Figure it took more time than money to make this one. All I need to do is get some hardware.

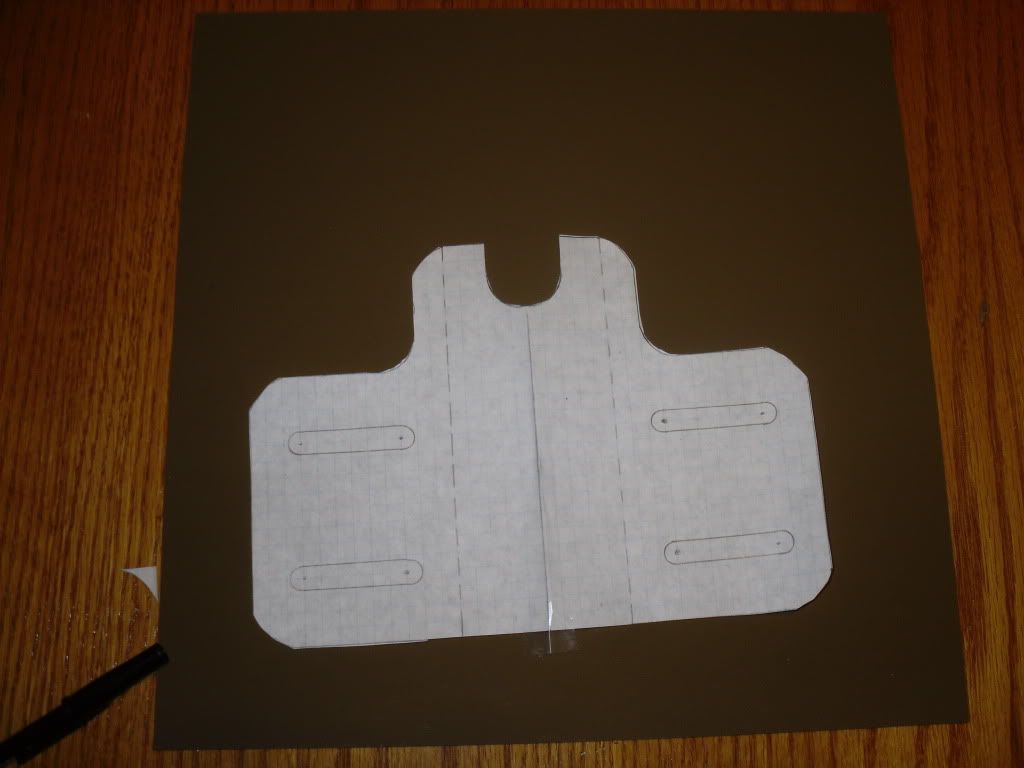

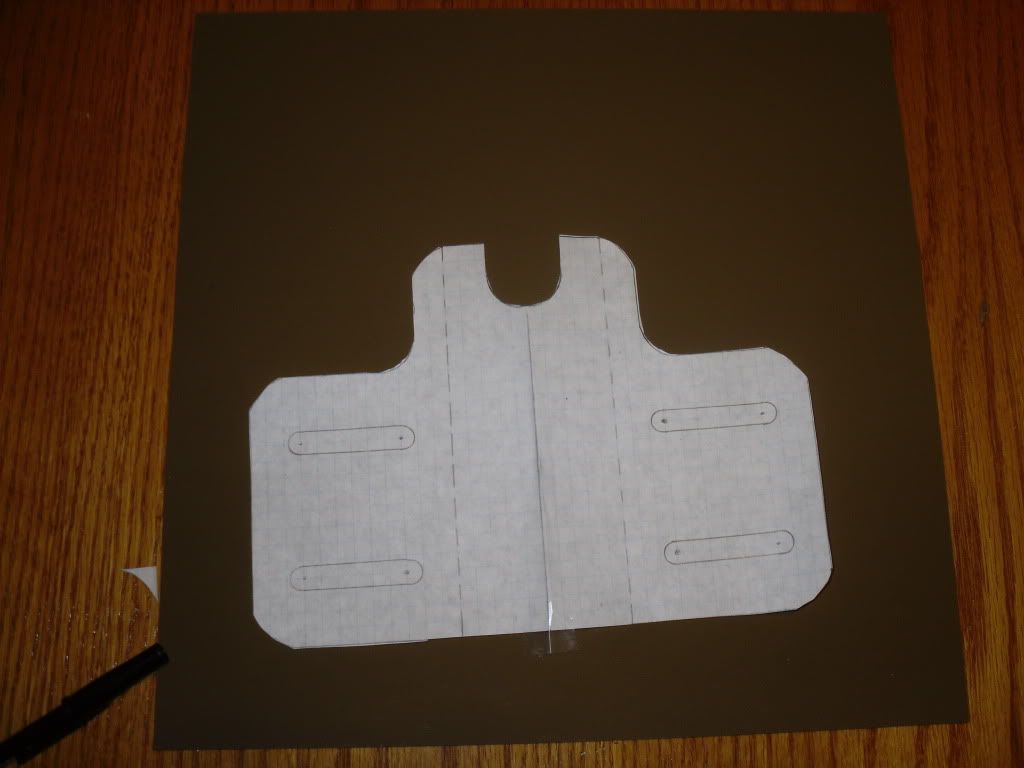

Sketched an idea onto graph paper, and cut it as a template.

Then I got some Coyote Brown Kydex .090 thick from Custom Knife Kits. Using tin snips, file and sand paper I worked the sketch onto the Kydex.

Oven @ 350* Kydex in for 5 minutes and it was very pliable. Its actually very easy to work and handle. I had penciled a centerline on the Kydex to use as a guideline for centering in the stock.

I saved any other cuts for last. I wanted the Kydex to set a perfect as I could to minimize distortion. It worked, there wasn't any.

Using a dremel, file and sand paper I cut and smoothed the slots, and bolt relief. Now off to the hardware store.

Oh, the cost of a 12x12 sheet of kydex is less than $8. I doubt the hardware will be more than $5. It took about an hour and a half to draw it out, another hour and a half to do the cut n mold. Not too bad.

Sketched an idea onto graph paper, and cut it as a template.

Then I got some Coyote Brown Kydex .090 thick from Custom Knife Kits. Using tin snips, file and sand paper I worked the sketch onto the Kydex.

Oven @ 350* Kydex in for 5 minutes and it was very pliable. Its actually very easy to work and handle. I had penciled a centerline on the Kydex to use as a guideline for centering in the stock.

I saved any other cuts for last. I wanted the Kydex to set a perfect as I could to minimize distortion. It worked, there wasn't any.

Using a dremel, file and sand paper I cut and smoothed the slots, and bolt relief. Now off to the hardware store.

Oh, the cost of a 12x12 sheet of kydex is less than $8. I doubt the hardware will be more than $5. It took about an hour and a half to draw it out, another hour and a half to do the cut n mold. Not too bad.