Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoplite Arms

- Thread starter THEIS

- Start date

- Status

- Not open for further replies.

With the integrated forend dovetail, is it still easy/comfortable to hold the forend by hand if you want to shoot from an unsupported standing/kneeling/sitting/prone position?

Hi,

Shit...Sorry for the delay in replying. I thought I had replied but clearly haven't.

I personally like the feel because it is not too wide as to where it "spreads" support hand open too far which would feel uncomfortable but gives me enough to grab a hold on, type of thing/feel.

BUT...I have a carbon print "hand" piece in my head just for those users to prefer a more "round" feel but I will not have it finished for Shot Show.

Sincerely,

Theis

Last edited:

Hi,

Component pieces arriving for the 10 demo builds.

Sincerely,

Theis

Component pieces arriving for the 10 demo builds.

Sincerely,

Theis

Hi,

Fresh off the machines...oil has not even been wiped off since they are not finished....

Bolt handles:

Firing Pin Body Attachment:

DBM Trigger Guard Spacers (Rear and Front)

Sincerely,

Theis

Fresh off the machines...oil has not even been wiped off since they are not finished....

Bolt handles:

Firing Pin Body Attachment:

DBM Trigger Guard Spacers (Rear and Front)

Sincerely,

Theis

Last edited:

Can you flush the dovetail to the bottom of the hand guard?

havnt used a RRS rail yet.Can you flush the dovetail to the bottom of the hand guard?

what would be the benefit if it was flush

i would think when wearing gloves or alike the extra room might be needed to grab on to something

Can you flush the dovetail to the bottom of the hand guard?

Hi,

I will have to check but at first glance I am not sure the lines will be very neat.

Since the pic rail section of the handguard slides and screw locks into the center chassis section at the height shown in the below image.

The "drop down" makes for a better transition IMO but I will get some measurements.

Sincerely,

Theis

Oh yeah. I forgot you had a pic section as well. From a user perspective it’s just really nice if everything can be as close to even with the magazine well when stowed (except grip). Makes transport easy. I like it either way. Just giving you feedback. We all want this thing to be a success.Hi,

I will have to check but at first glance I am not sure the lines will be very neat.

Since the pic rail section of the handguard slides and screw locks into the center chassis section at the height shown in the below image.

The "drop down" makes for a better transition IMO but I will get some measurements.

View attachment 7172565

Sincerely,

Theis

Hi,

O I know exactly where you coming from in regards to assistance and feedback! It is much appreciated.

Even with the "dropped" RRS Dovetail we are pretty straight "in-line" for transportation and overall feel.

Just take this earlier T&E build pictured here and the new handguard with RRS Dovetail will sit slightly lower, but still flow properly.

The pic rail on bottom of new Dovetail handguard will be unseen on rifle once installed into the chassis center section.

Sincerely,

Theis

O I know exactly where you coming from in regards to assistance and feedback! It is much appreciated.

Even with the "dropped" RRS Dovetail we are pretty straight "in-line" for transportation and overall feel.

Just take this earlier T&E build pictured here and the new handguard with RRS Dovetail will sit slightly lower, but still flow properly.

The pic rail on bottom of new Dovetail handguard will be unseen on rifle once installed into the chassis center section.

Sincerely,

Theis

Last edited:

this makes so much more sense now regarding the pic portionHi,

O I know exactly where you coming from in regards to assistance and feedback! It is much appreciated.

Even with the "dropped" RRS Dovetail we are pretty straight "in-line" for transportation and overall feel.

Just take this earlier T&E build pictured here and the new handguard with RRS Dovetail will sit slightly lower, but still flow properly.

The pic rail on bottom of new Dovetail handguard will be unseen on rifle once installed into the chassis center section.

Sincerely,

Theis

View attachment 7172637

this makes so much more sense now regarding the pic portion

Hi,

Yes, that is something I should have made more clear in the images of the handguard marking methods post up the page....

That the pic rail would not be seen once installed into the chassis.

The RRS Dovetail is Mlok down the center, so IF you wanted to add pic rail section(s) to the bottom you could.

Sincerely,

Theis

The RRS Dovetail is Mlok down the center, so IF you wanted to add pic rail section(s) to the bottom you could.

Sincerely,

Theis

I'd probably do that to run an Elite Iron bipod and I guess depending on the total diameter either directly over the end of the handguard or with the little push forward spacer to take it just forward of the handguard

I'd probably do that to run an Elite Iron bipod and I guess depending on the total diameter either directly over the end of the handguard or with the little push forward spacer to take it just forward of the handguard

Hi,

I personally would probably go with Elites 2.1 to 2.3 offset mount just to pretty much (I have not measured directly so guessing) have the "circular" portion of the bipod mount right at end of handguard without much gap in-between.

I will email him and ask if he could send me over the measurements so that I can catalog them in my records for when someone ask suggestions for just such matter.

Thanks for bringing that situation up.

Sincerely,

Theis

Hi,

Tub full of Aspis (LM Sized) model chassis off the machine from first Op, start second Op Wednesday...

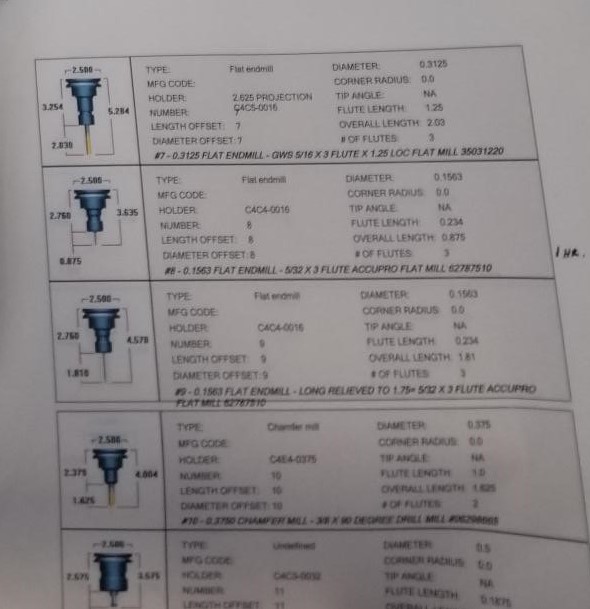

Mill Setup sheet for 1st Op: Not something you typically see posted

Sincerely,

Theis

Tub full of Aspis (LM Sized) model chassis off the machine from first Op, start second Op Wednesday...

Mill Setup sheet for 1st Op: Not something you typically see posted

Sincerely,

Theis

Last edited:

Hi,

Tub full of Aspis (LM Sized) model chassis off the machine from first Op, start second Op Wednesday...

View attachment 7172713

Mill Setup sheet for 1st Op: Not something you typically see posted

View attachment 7172733

Sincerely,

Theis

Hey @THEIS,

guhring endmills tend to perform better than the accupros for not much more cost. The added life and reduced cycle time generally drive tooling cost per price down. OSG blizzards aren’t bad either.

Sincerely,

LM

Hey @THEIS,

guhring endmills tend to perform better than the accupros for not much more cost. The added life and reduced cycle time generally drive tooling cost per price down. OSG blizzards aren’t bad either.

Sincerely,

LM

Hi LM,

True but 7075 T6 is pretty simple and easy on tools compared to the receiver alloys we are using

Sincerely,

Theis

Hi LM,

True but 7075 T6 is pretty simple and easy on tools compared to the receiver alloys we are using.

Sincerely,

Theis

Can’t argue with that. I’ve had the best luck with Guhring 6 flute endmills when cutting nickel alloys and steels up to 55Rc. For tough stringy steels I’ve found favor in the Kennametal line.

Best,

LM

Can’t argue with that. I’ve had the best luck with Guhring 6 flute endmills when cutting nickel alloys and steels up to 55Rc. For tough stringy steels I’ve found favor in the Kennametal line.

Best,

LM

Hi,

I have had the best luck with listening to my programmers, operators, QC auditors and keeping my hands OFF any machine or tool, lololol.

Nobody wants me handling that aspect of this business for sure!

This is a business of "People", whether they get a paycheck from Hoplite Arms or write a check to Hoplite Arms; the strategy from the onset was to listen to them instead of just talking TO them.

Better to know what you do not know.....Machines, Tooling, Programming, Operation procedures.....I do NOT know more than the Team members I have in those departments.

Sincerely,

Theis

Last edited:

Hi,

Design almost finished for clean separating sabot .

.

It works great with titanium solid, lol

Sabot not set to correct depth for picture.

Sincerely,

Theis

Design almost finished for clean separating sabot

It works great with titanium solid, lol

Sabot not set to correct depth for picture.

Sincerely,

Theis

Hi,

Design almost finished for clean separating sabot.

It works great with titanium solid, lol

Sabot not set to correct depth for picture.

View attachment 7181412

Sincerely,

Theis

So ammunition that makes Communists/Democrats cry just by it's very existence?

We'll need to do an Army Jerry style buying spree...

Hi,

Design almost finished for clean separating sabot.

It works great with titanium solid, lol

Sabot not set to correct depth for picture.

View attachment 7181412

Sincerely,

Theis

Will these be made available to use plebs still running ancient cartridges like the .308 or are these just for your new rounds?

Looks awesome either way and am looking forward to seeing what your data is.

Hi,

I am pretty sure you do not want to shoot a titanium mono in your normal .308 as it will make short barrel life for sure.

Sincerely,

Theis

I am pretty sure you do not want to shoot a titanium mono in your normal .308 as it will make short barrel life for sure.

Sincerely,

Theis

Hi,

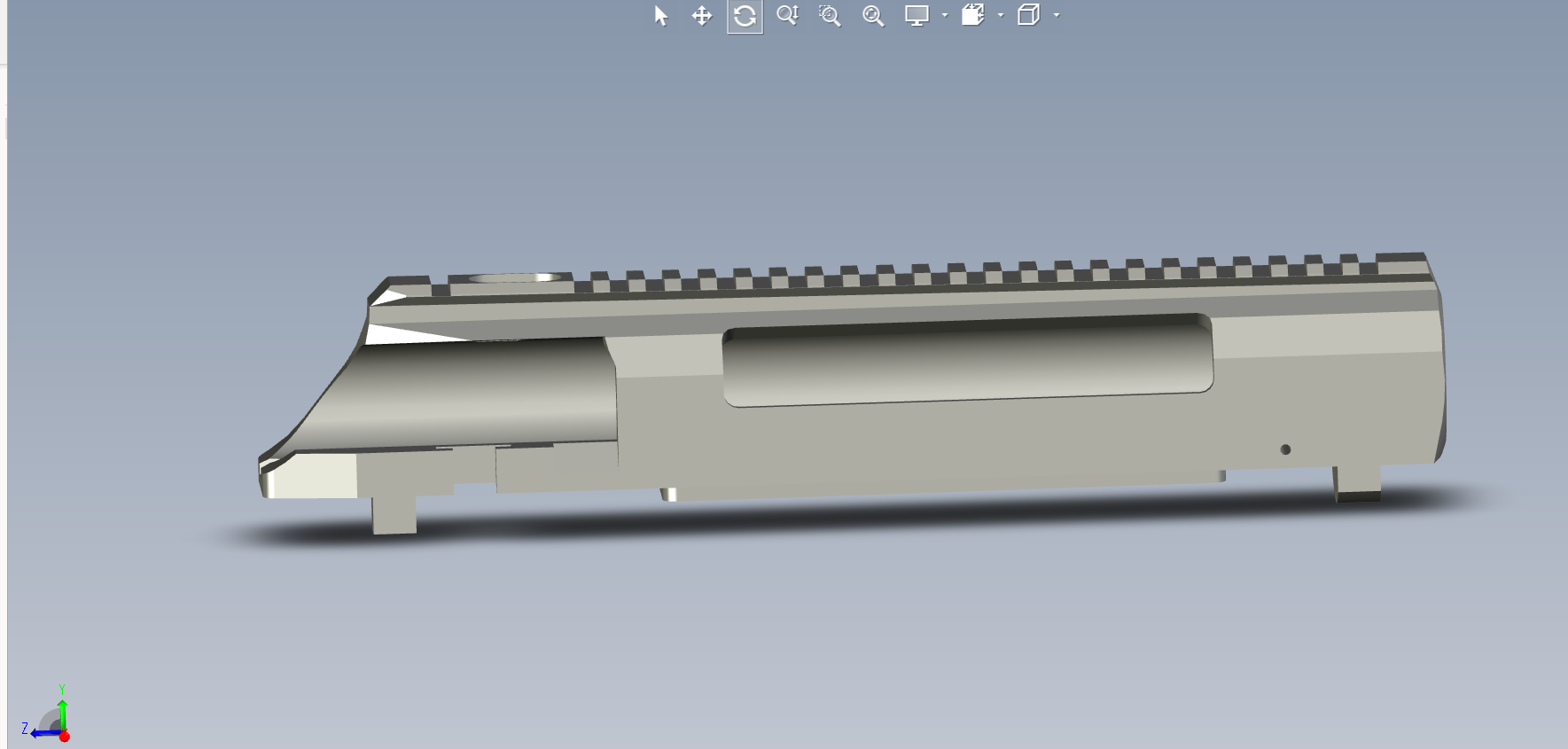

Finalization of the Phalanx (BMG sized) system is complete. Time to get the process going for manufacturing.

Sincerely,

Theis

Finalization of the Phalanx (BMG sized) system is complete. Time to get the process going for manufacturing.

Sincerely,

Theis

That’s a niceHi,

Finalization of the Phalanx (BMG sized) system is complete. Time to get the process going for manufacturing.

View attachment 7182818

Sincerely,

Theis

I hope this question isn't too naive and it is absolutely not meant to be disparaging just trying to better understand these tools and their application.

Do rifles such as these tend more toward the spectrum of durability and reliability or to benchrest precision...or perhaps both?

thank you

Sorry...i should have clarified, i was hoping to hear Mr. Theis' thoughts.

I doubt i'll ever be able to afford a rifle such as this and i do understand that I'll never be a competitive athlete, relegated to trying to learn the science and physics of the sport while hoping to shoot little groups at our local range.

I'm intrigued by the quality and craftsmanship that goes into making and designing these rifles. I find them very attractive at least academically, an effort similar to that noted when studying premier sports cars or other finely crafted metal works.

I find it all so fascinating and wonder at the end of the day...to what end? Is it to handle the rigors of a warrior or biased to accuracy and precision. There must be a balance, a scale...just trying to figure out where they place.

Hi,

@want2learn

I hope you do not mind that I copy and pasted your comments/questions that were in another thread into this thread as it IMO is more appropriate for me to discuss my rifles and thoughts in my own thread instead of another manufacturers thread.

So here are my thoughts and such in regards to your question of durability/reliability or benchrest precision.....

Benchrest is 90% ammunition IMO..that genre of shooting flat out spend more time in not only load development but load obsessive compulsive disorder, lol.

In regards to weapon design difference of the 2 genres of shooting..Field vs BR:

IMO accuracy and precision comes from bolt lugs forward while durability/reliability comes from bolt lugs rearward.

In short...IMO (Take that for what it is) you can take a "Field" designed rifle and as long as ammunition side of the BR genre was adhered to you could have just as precise rifle as dedicated "BR" designed rifle, BUT you cannot take a "BR" designed rifle and make it a "Field" rifle.

Sincerely,

Theis

thank you.... I was hoping that would be the case.

I really love to seeing your work posted here...fascinating.

I really love to seeing your work posted here...fascinating.

Hi,

Finalization and readying for inventory.

Sincerely,

Theis

Finalization and readying for inventory.

Sincerely,

Theis

Hi,

Finalization and readying for inventory.

Sincerely,

Theis

View attachment 7186162View attachment 7186164View attachment 7186165View attachment 7186166

Let’s try this again, from a different angle

Can I please have one!!!

Whats the name of this mount? Jism²?Hi,

Finalization and readying for inventory.

Sincerely,

Theis

View attachment 7186162View attachment 7186164View attachment 7186165View attachment 7186166

Looks a lot better and actually fully functional compared to the other spunk mount released this month.

if you could make sure there's one on my rifle when it ships that'd be greaaattttt mmmkayyy

You gonna call it the Jizz mount or something ? ???Hi,

Finalization and readying for inventory.

Sincerely,

Theis

View attachment 7186162View attachment 7186164View attachment 7186165View attachment 7186166

You forgot your question mark. To the back of the line with you!Let’s try this again, from a different angle

Can I please have one!!!

Hi,

"Artemis" scope mounts or AKA "Respect My Authority" scope mount with ambidextrous screws.

or AKA "Respect My Authority" scope mount with ambidextrous screws.

Sincerely,

Theis

"Artemis" scope mounts

Sincerely,

Theis

You mean it mixes left hand screws and right hand screws? Or are the screws both left handed and right handed at the same time? That is awesome!!!Hi,

"Artemis" scope mountsor AKA "Respect My Authority" scope mount with ambidextrous screws.

Sincerely,

Theis

Don’t tell anyone on the hide (might get flamed) but I love a bubble level on the mount.

One less piece of gear to get bumped or adjusted.

I’m guessing with the proprietary chassis, one piece action/rail and serious mount I could just level the scope to the mount and not have to worry

One less piece of gear to get bumped or adjusted.

I’m guessing with the proprietary chassis, one piece action/rail and serious mount I could just level the scope to the mount and not have to worry

Hi,

"Artemis" scope mountsor AKA "Respect My Authority" scope mount with ambidextrous screws.

Sincerely,

Theis

At the cost of TEN!! Mounting points though, is ambidextrous screws really worth it?

Hi,

Counting down to season finale .

.

Now in mad rush to bring all the pieces together for full package debut.

Sincerely,

Theis

Counting down to season finale

Now in mad rush to bring all the pieces together for full package debut.

Sincerely,

Theis

Any chance of package deal possibilities for standard calibers with loaded RCC brass for getting you shooting right away then having the brass for reloading later on?

I'm assuming your super calibers and super tungsten, nano polymer coated, liberal tear inducing, rounds might be a little bit further out?

I'm assuming your super calibers and super tungsten, nano polymer coated, liberal tear inducing, rounds might be a little bit further out?

Any chance of package deal possibilities for standard calibers with loaded RCC brass for getting you shooting right away then having the brass for reloading later on?

I'm assuming your super calibers and super tungsten, nano polymer coated, liberal tear inducing, rounds might be a little bit further out?

Hi,

We have no problem providing loaded and tuned ammunition with RCC brass and projectile of customers choice (Of course barrel specifications would be tailored to the customers projectile choice).

Liberal tears ammunition is still in T&E phase...lots of moving parts on that side of the house!!

Sincerely,

Theis

Look againDon’t tell anyone on the hide (might get flamed) but I love a bubble level on the mount.

One less piece of gear to get bumped or adjusted.

I’m guessing with the proprietary chassis, one piece action/rail and serious mount I could just level the scope to the mount and not have to worry

I think that he means you missed this picture and angle. I know that I did at first and had to go back and read through the last page to find it:^^^ missing you on that one

either im getting made fun of and dont get it (not the first time)

or im looking at the wrong pictures?

Whats the name of this mount? Jism²?

Looks a lot better and actually fully functional compared to the other spunk mount released this month.

Lol!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 106

- Replies

- 0

- Views

- 490

- Replies

- 0

- Views

- 317