What's the best release agent for Devcon Steel putty when bedding actions? I'm using acraglas aerosol release agent, which I've used with acraglas-gel with no problems, but am not too happy with it for the Devcon Steel putty.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Best release agent for Devcon?

- Thread starter buffalowinter

- Start date

This subject pops up often on GS type forum pages. The litany of answers you'll get range from shoe polish to Pam Cooking spray. I'll share this: I've been doing this stuff for almost 2 decades professionally. I've bedded a lot of rifle stocks and I've invested a great deal of money/effort pursuing the process that I have settled upon.

There's just no universal do all answer to this is the summary I've come to. A few products need to be purchased to have a worry free, predictable outcome.

1. Johnson's paste wax.

2. McLube aerosol mold release agent.

Paste wax:

I use this to grease up threads on studs/guard screws. Glue a screw into an action once and you'll learn a whole new vocabulary of expletives...

I punch pillar holes to .3125 prior to bedding. To align them I wrap the studs/screws with yellow masking tape. Wax puts a nice layer on the tape without soaking into it and softening the adhesive. The rattle can stuff uses ether as the carrier. Tape glue no likey that.

McLube:

Shake the can till your wrist hurts and spray everything. It'll leave a slick, inclusion free film once it flashes off. It will present to the resin a 100% accurate mirror of the parts being cast. It won't break down as the stuff cures and you won't have to deal with swirling inclusions from buffing shoe polish. I found this product over 15 years ago and used it ever since. I went so far as to buy it in volume so that I can sell it to DIY'rs. It's the best out there. A can lasts us about 3 months here so most guys at home will end up with it going into their casket...lol. It's not absurdly expensive, not when you consider the risks involved should you ever stick an action to a stock and try to pop it out afterward. -that sucks. Using this product its never happened to me. Not even a little bit.

https://www.longriflesinc.com/collec...t-mclube-1700l

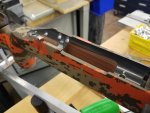

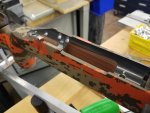

With a careful prep work, this can be achieved at home:

Good luck on your project.

C.

There's just no universal do all answer to this is the summary I've come to. A few products need to be purchased to have a worry free, predictable outcome.

1. Johnson's paste wax.

2. McLube aerosol mold release agent.

Paste wax:

I use this to grease up threads on studs/guard screws. Glue a screw into an action once and you'll learn a whole new vocabulary of expletives...

I punch pillar holes to .3125 prior to bedding. To align them I wrap the studs/screws with yellow masking tape. Wax puts a nice layer on the tape without soaking into it and softening the adhesive. The rattle can stuff uses ether as the carrier. Tape glue no likey that.

McLube:

Shake the can till your wrist hurts and spray everything. It'll leave a slick, inclusion free film once it flashes off. It will present to the resin a 100% accurate mirror of the parts being cast. It won't break down as the stuff cures and you won't have to deal with swirling inclusions from buffing shoe polish. I found this product over 15 years ago and used it ever since. I went so far as to buy it in volume so that I can sell it to DIY'rs. It's the best out there. A can lasts us about 3 months here so most guys at home will end up with it going into their casket...lol. It's not absurdly expensive, not when you consider the risks involved should you ever stick an action to a stock and try to pop it out afterward. -that sucks. Using this product its never happened to me. Not even a little bit.

https://www.longriflesinc.com/collec...t-mclube-1700l

With a careful prep work, this can be achieved at home:

Good luck on your project.

C.

While LRIs recommendations probably are the best you can get I go with the shoe polish as well. Its works good enough and its something I already have in my cabinet and havent had a hiccup in my comparatively minimal experience. Ive heard of hornady one shot as well.

Damn, I get sick of looking at Chad's bedding jobs  ...it isn't the bedding I have "issues" with- it's the damn cleanup around the magwell, etc. I refuse to pop an action out of the stock before an overnight cure; I know a lot do this while the epoxy is still pliable and trim it with an exacto knife, but not moi.

...it isn't the bedding I have "issues" with- it's the damn cleanup around the magwell, etc. I refuse to pop an action out of the stock before an overnight cure; I know a lot do this while the epoxy is still pliable and trim it with an exacto knife, but not moi.

Any hoo...I gotta look for that spray Chad mentioned, I use the wax and the Acra-Release aerosol, but do sometimes have a problem spot or two with the spray. Sprays will get into tiny areas (if any) that you can't get into with a cotton swab and wax, and I always spray everything first before I start filling the action with clay/putty as added insurance.

Any hoo...I gotta look for that spray Chad mentioned, I use the wax and the Acra-Release aerosol, but do sometimes have a problem spot or two with the spray. Sprays will get into tiny areas (if any) that you can't get into with a cotton swab and wax, and I always spray everything first before I start filling the action with clay/putty as added insurance.

Any hoo...I gotta look for that spray Chad mentioned,

You can buy it from him. I'm a student on this subject, not a teacher, but here is my tip on centering the action screws in the pillars.

I think using this is easier than tape.

https://www.fluorostore.com/products/fractional-metric-ptfe-fluoropolymer-tubing

Last edited:

This subject pops up often on GS type forum pages. The litany of answers you'll get range from shoe polish to Pam Cooking spray. I'll share this: I've been doing this stuff for almost 2 decades professionally. I've bedded a lot of rifle stocks and I've invested a great deal of money/effort pursuing the process that I have settled upon.

There's just no universal do all answer to this is the summary I've come to. A few products need to be purchased to have a worry free, predictable outcome.

1. Johnson's paste wax.

2. McLube aerosol mold release agent.

Paste wax:

I use this to grease up threads on studs/guard screws. Glue a screw into an action once and you'll learn a whole new vocabulary of expletives...

I punch pillar holes to .3125 prior to bedding. To align them I wrap the studs/screws with yellow masking tape. Wax puts a nice layer on the tape without soaking into it and softening the adhesive. The rattle can stuff uses ether as the carrier. Tape glue no likey that.

McLube:

Shake the can till your wrist hurts and spray everything. It'll leave a slick, inclusion free film once it flashes off. It will present to the resin a 100% accurate mirror of the parts being cast. It won't break down as the stuff cures and you won't have to deal with swirling inclusions from buffing shoe polish. I found this product over 15 years ago and used it ever since. I went so far as to buy it in volume so that I can sell it to DIY'rs. It's the best out there. A can lasts us about 3 months here so most guys at home will end up with it going into their casket...lol. It's not absurdly expensive, not when you consider the risks involved should you ever stick an action to a stock and try to pop it out afterward. -that sucks. Using this product its never happened to me. Not even a little bit.

https://www.longriflesinc.com/collec...t-mclube-1700l

With a careful prep work, this can be achieved at home:

Good luck on your project.

C.

Beautiful bedding job !!

.

Sent from my iPad using Tapatalk

One shot spray lube has worked for "insurance" along with wax for me. My router cleanup just isn't up to Chad's photo tho.

One shot spray lube has worked for "insurance" along with wax for me. My router cleanup just isn't up to Chad's photo tho.

All you need is a knee mill to get those edges.

All you need is a knee mill to get those edges.

Takes a little more than that to generate outside radius contours. Look closer.

This subject pops up often on GS type forum pages. The litany of answers you'll get range from shoe polish to Pam Cooking spray. I'll share this: I've been doing this stuff for almost 2 decades professionally. I've bedded a lot of rifle stocks and I've invested a great deal of money/effort pursuing the process that I have settled upon.

There's just no universal do all answer to this is the summary I've come to. A few products need to be purchased to have a worry free, predictable outcome.

1. Johnson's paste wax.

2. McLube aerosol mold release agent.

Paste wax:

I use this to grease up threads on studs/guard screws. Glue a screw into an action once and you'll learn a whole new vocabulary of expletives...

I punch pillar holes to .3125 prior to bedding. To align them I wrap the studs/screws with yellow masking tape. Wax puts a nice layer on the tape without soaking into it and softening the adhesive. The rattle can stuff uses ether as the carrier. Tape glue no likey that.

McLube:

Shake the can till your wrist hurts and spray everything. It'll leave a slick, inclusion free film once it flashes off. It will present to the resin a 100% accurate mirror of the parts being cast. It won't break down as the stuff cures and you won't have to deal with swirling inclusions from buffing shoe polish. I found this product over 15 years ago and used it ever since. I went so far as to buy it in volume so that I can sell it to DIY'rs. It's the best out there. A can lasts us about 3 months here so most guys at home will end up with it going into their casket...lol. It's not absurdly expensive, not when you consider the risks involved should you ever stick an action to a stock and try to pop it out afterward. -that sucks. Using this product its never happened to me. Not even a little bit.

https://www.longriflesinc.com/collec...t-mclube-1700l

With a careful prep work, this can be achieved at home:

Good luck on your project.

C.

Chad, maybe you can comment on the prep work for the McLube. I cleaned the action with Acetone, wiped it dry with some clean patches and let it sit for about an hour. I then sprayed the McLube on and let it dry for about 15 minutes, then gave it another coat. After another 15 minutes it looked dry and hazy.

However, I had a few small spots at the front of the action that wanted to stick just a little bit. It sort of "flaked off" some of the epoxy. I had to scrape those flakes off the action with a razor blade. Same with the excess above the chassis. I wiped most off with Q-tips, but the residue was really, really stuck on there.

The rear tang area worked beautifully. So I'm guessing something in my prep work was not quite right and I got lucky with that area.

Thanks,

Steve

Shake the can till the ball stops rattling...

There's no need to wait 15m. This stuff flashes off in less than a minute. Shake the snot out of the can, do not be shy when applying, and go to work. That's all I do.

There's no need to wait 15m. This stuff flashes off in less than a minute. Shake the snot out of the can, do not be shy when applying, and go to work. That's all I do.

Some of this on the way for some 'sperimenting....

http://www.mgchemicals.com/products/potting-compounds/sundries/8329-epoxy-mold-release

Always looking for a better mousetrap.

http://www.mgchemicals.com/products/potting-compounds/sundries/8329-epoxy-mold-release

Always looking for a better mousetrap.

The spray on Acra-release sold by brownells is the best release I've ever seen. It's fool-proof perfection.

I did once about 18 years ago and it sucked. Makes the action and anything close to it look like it got fingerbanged by a bottle of Mrs. Butterworths.

Dry slick = better

Dry slick = better

I used the Hornady Case Lube aerosol and it worked pretty good. It's something I have on the reloading bench anyway.

Similar threads

- Replies

- 5

- Views

- 478

- Replies

- 1

- Views

- 395