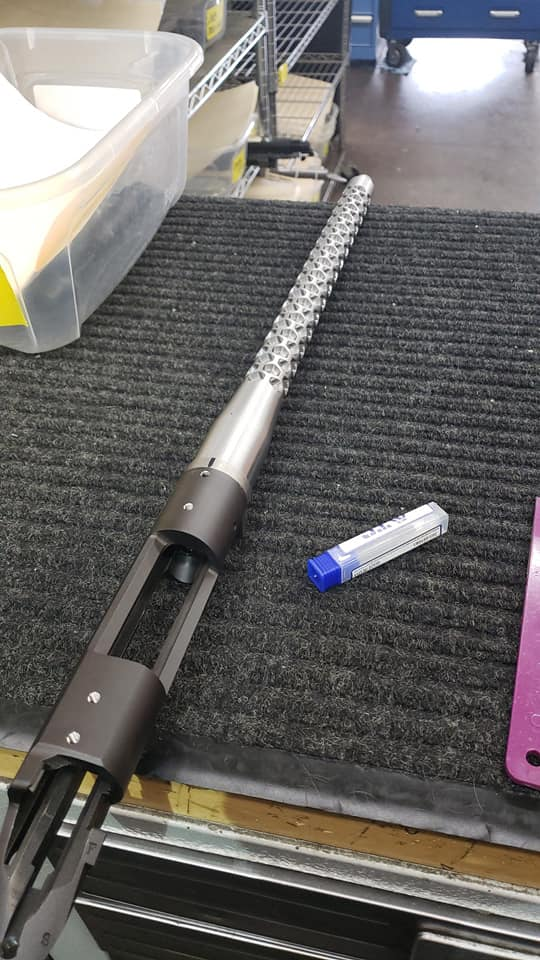

We've taken on some contractual work where we'll be doing a pile of this for some folks. Hexagon fluting is nothing new and I make no claims as to whatever, lol.

The one little difference here. From what I've seen online, the strategy is some X/Y pockets shaped in a hex. No real difference with ours except that the Y axis is now an A axis move. What this does is give the bottom of the pockets a radius. It makes the work appear as though the barrel has been "sleeved" by a really kinky pair of fishnet stockings. Instead of the features being straight walled, they actually grow in size as the distance from the floor increases.

Nothing earth shattering, but it does change the appearance. The pockets also follow the diameter changes along the length of the contour so the wall thickness between bore/pocket follows the outside contour. In this case, it grows proportional towards the breech.

Kinda neat. Certainly different from the other stuff we've done for the last ten years.

We have this on the store now as well. The price isn't the cheapest. It's a solid hour of spindle time to do it this way. Weight reduction is fairly significant. On a 16" OEM Sendero contour barrel for the 300AAC BO we pulled 13ounces from the starting weight. (From 3lbs even to 2lbs, 2oz.) This is approaching a 30% reduction.

Hope you all like it. Comments welcome.

BeeHive fluting

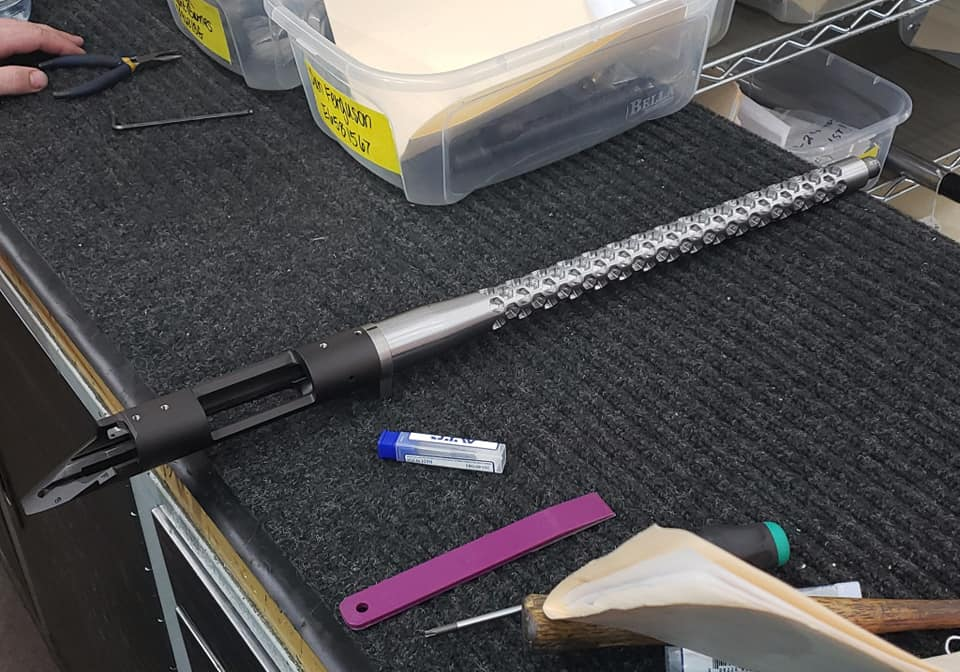

The one little difference here. From what I've seen online, the strategy is some X/Y pockets shaped in a hex. No real difference with ours except that the Y axis is now an A axis move. What this does is give the bottom of the pockets a radius. It makes the work appear as though the barrel has been "sleeved" by a really kinky pair of fishnet stockings. Instead of the features being straight walled, they actually grow in size as the distance from the floor increases.

Nothing earth shattering, but it does change the appearance. The pockets also follow the diameter changes along the length of the contour so the wall thickness between bore/pocket follows the outside contour. In this case, it grows proportional towards the breech.

Kinda neat. Certainly different from the other stuff we've done for the last ten years.

We have this on the store now as well. The price isn't the cheapest. It's a solid hour of spindle time to do it this way. Weight reduction is fairly significant. On a 16" OEM Sendero contour barrel for the 300AAC BO we pulled 13ounces from the starting weight. (From 3lbs even to 2lbs, 2oz.) This is approaching a 30% reduction.

Hope you all like it. Comments welcome.

BeeHive fluting

Last edited: