I'm taking it to the range this coming weekend and get another couple hundred rounds through it before I start messing with it.. Mine does break nice, just a little heavy..imho I have a Kidd/Titan 1022 with a two stage Kidd trigger..it's at 10oz.. but honestly the CZ was shooting comparable groups with SK Rifle Match @ 50 yards.. 1/2" and under.. thought that was pretty good for just having 225 rounds through it

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CZ 457

- Thread starter A-Rob

- Start date

What procedure are you using to adjust your 457 trigger? I left the overtravel & weight of pull screws alone, and with the rifle cocked on an empty chamber, backed-off the sear engagement (the really small vertical screw at the top/front of the trigger itself) until it fired. Then set it for a little more sear engagement, and bump-tested it for safety. Easily got my American's trigger down to just a hair over 1lb, and the MTR to right at or just under 1lb.I only adjusted the pull weight on mine. I was only able to get mine down to just over 2 lbs. it breaks nice and clean but is just too heavy for my taste. I like my triggers around 1 1/4- 1 1/2 lbs. I need to order one of the yodave springs but I just can’t get past spending $27 on a $0.05 spring. I may have to see if I have something on hand that is the right size and weight before I pull that trigger. See what I did there. Pull that trigger ? I’ll be here all week guys and be sure to tip your hosts and hostesses.

What procedure are you using to adjust your 457 trigger? I left the overtravel & weight of pull screws alone, and with the rifle cocked on an empty chamber, backed-off the sear engagement (the really small vertical screw at the top/front of the trigger itself) until it fired. Then set it for a little more sear engagement, and bump-tested it for safety. Easily got my American's trigger down to just a hair over 1lb, and the MTR to right at or just under 1lb.

I honestly did a pretty hasty adjustment before going to the range. I adjusted the pull weight screw and checked pull weight several times until I ran the screw out as far as I felt comfortable with. I didn’t make any real adjustments to the other two adjustment screws at that point. It sounds like if I adjust the sear engagement screw though I may be able to drop the pull weight to where I want. I have seen a big variation in factory trigger pull weights though. I know several guys who couldn’t get their tikka factory triggers any lower than 2 1/2 lbs. I was able to get all three of mine down to 1 1/2 lbs without a problem. I’ll have to take it apart again and see if I can get it to go a little lower. This is my first CZ and I need to play around with the various adjustment points on the trigger. Hopefully I can get the trigger where I want it before I break down and change out the spring. I will say that it seems like a damn nice trigger for a rimfire. All the adjustability built into it was a real surprise.

I'm taking it to the range this coming weekend and get another couple hundred rounds through it before I start messing with it.. Mine does break nice, just a little heavy..imho I have a Kidd/Titan 1022 with a two stage Kidd trigger..it's at 10oz.. but honestly the CZ was shooting comparable groups with SK Rifle Match @ 50 yards.. 1/2" and under.. thought that was pretty good for just having 225 rounds through it

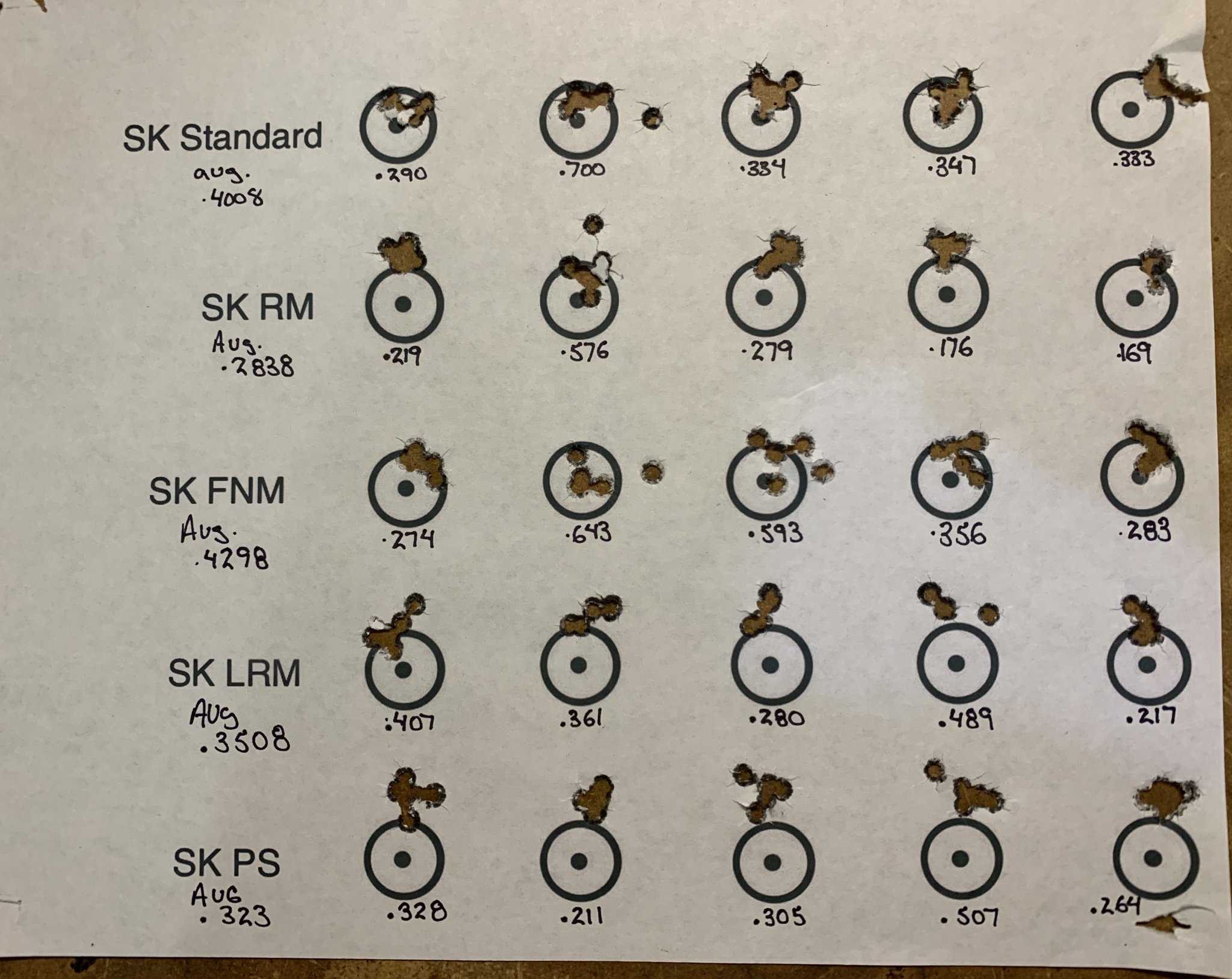

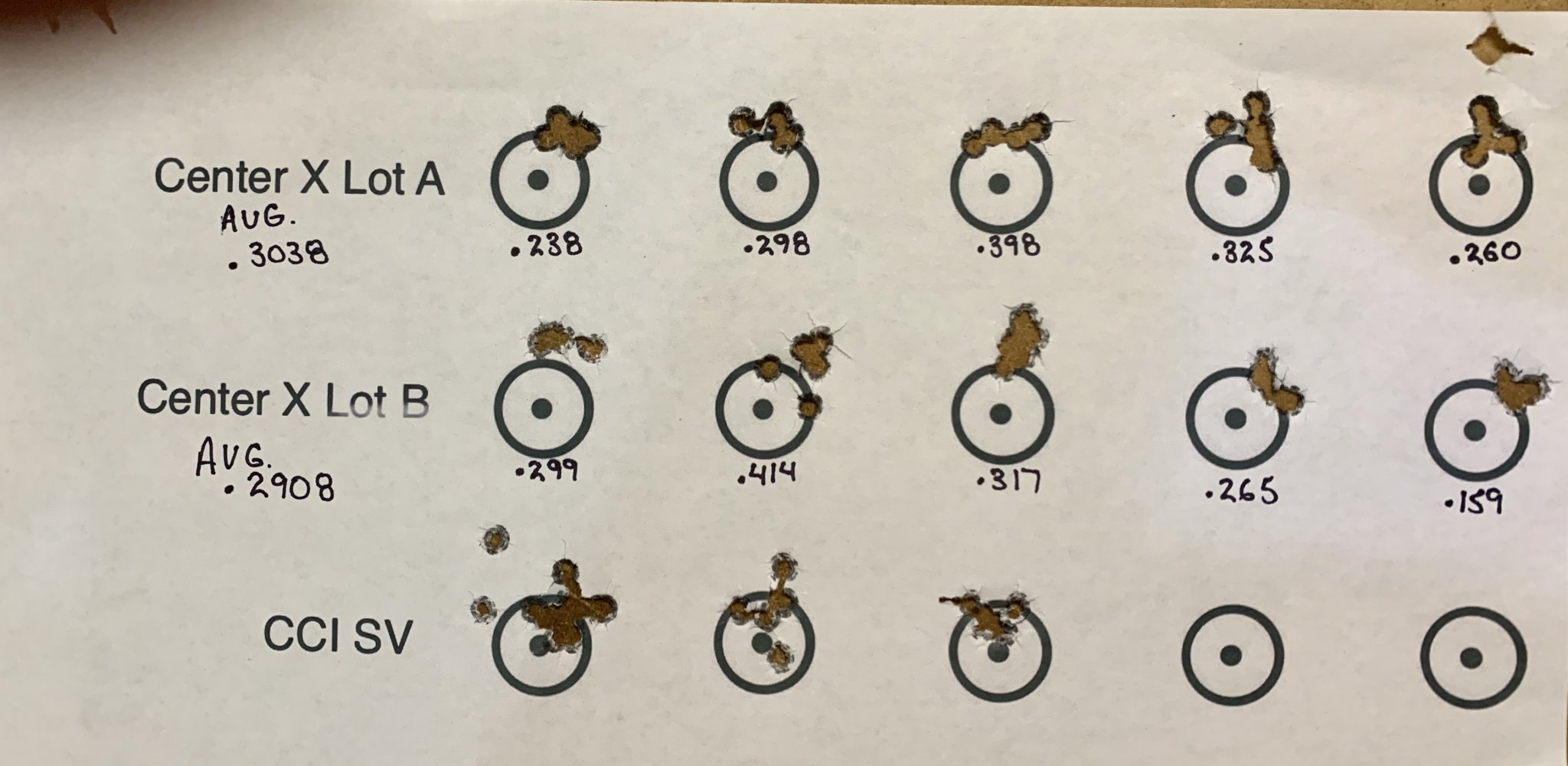

If you can get your hands on some of the SK Pistol Match Special try some of that out. That particular ammo has consistently shot the best of all the SK ammos in every rifle I own. I was blown away by how it shot in my CZ. It also shoots pretty amazing in my sons Tikka. The SK Rifle match and long range match for whatever reason have just never shot as well. Its also typically cheaper than the rifle match I believe. Either that or it always seems to be on sale.

I agree Eoddave27 - the action, trigger, and quality of the fit & finish of my 457 American impressed me enough to re-barrel it when the factory bbl turned out to be a stinker. And after putting the Shilen on it, and getting a very large improvement in accuracy, I have absolutely no regrets over the extra $$ spent & time invested. I'd played around with the weight of pull screw before reading that the best way to go about adjusting for a lighter pull was to reduce sear engagement. So before I did that, I put the weight of pull adjustment back as close as I could get it to where it was when I got the rifle, then went through the sear engagement adjustment. I increased engagement to the point where there was no accidental release while running the bolt as fast & hard as I could, and bumped the rifle stock's butt against the floor as hard as I dared to make sure it was safe.

Thanks for the tip. I actually have my rifle on loan to my gunsmith right now. He is a good friend and I believe he wants to get one and is going to try mine out at the range to see what he thinks. As soon as I get it back I’ll see what I can do adjusting the sear v/s the pull weight screw. That’s why I love forums. Do you have any idea how long I would have been digging before I picked up that little gem of info if I did at all. Thanks again. You probably just saved me $27. I guess I owe you a beer if you ever make it to Maryland. Of course no sane gun owner would willingly come to this state.

I have friends living in Kansas from Maryland - so I agree with your point about "no sane gun owner". I will say though - there are some very attractive ladies from Maryland....

IIRC, I got the tip on how to adjust the 457 trigger from someone on RFC - just passing along the tip to a fellow CZ owner.

IIRC, I got the tip on how to adjust the 457 trigger from someone on RFC - just passing along the tip to a fellow CZ owner.

If you can get your hands on some of the SK Pistol Match Special try some of that out. That particular ammo has consistently shot the best of all the SK ammos in every rifle I own. I was blown away by how it shot in my CZ. It also shoots pretty amazing in my sons Tikka. The SK Rifle match and long range match for whatever reason have just never shot as well. Its also typically cheaper than the rifle match I believe. Either that or it always seems to be on sale.

I've had the same results in my Tikka... Rifle Match and LRM just don't shoot all that well. I haven't gotten my hands on Pistol Match Special to try yet though. I just stuck with SK+, but then moved on to Eley Stuff.

What's your CZ liking the most? SK as well? Not the Eley Contact?

This is from almost three years ago, so take it with a grain of salt, as things may have changed since then. I kept reading posts on RFC about how well SK Pistol Match shot in several different makes & models of .22RF rifles, so I ordered in several sample boxes of various lots of it. Didn't take long to see why so many shooters were making favorable comments on it. I bought six different lots to test, and the hardest thing for me to figure out was which one shot the best - because five out of the six lots shot really well at 50yds. After shooting more 10-shot groups through several different custom-barreled repeaters, I finally settled on buying a case of one lot that seemed a little more consistent than the others - even though there wasn't a lot of difference between the top four lots. I felt I could've flipped a coin to pick which lot to buy, and probably come out about as good as I did - they were all that close.

Someone back then couldn't find any plain Pistol Match, so bought Pistol Match Special, and posted that he wasn't getting groups nearly as good as what he'd gotten before with the plain Pistol Match. A couple of other regulars chimed in, saying their experiences with Special mirrored his, and they wouldn't be buying any more of the Special. Since I was so pleased with the regular PM, I saw no reason to experiment with the Special, so have never tried any of it through my rifles.

Someone back then couldn't find any plain Pistol Match, so bought Pistol Match Special, and posted that he wasn't getting groups nearly as good as what he'd gotten before with the plain Pistol Match. A couple of other regulars chimed in, saying their experiences with Special mirrored his, and they wouldn't be buying any more of the Special. Since I was so pleased with the regular PM, I saw no reason to experiment with the Special, so have never tried any of it through my rifles.

I've had the same results in my Tikka... Rifle Match and LRM just don't shoot all that well. I haven't gotten my hands on Pistol Match Special to try yet though. I just stuck with SK+, but then moved on to Eley Stuff.

What's your CZ liking the most? SK as well? Not the Eley Contact?

My CZ didn’t seem to shoot any of the Eley very well. It shot it okay but nothing to write home about. The 16” barrel on my CZ was shooting quite a bit faster than my 20” barrels but that has been pretty common across the board. The Contact averages about 1095 out of my 20” barrels and about 1125 out of my 16” barrels. All the SK I shot performed better than the Eley with the Pistol Match Special really standing out. I actually haven’t tried just the pistol match but I will get a few boxes of that to see how it shoots too. It’s a shame because I really wanted my CZ to like the Contact. I don’t like the wax on the Lapua/SK ammo. The Contact also does a lot better ballistically for me. Maybe after a get some more ammo through it the groups with the Eley Ammo will improve. I honestly may end up changing the barrel just so I don’t have to shoot SK/Lapua ammo.

My CZ didn’t seem to shoot any of the Eley very well. It shot it okay but nothing to write home about. The 16” barrel on my CZ was shooting quite a bit faster than my 20” barrels but that has been pretty common across the board. The Contact averages about 1095 out of my 20” barrels and about 1125 out of my 16” barrels. All the SK I shot performed better than the Eley with the Pistol Match Special really standing out. I actually haven’t tried just the pistol match but I will get a few boxes of that to see how it shoots too. It’s a shame because I really wanted my CZ to like the Contact. I don’t like the wax on the Lapua/SK ammo. The Contact also does a lot better ballistically for me. Maybe after a get some more ammo through it the groups with the Eley Ammo will improve. I honestly may end up changing the barrel just so I don’t have to shoot SK/Lapua ammo.

I have so much SK+ and since I had good luck early on with it but I stopped since I couldn't stand the lube they used. Especially if I forget to bring a rag with me to wipe my hands. Good reminder why I shouldn't go back and buy a brick of pistol match special

From what I've been told, and have seen on SK's website, Pistol Match Special is loaded slightly hotter/faster than regular Pistol Match. This was supposedly done to make it cycle more reliably in specific semi-auto pistols. But since I've never tried any of the Special, I can't comment on the relative velocity of it vs regular PM.

SK's bullet lube is more of an oil-based lube, while Eley uses lube with more wax. I've got some SK-made Wolf Match Target & Match Extra that's about 15-16 years old, and the lube is still pretty slick, although I can see & feel that it's drier than fresh SK. I bought almost 3/4 of a case of some Eley Match Xtra that was out-dated when I got it about 20yrs ago - if I try to run it through any of my repeaters, some of the dried-out wax lube flakes off.

I carry a sheet or two of the blue paper shop towels with me when I go out to shoot .22RF, whether it's plinking, practice, or at a match. These paper towels work better than about anything else I've tried when it comes to wiping oil, grease, or bullet lube off my hands.

SK's bullet lube is more of an oil-based lube, while Eley uses lube with more wax. I've got some SK-made Wolf Match Target & Match Extra that's about 15-16 years old, and the lube is still pretty slick, although I can see & feel that it's drier than fresh SK. I bought almost 3/4 of a case of some Eley Match Xtra that was out-dated when I got it about 20yrs ago - if I try to run it through any of my repeaters, some of the dried-out wax lube flakes off.

I carry a sheet or two of the blue paper shop towels with me when I go out to shoot .22RF, whether it's plinking, practice, or at a match. These paper towels work better than about anything else I've tried when it comes to wiping oil, grease, or bullet lube off my hands.

I just picked up a 457 AT-ONE earlier today and have a question related to bipods. I see a lot of people opted for the Harris bipod that pops onto the sling swivel. I personally like atlas bipods and have a couple on hand. Has anyone found a good picatinny rail option for the bottom of the forend that would facilitate a QD mount atlas bipod?

I just picked up a 457 AT-ONE earlier today and have a question related to bipods. I see a lot of people opted for the Harris bipod that pops onto the sling swivel. I personally like atlas bipods and have a couple on hand. Has anyone found a good picatinny rail option for the bottom of the forend that would facilitate a QD mount atlas bipod?

Accu-Shot Monopod Precision Shooting Rifle Rest Magpul PRS Rail

Accu-Shot precision monopods, Atlas bipods and rifle accessories provide a high-degree of accuracy for long-range hunting, law enforcement or military duty.

on its way yea after 8 months of a looking the clouds parted at buds I lost the bid on a k31 but won with the mtr

I used the Atlas Bipod Flush Cup 1913 rail for mine. Had to take out the swivel studs and buy screws to replace them when installing the rail.

Accu-Shot Monopod Precision Shooting Rifle Rest Magpul PRS Rail

Accu-Shot precision monopods, Atlas bipods and rifle accessories provide a high-degree of accuracy for long-range hunting, law enforcement or military duty.www.accu-shot.com

I took the weight of pull all the way out and locked the nut. That didn't seem to change the pull weight all that much, so I adjusted the sear engagement screw all the way out till it went off. Then i tightened it back till it would hold. Got the trigger to 1# of pull. Took it out and it shot great for a while and then it started going off when I would close the bolt. So I adjusted it again to 1.5# and now it works great.Question regarding trigger adjustment on the 457.. Is it necessary to adjust the over travel and pre travel adjustments when lowering the trigger weight ?? or can you just adjust the trigger weight ? going to try a lower weight trigger pull.. it's about 2 1/4# out of the box

I used the Atlas Bipod Flush Cup 1913 rail for mine. Had to take out the swivel studs and buy screws to replace them when installing the rail.

@red_dog79 have any pics of how it turned out?

Here are a few pictures. Let me know if you have any questions.@red_dog79 have any pics of how it turned out?

What size screws did you use to replace the swivel studs? Did you have to use a T-nut on the inside? I have a Pro Varmint stock coming soon and would like to have the mounting hardware ready when it arrives.

Thanks for the pictures! They show that the rail is just the right size for the screw spacing.

Thanks for the pictures! They show that the rail is just the right size for the screw spacing.

I did the same thing on another Boyd’s stock I have. I just put a nut and washer under the barrel. It is easier to find than a t nut. You should be able to get everything you need at Home Depot. As long as you counter sink it under the barrel you should be good.

No problem! Sorry i don't remember the screw size and would have to pull it apart to measure the screws etc. There is plenty of room under the barrel for the lock nut that the swivel is attached to. I just got the same size screw for the lock nut and reused it to attach the rail. Got the screws at Ace Hardware since they have a good selection of stuff. Hope that helps.What size screws did you use to replace the swivel studs? Did you have to use a T-nut on the inside? I have a Pro Varmint stock coming soon and would like to have the mounting hardware ready when it arrives.

Thanks for the pictures! They show that the rail is just the right size for the screw spacing.

Yeah, that does help, thanks. Sounds like there's plenty of room to use a nut without modification to the stock, since the existing studs are using nuts. Nevertheless, I ordered the suggested screw and T-nut set along with the rail from B&T just in case.

I’m interested in a CZ 457 (not sure if I’ll go with the MTR or the VPT). From what I’m reading choosing the MTR with the match chamber you have more chances of getting a good barrel rather than the VPT. You were saying about a shillen cut with a match reamer and glued... Can you please explain? What you mean by glued? How much better is that vs a Lilja

Thanks.

Sent you a PM Bill.

Glued-in refers to using Loctite #609 retaining compound to 'glue' the new bbl shank into the 457's bbl socket. There are plenty of smallbore shooters that have used this method for it to be a proven way to go. Also, as I understand it, Walther has been using a similar adhesive to glue in barrels on some of their top line target .22RF rifles. It's a stress-free way to fit a .22RF bbl to an action, although it's probably not the way to go if a shooter is wanting to experiment with headspace, or if you're wanting to swap barrels & calibers between the 22LR, 22WMR, 17HMR, or 17M2.

One Bill, I have a CZ 457 MTR with an Arear 419 rail and a 419 bolt knob. The only work that I did to it is put in a Yo-Dave trigger spring kit for about 20.00. She shoots with my Vudoo all day long. I have a Trijicon 5-50x56 on her and that is a great scope as well. Please get the AREA 419 bolt knob if you get the CZ. It makes the little carbine an absolute joy

Question regarding trigger adjustment on the 457.. Is it necessary to adjust the over travel and pre travel adjustments when lowering the trigger weight ?? or can you just adjust the trigger weight ? going to try a lower weight trigger pull.. it's about 2 1/4# out of the box

to shoot.

A Yo Dave trigger kit reduced my trigger pull to 9 oz. With the blade on the MTR it feels more like my six oz. Annies. If you go that route, be aware that the trigger blade pin is a scary tight press fit into the blade. That is why they supply you with a small polymer block to support the trigger housing. I would HIGHLY recommend that you put the trigger pin in an electric drill and reduce its diameter to a light slip fit into the blade. Then you can use fingernail polish or the like to retain the pin. It is an easy job but a little nerve racking without a little guidance.Question regarding trigger adjustment on the 457.. Is it necessary to adjust the over travel and pre travel adjustments when lowering the trigger weight ?? or can you just adjust the trigger weight ? going to try a lower weight trigger pull.. it's about 2 1/4# out of the box

Attachments

A YoDave kit allowed me to get my trigger down to a safe 9 oz. With the trigger shape it feels more like my 6 oz. Annies. If you don't reduce the diameter of the trigger pin that is a press fit in your trigger blade, you risk breaking your trigger housing. Chuck the trigger pin up in a drill and reduce its diameter to a slip fit. Then use some fingernail polish to retain it from sliding out. Please don't risk breaking your gun.I only adjusted the pull weight on mine. I was only able to get mine down to just over 2 lbs. it breaks nice and clean but is just too heavy for my taste. I like my triggers around 1 1/4- 1 1/2 lbs. I need to order one of the yodave springs but I just can’t get past spending $27 on a $0.05 spring. I may have to see if I have something on hand that is the right size and weight before I pull that trigger. See what I did there. Pull that trigger ? I’ll be here all week guys and be sure to tip your hosts and hostesses.

Shawn

Put on an AREA 419 scope rail and the mandatory 419 bolt knob and the YoDave trigger spring kit to get your

trigger down to say a safe 9 oz and your going to love your MTR. Be careful with the trigger blade pivot pin.

It is a heavy press fit into the blade. The pin needs a little adjustment to ease its reassembly.

Shawn

trigger down to say a safe 9 oz and your going to love your MTR. Be careful with the trigger blade pivot pin.

It is a heavy press fit into the blade. The pin needs a little adjustment to ease its reassembly.

Shawn

Attachments

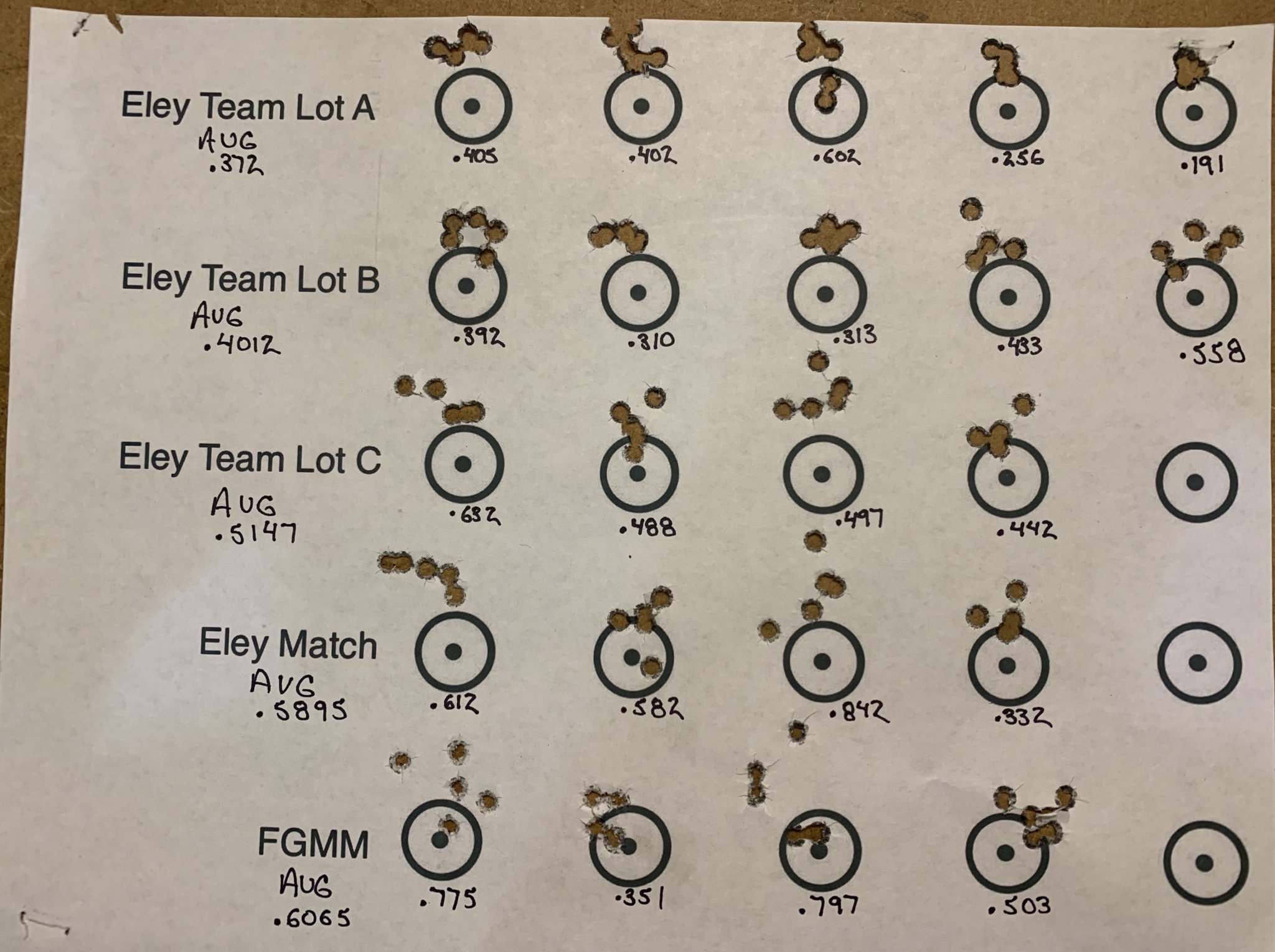

Finally got a day off and decent weather to do a ammo test on my CZ 457 with the new Lilja barrel. All groups where shot at 50 yards off bipod and rear bag.

SK Rifle Match shot the best followed closely by the Lapua Center X. I’ll try these three with my tuner once I get it back from a friend that’s reboring it out so it’ll fit the larger contour of the Lilja.

SK Rifle Match shot the best followed closely by the Lapua Center X. I’ll try these three with my tuner once I get it back from a friend that’s reboring it out so it’ll fit the larger contour of the Lilja.

It started out as the Cz Varmint but the only thing still original is basically the action and bolt.drglock which model is it?

Question for the 457 & 455 guys who have run their rifles in NRL22 matches; Do those long 10-round mags get hung up on barracades? Or worse yet, have you damaged them in the process of getting them hung up?

No, mine never have. I always use a bag. If anything, the mag will sit on the bag occasionally, but is never a problem.

Question for the 457 & 455 guys who have run their rifles in NRL22 matches; Do those long 10-round mags get hung up on barracades? Or worse yet, have you damaged them in the process of getting them hung up?

no issues with mine either and I run 2 round extensions on my mags as well

What procedure are you using to adjust your 457 trigger? I left the overtravel & weight of pull screws alone, and with the rifle cocked on an empty chamber, backed-off the sear engagement (the really small vertical screw at the top/front of the trigger itself) until it fired. Then set it for a little more sear engagement, and bump-tested it for safety. Easily got my American's trigger down to just a hair over 1lb, and the MTR to right at or just under 1lb.

I took my 457 apart and adjusted the trigger using the sear adjustment as you suggested. Just working with that I was able to get my trigger down to a really nice crisp 1 1/2 lb pull which is perfect for me. I’m pretty sure I could have gone lower but for positional shooting I like right around 1 1/2 lbs. I did some pretty serious bump testing with no problems. I’ll get it back out to the range in the next few days and do some function testing but I think it will be perfect.

You may consider a "YoDave" trigger spring kit. It took my 457 MTR trigger down to nine oz. I like the MTR so much that I just bought a Royal yesterday and another Area 419 rail and bolt knob. I should have it in a few short days.I took my 457 apart and adjusted the trigger using the sear adjustment as you suggested. Just working with that I was able to get my trigger down to a really nice crisp 1 1/2 lb pull which is perfect for me. I’m pretty sure I could have gone lower but for positional shooting I like right around 1 1/2 lbs. I did some pretty serious bump testing with no problems. I’ll get it back out to the range in the next few days and do some function testing but I think it will be perfect.

Shawn, I will not be spending $25 on a $0.02 spring anytime soon. 1 1/2 lbs is where I want me trigger. For me any lower doing positional shooting just doesn’t feel safe. I use my rifles for positional matches. For me anything lighter is just asking for a ND and. DQ in a match.

I tend to agree with your opinion on trigger weight. Even though I've got the TT Diamonds on my V-22 comp rifles set at under 1lb, I'm pretty comfortable with the triggers on my 457 American & MTR set at just a bit over 1lb. The way I see it - keeping in mind that Trigger Tech designed the Diamond to go this light from the start - CZ obviously had to deal with the reality that their 457s were going to be used by shooters with widely varied ranges of experience, as well as - especially in the case of the Scout version - knowing that young shooters were going to be introduced to the sport of rifle shooting with these rifles. So, while I applaud CZ for putting a trigger as good as the 457's on the market, I doubt they're all that keen on the idea of owners putting lighter springs in these triggers and winding up with a break well under the range they designed the trigger for. Some of these rifles with modified triggers are inevitably going to wind up on the used market, and as hard as I hear it is to remove the trigger pin to change the spring, I seriously doubt the original owners of most that do get sold are going to take the time to put the OEM spring back into the trigger. I re-barreled a CZ527 7.62x39 Carbine to 6RAT several years ago, and not liking the single set trigger, replaced it with one from Rifle Basix. It now breaks at under 1lb, and unless I can adjust it up to at least 2lbs, I'd not feel at all comfortable in selling this little rifle.Shawn, I will not be spending $25 on a $0.02 spring anytime soon. 1 1/2 lbs is where I want me trigger. For me any lower doing positional shooting just doesn’t feel safe. I use my rifles for positional matches. For me anything lighter is just asking for a ND and. DQ in a match.

Dennis, Your right, the CZ 457 trigger pin is a bear to get out the first time because it is press fit into the blade. That is why I reduced the diameter a bit to make it a slip fit. I hold the pin in with fingernail polish, see attachment. Let us please keep in mind that I replaced a spring and am in no way suggesting that anyone reduce the sear engagement to an unsafe level. I rarely sell a gun but when I do, I also hand over any OEM parts to that gun in a zip loc bag to the new owner. The second photo is of a trigger that I lapped. I think that we could all agree that lapping a sear will only change the way the trigger feels and not in and of itself make it a hazard. In the forth drawing done by Lefty 222, you can get an idea of how the 457 trigger works. The YoDave spring pushes against the blade itself and that is why it feels so heavy. BTW... Lefty has made two mistakes on his adjustment screws. As I recall, he has #49 backwards. As far as my guns go, only my .223 has a trigger over a pound. It has a stock Geissele at around 3 pounds. The rest are between four and eight oz. Most of them are stock units IE: BSA, Annie's, FWB, Trigger Tech Diamond in my V-22. They are there because that is where I prefer them. I was simply offering up an Idea incase some people were unaware of the spring kit.I tend to agree with your opinion on trigger weight. Even though I've got the TT Diamonds on my V-22 comp rifles set at under 1lb, I'm pretty comfortable with the triggers on my 457 American & MTR set at just a bit over 1lb. The way I see it - keeping in mind that Trigger Tech designed the Diamond to go this light from the start - CZ obviously had to deal with the reality that their 457s were going to be used by shooters with widely varied ranges of experience, as well as - especially in the case of the Scout version - knowing that young shooters were going to be introduced to the sport of rifle shooting with these rifles. So, while I applaud CZ for putting a trigger as good as the 457's on the market, I doubt they're all that keen on the idea of owners putting lighter springs in these triggers and winding up with a break well under the range they designed the trigger for. Some of these rifles with modified triggers are inevitably going to wind up on the used market, and as hard as I hear it is to remove the trigger pin to change the spring, I seriously doubt the original owners of most that do get sold are going to take the time to put the OEM spring back into the trigger. I re-barreled a CZ527 7.62x39 Carbine to 6RAT several years ago, and not liking the single set trigger, replaced it with one from Rifle Basix. It now breaks at under 1lb, and unless I can adjust it up to at least 2lbs, I'd not feel at all comfortable in selling this little rifle.

Best regards

Shawn Carroll

Attachments

Last edited:

Shawn,

I didn't intend my post to be taken as aimed at anyone person, rather as a general statement for 457 owners to consider. The reason I brought it up is that I had the trigger on my 457 American work fine at the initial setting I arrived at by backing-off the sear engagement until it released, then increasing the engagement until it held through fast & hard bolt operation & a bump test. However, a few range sessions later, it went off while I was closing the bolt - and I wasn't running it fast or hard. Maybe my engagement adjustment didn't stay set where I had it, or perhaps the engagement surfaces wore-in a bit - or? I've since increased sear engagement again, after flushing the trigger housing with brake & parts cleaner, followed by several blasts of compressed air. That was several months ago, and since then, I've re-barreled the American with a Shilen blank, added a longer bolt knob, and shot it quite a bit, enjoying the improved accuracy afforded by the Shilen bbl. Never had another problem, never experienced any creep or other unpleasantness - and the more I shoot this rifle, the more I enjoy it. I believe the trigger breaks at 1-1/4lb currently, and though at first I thought it'd be easier to shoot if I did the YoDave spring installation, I've decided to leave it alone. It works great in offhand, isn't that hard to shoot off rests, and I feel pretty safe with it. That's not to say that I'm critical of owners doing the YoDave installation - to each his own.

Indeed, not too long ago, I posted my intentions to put the YoDave springs in both the American & my MTR. And I may yet use the spring in the MTR's trigger - it's a work in progress, also with a Shilen select match, ratchet rifled bbl. Though the Shilen on this rifle does shoot a bit better than the OEM MTR bbl, I feel there's more potential there, and to that end, will drill out the plastic pillars, replace them with aluminum ones, and bed the action. If that helps the accuracy, but I feel the OEM trigger is holding me back, I'll go with the lighter spring.

I remember that photo of the trigger you'd lapped from an earlier thread - that's impressive work. Not everyone has the skill or patience to get results like that. It does bring up the thought that, if both engagement surfaces have that fine a finish, I would think it has the potential of actually increasing the weight of pull due to more complete meshing/engagement of the two surfaces. It would need lubricant to avoid slip-stick or creep - or at least, that's what seems logical to me. Your thoughts?

As far as lefty222's drawing of the 457 trigger - when I first saw it, the sear engagement instructions were reversed, but he'd put up a note saying so. I don't recall whether he put the correction in textual form in a follow-up post, or added a note to his drawing? I first saw his drawing on RFC, and appreciated his taking the time to draw it out & label parts.

One more thought - I used to think the triggers on my Anschutz 1611 & 2011 rifles were lighter than anything else I'd used (with the exception of a 2oz Jewell on a used 6PPC BR rifle I'd bought), but after setting the Diamonds down to around 6-8oz, it made the trigger break on my 2011 seem rather heavy by comparison. I'll have to do some adjusting on the 2011's trigger down the road...

I didn't intend my post to be taken as aimed at anyone person, rather as a general statement for 457 owners to consider. The reason I brought it up is that I had the trigger on my 457 American work fine at the initial setting I arrived at by backing-off the sear engagement until it released, then increasing the engagement until it held through fast & hard bolt operation & a bump test. However, a few range sessions later, it went off while I was closing the bolt - and I wasn't running it fast or hard. Maybe my engagement adjustment didn't stay set where I had it, or perhaps the engagement surfaces wore-in a bit - or? I've since increased sear engagement again, after flushing the trigger housing with brake & parts cleaner, followed by several blasts of compressed air. That was several months ago, and since then, I've re-barreled the American with a Shilen blank, added a longer bolt knob, and shot it quite a bit, enjoying the improved accuracy afforded by the Shilen bbl. Never had another problem, never experienced any creep or other unpleasantness - and the more I shoot this rifle, the more I enjoy it. I believe the trigger breaks at 1-1/4lb currently, and though at first I thought it'd be easier to shoot if I did the YoDave spring installation, I've decided to leave it alone. It works great in offhand, isn't that hard to shoot off rests, and I feel pretty safe with it. That's not to say that I'm critical of owners doing the YoDave installation - to each his own.

Indeed, not too long ago, I posted my intentions to put the YoDave springs in both the American & my MTR. And I may yet use the spring in the MTR's trigger - it's a work in progress, also with a Shilen select match, ratchet rifled bbl. Though the Shilen on this rifle does shoot a bit better than the OEM MTR bbl, I feel there's more potential there, and to that end, will drill out the plastic pillars, replace them with aluminum ones, and bed the action. If that helps the accuracy, but I feel the OEM trigger is holding me back, I'll go with the lighter spring.

I remember that photo of the trigger you'd lapped from an earlier thread - that's impressive work. Not everyone has the skill or patience to get results like that. It does bring up the thought that, if both engagement surfaces have that fine a finish, I would think it has the potential of actually increasing the weight of pull due to more complete meshing/engagement of the two surfaces. It would need lubricant to avoid slip-stick or creep - or at least, that's what seems logical to me. Your thoughts?

As far as lefty222's drawing of the 457 trigger - when I first saw it, the sear engagement instructions were reversed, but he'd put up a note saying so. I don't recall whether he put the correction in textual form in a follow-up post, or added a note to his drawing? I first saw his drawing on RFC, and appreciated his taking the time to draw it out & label parts.

One more thought - I used to think the triggers on my Anschutz 1611 & 2011 rifles were lighter than anything else I'd used (with the exception of a 2oz Jewell on a used 6PPC BR rifle I'd bought), but after setting the Diamonds down to around 6-8oz, it made the trigger break on my 2011 seem rather heavy by comparison. I'll have to do some adjusting on the 2011's trigger down the road...

Dennis,

I have two Annie's with the 64 action and they both have the 5098 triggers. They are set from the factory at about 6.38 oz. they will only go down to 6.25 oz. Some Annie's have other triggers that are much heavier. To my recollection, they only make one trigger lighter than the 5098 and that unit alone is about 650.00

I too recall Lefty making a correction in another post and I too appreciate the time he took to help us all out.

As far as the lapped trigger goes, I would never tolerate any kind of slip/stick of any kind. lol

If this were a car engine, you would be correct in thinking that you would never have a high polish on the surfaces. In that case you erase the micro reservoirs for the oil to stay in. Their is a name for the hone process for that case that escapes me at this moment.

I use a moly based lube on my triggers (MOS2) In very small amounts. It has a super low coefficient of friction. If you could look at any machined surface you will find scratches and waves and they have an Arithmetical Average or roughness and those waves can hang up on each other. When I lap my triggers, I am not going for shinny but dead flat. It is that roughness that you feel as creep. In my minds eye, it's like miniature interlocking lines. Or on a large scale, a chain and sprocket. I should take this time to note that you also want to lap your sears in the direction of travel. You have to have a certain "Lay" pattern.

I would also never tolerate a gun going off on it's own. I had my V-22 and its TT Diamond set at 4 oz. I was running it fast and it goes off. I had to increase it to 8 oz. to prevent it discharging. As I write this, it should probably go back for service. I am actually a big fan of a two stage trigger with lots of first stage sear engagement. Another way that I can tell that the lapped trigger reduces friction is that with guns that have heavy loads on the sears, you can pull in the first stage and release the trigger and it will return to battery. A trigger that is not dressed properly wont.

In truth, I take safety very seriously.

I just had a chat with Dave and suggested providing new trigger pins and having people stake the pins in place after assembly. https://en.wikipedia.org/wiki/Staking_(manufacturing) It would be a simple solution to the reassembly and pin retention issue of the 457 trigger. Getting the pin out is still a scary process. I know some feel that using fingernail polish is flaky so that is the best low cost solution. They have been doing staking in aircraft for at least 50 years.

Best

Shawn

I have two Annie's with the 64 action and they both have the 5098 triggers. They are set from the factory at about 6.38 oz. they will only go down to 6.25 oz. Some Annie's have other triggers that are much heavier. To my recollection, they only make one trigger lighter than the 5098 and that unit alone is about 650.00

I too recall Lefty making a correction in another post and I too appreciate the time he took to help us all out.

As far as the lapped trigger goes, I would never tolerate any kind of slip/stick of any kind. lol

If this were a car engine, you would be correct in thinking that you would never have a high polish on the surfaces. In that case you erase the micro reservoirs for the oil to stay in. Their is a name for the hone process for that case that escapes me at this moment.

I use a moly based lube on my triggers (MOS2) In very small amounts. It has a super low coefficient of friction. If you could look at any machined surface you will find scratches and waves and they have an Arithmetical Average or roughness and those waves can hang up on each other. When I lap my triggers, I am not going for shinny but dead flat. It is that roughness that you feel as creep. In my minds eye, it's like miniature interlocking lines. Or on a large scale, a chain and sprocket. I should take this time to note that you also want to lap your sears in the direction of travel. You have to have a certain "Lay" pattern.

I would also never tolerate a gun going off on it's own. I had my V-22 and its TT Diamond set at 4 oz. I was running it fast and it goes off. I had to increase it to 8 oz. to prevent it discharging. As I write this, it should probably go back for service. I am actually a big fan of a two stage trigger with lots of first stage sear engagement. Another way that I can tell that the lapped trigger reduces friction is that with guns that have heavy loads on the sears, you can pull in the first stage and release the trigger and it will return to battery. A trigger that is not dressed properly wont.

In truth, I take safety very seriously.

I just had a chat with Dave and suggested providing new trigger pins and having people stake the pins in place after assembly. https://en.wikipedia.org/wiki/Staking_(manufacturing) It would be a simple solution to the reassembly and pin retention issue of the 457 trigger. Getting the pin out is still a scary process. I know some feel that using fingernail polish is flaky so that is the best low cost solution. They have been doing staking in aircraft for at least 50 years.

Best

Shawn

Attachments

Dennis,

I found an example of a "Staked" item. It is the bolt from an AR-15 and its bolt carrier key and screws. The material adjacent to the screws has been upset to keep the screws from getting loose. In the case of the 457 trigger pin you cant approach it from the sides so you would just use a prick punch to upset or deform the surface material adjacent to the pin. That creates a localized press fit on the trigger pin and would retain it from any lateral movement.

That was my suggestion to Dave for his problem. Supply a new trigger pin and have folks Stake the new pins in place. I'm sure most would feel better with that than using my fingernail polish approach. I can hear the naysayers laughing now....

I found an example of a "Staked" item. It is the bolt from an AR-15 and its bolt carrier key and screws. The material adjacent to the screws has been upset to keep the screws from getting loose. In the case of the 457 trigger pin you cant approach it from the sides so you would just use a prick punch to upset or deform the surface material adjacent to the pin. That creates a localized press fit on the trigger pin and would retain it from any lateral movement.

That was my suggestion to Dave for his problem. Supply a new trigger pin and have folks Stake the new pins in place. I'm sure most would feel better with that than using my fingernail polish approach. I can hear the naysayers laughing now....

Attachments

Can you imagine how much trouble a gas key coming loose would cause? I've put together a lot of AR15/10s over the years, and have seen only one gas key come loose - due to improperly staked key screws.

I have no problem with your use of fingernail polish on the 457 trigger pin - as long as it doesn't flake off over time, why not use it? There may be a Loc-tite product that's perhaps better for the application, but I don't know which one would be correct. I'd be concerned with a wicking compound like #290 weeping on into the trigger & locking it up on the pin. I used Loc-tite #609 to glue the two Shilen bbls into my 457 American & MTR, and haven't had any issues so far - did the American bbl job May 1 and the MTR on the 19th, so it's been around five months for both. Have to admit though, that I shoot my V-22s a whole lot more often than I have the two CZs, but after reading that Walther has been using a similar adhesive to glue bbls into receivers of some of their target rifles, I'm not worried about the longevity of #609. The problem I see with staking the trigger pin would be if it's over-done slightly, and someone tries to drive it out, it may do irreparable damage to the trigger housing. OTOH, I see little or no downside to the use of fingernail polish....

I have no problem with your use of fingernail polish on the 457 trigger pin - as long as it doesn't flake off over time, why not use it? There may be a Loc-tite product that's perhaps better for the application, but I don't know which one would be correct. I'd be concerned with a wicking compound like #290 weeping on into the trigger & locking it up on the pin. I used Loc-tite #609 to glue the two Shilen bbls into my 457 American & MTR, and haven't had any issues so far - did the American bbl job May 1 and the MTR on the 19th, so it's been around five months for both. Have to admit though, that I shoot my V-22s a whole lot more often than I have the two CZs, but after reading that Walther has been using a similar adhesive to glue bbls into receivers of some of their target rifles, I'm not worried about the longevity of #609. The problem I see with staking the trigger pin would be if it's over-done slightly, and someone tries to drive it out, it may do irreparable damage to the trigger housing. OTOH, I see little or no downside to the use of fingernail polish....

Can you imagine how much trouble a gas key coming loose would cause? I've put together a lot of AR15/10s over the years, and have seen only one gas key come loose - due to improperly staked key screws.

I have no problem with your use of fingernail polish on the 457 trigger pin - as long as it doesn't flake off over time, why not use it? There may be a Loc-tite product that's perhaps better for the application, but I don't know which one would be correct. I'd be concerned with a wicking compound like #290 weeping on into the trigger & locking it up on the pin. I used Loc-tite #609 to glue the two Shilen bbls into my 457 American & MTR, and haven't had any issues so far - did the American bbl job May 1 and the MTR on the 19th, so it's been around five months for both. Have to admit though, that I shoot my V-22s a whole lot more often than I have the two CZs, but after reading that Walther has been using a similar adhesive to glue bbls into receivers of some of their target rifles, I'm not worried about the longevity of #609. The problem I see with staking the trigger pin would be if it's over-done slightly, and someone tries to drive it out, it may do irreparable damage to the trigger housing. OTOH, I see little or no downside to the use of fingernail polish....

Hi Dennis,

When I emailed Dave, I told him that I did not use Loc-tite because of the wicking concern. As for the trigger pins, it only takes the smallest upset to retain the trigger pins and noting like the gas key needs. I did want to give Dave an alternative to the fingernail polish or E-clips. Something tried and tested. I really enjoy my MTR. It shoots on par with my V-22. I like the CZ so much that I just bought a Royal on Friday with the longer bbl. When I spoke with Dave, he told me that the springs he sells were custom made for size and spring rate. I will however look for a cheap replacement out of idle curiosity. When I originally changed out my spring, I wrote up a post about the perils of the task. While driving the pin out I bent a brass punch and was starting to bend a steel punch. The trigger pin in my gun was a heavy press fit. So as to not damage anything putting it back together, I chucked up the pin in my drill and reduced the diameter a couple thousandths with some 220 wet/dry. Just to a slip fit. Maybe over the years I have lost sight of how these seemingly simple things may not be so simple for others. It is difficult to know how has good ideas that work and how is just talking. That is one reason that I like to support my claim with some kind of rational, IE: staking the gas key. I like to give people the confidents to use an idea and not just follow it blindly.

chat soon

Shawn

just got mine yesterday 8 months and the sun was shinning yesterday picked up the 457 varmint mtr still need everything rail , bipod scope but i got the gun thank god .

What did you shoot those groups with? they look very nice! If you mean that you need everything for your MTR.... I would recommend the AREA 419 rail and as a must have item, the 419 bolt knob. The knob totally changes the feel of the gun. I used 222 (Purple) loc-tite and only screw the knob on until it covered the threads. At first it looked funky to me and I had strong doubts about the knob but it feels and functionsjust got mine yesterday 8 months and the sun was shinning yesterday picked up the 457 varmint mtr still need everything rail , bipod scope but i got the gun thank god .

great. It feels like it is exactly what should be there. Lefty 222 took the time to make this drawing of the 457 trigger. He later came back and corrected item number 49 as being backwards. "In" is less engagement. I like my MTR so much that I just bought a 457 Royal on Friday and have ordered another 419 rail and knob for it.

Enough has been said about the Yo Dave spring kit, but I also have another one of those on order too. It brought my MTR trigger down to 9 oz. and is perfectly safe. Except for my trigger, the MTR is stock and shoots on par with my VuDoo.

Again great shooting.....

Shawn Carroll

Attachments

I went with a BScar 25 MOA rail on both 457s - American & MTR. It's about half the height/thickness of the Area 419 rail, which worked out well when it comes to not needing any sort of stock pack or riser to get a good cheek weld on both rifles. It also cost just $35, including shipping.

I was going to order the Area 419 bolt knob for my MTR, but they were out of stock, so I went to work to turn one very similar on my lathe. I agree with Shawn that it makes a very impressive difference in the ease of operating the 457's bolt. I feel this big knob looks fine on the MTR, but I wanted something a little smaller in profile that wouldn't look so out of place on the American sporter, yet enough longer to give the extra leverage that makes opening the bolt on these rifles quite a bit easier. The attached photo shows the knob on the American, and also shows how low the BScar 25 MOA rail is. I put an Athlon Midas TAC 6-24x50 scope in TPS TSR low rings on this rifle, and as you can see, the low rings give adequate clearance to allow the scope's power ring to clear the top of the rail, yet keeps the scope low enough to result in a very comfortable head position (at least for me).

I was going to order the Area 419 bolt knob for my MTR, but they were out of stock, so I went to work to turn one very similar on my lathe. I agree with Shawn that it makes a very impressive difference in the ease of operating the 457's bolt. I feel this big knob looks fine on the MTR, but I wanted something a little smaller in profile that wouldn't look so out of place on the American sporter, yet enough longer to give the extra leverage that makes opening the bolt on these rifles quite a bit easier. The attached photo shows the knob on the American, and also shows how low the BScar 25 MOA rail is. I put an Athlon Midas TAC 6-24x50 scope in TPS TSR low rings on this rifle, and as you can see, the low rings give adequate clearance to allow the scope's power ring to clear the top of the rail, yet keeps the scope low enough to result in a very comfortable head position (at least for me).

Attachments

Similar threads

- Replies

- 31

- Views

- 9K

- Replies

- 4

- Views

- 1K

- Replies

- 0

- Views

- 887

- Replies

- 9

- Views

- 730