The truth is always best. All OTB has to do is change the description to something like "this is a PTG reissue of the classic M24 from old Remington stock." PTG could do the same thing and not let their reputation get stained. Not hard.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have a fair amount of insight into what is going on with the PTG pieces after talking with multiple people involved inside and out of PTG. I don’t necessarily want to post a huge wall of text with quotes from people, but the bottom line is you are probably not interested in what they have for sale unless the piece is described exactly as the photo shows.

Are the barrels that PTG uses on these clones an actual Remington M24 5R hammer forged rifling?

Any recommendations on a firing pin assembly?

PTG states that these items are “exactly as they came from the Sturgis Custom Shop” with that being said, it seems that they may be post bankruptcy pieces. I emailed about a month ago specifically asking about barrel markings and received no response. The only reason I even thought to ask was I picked up a barreled action from JFE and the barrel has no markings whatsoever. Someone else in the thread got the same recently.Are the barrels that PTG uses on these clones an actual Remington M24 5R hammer forged rifling?

If you mean completely to spec, I would say no. They appear to be Varmint/Sendero contour.Are the barrels that PTG uses on these clones an actual Remington M24 5R hammer forged rifling?

How about the rifling? Does it have the 5R 1:11.25" twist that Remington made in-house on their hammer forge presses? I know they offered Varmint/Sendero contour bbls with 5R as a factory option for awhile. That would be a subtle positive attribute, even if they arent correct military profile.If you mean completely to spec, I would say no. They appear to be Varmint/Sendero contour.

On a side note, anybody remember those triangle contour bbls Remington sold for a short time? Cant recall what they named them?

The VTRHow about the rifling? Does it have the 5R 1:11.25" twist that Remington made in-house on their hammer forge presses? I know they offered Varmint/Sendero contour bbls with 5R as a factory option for awhile. That would be a subtle positive attribute, even if they arent correct military profile.

On a side note, anybody remember those triangle contour bbls Remington sold for a short time? Cant recall what they named them?

I don’t remember what was issued but I like smooth. Looks less “commercial” to me than the webbing

I am fairly confident that smooth was issued. Also, I agree with @shlouf that I like smoothSmooth or textured on a m24a2 stock? What was issued? What do you dudes recommend?

Smooth is the correct texture if doing a military m24a2 build. You can call HS precision and request the old smooth texture stock vs their current black 'spider web' texture. If you dont call and specify, they will send you spider web, which is correct for later law enforcement m24a2Smooth or textured on a m24a2 stock? What was issued? What do you dudes recommend?

Just ordered a smooth stock. Going to be 12-14 weeks before it’s ready. In the meantime, should I send my barrel and everything to RWS to work his magic and then drop it in the stock when it comes? Or should I just wait and send it all off to RWS at once?

What is RWS' lead time on the barreled action? If it was me, I'd send the barrel and action out to get worked on while waiting for the stock and if the stock beats the barreled action, send it to RWS to make sure the bottom metal, mag box, etc...play nice.

He quoted me a couple months for the full job with the stock. Bedding the stock, refinishing and everything you mentioned. So I’d probably get my barreled action back from RWS a couple weeks before the stock is done. I guess I could always send it all back to him…What is RWS' lead time on the barreled action? If it was me, I'd send the barrel and action out to get worked on while waiting for the stock and if the stock beats the barreled action, send it to RWS to make sure the bottom metal, mag box, etc...play nice.

Bedding the stock? What's all this nonsense? lol...drop that puppy in and torque it down like the good book (FM23-10) says lol. J/K...but only a little bit.

To me it makes sense to see if he can hold the barreled action once its done and then send the stock to him when you get it so he can finish the work. It saves everyone the hassle of shipping the action and everything back and forth several times and reduces the risk of any negative outcomes while navigating the parcel system.

To me it makes sense to see if he can hold the barreled action once its done and then send the stock to him when you get it so he can finish the work. It saves everyone the hassle of shipping the action and everything back and forth several times and reduces the risk of any negative outcomes while navigating the parcel system.

God willing they will be moving it out of that communist hell holeRemington announces permanent closure of Illion NY plant

They should find a more welcoming environment here in Georgia.God willing they will be moving it out of that communist hell hole

I have a few sets of the front and rear Redfield Palma sightsQuestion. Building my clone. Barrel got ordered yesterday, but as this is a pre GWOT 24, I need the front site base and rear, who these days make them and or where can they be found?

I have the front post. All I need is the read sight mount, do you have that?I have a few sets of the front and rear Redfield Palma sights

That don't suck…. What did you get?Some information I got back on my receiver from the DOD.

Figured I needed an M24ish rifle to go with my M40s. 300WM, Surgeon, Obermeyer, HS/Dakota, NF 3.5-15. Shoots great!

Just an FYI... not mine and no affiliation.... M 24 Action, Trigger, Bottom Metal

Remington M24 Action : 992906314

Buy a Other <p>Remington Model 24 Action long action,from the custom shop,never used. GUN COLLECTIONS WANTED FOR for sale by First Stop Gun on GunsAmerica.com the best online marketplace for buying and selling semi auto pistols, firearms, accessories, and collectibles : 992906314

www.gunsamerica.com

If they are the Remington Varmint/Sendero contour… I’d be skeptical. The prints that I have and barrels we made for the Army for the M24 and the M2010 where straight taper barrels. We made barrels for the Army I believe three different times when Remmy’s tooling was down and couldn’t deliver and the Army had troops being deployed and needed guns that needed rebuilding before they could put them back into service.If you mean completely to spec, I would say no. They appear to be Varmint/Sendero contour.

If I recall correctly the exact barrel dimensions are 1.238” x 3.000” and straight tapered to .905” at the muzzle regardless of the finish length. This was also the same contour we made Remington for R&D and for productions guns for the MSR rifle. We made barrels that a finished at 20”, 24” and 27” long. So we always made the blank +1” longer on the muzzle end for finishing.

I can look next week to double check the contour but if you have a varmint contour… I‘d say it’s not correct.

Later, Frank

Bartlein Barrels

Varmint / Sendero is lighter and much more tapered than M24.

One of the many things that help make M24 more precise is the barrel's mass and dampening weight.

One of the many things that help make M24 more precise is the barrel's mass and dampening weight.

Can you share the chamber print specs for M24 ?If they are the Remington Varmint/Sendero contour… I’d be skeptical. The prints that I have and barrels we made for the Army for the M24 and the M2010 where straight taper barrels. We made barrels for the Army I believe three different times when Remmy’s tooling was down and couldn’t deliver and the Army had troops being deployed and needed guns that needed rebuilding before they could put them back into service.

If I recall correctly the exact barrel dimensions are 1.238” x 3.000” and straight tapered to .905” at the muzzle regardless of the finish length. This was also the same contour we made Remington for R&D and for productions guns for the MSR rifle. We made barrels that a finished at 20”, 24” and 27” long. So we always made the blank +1” longer on the muzzle end for finishing.

I can look next week to double check the contour but if you have a varmint contour… I‘d say it’s not correct.

Later, Frank

Bartlein Barrels

I'm going to tell you that you have two options. Most of the barrels we made Remington and Army where contoured and rifled blanks. No chamber work.Can you share the chamber print specs for M24 ?

The barrels we did make them all had 5R rifling and.... I'll say the vast majority had the standard Saami spec. chamber in them but we did make some and I want to say mostly for testing had the Navy reamer spec chamber in them.

The barrels we made the Army.... contoured and rifled blanks. They did the chamber work themselves. What they put into them I'd be guessing as to the chamber but I would lean towards the Saami spec. These where for either the M24 or M2010 guns. Not sure what they were putting them on. It's a long story.

My preference... the Saami reamer spec. sucks the bag from an accuracy stand point. I'd use the Navy spec. reamer myself and it will chamber box ammo etc.... with no issues.

Don't kid yourself or let someone tell you this or that spec. is the golden rule because it's on this or that print. Here is good example... and this might be tied in/overlaps with the M24 and it might not.... so don't quote me on it. The first time we had to make Navy accuracy ammunition test barrels for the ammo maker.... when they called to put a order in I asked.... 4 groove, 6 groove or 5R rifling? And.... which chamber... Saami spec or Navy spec.? He said what do you mean? I said I know for fact they have had 4 groove and 5R rifling but Saami spec. is 6 groove for rifling and currently are using 4 groove to my knowledge. In regards to the chamber I said 300WM Saami spec but I do know that the Navy at some point is or they were using the Navy spec. reamer. So what do you want? I'm not going to make what I think you need... you get them and then I get a phone call saying they are wrong and we have to remake them. You spell it out for me! So he says, "we've got 6 Navy spec guns in the vault. I'll go take a look at the rifling and call you in the morning." He calls me up the next day and says, "Holy shit! You where right.... they've got 4 groove barrels on them!" I then asked again...so what reamer do you want? They didn't know what chamber was in them. So the first several batches we made them for accuracy and pressure testing where all 4 groove rifling and on the first batch they ordered a 50/50 split with the Saami spec. reamer chamber and the Navy spec reamer chamber. The next few orders they gave us they had us make them all with the Navy chamber. They said the accuracy was better (no surprise to me) and it helped with pressures a little as well. Then a while later....someone from the Gov't came in and was doing an inspection and made them go back to the Saami chamber! Go figure!!!!!

Later, Frank

"Someone from the government ..."... I'd be guessing as to the chamber but I would lean towards the Saami spec. These where for either the M24 or M2010 guns. Not sure what they were putting them on. It's a long story.

My preference... the Saami reamer spec. sucks the bag from an accuracy stand point. I'd use the Navy spec. reamer myself and it will chamber box ammo etc.... with no issues.

The first time we had to make Navy accuracy ammunition test barrels for the ammo maker.... when they called to put a order in I asked.... 4 groove, 6 groove or 5R rifling? And.... which chamber... Saami spec or Navy spec.? He said what do you mean? I said I know for fact they have had 4 groove and 5R rifling but Saami spec. is 6 groove for rifling and currently are using 4 groove to my knowledge. In regards to the chamber I said 300WM Saami spec but I do know that the Navy at some point is or they were using the Navy spec. reamer. So what do you want? I'm not going to make what I think you need... you get them and then I get a phone call saying they are wrong and we have to remake them. You spell it out for me! So he says, "we've got 6 Navy spec guns in the vault. I'll go take a look at the rifling and call you in the morning." He calls me up the next day and says, "Holy shit! You where right.... they've got 4 groove barrels on them!" I then asked again...so what reamer do you want? They didn't know what chamber was in them. So the first several batches we made them for accuracy and pressure testing where all 4 groove rifling and on the first batch they ordered a 50/50 split with the Saami spec. reamer chamber and the Navy spec reamer chamber. The next few orders they gave us they had us make them all with the Navy chamber. They said the accuracy was better (no surprise to me) and it helped with pressures a little as well. Then a while later....someone from the Gov't came in and was doing an inspection and made them go back to the Saami chamber! Go figure!!!!!

Later, Frank

Huge difference between Army compliance inspectors (with duty in the Remington plant on the M2010 line) and USSOCOM (at two separate operating locations (Mark 13 rifles between respective Crane Naval Surface Weapons Center and Lexington Blue Grass Army Depot).

They do NOT mix and are NOT related. Rifle and barrel contracts are distinct and separate.

The common requirement for both rifles is what the ammunition manufacturer provides: Mark 248 Mod 1. How it performs in either customers' weapons is stated in the Army's and SOCOM's separate requirements.

Kinda-sorta like the difference between the SOCOM Mark 11 Sniper Rifle and the Army's M110: They both came out of the same plant in Florida, but SOCOM's contract acceptance standards are not the same as the Army's -- and Big Army wonders why the guns don't group and function the same.

The Army gets exactly what they asked for.

I've been told Remington used the PTG M852 chamber reamer after supplies of M118 ran out. Havnt been able to verify. But it isnt SAMMI spec

Attachments

Last edited:

Frank, can you give the specs on the Navy reamer? Not familiar with it. Also, can you give a short explanation why reamers need to be matched to a specific barrel groove/ twist rate? I'm not a gunsmith, but that seems like something worth understanding. Thx

I don't know about that. M852 is loaded with the Sierra 168-grain Match King.I've been told Remington used the PTG M852 chamber reamer after supplies of M118 ran out. Havnt been able to verify. But it isnt SAMMI spec

My reply was in regards to the 300wm rifles.I've been told Remington used the PTG M852 chamber reamer after supplies of M118 ran out. Havnt been able to verify. But it isnt SAMMI spec

As far as the 308win chambered rifles goes I’ve never heard of anything different than Saami 308win. Doesn’t mean they couldn’t have used some modified version of the 308win/match type reamer but I myself have never heard of something being used differently.

Interested to hear your opinion Sinister. I know M852 uses the SMK168gr. That's the cartridge used by Army/SOTIC after M118 was declared obsolete. This was prior to M118LR introduction in 1997, and the Mk316 Mod O. Remington no longer needed to warranty M24's by this time, and a "last profer" barrel replacement policy went into effect.I don't know about that. M852 is loaded with the Sierra 168-grain Match King.

At work we shot what the Army issued.

Depending on where you worked that could be M852, M118 Special Ball (fairly shitty ammo for anything past 400 yards), Federal Gold Medal Match, Black Hills Match, HSM Match, Hornady Match, or handloads. 168 Match Kings are a very good bullet to 850 yards. The Army's doctrinal "7.62 Match maximum effective range of 800 Meters" is based on the bullet's limits, not the entire system.

We were all excited when Sierra introduced the 175-grain Match King, initially for handloads.

Depending on where you worked that could be M852, M118 Special Ball (fairly shitty ammo for anything past 400 yards), Federal Gold Medal Match, Black Hills Match, HSM Match, Hornady Match, or handloads. 168 Match Kings are a very good bullet to 850 yards. The Army's doctrinal "7.62 Match maximum effective range of 800 Meters" is based on the bullet's limits, not the entire system.

We were all excited when Sierra introduced the 175-grain Match King, initially for handloads.

Last edited:

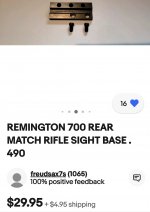

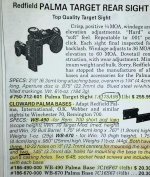

If you're searching for rear Redfield sight bases to complete a M24 build, the late stockmaster Jim Cloward fabricated copies of the most common versions. This eBay auction currently lists a handful of his remaining WB-490 rear sight mount bases for 30 sheckles each. Remington installed Cloward's on factory M24 after Redfield supply dried up, before converting over to RPA Trakker.

Attachments

Last edited:

These sight bases are not radiused/beveled to clear early issue Ultra ring bolts. Remington did that sight base modification in-house to compensate for the short shoulder length found on original L&S Ultra ring bolts

Attachments

Those Cloward rear bases are very like the ones Outback used to make, a good alternative if you can't get a wb490, Steve Earle made one as well which was very close to the wb490 dimensions.

I am looking for the Eagle green stock pad that is used for the M 24. I have all of the other green Eagle kit.

Similar threads

- Replies

- 3

- Views

- 108