Re: Cutting fluid for flush reaming

I went through several discussions and 3-4 combinations before I settled on Re-li-on. I tried the Rigid oil but it seem quite thick to me and did not offer the flow I was looking for with my particular system components. The Relion flows nicely and flushes out the chips sufficiently as long as your feed rate is reasonable. I think that different set ups may utilize a given oil better than the others. I did not even consider the water based solutions like Rustlick as I wanted to avoid the chance of rancid coolant smelling up the shop, getting the oil and water based mixed ,etc.

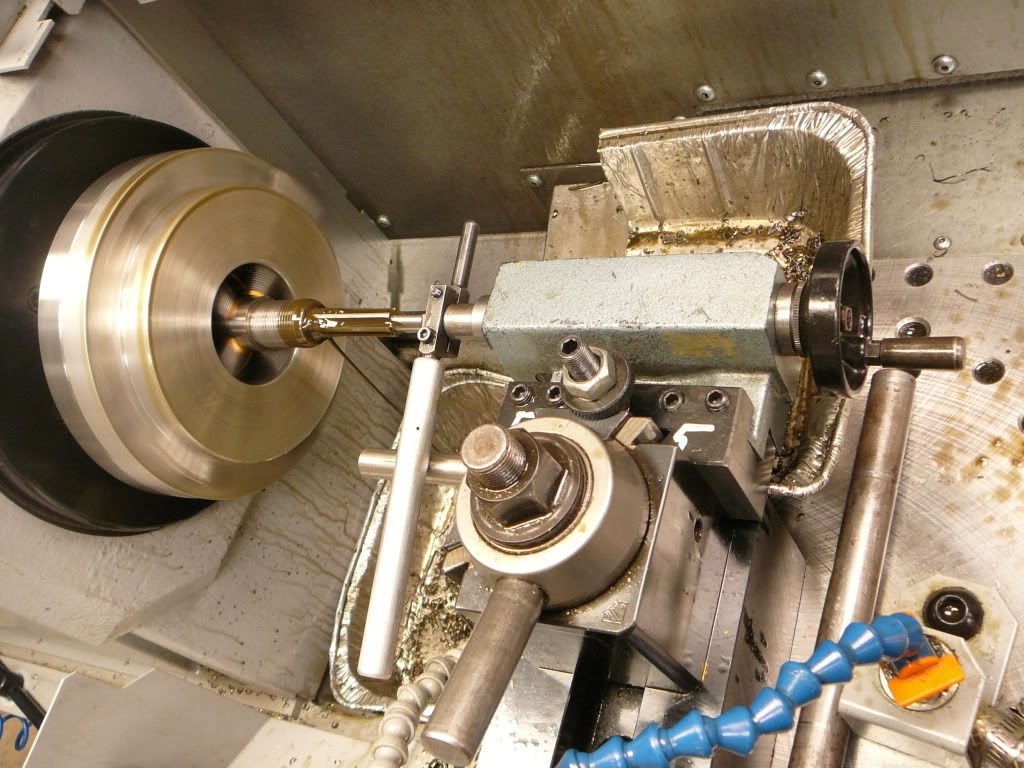

Here are a few pics of the system I use.

I made the "system" all inclusive to the lathe itself as I did not want stand alone stands, buckets, etc. I mounted the plumbing on the lathe itself without drilling it full of holes with the use of a 6061 bar and a couple brackets I made on the mill. The complete system is integral to the lathe and "streamlined" for simplicity.

I use a manifold block to serve as a both a pressure regulator and for usage to split the flow for use when threading, etc. I mounted a push button switch at easy reach for easy on-off pump operation.

I used the existing coolant tank on the lathe for the Relion and use a lathe mounted FloJet pump for the supply. It will push 95 lbs but I usually chamber at 65lbs or so.

For a filter, I use a series of magnets in the chip pan and a screen on the drain for the big stuff and then a Baldwin filter head and B5134 filter.

After the filter and manifold the oil makes it way to a Duff Norton rotary union I mounted in an adjustable aluminum bracket. I can reposition it for different length barrels. The bracket is attached to the lathe via a collet closer eye stud attached to the lathe.

Before the barrel goes into the 4 jaw for indicating, I turn a nipple on the muzzle end to secure the supply. I know, another step yes, but it only takes 5 minutes and is a solid leak free connection.

Barrel indicated in, hooked up, and ready to go.

Tenon turned, threaded, pre-bored, pump is "on" and ready for reaming.

SR