Getting my V4 dialed in and dropped 50 loads of 31.6 Varget. Zero over throws and speeds are good. Haven’t timed the drops but by the time I set the cup back on scales and I move the funnel to my next case it’s just a really short pause. The green light just confirms weight without thinking about it.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AutoTrickler V4

- Thread starter adamjmac

- Start date

have to be honest pretty frustrated with how many settings and hacks you need to get this to work good.

Mine started promising but overthrows like crazy now. Have to have big tube set at 1. And I always calibrate twice in a row. 31.6 of Varget is usually the weighthave to be honest pretty frustrated with how many settings and hacks you need to get this to work good.

Can't say yes or no. No one posts their set ups or settings after calibrating. I still think most of these "issues" are a user interface problem.But these problems don't exist...

Negative, this is an ATV4 problem. It's well documented here, a handful of other forums (accurateshooter), and all over YouTube...Can't say yes or no. No one posts their set ups or settings after calibrating. I still think most of these "issues" are a user interface problem.

That's because you just can't please some people. If it sucks that bad sell it and move on.

Hmm. Glad people accept lemons.That's because you just can't please some people. If it sucks that bad sell it and move on.

Yea great logic. Homey owns/owned 2 ATV3 and and ATV4 but he should just sell it because the new and improved version has issues?That's because you just can't please some people. If it sucks that bad sell it and move on.

Yea its the customers fault.

Some people.......

So I went and looked at some of those posts. Most were resolved. The majority were set up issues, not V4 issues. Scale resolution not being set to fast. New scale settings for V4 not being input. OR - the scale dumped the settings, but once reset with proper inputs all was good. My favorite is the video of the V4 being shimmed from the 2 front feet on the lid and claiming it is a V4 issue. Still makes me laugh. In one of the videos he did show settings. Small tube calibrated flow rate of .11. That is called a clue. It is not within spec for running powder.Negative, this is an ATV4 problem. It's well documented here, a handful of other forums (accurateshooter), and all over YouTube...

This has nothing to do with scales bring setup improperly.So I went and looked at some of those posts. Most were resolved. The majority were set up issues, not V4 issues. Scale resolution not being set to fast. New scale settings for V4 not being input. OR - the scale dumped the settings, but once reset with proper inputs all was good. My favorite is the video of the V4 being shimmed from the 2 front feet on the lid and claiming it is a V4 issue. Still makes me laugh. In one of the videos he did show settings. Small tube calibrated flow rate of .11. That is called a clue. It is not within spec for running powder.

Would you like me to post the links of the issues? Reddit? Or maybe even issues found by FClass John on YouTube? Or are you limiting your search range to SH? Believe it or not, precision shooters exist elsewhere on the internet.

This is like saying be happy your car has 3 working tires, when you're expecting 4.

I had quite a few issues with mine as well when I first got it, but when I actually made sure that the small tube was right at the .20ish gr per second that was recommended everything started working alot better. When I started using the settings Adam posted a while back, things even started working better. I know that my situation is not everyone's situation but doing those two things made my v4 a joy to use. I hardly ever get an overthrow now, and I can drop a 30.8 grain charge of varget in 9-12 seconds, which works well for me.

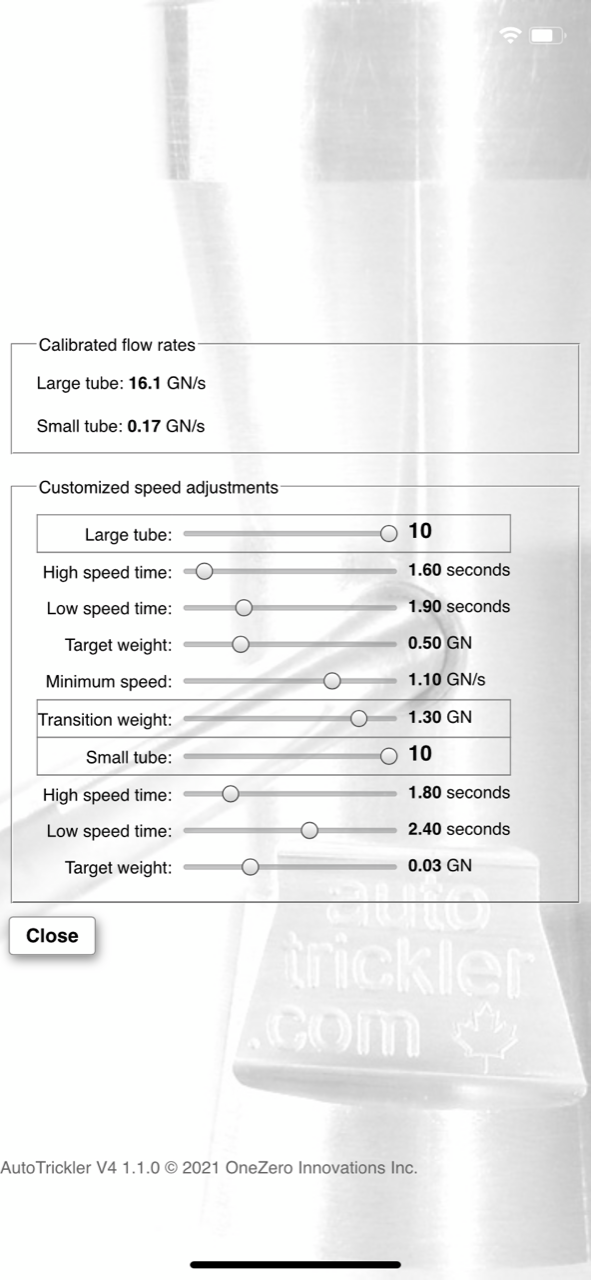

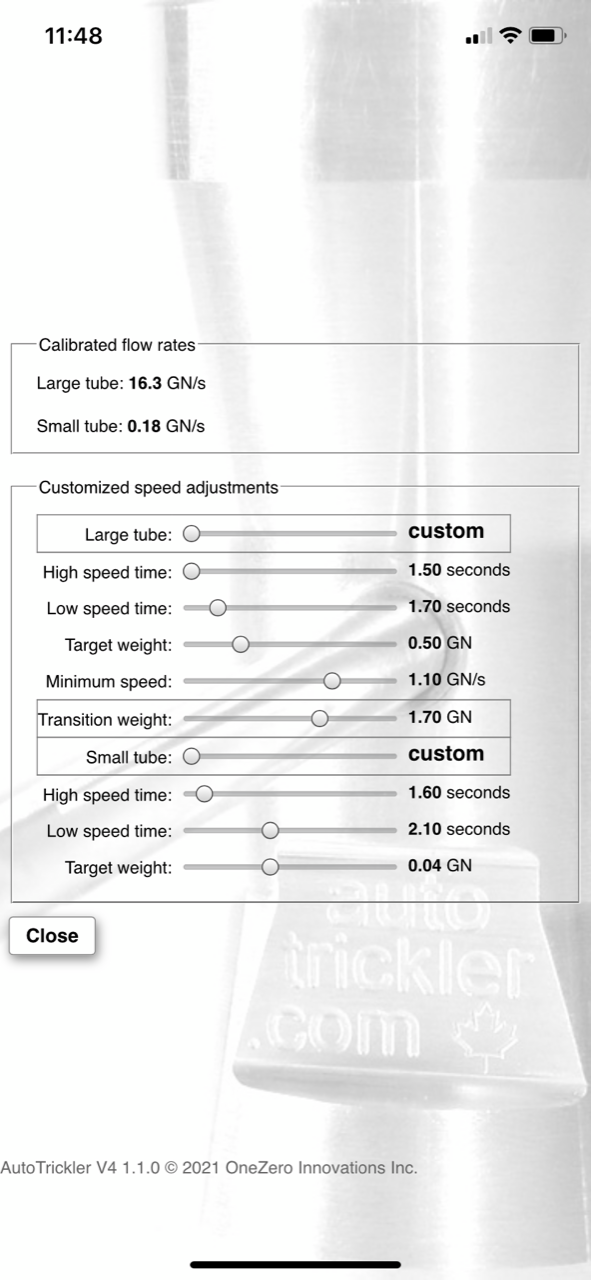

I've attached my settings. The 'twice calibrated setting' picture is what the app defaulted to. This setting would result in overthrows 75% of the time and has had the same result over 3 separate reloading sessions across a months' time. I've had to tune the large tube setting down to 1 which is shown in the "Modified Setting" picture, which only overthrows 1 of 10 times approximately.

The V4 ran great to begin with, I don't know what changed this. I'll have to double check to make sure my scale settings didn't magically change.

The V4 ran great to begin with, I don't know what changed this. I'll have to double check to make sure my scale settings didn't magically change.

Attachments

Last edited:

One million percent not. Read one single page of this thread.Can't say yes or no. No one posts their set ups or settings after calibrating. I still think most of these "issues" are a user interface problem.

My point exactly. You’re going half as fast as the previous model after investing a bunch of time into messing with settings and hacks. That’s not worth a premium priceI had quite a few issues with mine as well when I first got it, but when I actually made sure that the small tube was right at the .20ish gr per second that was recommended everything started working alot better. When I started using the settings Adam posted a while back, things even started working better. I know that my situation is not everyone's situation but doing those two things made my v4 a joy to use. I hardly ever get an overthrow now, and I can drop a 30.8 grain charge of varget in 9-12 seconds, which works well for me.

My posts are not to insult or poke the people (and creator) who made a monetary commitment to the ATV4. Do not get me wrong, it is a fantastic machine. The ability to change powders easily and calibrate between such is a game changer. However, it seems to me (and many others in the precision rifle community) that there were many shortcomings on the unit. While there are no guarantees, there are certainly expectations given the high investment in such a reloading product. Frankly, the best on the market from what I gather.

As an owner of several generations of autotricklers, many expected more. If the problems did not exist, there wouldn't be a market for shims, spacers, adjustment knobs, risers, etc. that range from $15 to as much as $100 on several forums across the internet. There wouldn't be a need to do custom settings. There wouldn't be a need to add custom tips. And there wouldn't be a sudden increase and desire to find V3 units at almost the same cost as a new V4 unit.

I have faith that Adam will address the issue. But for users here to simply say that they don't exist or to live with it, is simply being voluntarily blind. We should all be smarter consumers, and constructive criticism only benefits the end consumer.

As an owner of several generations of autotricklers, many expected more. If the problems did not exist, there wouldn't be a market for shims, spacers, adjustment knobs, risers, etc. that range from $15 to as much as $100 on several forums across the internet. There wouldn't be a need to do custom settings. There wouldn't be a need to add custom tips. And there wouldn't be a sudden increase and desire to find V3 units at almost the same cost as a new V4 unit.

I have faith that Adam will address the issue. But for users here to simply say that they don't exist or to live with it, is simply being voluntarily blind. We should all be smarter consumers, and constructive criticism only benefits the end consumer.

Your perspective is well reasoned and fair. I had a V4 on order, but cancelled it in January. In part, due to the known issues about it, but also in part to me already having a V3. I started way back in the beginning with AT/Adam, arriving at V3 configuration via upgrades, plus a bunch of Area 419 additions. I have been very happy with it and I am confident that Adam will get things worked out on V4. Will I upgrade to V4 ? Probably, but I'm in no hurry to do so.My posts are not to insult or poke the people (and creator) who made a monetary commitment to the ATV4. Do not get me wrong, it is a fantastic machine. The ability to change powders easily and calibrate between such is a game changer. However, it seems to me (and many others in the precision rifle community) that there were many shortcomings on the unit. While there are no guarantees, there are certainly expectations given the high investment in such a reloading product. Frankly, the best on the market from what I gather.

As an owner of several generations of autotricklers, many expected more. If the problems did not exist, there wouldn't be a market for shims, spacers, adjustment knobs, risers, etc. that range from $15 to as much as $100 on several forums across the internet. There wouldn't be a need to do custom settings. There wouldn't be a need to add custom tips. And there wouldn't be a sudden increase and desire to find V3 units at almost the same cost as a new V4 unit.

I have faith that Adam will address the issue. But for users here to simply say that they don't exist or to live with it, is simply being voluntarily blind. We should all be smarter consumers, and constructive criticism only benefits the end consumer.

One can say that the V4 (or V3 for that matter) is expensive. OK, but if you remove the cost of the scale, it is more than most, but not substantially so. Personally, I wouldn't make a direct comparison to units like the Chargemaster. From what I have seen, units like Chargemasters and their competition are slower and not as accurate. Speed has never been a big deal with me (within reason). I go out to the Mancave and reload for relaxation. A couple of seconds plus or minus makes no difference to me. So, in that sense, speed is not the main criteria for my V3. The fact that it pretty consistently throws with the accuracy/repeatability is of primary importance.

Last edited:

I am one of the guys that have not had the overcharging issue. I literally took it out the box, followed instructions, tweaked the setting a little and just have not seen the issues everyone is talking about.

I was just wondering if the over throw issue is just relegated to the guys that are trying to squeeze out as much speed as possible?

I am certainly not advocating that it's not happening and for full discloser I have only ran H1000 as well as throw powder then seat, so I just don't need the speed that the guys that are powering all rounds before seating.

I was just wondering if the over throw issue is just relegated to the guys that are trying to squeeze out as much speed as possible?

I am certainly not advocating that it's not happening and for full discloser I have only ran H1000 as well as throw powder then seat, so I just don't need the speed that the guys that are powering all rounds before seating.

Thats another thing, work flow. I don't powder a hundred rounds then seat a hundred straight. Throw powder, seat bullet, throw next charge while seating first one. If you are trying to fill a hundred cases straight then yeah I can see 15 seconds vs 8 being a thing.I am one of the guys that have not had the overcharging issue. I literally took it out the box, followed instructions, tweaked the setting a little and just have not seen the issues everyone is talking about.

I was just wondering if the over throw issue is just relegated to the guys that are trying to squeeze out as much speed as possible?

I am certainly not advocating that it's not happening and for full discloser I have only ran H1000 as well as throw powder then seat, so I just don't need the speed that the guys that are powering all rounds before seating.

I do the same. I throw and then seat. Safety also an issue, this prevents a squib load.

I throw and seat for this reason exactly too. Been there, done that, don't want to again.I do the same. I throw and then seat. Safety also an issue, this prevents a squib load.

I throw all cases then seat after that. I like the simplicity of that process to prevent mistakes. I keep uncharged cases in a tray on my left, pick up the case, drop powder than put it down in a different tray on my right.

Other comments about my V4 experience.

I never had a V3 or prior so coming from a chargemaster + dandy trickler the V4 if of course much better.

I like my Jthor tip, glad I got one while it was for sale. It seems to me that it prevents multiple kernels from dumping at once.

I'm interested in seeing what the app updates do. I like the advanced settings in the app currently but I don't know what each slider means or does so messing with them to dial in charges is a bit of voodoo but once it's dialed it's been better.

It would be a nicer experience to have a single dial to adjust tilt and have reference numbers or on the dial. Switching between varying powders requires changing the tilt angle and the scale has feet and adjusting both feet at once. It's not awful but I'd rather have a single dial with reference numbers so when I change from say Varget to n470 I know I need to come up 40 units then test through calibration.

Other comments about my V4 experience.

I never had a V3 or prior so coming from a chargemaster + dandy trickler the V4 if of course much better.

I like my Jthor tip, glad I got one while it was for sale. It seems to me that it prevents multiple kernels from dumping at once.

I'm interested in seeing what the app updates do. I like the advanced settings in the app currently but I don't know what each slider means or does so messing with them to dial in charges is a bit of voodoo but once it's dialed it's been better.

It would be a nicer experience to have a single dial to adjust tilt and have reference numbers or on the dial. Switching between varying powders requires changing the tilt angle and the scale has feet and adjusting both feet at once. It's not awful but I'd rather have a single dial with reference numbers so when I change from say Varget to n470 I know I need to come up 40 units then test through calibration.

If you guys are interested, fast forward to 1:45 for upcoming fixes to V4

We’re still waiting on software fix beta testing.

I’ll give it another week, if it doesn’t come then I’ll sell the tip again, but I will caveat it might not work well after the update.

I’ll give it another week, if it doesn’t come then I’ll sell the tip again, but I will caveat it might not work well after the update.

Follow up to post #847.

To be clear I'm not going in the tip business. If this works well across a broad range of powders then I'll open source what & were to get the parts.

I had to machine the part shown so it wasn't a simple order/install deal.

I'm doing this to satisfy my own curiosity, test my theory, & hopefully offer a constructive improvement Adam may choose to apply to future revisions.

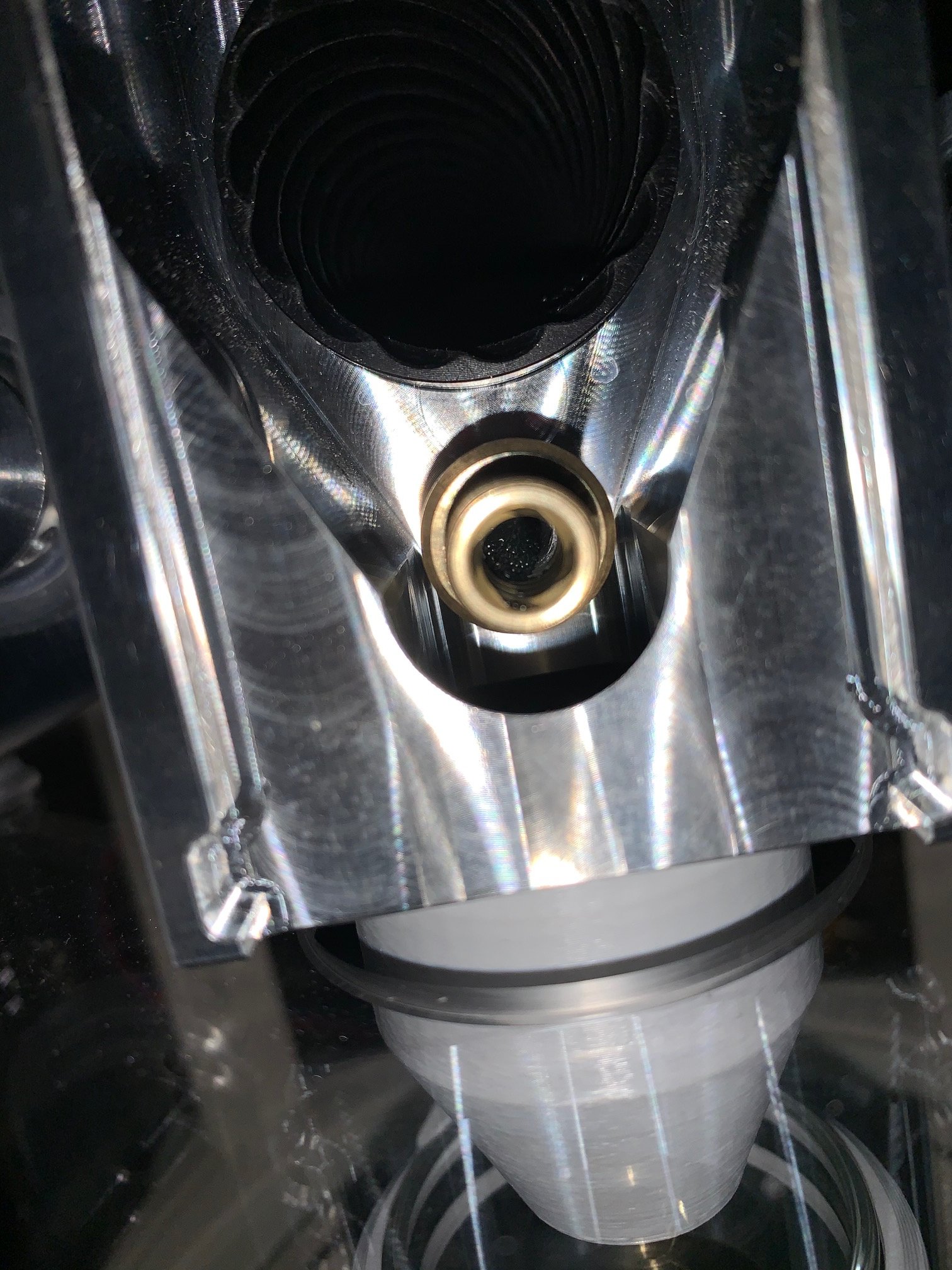

I had ordered 2 parts & started with the most aggressive thread lead. It has 3 turns per inch & 4 thread starts. These have very deep grooves for such a small diameter (for large stick powders).

First test is with fine ball powder - Lever Revolution.

I did not expect this to be plug and play, but it kind of was. All I had to change was the level. Previously with no tip I'd had to raise the front with the leveling adjusters to have the bubble half out of the circle line. This was required to get small tube feed under .2 for both Lever & H4350. I was still getting a few overthrows, but it was much better when the small tube was below .2 on calibration.

First Lever test with the Acme .333 lead 4 start tip.

Ran 20 loads @29.7gr 8.13 sec avg. No overthrows, ES 4.02 sec, fastest = 6.57 (only one sub 7 sec) & slowest 10.59sec (only one above 9 sec).

Not to shabby.

Edit: Added data. Of the 20 drops 4 were 29.68, 2 were 29.72, & 14 were 29.70

Then adjusted advanced settings & ran 29.7 again, this time 25 drops. Avg drop = 6.5 sec No overthrows, ES 1.84 sec, fastest = 5.21 ( x 3 sub 6 sec) & slowest 7.05 ( only 2 above 6 sec both were 7.05).

Edit: Of the 25 drops 3 were 29.68, 4 were 29.72, & 18 were 29.70

This was not the most aggressive setting I tried, it can go faster. I backed off a little as I'm hoping it will work across a good range of powders without having to screw with setting everytime.

Front on pic shows transition of small tube - Tip. With everything leveled the small tube has no issue keeping the tip fed. The kernels now just line up in the grooves & feed very consistent. Running like 5 calibrations flow rates never varied more than .1 on small tube, an improvement.

More testing to follow. I've got about a hundred Lever loads to do & then I'll throw some N570 in there and run some more tests.

To be clear I'm not going in the tip business. If this works well across a broad range of powders then I'll open source what & were to get the parts.

I had to machine the part shown so it wasn't a simple order/install deal.

I'm doing this to satisfy my own curiosity, test my theory, & hopefully offer a constructive improvement Adam may choose to apply to future revisions.

I had ordered 2 parts & started with the most aggressive thread lead. It has 3 turns per inch & 4 thread starts. These have very deep grooves for such a small diameter (for large stick powders).

First test is with fine ball powder - Lever Revolution.

I did not expect this to be plug and play, but it kind of was. All I had to change was the level. Previously with no tip I'd had to raise the front with the leveling adjusters to have the bubble half out of the circle line. This was required to get small tube feed under .2 for both Lever & H4350. I was still getting a few overthrows, but it was much better when the small tube was below .2 on calibration.

First Lever test with the Acme .333 lead 4 start tip.

- Only change was to center the bubble level. New calibration flow leveled = Large 16.3 / Small .18

- All other calibration settings stock

Ran 20 loads @29.7gr 8.13 sec avg. No overthrows, ES 4.02 sec, fastest = 6.57 (only one sub 7 sec) & slowest 10.59sec (only one above 9 sec).

Not to shabby.

Edit: Added data. Of the 20 drops 4 were 29.68, 2 were 29.72, & 14 were 29.70

Then adjusted advanced settings & ran 29.7 again, this time 25 drops. Avg drop = 6.5 sec No overthrows, ES 1.84 sec, fastest = 5.21 ( x 3 sub 6 sec) & slowest 7.05 ( only 2 above 6 sec both were 7.05).

Edit: Of the 25 drops 3 were 29.68, 4 were 29.72, & 18 were 29.70

This was not the most aggressive setting I tried, it can go faster. I backed off a little as I'm hoping it will work across a good range of powders without having to screw with setting everytime.

- I'll show settings used, however this only applies for use with this tip.

Front on pic shows transition of small tube - Tip. With everything leveled the small tube has no issue keeping the tip fed. The kernels now just line up in the grooves & feed very consistent. Running like 5 calibrations flow rates never varied more than .1 on small tube, an improvement.

More testing to follow. I've got about a hundred Lever loads to do & then I'll throw some N570 in there and run some more tests.

Last edited:

I have. I got basically got not anytime soon.Email Adam, he might know.

i thought maybe the guys beta testing the new version would have a decent answer.

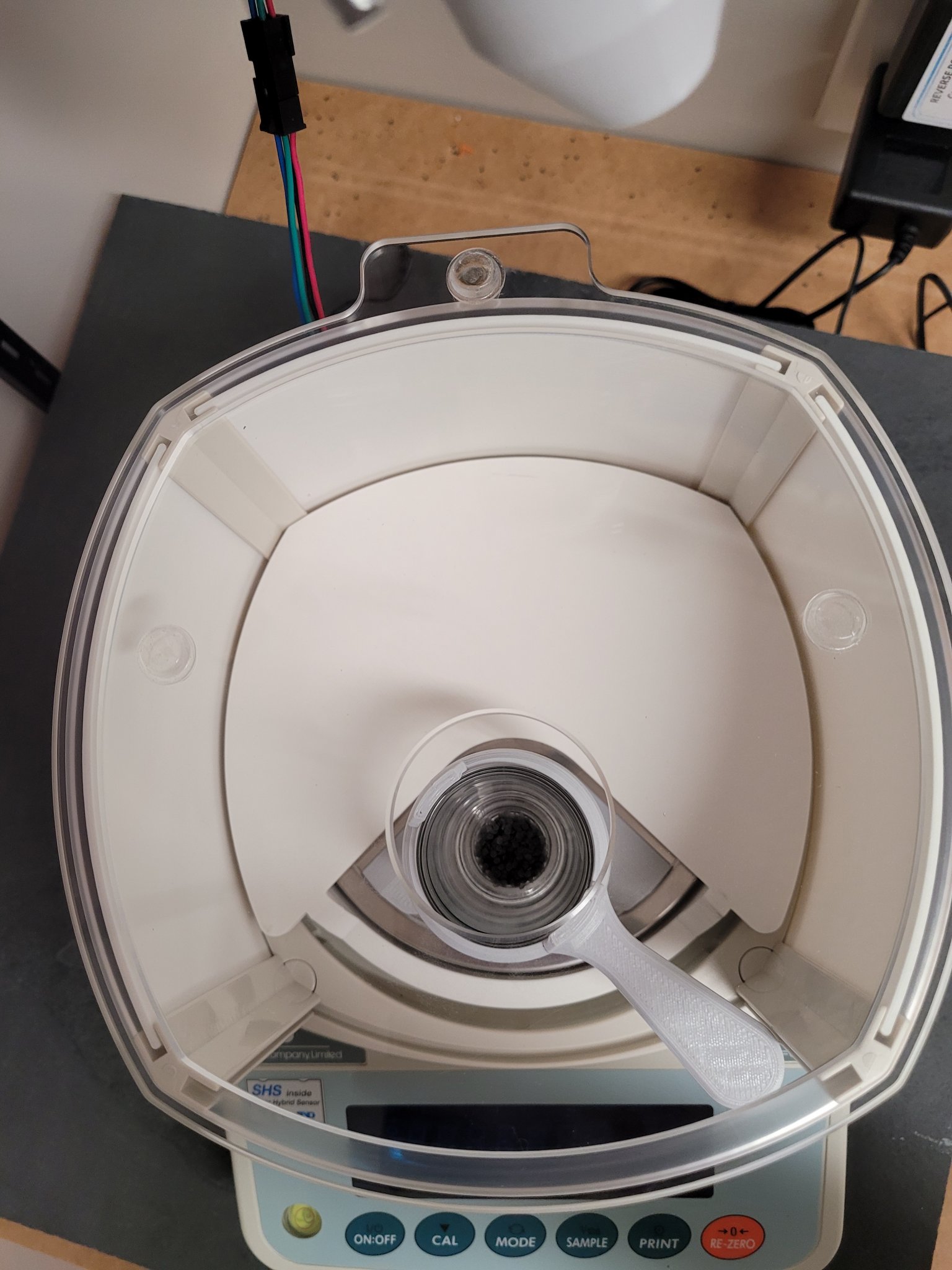

I got around to getting some parts printed for my V4. Added in some Krylon Almond spray paint and it looks just like it came from the factory.

No more worrying about random kernels flying around and messing things up and more of the pan is sheltered from breezes.

Edited to add... These parts were designed by Obsessed. If you want the files or anything like it, please contact him. Stealing his IP for profit isnt cool.

No more worrying about random kernels flying around and messing things up and more of the pan is sheltered from breezes.

Edited to add... These parts were designed by Obsessed. If you want the files or anything like it, please contact him. Stealing his IP for profit isnt cool.

Last edited:

Verrrry nice !I got around to getting some parts printed for my V4. Added in some Krylon Almond spray paint and it looks just like it came from the factory.

No more worrying about random kernels flying around and messing things up and more of the pan is sheltered from breezes.

I'd like to have that for my V3 with 419 kitI got around to getting some parts printed for my V4. Added in some Krylon Almond spray paint and it looks just like it came from the factory.

No more worrying about random kernels flying around and messing things up and more of the pan is sheltered from breezes.

Count me in if you print moreI got around to getting some parts printed for my V4. Added in some Krylon Almond spray paint and it looks just like it came from the factory.

No more worrying about random kernels flying around and messing things up and more of the pan is sheltered from breezes.

I'm interested in one as well. Group buy?

What he said ^^^^^^^^

Autotrickler Inner Panel Set by Obsessed

This is an inner panel set for the Autotrickler reloading powder measure. This panel set is designed to make for a cleaner look and an easier backdrop in which to spot the green "go" LED that is lit when the charge is dispensed accurately. I'd recommend printing this in white PLA, 0.2mm layer...

Looks like it’s an open source file designed by someone. I’m printing one for myself and another person!

My son is printing some spacers to change the angle of the V4 for what its worth. He's also making dust covers for the guys that upgraded from the v3 to v4 and have a hole in the back of their machine.

www.snipershide.com

www.snipershide.com

Reloading Equipment - Autotrickler v4 spacer mod

Hi everyone, my 10 year old son got a 3d printer recently and we have been busy learning how to make cool stuff. He has an entrepreneurial spirit and wants to offer up some of the designs we came up with. My son is printing, and shipping. All of the money goes to him, I am simply the middle man...

So how does your son feel about churning out some pan cover sets referenced above?My son is printing some spacers to change the angle of the V4 for what its worth. He's also making dust covers for the guys that upgraded from the v3 to v4 and have a hole in the back of their machine.

Reloading Equipment - Autotrickler v4 spacer mod

Hi everyone, my 10 year old son got a 3d printer recently and we have been busy learning how to make cool stuff. He has an entrepreneurial spirit and wants to offer up some of the designs we came up with. My son is printing, and shipping. All of the money goes to him, I am simply the middle man...www.snipershide.com

Seems like there is a demand.......

Hey guys, new here, but I'm active on another forum. The panel set is my design.

If people are honestly wanting a group buy I am happy to get filament to support that, however I must say the set was listed as attribution non commercial only.

I've received a message through Thingiverse noting that both conditions of the creative license was being violated so I have pulled the files.

Please message me if you're interested and whether you want it color matched to the 120i or if you'd prefer bright white.

This is a screenshot of the full set (an earlier design of it anyway). I originally designed it during the beta testing phase of the ATV4 that I was doing for Adam, in order to better see the green light, that at least in my reloading room wasn't super visible against the stainless pan and clear screens.

If people are honestly wanting a group buy I am happy to get filament to support that, however I must say the set was listed as attribution non commercial only.

I've received a message through Thingiverse noting that both conditions of the creative license was being violated so I have pulled the files.

Please message me if you're interested and whether you want it color matched to the 120i or if you'd prefer bright white.

This is a screenshot of the full set (an earlier design of it anyway). I originally designed it during the beta testing phase of the ATV4 that I was doing for Adam, in order to better see the green light, that at least in my reloading room wasn't super visible against the stainless pan and clear screens.

As mentioned above I'm interested.

Don't really mind if it is white or colour matched to the 120i.

Don't really mind if it is white or colour matched to the 120i.

So how does your son feel about churning out some pan cover sets referenced above?

Seems like there is a demand.......

Doesn’t feel good about it at all. Not his design and I wouldn’t allow him to make money on someone else’s work. I sent a message to the person who did design it and hopefully he jumps on here.So how does your son feel about churning out some pan cover sets referenced above?

Seems like there is a demand.......

Hey guys, Ive received a few messages already wanting a set. I will work over getting shipping supplies over the next couple of days and will also determine a fair (for all) price for a set. If anyone has a suggestion on what these should go for message me.

Appreciate the patience. I promise I'll quickly work to get a set to anyone who wants one.

Also I guess I'm signing up for a paid account so I don't get banned.

Appreciate the patience. I promise I'll quickly work to get a set to anyone who wants one.

Also I guess I'm signing up for a paid account so I don't get banned.

Last edited:

Does this set work with the area 419 pan and cup on the V3?Hey guys, Ive received a few messages already wanting a set. I will work over getting shipping supplies over the next couple of days and will also determine a fair (for all) price for a set. If anyone has a suggestion on what these should go for message me.

Appreciate the patience. I promise I'll quickly work to get a set to anyone who wants one.

This set is only designed for the ATV4. That said, making a version for the ATV3 would be possible, it would just require some tweaking of the top plate. If I get enough interest I can certainly do that.Does this set work with the area 419 pan and cup on the V3?

Also, to keep this thread clean, I'm going to create a thread over in the PX to be able to post to...you can also just send me a message directly.