Re: Explain your load development process

0.) The rifle has to be straight and rig put together right to begin with.

1.) Decide first whether you want to shoot Secant or Tagent ogive bullets.

http://www.riflebarrels.com/articles/bullets_ballastics/throat_angles.htm

Tangent ogive bullets are tolerant of free bore jump. Secant, or VLD designs are not as tolerant of free bore jump. Matchkings are good Tangent bullets, Berger are good Secant bullets. Matchkings are less finicky, according to some.

The barrel twist rate will help you choose bullet weight. Consult with a shooter who is an expert with your chosen caliber. Some have experienced secant bullets to shoot better kissing the lands, while some have experienced them shooting better with .030+- jump.

2.) Next, decide on a powder. Varget is very stable and works in most non-magnum rifle loads, resisting ambient temp changes that affect velocity. Hogdon powders are more ambient temperature change resistant than others according to some tests.

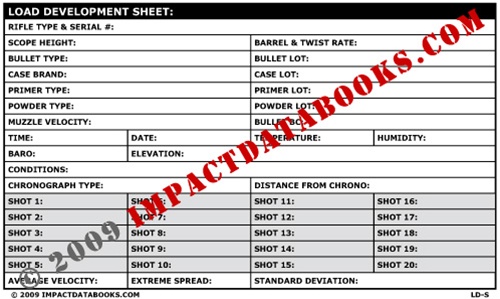

3.) Decide on a primer. Small rifles, right now, Rem 7 1/2 are working well. Some prefer primers that purport to be "match" grade. I don't.

4.) Use good brass. Get Lapua and look forward, or the kind good shooters are using for your caliber.

5.) Use a Redding or Forster Bonanza micrometer seater die (or custom die). Full length siz your brass without an expander button. If you insist on something sizing the inside, use a mandrel. Also, use the tool to monitor shoulder bump. This is how far into the sizer die you know to run the case. Ignore manuals instructing you to cam over the ram and proceed loading without regard to shoulder bump.

6.) Load clean brass. Shoot clean ammo (absent sizing lube).

7.) Measure your rifle's chamber length using a tool or seat a bullet in a sized case without powder and primer lubing the bullet with sizing lube barely into the case mouth, then completely seat bullet by chambering the dummy round, closing the bolt completely. With a caliper and an ogive measuring tool such as a hex nut from Sinclair, measure the overall length of this round and record it. Keep the dummy too. Open the seater die, insert the dummy round by raising the press ram. Screw down the seater stem of the seater die until it touches the bullet nose cone and then seat the bullet about .005" deeper into the case mouth. Because you jammed the bullet into the lands with the caming of the bolt, seating the bullet .005 shorter will likely put it still kissing the lands. Load five rounds at this cartridge over-all length with your chosen powder and beginning, safe charge weight. Then load five more rounds with .5 grs charge weight more and so forth until you get pressure indicator(s). Stop! At some point, on the target you will see a group from one of those charges that appears to exhibit superior accuracy. Load that charge again to confirm it using the same cartridge overall length. If the group repeats itself, go to the seating depth step in load development.

8.) Begin seating the bullet .0500 deeper into the case, five rounds each up to .1500 deep unless pressure is encountered along the way. Again, a group on the target should exhibit superior accuracy. Return to that seating depth and confirm it. Seat bullets .0010 deeper and go up in increments of .005 up to about .0015 over the accurate group depth. Once again, you should see a group that is better than others.

9.) Conduct a ladder test. Read about that on 6mmbr.com.

10.) Shoot allot and resist the temptation to continue load testing after finding a load unless you want to become a load tester instead of a shooter. I'm always chasing a load. Just go shoot the gun and enjoy. I'll try and do the same.

Get this book:

HANDLOADING FOR COMPETITION; MAKING THE TARGET BIGGER, by Glenn Zediker, and read everthing else he writes on handloading and ammo.

Other good handloaders are ChadTRG, Rich Emmons and WmRoscoe that I know of.

Avoid some benchrest loaders' advice unless your shooting bench rest. They accept powders intolerant of atmospheric stability because they often load at the range according to current conditions. We can't do that in tactical or hunting.

It helps if you do this stuff at the range. At least seat the bullets long and then seat them deeper at the range with your seater die and press as you fire the loads to get that done in one trip to the range.

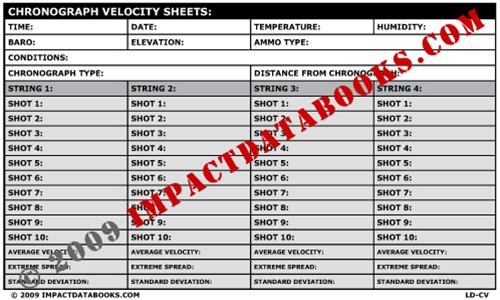

Use a chronograph that works well.

Test the load at the distances you plan to shoot the gun.

This is one way to develop loads. Variations are innumerable, but this will probably get you there without wearing out a barrel.