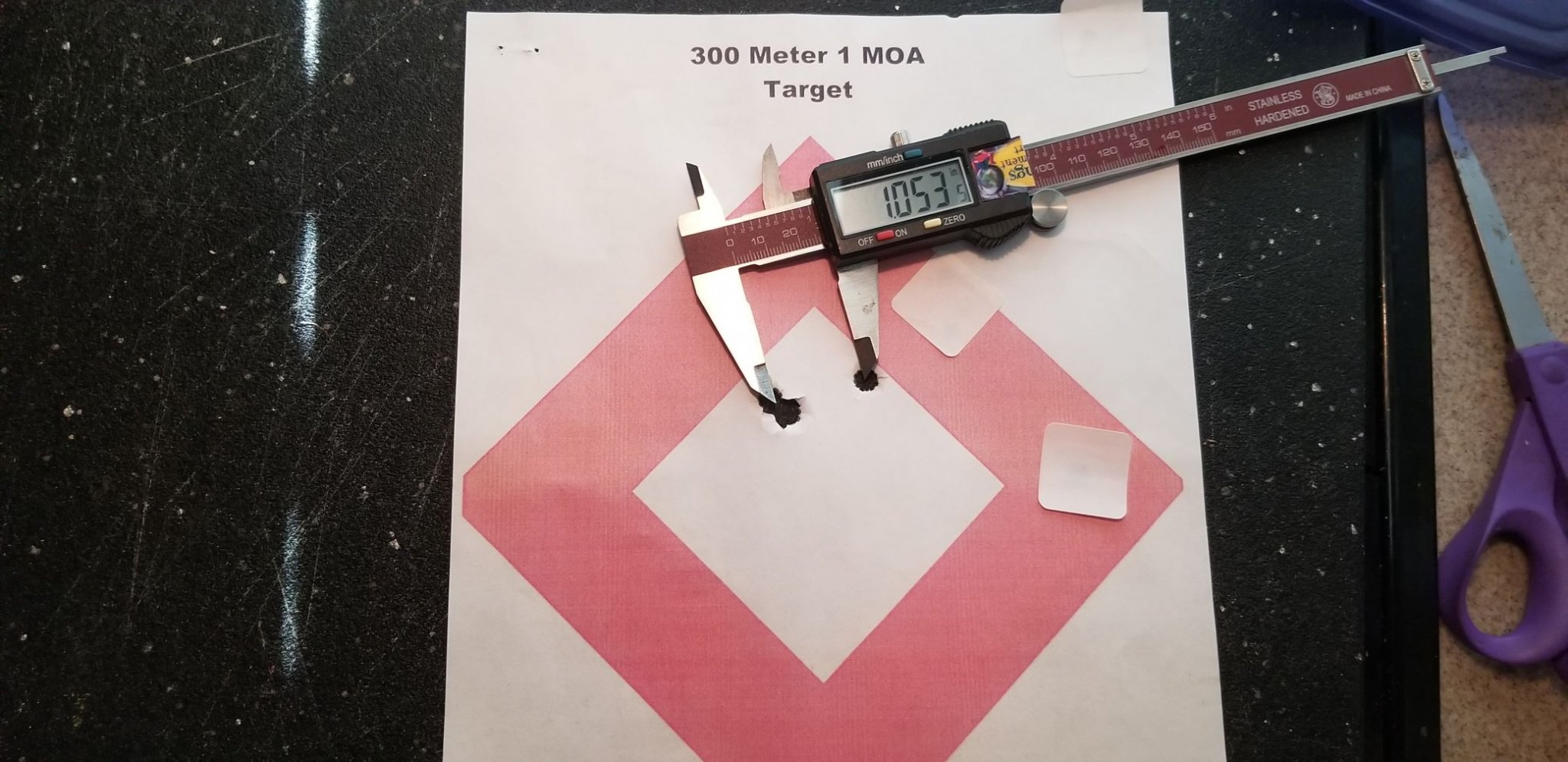

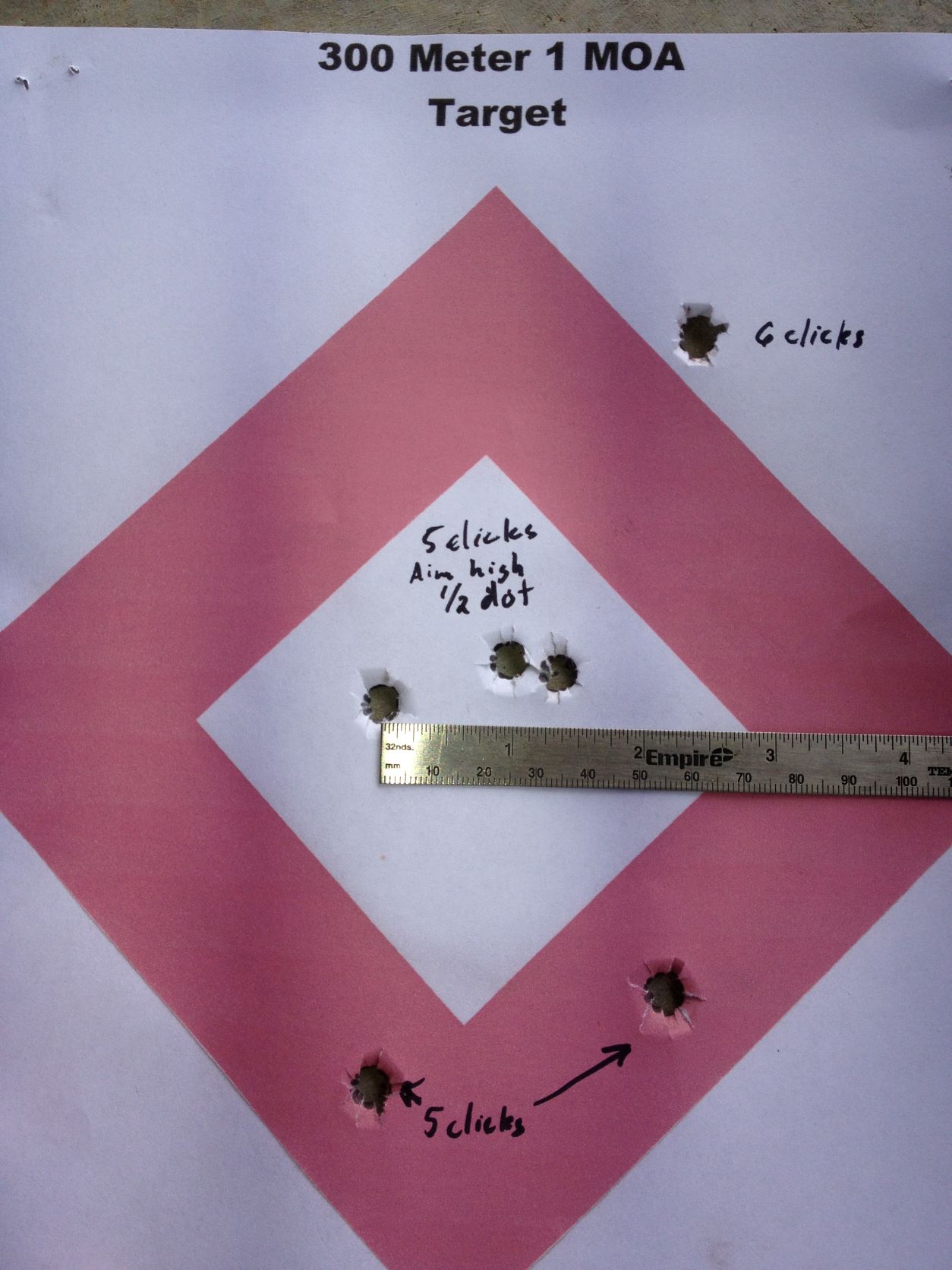

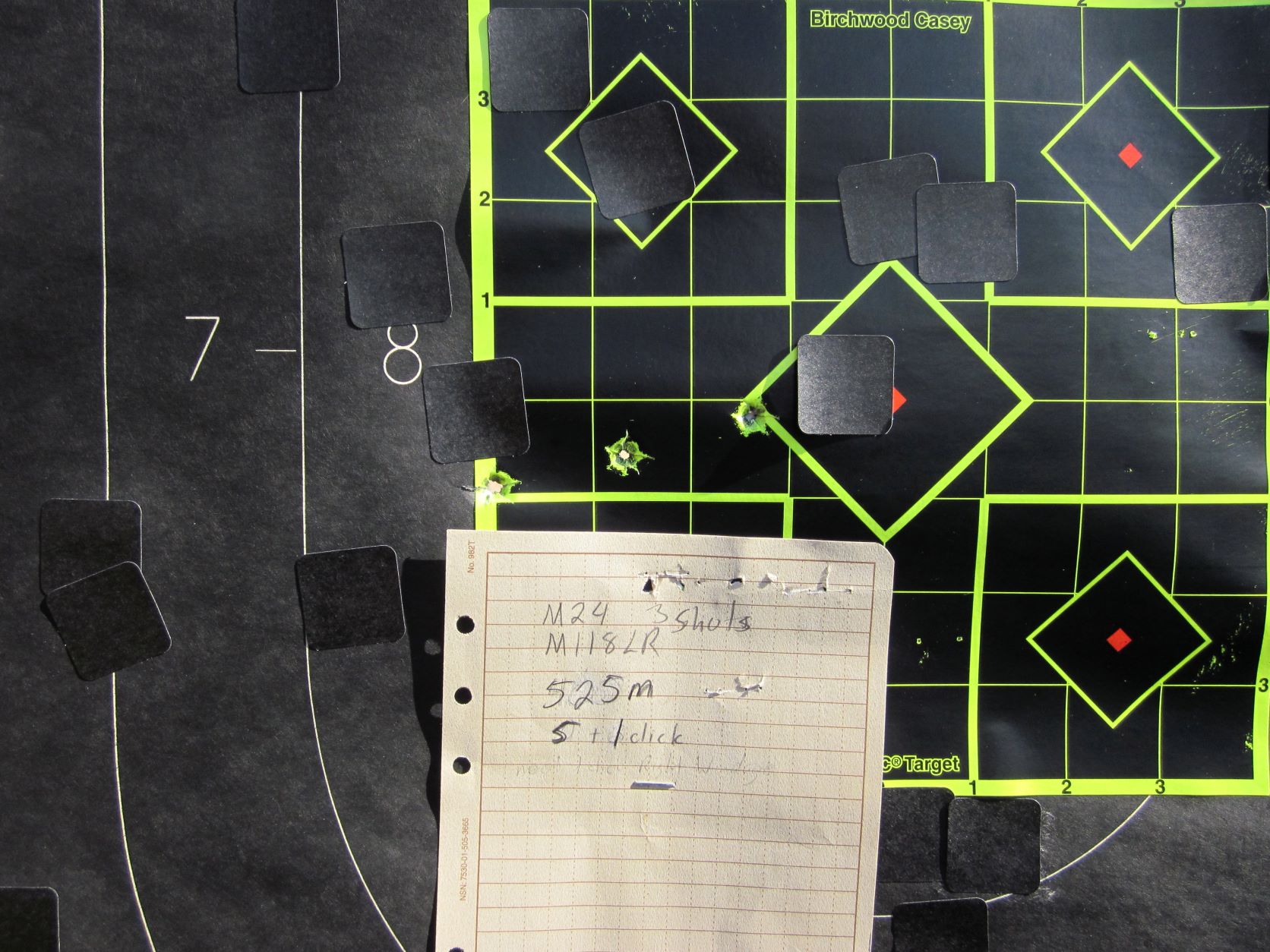

It shot 10-shot groups like this with 168s and a 10X scope at 5000 feet above sea level:

The mag fit is very close -- the tops of the feed lips almost drag on the bolt body (the scratches on the bolt track the tops of the lips [probably from when I push the mags into the weapon], and you can see where the bluing shows when and where the bolt turns to lock). Function was great, but like yours, shlouf, it was just a few thousandths proud of the bottom of the stock. I kept it that way for years until barrel replacement. Now it sits in a KRG Bravo.

I'm sure it'll work in your conversion.

Gratuitous slain and eaten animal photo (354 lasered yards at 10,000 feet above sea level, about a 30-degree down-angle):

It shot 10-shot groups like this with 168s and a 10X scope at 5000 feet above sea level:

The mag fit is very close -- the tops of the feed lips almost drag on the bolt body (the scratches on the bolt track the tops of the lips [probably from when I push the mags into the weapon], and you can see where the bluing shows when and where the bolt turns to lock). Function was great, but like yours, shlouf, it was just a few thousandths proud of the bottom of the stock. I kept it that way for years until barrel replacement. Now it sits in a KRG Bravo.

I'm sure it'll work in your conversion.

Gratuitous slain and eaten animal photo (354 lasered yards at 10,000 feet above sea level, about a 30-degree down-angle):

Last edited:

OK, Holy Shit. How is that PEQ-2 attached? I never saw a SIMRAD match like that.

Very cool. Curious minds want to know!

Last edited:

1987 refers to the year the United States Army Infantry Center and School opened a sniper school for the leg army.... production is capped at 500, and they carry special s/n ASA1987xxxx.

Given the sophomoric hijinks that go on there in the name of making snipers, it is no surprise they'll never man the sniper billets of the Army's 60 regular, active, and reserve infantry battalions with school-trained and B4-qualified soldiers in this (or any other) lifetime.

If the Army did this with helicopter pilots we'd walk everywhere.

The National Guard Marksmanship Training Center pulls up a fraction of Fort Benning's slack, with the same school, producing the same Additional Skill Identifier qualification, occasionally training regular army guys.

One of the other current Army snipers who posts here researched where the Army's Joe Skill Level 1 and 2 sniper position fill is very low, while qualified E6s and E7s still around are something outrageous, like 6000% of the Army's requirements.

Last edited:

OK, Holy Shit. How is that PEQ-2 attached? I never saw a SIMRAD match like that.

Very cool. Curious minds want to know!

SPA Defense used to make a similar Laser/Light mount for the Simrad but they were limited and didn't last too long. In view of that fact, I got the next best thing, the Badger Ordnance SLAM (Side Laser Aiming Mount) that was intended for use on the M82 Barretts. To prove the concept, I drilled and tapped the Simrad mounting bracket on screwed on a piece of Pic Rail. Worked so well, that I made the mod permanent by drilling and tapping the SLAM as well and just screwed the SLAM onto the Simrad bracket.

Bump. Good question.How common were the illuminated mark 4s on the later rifles that got upgraded from the fixed 10x?

It’s crazy how the army does things. In the Corps we had 8 sniper teams per infantry battalion but we were lucky to have half that filled with school trained snipers. The chief scout was a Sgt or SSgt. I went to school in 88. M40A1. 2 seals were in our class. They had bolt guns that had Leuys M1’s I’m pretty sure. We also had a soldier with an M21. He didn’t make it. Due to the weapon not being good enough I think. The seals made it. We graduated 9-20 pigs to Hogs. (My 2nd time through)1987 refers to the year the United States Army Infantry Center and School opened a sniper school for the leg army.

Given the sophomoric hijinks that go on there in the name of making snipers, it is no surprise they'll never man the sniper billets of the Army's 60 regular, active, and reserve infantry battalions with school-trained and B4-qualified soldiers in this (or any other) lifetime.

If the Army did this with helicopter pilots we'd walk everywhere.

The National Guard Marksmanship Training Center pulls up a fraction of Fort Benning's slack, with the same school, producing the same Additional Skill Identifier qualification, occasionally training regular army guys.

One of the other current Army snipers who posts here researched where the Army's Joe Skill Level 1 and 2 sniper position fill is very low, while qualified E6s and E7s still around are something outrageous, like 6000% of the Army's requirements.

I became a bigger fan of the M24 after getting some time behind one in desert storm. This might go against the grain but I find the M24 to be better the the M40A1/A3. Especially with a better scope. Unertl has a god like following but once I got on other platforms, I realized there were better. The Navy uses a better rifle. I will say this. The Marine Sniper is the best trained and best sniper in the world in my Biased opinion.

I do think the M40A1 is the most beautiful tactical rifle ever built. The look of it from the unmistakable Unertl USMC 10x to the Macmillan woodland camo stock

Last edited:

Damn, son -- you a SMART Ranger!SPA Defense used to make a similar Laser/Light mount for the Simrad but they were limited and didn't last too long. In view of that fact, I got the next best thing, the Badger Ordnance SLAM (Side Laser Aiming Mount) that was intended for use on the M82 Barretts. To prove the concept, I drilled and tapped the Simrad mounting bracket on screwed on a piece of Pic Rail. Worked so well, that I made the mod permanent by drilling and tapping the SLAM as well and just screwed the SLAM onto the Simrad bracket.

"No shit, there I was ... "

In the "Years before Picatinny" Dark Ages we made do. In 1994 (when Mike Haugen was still in the Army and stationed on Okinawa), I was still in the States. I was passed a MacMillan with a Leupold 16X that came from a legend, KIA in Somalia. I shot a guy about a hundred yards away through a glass porch door with a SIMRAD on that rifle, but I had to have my spotter paint the guy with the PAQ-4 on his CAR-15, talking him through. "Up just a hair - HOLD. Now left a bit ... left ... OK, hold it." Bang.

The 308 bullet made a hole in the glass and the guy fall down, go boom. Strangest thing about that glass door -- it never shattered - disintegrated, never spidered from the point of impact -- there was just a 30-cal hole in the glass.

Last edited:

In my day, Special Forces categorized two sniper qualification levels: Level I and Level II.... The Navy uses a better rifle. I will say this. The Marine Sniper is the best trained and best sniper in the world in my Biased opinion.

A Level I Sniper is a graduate of the Special Forces Target Interdiction Course (the old SOTIC, which got a GWOT name change to Special Forces Sniper School), or the Marine Sniper-Instructor Course at Quantico.

A graduate from anywhere else (like me) is a Level II Sniper. This helps juggle who can teach courses (based on quality and experience to teach our own internal courses) but also sustainment.

As far as I know, Army units still send a very few guys to Quantico and SEAL courses.

Last edited:

It may be in the thread but what is the story with these rifles? Are they still M24s? The top picture looks to still be a long action but the other picture appears to b e a short action.

View attachment 7321754View attachment 7321755

Is the the scope in the top pic a 8.5-25 or the 4.5-14 Mk4? It definitely doesn't look like a 3.5-10.

It's an M1 3.5-10Is the the scope in the top pic a 8.5-25 or the 4.5-14 Mk4? It definitely doesn't look like a 3.5-10.

had some free time tonight and finished fitting the pst 013 for the m24 dbm. Forgot to grab a pic before I started, but it was protruding a good 1/8" out of the bottom of the stock. Turned out nice. A few small voids in the epoxy, but nothing a couple coats of krylon can't fixDid you mill down to get the bottom metal flush with the belly of of the stock or were those thicknesses from pillar base to block trough different for you?

Mine you can see the thicker bottom metal isn't flush because the 013 isn't as deep (not sure of the proper term) in that area in order for the commercial bottom metals to sit flush. I already started building up the area with a CaCO3 filled epoxy to re-profile it. I'll post some pics next week when it's done.

What is this M24?

So I have ended up down this rabbit hole of M24 isms. And while I know a lot about the Mk 13 having built one I know damn little about M24 so hopefully someone here can help. Buddy is looking at this rifle at a LGS in the Midwest. Seller wants 4K for it. The information is all over the map...

If I could have found this thread last night… I’d have posted here not in Vintage. My apologies. Somehow I scrolled right past the Sticky!

Can any of you help here? I know this is where the best M24 historical knowledge (and clone/rebuild) and info resides.

Thanks in advance!!

Sirhr

No, it's a Remington 700 LA that says M24 on the side, other than that nothing else was done to the receivers that would differentiate it from a standard action.Disassembling M24 bolts I've noticed very tight tolerances, and some difficulty reassembling them. Were they machined to different specs compared to regular production M700's, and is the fp spring weight different?

For such a production level rifle, I am very surprised at the accuracy of the 24. They shoot with pretty much any 308 out there from my experience. I have an FN SPR A2/A4 and the M24 is slightly more accurate. FN is a 1/2 MOA gun too.No, it's a Remington 700 LA that says M24 on the side, other than that nothing else was done to the receivers that would differentiate it from a standard action.

Under 1/2 moa is pretty cake taking my time at 100m with Mk316. Has shot under moa to 600 and hits on steel to 1k has presented no issues.For such a production level rifle, I am very surprised at the accuracy of the 24. They shoot with pretty much any 308 out there from my experience. I have an FN SPR A2/A4 and the M24 is slightly more accurate. FN is a 1/2 MOA gun too.

Factory barrel with a throat a mile long, rough bore, used stock w/ zero bedding etc.

Say what you want about Remingtons (well deserved) reputation Re quality but- this thing hammers.

Same, sometimes I get lucky but it’s usually floating around 0.6004… based on 5, 5 round targets (lack of skills and other shit). 100 yard targets.Under 1/2 moa is pretty cake taking my time at 100m with Mk316. Has shot under moa to 600 and hits on steel to 1k has presented no issues.

Factory barrel with a throat a mile long, rough bore, used stock w/ zero bedding etc.

Say what you want about Remingtons (well deserved) reputation Re quality but- this thing hammers.

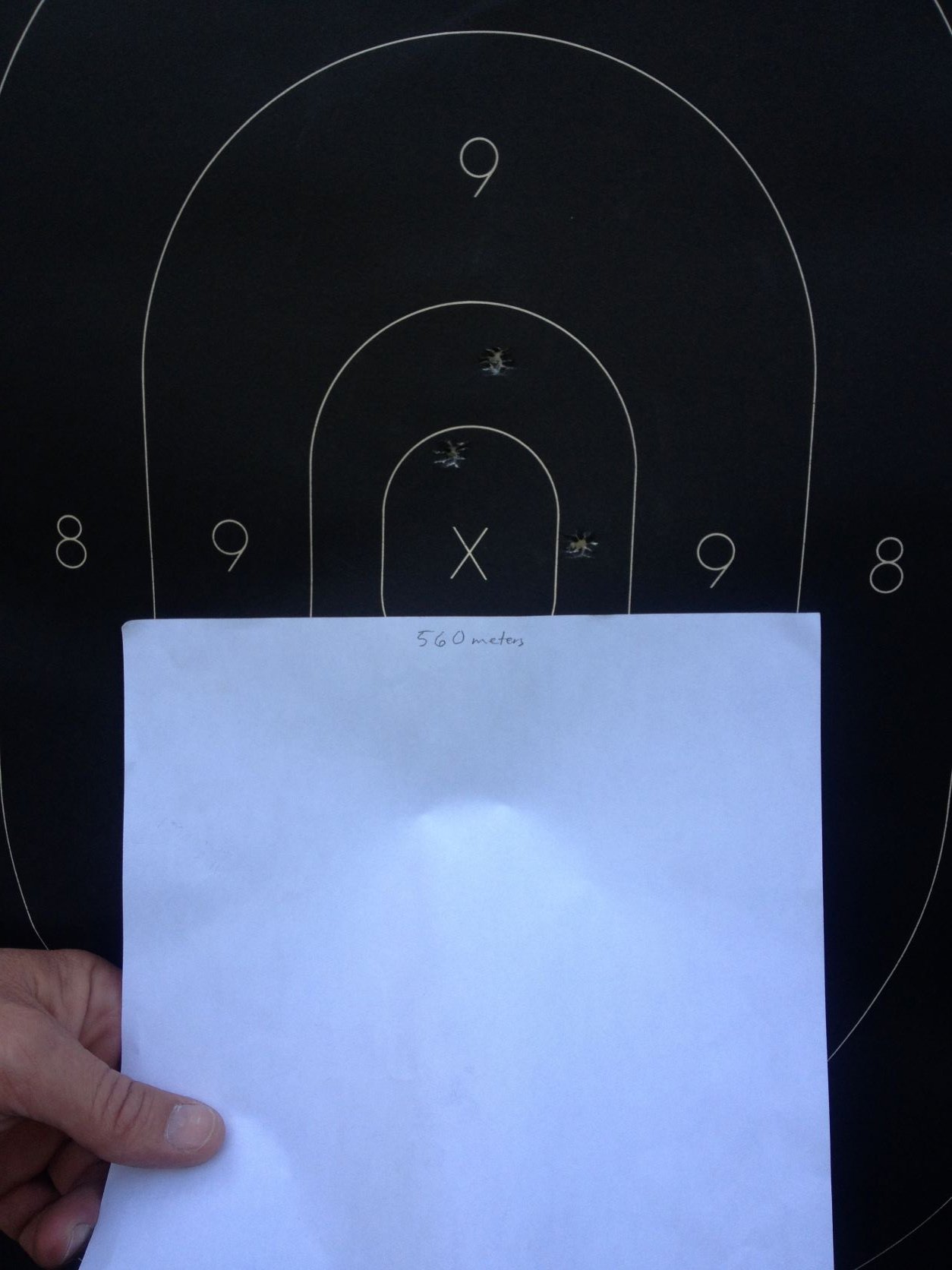

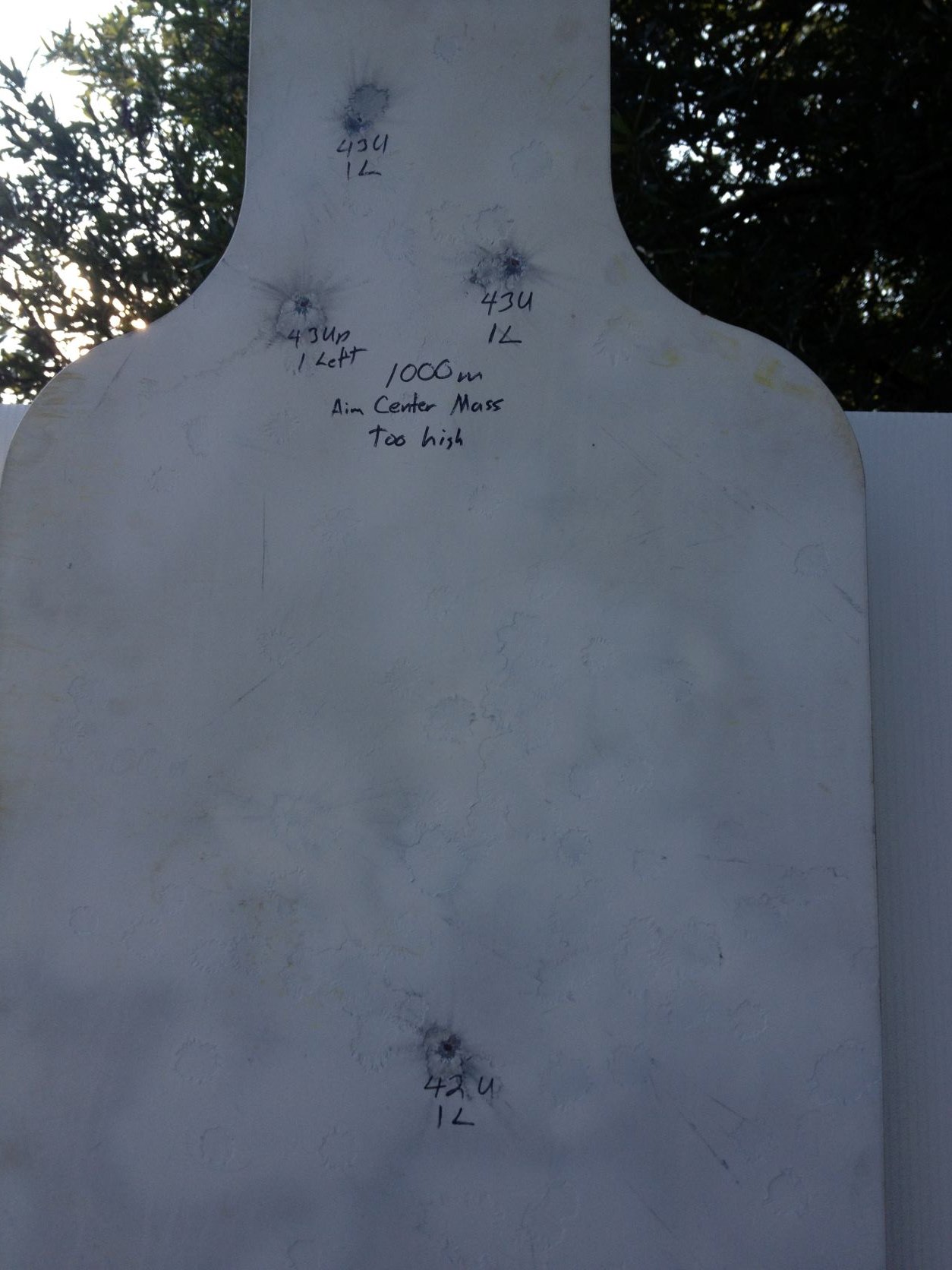

These are some groups from the last few years from my M24

Attachments

-

C55EBA94-7D53-490B-91CF-8DC4B3167747.jpeg782.3 KB · Views: 106

C55EBA94-7D53-490B-91CF-8DC4B3167747.jpeg782.3 KB · Views: 106 -

EB1793B1-D308-4EA0-A17D-C064FC11F16D.jpeg285.5 KB · Views: 108

EB1793B1-D308-4EA0-A17D-C064FC11F16D.jpeg285.5 KB · Views: 108 -

59B11885-3AAC-4274-B5B1-20E20A0E3EBB.jpeg558.3 KB · Views: 100

59B11885-3AAC-4274-B5B1-20E20A0E3EBB.jpeg558.3 KB · Views: 100 -

EE90B2E8-86AE-4A91-9281-D1BBB2196EAF.jpeg369.1 KB · Views: 99

EE90B2E8-86AE-4A91-9281-D1BBB2196EAF.jpeg369.1 KB · Views: 99 -

A26EC79E-EB51-4E6C-8D11-370F73048101.jpeg516 KB · Views: 106

A26EC79E-EB51-4E6C-8D11-370F73048101.jpeg516 KB · Views: 106 -

BA3F0861-7185-44A4-B5B4-2702D1EAEF22.jpeg649.8 KB · Views: 108

BA3F0861-7185-44A4-B5B4-2702D1EAEF22.jpeg649.8 KB · Views: 108 -

01454A29-0946-44FF-A0AE-8798123EEC2E.jpeg630.9 KB · Views: 85

01454A29-0946-44FF-A0AE-8798123EEC2E.jpeg630.9 KB · Views: 85

This type of accuracy above and here below should be expected from the M24. If you have one and it doesn't print like what you see above, then its your ammo or you or a combination of both. Below I have some pics that I dug up from my recent past with my M24 to show what it can do BEYOND 100yd to give you a feel for what it's capable of. NOTE these are all in meters not yards. Two pics I couldn't find were 2 1/2" at 725m and 3" at 800m. This weapon shoots consistently below 1/2 MOA and if it doesn't print that way, it was my fault.

Last edited:

Nice!This type of accuracy above and here below should be expected from the M24. If you have one and it doesn't print like what you see above, then its your ammo or you or a combination of both. Below I have some pics that I dug up from my recent past with my M24 to show what it can do BEYOND 100yd to give you a feel for what it's capable of. NOTE these are all in meters not yards. Two pics I couldn't find were 2 1/2" at 725m and 3" at 800m. This weapon shoots consistently below 1/2" MOA and if it doesn't print that way, it was my fault.View attachment 7728411View attachment 7728412

Last edited:

Nice shooting broThis type of accuracy above and here below should be expected from the M24. If you have one and it doesn't print like what you see above, then its your ammo or you or a combination of both. Below I have some pics that I dug up from my recent past with my M24 to show what it can do BEYOND 100yd to give you a feel for what it's capable of. NOTE these are all in meters not yards. Two pics I couldn't find were 2 1/2" at 725m and 3" at 800m. This weapon shoots consistently below 1/2" MOA and if it doesn't print that way, it was my fault.View attachment 7728424View attachment 7728425View attachment 7728426View attachment 7728428View attachment 7728434View attachment 7728435

About done with this rifle. M24R and what I feel is a pretty good representation of the BII issued over the years. I have more stuff not shown (other spotters, the ammo selection from early to late, more Eagle gear etc)

Of note- I set this rifle up to be as an original issue piece. 1988 Ultra M3A with matching early rings/base, a Redfield rear base I modified as the originals were and then parkerized, .175s front sight, early stock with small logo, Dakota bottom metal and on and on. Everything is as "real" as I could make it, often times acquiring used surplus parts vs new civilian pieces. Hope you guys like it!

Of note- I set this rifle up to be as an original issue piece. 1988 Ultra M3A with matching early rings/base, a Redfield rear base I modified as the originals were and then parkerized, .175s front sight, early stock with small logo, Dakota bottom metal and on and on. Everything is as "real" as I could make it, often times acquiring used surplus parts vs new civilian pieces. Hope you guys like it!

Last edited: