Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bore Tech Suppressor cleaner

- Thread starter Lunchbox27

- Start date

There really isn't anything quality made that works half as well out there at the moment, niche product but would certainly sell to the suppressor folks like me for cleaning. I'll admit I've also used it for cleaning other non-suppressor things with similar issues of access.Do existing options not fit the mold? I could see combining a metal printed tip with the right placement of holes with existing small "pipe" that wouldn't be so egregiously long-but it would be way more expensive than the made in china options.

Question, does the plastic shield on the lance move toward the hose so the metal part extends into the can or is it just fixed to the working end?There really isn't anything quality made that works half as well out there at the moment, niche product but would certainly sell to the suppressor folks like me for cleaning. I'll admit I've also used it for cleaning other non-suppressor things with similar issues of access.

I still just toss it into the US. I found out soon enough not to wait for 1000+ rounds before cleaning if at all possible.Fully welded sealed suppressors....

You clean your suppressor after every time you shoot it?

Yep. All of my rifles as well.

Sadly, I do not have one of his barrels. but I have a lot of rifles and pistols and make it a priority to take care of them and keep them clean.That is a new level of OCD.

PS, don't tell Frank Green if you're using his barrels, lol

I'd be interested to hear Frank's views on the subject however. Perhaps I'll search for any posts where he talks about cleaning.

Its interesting, the hardest barrels for me to clean are brand new one's with only test shots fired that have sat on some shelf before being sold. I worked 3 hours on my latest Colt 20" barrel for an A1 build. It was filthy and did not want to get clean.

Cans, bolts and such are easy, just toss them in the Ultrasonic, soak them in some kerosene and viola.

Last edited:

Yes, it's basically a splash guard on a spring, and is great for not getting shitwater everywhere and on you given some suppressor geometries, one of the reasons I'd like a quality stand-alone product.Question, does the plastic shield on the lance move toward the hose so the metal part extends into the can or is it just fixed to the working end?

Ah, ok...so the wand part extends into the can by compressing a spring. Thanks for the reply.Yes, it's basically a splash guard on a spring, and is great for not getting shitwater everywhere and on you given some suppressor geometries, one of the reasons I'd like a quality stand-alone product.

I just wish the damn thing (the kit) wasn't so expensive. I too get crap all over the place taking a hose to the can after soaking in carbon remover. And...I think the wand would do a better job than just putting a hose nozzle against one end of the can.

Cheers

Can't someone just make a quick connection that fits a pressure washer quick connect tip and that will let us screw our hub mount on it or that has a 5/8x24 thread so we can screw the can on and blast it with a pressure washer?

2(Sets) Pressure Washer Sewer Jetter Nozzle with 1/4'' Quickly Connector,Pressure Drain Jet Hose Nozzle https://a.co/d/6lC9QQP

Something like this but smaller hasn’t been made yet?

Something like this but smaller hasn’t been made yet?

Not that I know of other than the boretech wand thing2(Sets) Pressure Washer Sewer Jetter Nozzle with 1/4'' Quickly Connector,Pressure Drain Jet Hose Nozzle https://a.co/d/6lC9QQP

Something like this but smaller hasn’t been made yet?

I broke down and bought the kit. Yeah the wand is the deal maker. It works. I used all their fluid up and then went to using my own stuff. Primarily M Pro 7 sold in bulk as an aircraft decarbon product. Stuff works well. I expect any cleaner of choice soaked for 24 hours would work fine also....the wand is the best part of the system. The wand blows out chunks of carbon after a soak in cleaner. For the hell of it I used it on some of my rimfire cans after soaking without disassembling them. They were probably 90% spotless when I took them apart.

The wand was essential for my starting point which was way too late to begin cleaning it was a 33 day process every day rinse, soak and blast. Having said that I don't even need the wand any longer I just keep a bike bottle of old CLR and drop it in every 500 rounds.....rinse in sink after 24 hours....goes right back to factory weight.Ah, ok...so the wand part extends into the can by compressing a spring. Thanks for the reply.

I just wish the damn thing (the kit) wasn't so expensive. I too get crap all over the place taking a hose to the can after soaking in carbon remover. And...I think the wand would do a better job than just putting a hose nozzle against one end of the can.

Cheers

I'll give you $30 for your boretech wandAmazon had a prime sale on ultrasonics

What do I need to know about using it in cans

Still need to get this bore tech thing out the box a year later

I got a wand your wife can use for $30I'll give you $30 for your boretech wand

Deal, she's on suppressor cleaning duty now. I can't pass on a good deal.I got a wand your wife can use for $30

Without getting deep here, but because someone tagged me, a significant majority of suppressor issues we see are due to people cleaning them improperly, or getting cleaning solvent in them and leaving it (this includes cleaning a rifle with the suppressor still on and letting the suppressor work as a solvent trap).

Just like owning a borescope, before you start cleaning a suppressor, make sure you know what you're doing, or you're going to cause you and the manufacturer more headaches than are likely necessary.

Just like owning a borescope, before you start cleaning a suppressor, make sure you know what you're doing, or you're going to cause you and the manufacturer more headaches than are likely necessary.

Well, you know that you can’t just put it that way and leave without at least dropping your suggestions for cleaning them properly right?Without getting deep here, but because someone tagged me, a significant majority of suppressor issues we see are due to people cleaning them improperly, or getting cleaning solvent in them and leaving it (this includes cleaning a rifle with the suppressor still on and letting the suppressor work as a solvent trap).

Just like owning a borescope, before you start cleaning a suppressor, make sure you know what you're doing, or you're going to cause you and the manufacturer more headaches than are likely necessary.

The best option right now, besides the purpose made Bore Tech wand is to try to find a really thin pressure washer wand, cut it off so you can still hold your suppressor in one hand and insert the wand with the other, thread the new tip and screw a bolt into the end to stop it up and drill a bunch of small holes into it. It's tough to know how thick the wands are from product websites tho. Supposedly this one is 1/4".

View attachment 8282418View attachment 8282419

That's not a1/4" piece of pipe. It has the 1/4" NPT thread. If you've ever aired up your tires, the hose generally has the 1/4 NPT.

1/4 NPT fits into most pressure washer wands if you remove the end piece.

You can make your own wand with a handle, a modified 1/4 NPT and air cleaning wand from Harbor Freight.

Yeah that's. Good idea. I found this on Amazon. Probably could just drill some holes and get a tip piece and drill some holes in it and hook it up to my preasure washer and go? I can do it with hot water too to my pressure washer so I would think it would work pretty well.

We need the details on how this was built. I have a couple of PW guns laying around.That's not a1/4" piece of pipe. It has the 1/4" NPT thread. If you've ever aired up your tires, the hose generally has the 1/4 NPT.

1/4 NPT fits into most pressure washer wands if you remove the end piece.

You can make your own wand with a handle, a modified 1/4 NPT and air cleaning wand from Harbor Freight.

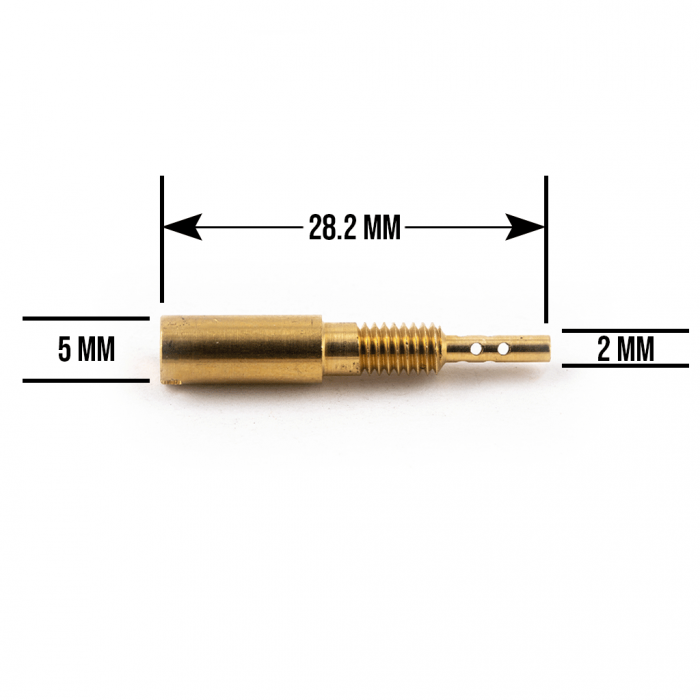

View attachment 8283523

To build this.

You'll need a brass male 1/4 NPT air adapter.

Buy one of these cleaner nozzles from HF. It comes with 3 or 4 stems like the one to the right. You'll need the long stem.

Cut the 1/4 NPT adapter and thread the inside to match the threads on the stem.

Thread the outside of the opposite end of the stem so you can attach the nozzle end.

Contour, drill and tap a nozzle to fit the stem. I used aluminum stock.

Drill a series of small, angled holes around the circumference of the nozzle.

Take another stem and cut the tubing off of it. Drill the inside so it will slide over the stem tubing. Remove the extra material as shown in this image.

Buy a couple of thin wire springs and a lamp nut.

Find a crappy scope objective cover and drill it to fit the threaded side of the second stem that you removed the tubing from. Use the lamp nut to secure it.

If you don't want to use the scope cover, you won't need the second stem, lamp nut or springs.

Just be prepared to get soaked.

Put all of it together and clean away.

Disclaimer, I used a mini lathe to do most of the work. For the tiny holes I used an X-Y vise on my drill press.

You'll need a brass male 1/4 NPT air adapter.

Buy one of these cleaner nozzles from HF. It comes with 3 or 4 stems like the one to the right. You'll need the long stem.

Cut the 1/4 NPT adapter and thread the inside to match the threads on the stem.

Thread the outside of the opposite end of the stem so you can attach the nozzle end.

Contour, drill and tap a nozzle to fit the stem. I used aluminum stock.

Drill a series of small, angled holes around the circumference of the nozzle.

Take another stem and cut the tubing off of it. Drill the inside so it will slide over the stem tubing. Remove the extra material as shown in this image.

Buy a couple of thin wire springs and a lamp nut.

Find a crappy scope objective cover and drill it to fit the threaded side of the second stem that you removed the tubing from. Use the lamp nut to secure it.

If you don't want to use the scope cover, you won't need the second stem, lamp nut or springs.

Just be prepared to get soaked.

Put all of it together and clean away.

Disclaimer, I used a mini lathe to do most of the work. For the tiny holes I used an X-Y vise on my drill press.

Yeah, I know it's a 1/4 NPT. But their website states the size is also 1/4" but the way it's vague it could be not true. That's why I said "supposedly ". I was queuing up the fact that's not an easy homemade solution bc I don't think you can find a wand small enough to fit in a suppressor.

You're correct. You have to buy or build it.

I built mine. See post above for parts and basic instructions.

So not sure what the pressure rating would be but all this talk of the cross holes for the lance got the gears creaking in my noggin and I recalled Mikuni bleed style pilot jets from back when I messed with motorcycles...

If I remember the threads are 4.0mm ("about" 5/32 on the major) x .7mm so it might work with a 1/4" O.D. tube. They would have to chopped but I think they are like $4.00 a piece.

If I remember the threads are 4.0mm ("about" 5/32 on the major) x .7mm so it might work with a 1/4" O.D. tube. They would have to chopped but I think they are like $4.00 a piece.

Last edited:

Talk to the manufacturer, but for us, we want Mavericks sent in so that we can fully disassemble, fully clean (we do it in an ultrasonic with Simple Green, nothing crazy), and MOST IMPORTANTLY - fully dry the components. In general I think centerfire suppressors need to be cleaned much less than people do it, but if you must clean, getting it PERFECTLY dry inside is the most important advice I can give. Moisture becomes glue in there, and once it starts to build up it only builds faster and faster.Well, you know that you can’t just put it that way and leave without at least dropping your suggestions for cleaning them properly right?

What works best to fully dry. Compressed air or ovenTalk to the manufacturer, but for us, we want Mavericks sent in so that we can fully disassemble, fully clean (we do it in an ultrasonic with Simple Green, nothing crazy), and MOST IMPORTANTLY - fully dry the components. In general I think centerfire suppressors need to be cleaned much less than people do it, but if you must clean, getting it PERFECTLY dry inside is the most important advice I can give. Moisture becomes glue in there, and once it starts to build up it only builds faster and faster.

Both can work, given appropriate measures. Don't overthink it, just make sure you're fully clean and fully dry, to the best of your ability.What works best to fully dry. Compressed air or oven

All I know is what we have seen from people that get too much liquid in the can and clearly shoot with something still in it, ESPECIALLY if it's something that has a bit of oil in it, which obviously does not dry.

Or a round or two through the can will blast out any moisture.What works best to fully dry. Compressed air or oven

Amazon product ASIN B07GDPQY9FDo existing options not fit the mold? I could see combining a metal printed tip with the right placement of holes with existing small "pipe" that wouldn't be so egregiously long-but it would be way more expensive than the made in china options.

Food dehydrator. Same one I used to dry my brass.What works best to fully dry. Compressed air or oven

I put mine in the traeger. It makes jerky too.Food dehydrator. Same one I used to dry my brass.

Everything is better smoked.

Thanks. That’s actually a great answer. Appreciate it.Talk to the manufacturer, but for us, we want Mavericks sent in so that we can fully disassemble, fully clean (we do it in an ultrasonic with Simple Green, nothing crazy), and MOST IMPORTANTLY - fully dry the components. In general I think centerfire suppressors need to be cleaned much less than people do it, but if you must clean, getting it PERFECTLY dry inside is the most important advice I can give. Moisture becomes glue in there, and once it starts to build up it only builds faster and faster.

I put them in the oven with the “warm” setting which I think is 200 F.

No need to cook the shit out of them. And it comes out perfectly dry.

I do wish someone made a wand for a reasonable price. It’s not that complicated and I can’t imagine BT has a patent on it…no unique art to it, IMO

No need to cook the shit out of them. And it comes out perfectly dry.

I do wish someone made a wand for a reasonable price. It’s not that complicated and I can’t imagine BT has a patent on it…no unique art to it, IMO

When they first came out with this stuff, I emailed them and asked if there was a money back guarantee.

Never heard back

Never heard back

?? Really wrong thread. Did you mean to post this here?Does anyone happen to know the weight of a new Omega w/ flat end cap and the 5/8x24 direct thread mount that comes with it?

If I had to guess, he’s wondering how much buildup/weight is in it?? Really wrong thread. Did you mean to post this here?

I guess I could’ve started with “since some of you guys were talking about weighing cans” related to the need for cleaning them…?? Really wrong thread. Did you mean to post this here?

The specs on SiCo’s site do not state the configuration for whatever weight is provided.

Anyway, thanks to @Lunchbox27 for the review! There was some discussion about this boretech product coming to market in another thread about cleaning years ago. Glad to see it come to market and that it works.

I’m going to get some to try to get the carbon out of my comps, on my USPSA “open” guns.

I’ve tried about every other chemical and the only thing that has worked for me is scraping

I’ve tried about every other chemical and the only thing that has worked for me is scraping

Any update on "the pig dick"?View attachment 8295108I made what I shall call “the pig dick” todayTook a scrap piece of 1/4” ss tubing, welded a ss dowel pin in the end, drilled two small holes through the tube (for a total of 4 holes) and put a swage to 1/4” NPT fitting on the other end. This should connect to the pressure washer qd fitting. I will report back when I try it out.

Never thought in my life I'd type a sentence like that

Not yet, it may be a while since I just cleaned my dirtiest can recently.Any update on "the pig dick"?

Never thought in my life I'd type a sentence like that

Similar threads

- Replies

- 61

- Views

- 6K

Precision Rifle Gear

The Barrel Burner App- help track your firearm and reloading components via phone

- Replies

- 24

- Views

- 2K

- Replies

- 13

- Views

- 1K