Hi,

So this is one of the great benefits of having a Mastercam guru running the programming and machining...

He can make improvements on the fly; that not only look better cosmetically but improves production efficiency at the same time.

Seconds lead to minutes, minutes lead to hours and hours lead to delays, so it is great when production efficiency partners with cosmetic features at the same time!!

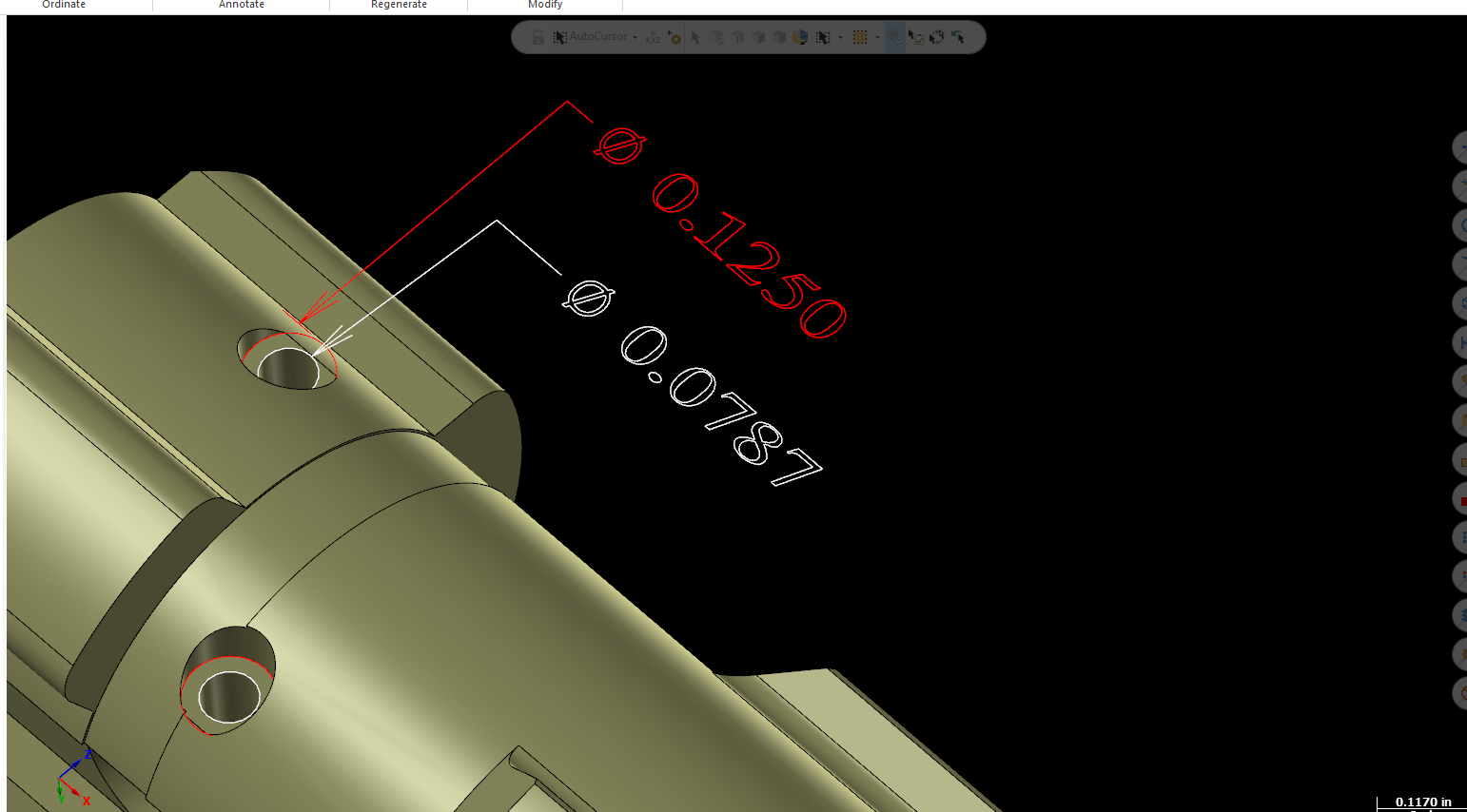

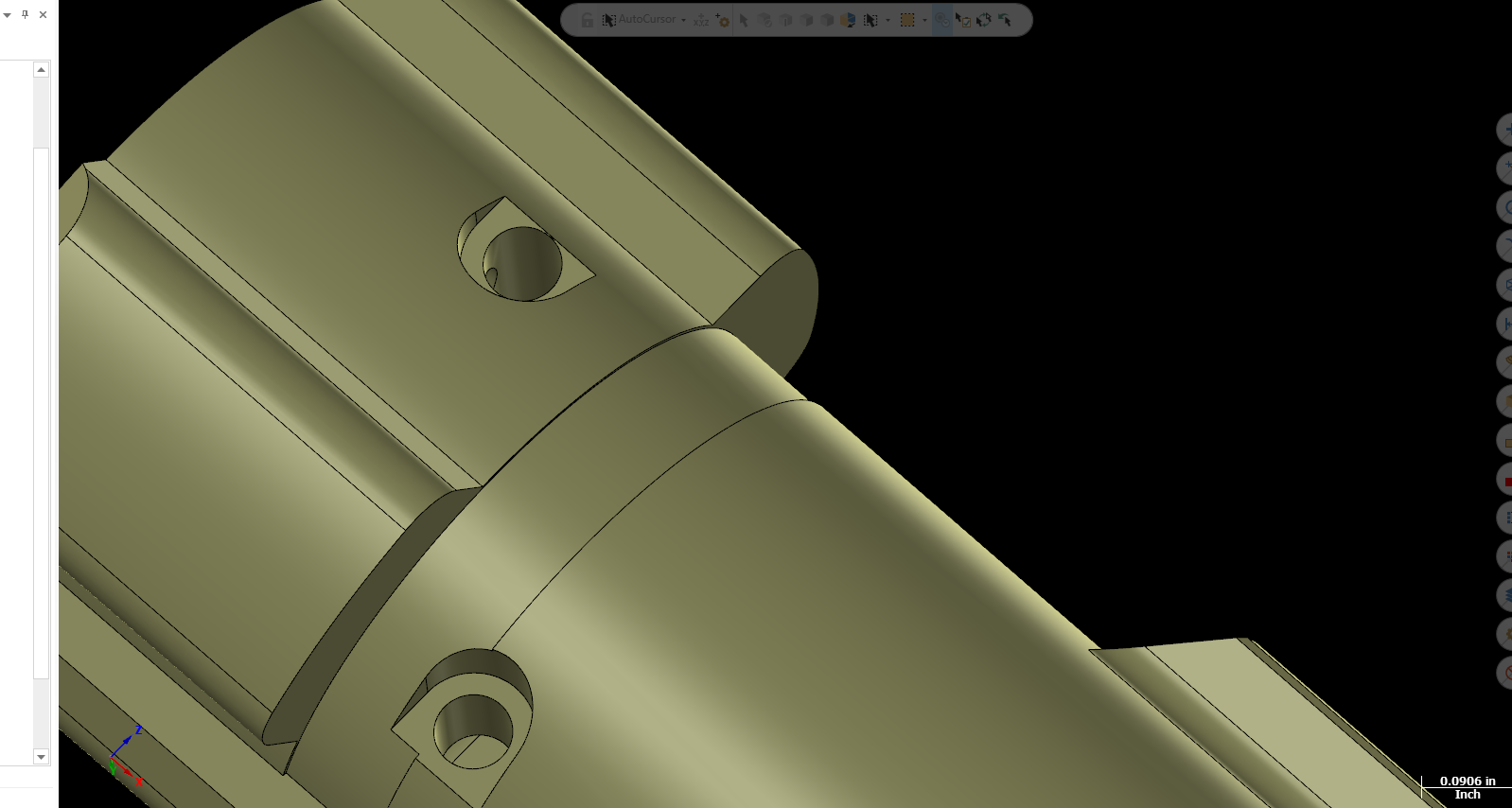

Small details such as making the holes in first picture into the holes in the second picture..Just an 1/8 counterbore 1mm deep makes a big difference.

Sincerely,

Theis

So this is one of the great benefits of having a Mastercam guru running the programming and machining...

He can make improvements on the fly; that not only look better cosmetically but improves production efficiency at the same time.

Seconds lead to minutes, minutes lead to hours and hours lead to delays, so it is great when production efficiency partners with cosmetic features at the same time!!

Small details such as making the holes in first picture into the holes in the second picture..Just an 1/8 counterbore 1mm deep makes a big difference.

Sincerely,

Theis