Glad that phone landed safely .

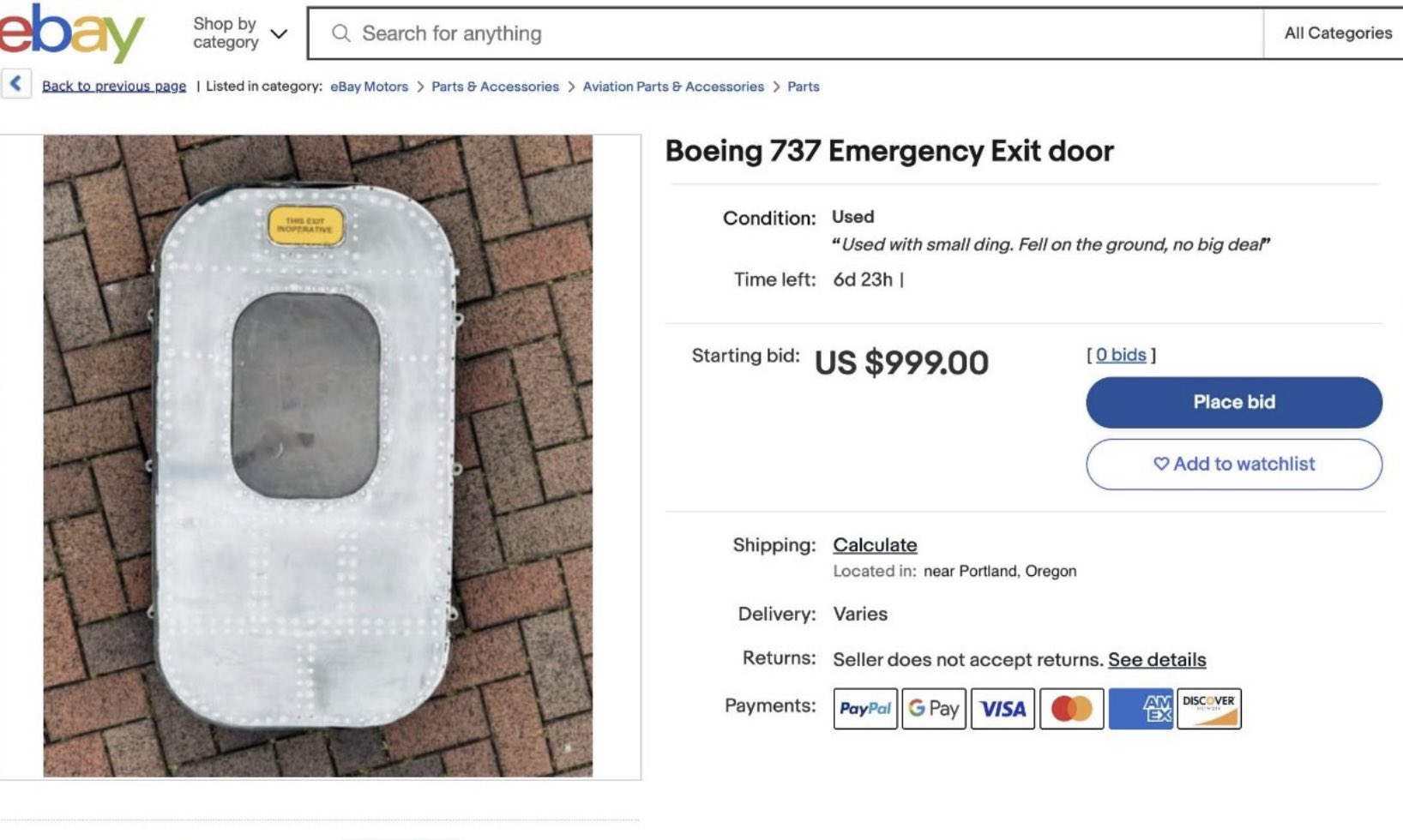

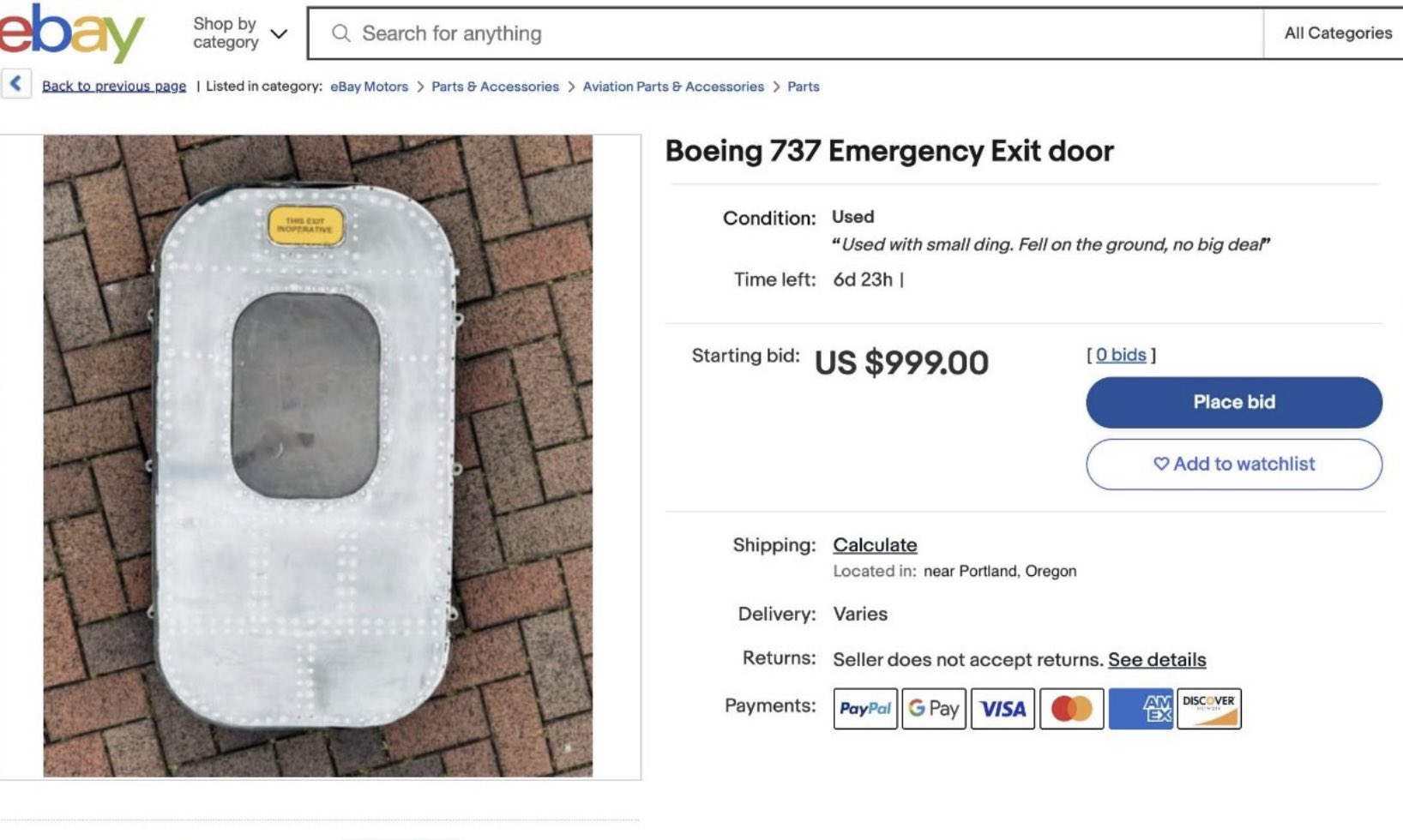

Now we wait for plug to pop up on ebay

Imagine walking down the road minding your own mutha fawking business and getting your noggin caved in by some pos iphone....lol

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Glad that phone landed safely .

Now we wait for plug to pop up on ebay

Imagine walking down the road minding your own mutha fawking business and getting your noggin caved in by some pos iphone....lol

And by the way the over water thing has everything to do with crashing and nothing to do with pressurization…..

I would rather not crash at all….I would rather ditch in a body of water that attempt to do a gear up off field landing... chances of success in water are pretty damn high if done properly. Chances of success doing an off field landing are not nearly as good... MAYBE in a Cessna, but definitely not in a large jet. There is evidence of a few purposeful ditchings in the past few years being 100% successful.

And by the way the over water thing has everything to do with crashing and nothing to do with pressurization….. if you don’t understand that leave this conversation…..

You know as well (or better) than I do that a lot of those places claim to have a process-dependent system, but ultimately there is some people-dependence at various spots and thus the loss of key personal proves catastrophic.

The fact that Spirit fired its CEO a couple of months ago does not suggest that all is well.

It's way too early to determine who might carry the burden of blame on the product side. Feels pretty safe to say that the airline did a good job of demonstrating normalcy bias by keeping the aircraft in service despite multiple warnings of a potential problem. "We get those warnings all the time", cries the peanut gallery - yep, and you better heed every single one if you wish to maintain a 10-sigma record of ensuring that the number of landings equals the number of takeoffs.

Idk man. Some Russian coasted a 320 into a field recently and they flew it out even. I don’t want either. Give me the choice, I just hope it’s daylight for whichever one I have to deal with.I would rather ditch in a body of water that attempt to do a gear up off field landing... chances of success in water are pretty damn high if done properly. Chances of success doing an off field landing are not nearly as good... MAYBE in a Cessna, but definitely not in a large jet. There is evidence of a few purposeful ditchings in the past few years being 100% successful.

6-8 seats away from the door is quiet in just about every aircraft. Just a few aircraft I’ve been in doors open at altitude on for referenceAll I know was it was eerily quiet inside for a plane flying at whatever speed it was with a large hole in the side.

ExactlyEverything in hindsight has a different perspective. But I’ll bet they are glad they did cause if that happened halfway to Hawaii in all likelihood could have also ended up in ditching in the pacific because they ran out of fuel.

I worked for 9 years at another OEM on the other side of the city..........I think I have a good idea of how it goes.

Looks like this might not be an isolated problem:

United finds loose bolts on 737 Max 9 planes in wake of Alaska Airlines door plug incident

United Airlines says that it has found loose bolts during inspections of its 737 Max 9 fleet in the wake of a door plug getting blown out of an Alaska Airlines plane.abcnews.go.com

"Since we began preliminary inspections on Saturday, we have found instances that appear to relate to installation issues in the door plug -- for example, bolts that needed additional tightening"

Can't wait for my next opportunity to use the term "bolts that needed additional tightening".

A twin engine commercial airplane can fly as far as 60 minutes from a suitable airport without needing to comply with ETOPS procedures, three and four engine commercial airplanes (unless you are cargo only then the FAA doesn't give fuck all) can go as far as 180 minutes from a suitable airport without needing to comply with ETOPS procedures.What is the difference in crashing over land as opposed to crashing over water ?

OK, a few thoughts from an old shade tree steamfitter / welder.

When you have a pressure vessel with an opening in the side.... Any patch / cover should be installed in such a manner that the more the pressure increases, the tighter the patch is pressed against the vessel.

Appears these covers were attached on the outside of the pressure vessel. As internal pressure increased it forced the covers off.

If these covers were installed on the inside the cabin pressure would have held them tight against the interior wall of the vessel.

JMHO

I am. And in reality it's nowhere near as many as you and the hobo Hilton idiot seem to think.Then you should be well aware of the number of ways in which things can go wrong.

Jesus Christ shut the fuck up already.OK, a few thoughts from an old shade tree steamfitter / welder.

When you have a pressure vessel with an opening in the side.... Any patch / cover should be installed in such a manner that the more the pressure increases, the tighter the patch is pressed against the vessel.

Appears these covers were attached on the outside of the pressure vessel. As internal pressure increased it forced the covers off.

If these covers were installed on the inside the cabin pressure would have held them tight against the interior wall of the vessel.

JMHO

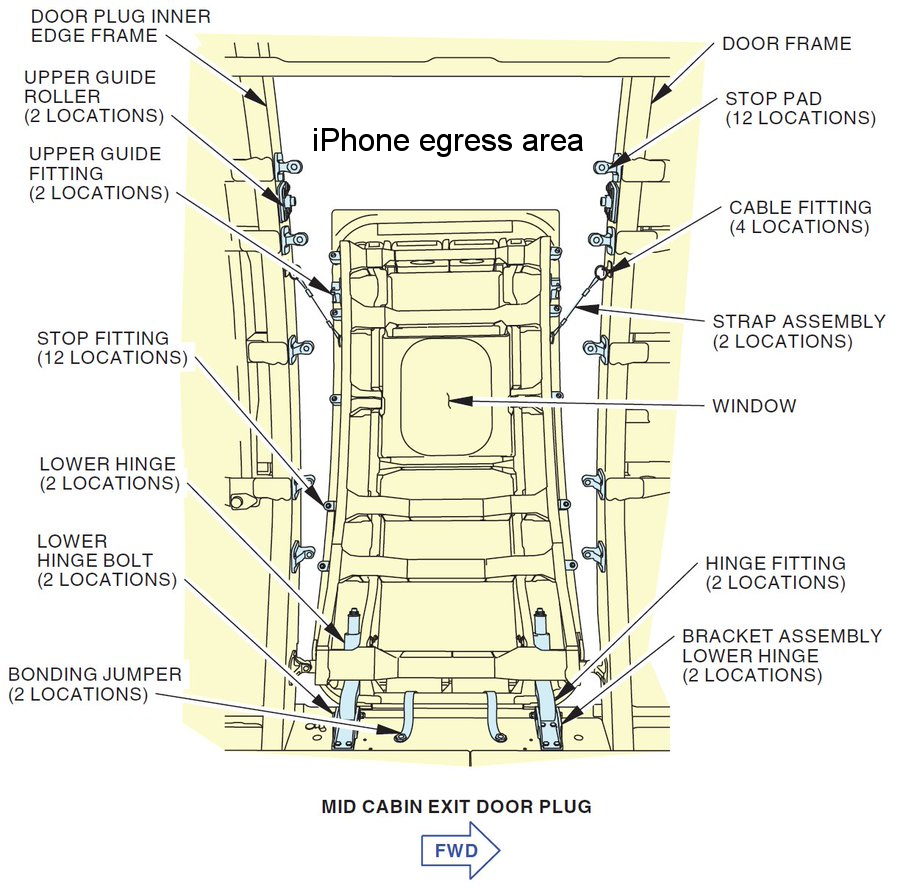

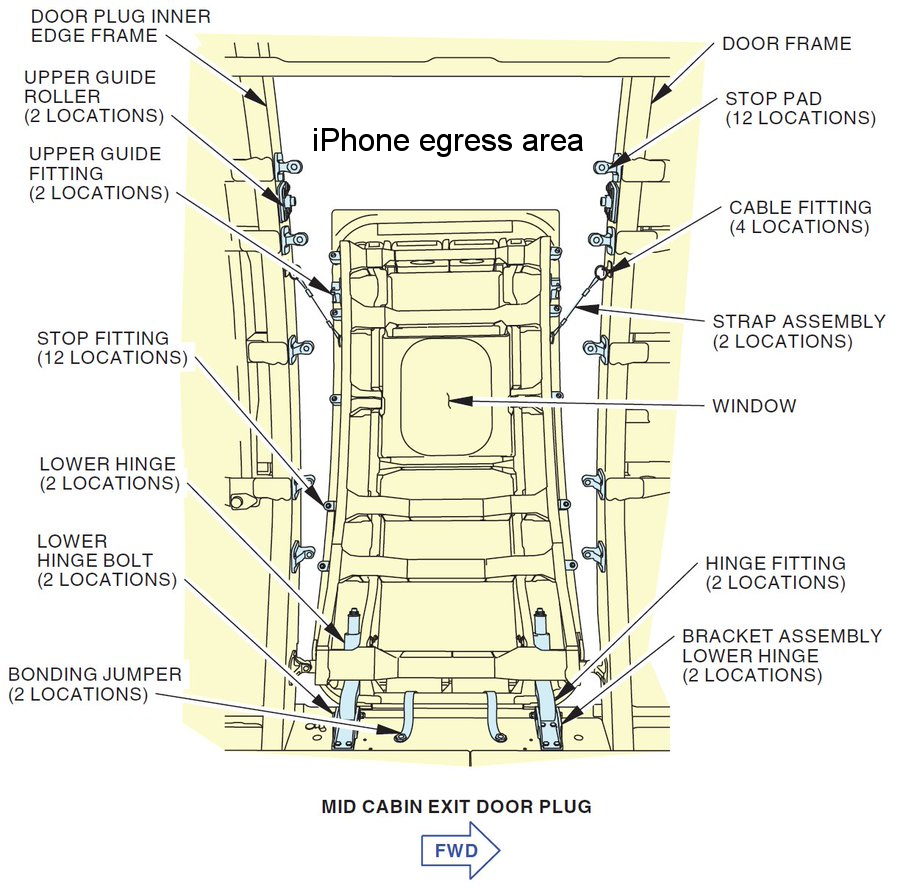

Homendy saidNo, they are "technically" on the inside, although not a true "plug". The fuselage frame has lugs on it. The door has lugs on it. Said door lugs sit INSIDE of the fuselage lugs. So when the aircraft is pressurized the plug does indeed push OUT against the fuselage frame lugs.

What's your FAA Airman's Certificate number?

Are you that "hint hint" idiot?Homendy said

“We were able to inspect the airframe itself from the exterior and found absolutely no structural damage to the airplane,” she told “CNN This Morning.” “Inside, there was a lot of damage to non-critical components.”

Interesting there was no structural damage if it was "lug to lug".

I am a pilot but also an A&P with a lot of hours working on B-737‘s but by all means I will defer to your google expertise…….What's your FAA Airman's Certificate number?

Rapid unscheduled disassembly.Looks like this might not be an isolated problem:

United finds loose bolts on 737 Max 9 planes in wake of Alaska Airlines door plug incident

United Airlines says that it has found loose bolts during inspections of its 737 Max 9 fleet in the wake of a door plug getting blown out of an Alaska Airlines plane.abcnews.go.com

"Since we began preliminary inspections on Saturday, we have found instances that appear to relate to installation issues in the door plug -- for example, bolts that needed additional tightening"

Can't wait for my next opportunity to use the term "bolts that needed additional tightening".

Interesting. I have never had the experience. (Thank you for your service). Just seems odd, wind whipping by at 400+ knots.6-8 seats away from the door is quiet in just about every aircraft. Just a few aircraft I’ve been in doors open at altitude on for reference

C17, C130, C123, Twin Otter, CH47(all the way up front by the crew chief area is even surprisingly quiet at drip altitude and speed).

Show me a perfectly good airplane and I’ll agree with you lol!!!!!!!!Interesting. I have never had the experience. (Thank you for your service). Just seems odd, wind whipping by at 400+ knots.

But, good to know. Always wanted to try that, but live by the adage. "Why jump out of a perfectly good areoplane".

Looks like this might not be an isolated problem:

United finds loose bolts on 737 Max 9 planes in wake of Alaska Airlines door plug incident

United Airlines says that it has found loose bolts during inspections of its 737 Max 9 fleet in the wake of a door plug getting blown out of an Alaska Airlines plane.abcnews.go.com

"Since we began preliminary inspections on Saturday, we have found instances that appear to relate to installation issues in the door plug -- for example, bolts that needed additional tightening"

Can't wait for my next opportunity to use the term "bolts that needed additional tightening".

I'd kinda really rather not know. Just let me be comfortable on the fight. And, if my time is up, I had a good ride.Show me a perfectly good airplane and I’ll agree with you lol!!!!!!!!

You better go read what I wrote again seems reading comprehension isn't strong with you.I am a pilot but also an A&P with a lot of hours working on B-737‘s but by all means I will defer to your google expertise…….

Idk man. Some Russian coasted a 320 into a field recently and they flew it out even. I don’t want either. Give me the choice, I just hope it’s daylight for whichever one I have to deal with.

I would not under any circumstances get on any aircraft operated by a Russian airline anytime soon. Especially Boeing or Airbus.I was going to ask your opinion on Russia's fleet.

I flew Aeroflot in 1988, December, lots of snow in CCCP.

Only plane I recall with house flies in the cabin but they landed that thing on a snow covered field and it oddly felt comforting like I was in an overbuilt tractor the way it handled the rough runway.

My only ain't experience is passenger.

I am. And in reality it's nowhere near as many as you and the hobo Hilton idiot seem to think.

I sat my ass down in more than one King Air on its first production acceptance test flight. And yet here I am.

Yeah, what does he know? Everything he ever designed has exploded midair...Just before this I spent winter break with an engineer from Boeing (in missiles, not aircraft), and he was telling me what a POS Airbus is, and how he wouldn't ride on one.

Homendy said

“We were able to inspect the airframe itself from the exterior and found absolutely no structural damage to the airplane,” she told “CNN This Morning.” “Inside, there was a lot of damage to non-critical components.”

Interesting there was no structural damage if it was "lug to lug".

Calhoun previously served as senior managing director and head of portfolio operations at The Blackstone Group beginning in January 2014. During his time with the investment firm, he focused on creating and driving added-value initiatives with Blackstone’s portfolio company CEOs.

Previously, he also served as executive chairman of the board for Nielsen Holdings from January 2014 to January 2016. He joined Nielsen in 2006 as chief executive officer shortly after it was acquired through a consortium of private equity investors, including Blackstone. Throughout his seven-year Nielsen tenure, Calhoun led the company’s transformation into a leading global information and measurement firm listed on the New York Stock Exchange and Standard & Poor’s 500 Index.

Calhoun began his career at General Electric Company (GE), where he rose to vice chairman of the company and president and chief executive officer of GE Infrastructure, its largest business unit. During his 26 years at GE, he held a number of operating, finance and marketing roles and led multiple business units, including GE Transportation and GE Aircraft Engines.

Calhoun has a bachelor’s degree in accounting from Virginia Tech.

A good discussion by some folks who seem to be "in the trade".The NTSB briefing stated the door had damage as if it "translated up before departing"... which would disengage the lugs...

I have never seen one of these particular "doors/plugs" but I said before that every one of these doors designed like this(basically every door on the airplane) drops in from the top and then there is a cam lock action somewhere to hold it in place(or in this case 4 bolts). The reason they drop in from the top is so they dont have room to fall out the bottom. The fail safe is basically just sitting on the floor of the aircraft so the lugs stay in tact, if the locking mechanism fails. So this loose plug basically was able to move up and depart the aircraft.

A good discussion by some folks who seem to be "in the trade".

Alaska Airlines 737-900 MAX loses a door in-flight out of PDX - PPRuNe Forums

Accidents and Close Calls - Alaska Airlines 737-900 MAX loses a door in-flight out of PDX - Originally Posted by dragon6172 Interesting that this location is about 2 miles lateral separation from the aircrafts ground track according to flightaware/flightradar24. That seems quite a bit.... Windage?www.pprune.org

Bro I hate that forum. Used to be great. Not so much now.The signal to noise ratio on pprune can be like a Bear Pit Mil vs MOA thread.

If only.GEE if only I was IN THE TRADE and knew what I was talking about...

The end user would mandate... But only after you removed the Government from the equation.Man, if we could only find the genesis of profits over quality. Who would mandate such a thing?

“shareholder supremacy”

View attachment 8318455

I am located close to a rural airport. After watching some questionable maneuvers, I bring up FlightAware.Pilots are idiots, that’s why they’re designing single pilot cockpits with a German Shepard as co-pilot……

let's his kids fly in circles around the airport.

Jesus Christ shut the fuck up already.

Nobody cares about your humble opinion.

Wait you're a steamfitter? I thought you were a Nobel laureate economist from all the bullshit you spew on THAT other topic.