Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

The Shot You’ll Never Forget Giveaway - Enter To Win A Barrel From Rifle Barrel Blanks!

Tell us about the best or most memorable shot you’ve ever taken. Contest ends June 13th and remember: subscribe for a better chance of winning!

Join contest Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ingenuity Powder System

- Thread starter Jsstalli

- Start date

Wow, tbh I don't see why the other thread was locked. I've seen MUCH worse animosity in threads that were allowed to continue. Wonder who bitched about it.Since the original thread went off the rails and got locked can we start a new one with actual info on release dates and news?

Oh well....its 28 Nov so I'm pretty sure that the "ship 1,000 units by end of Nov" is not happening. Actually bit of an understatement.

Cry babies from both sides, dumb that it got locked but oh well. Happy thanksgiving hide!

Dear Mods,

For Christmas and in good faith, can you please unlock my thread?

For Christmas and in good faith, can you please unlock my thread?

I think the message was that this horse is dead, stop beating it.

But, that's just me. I have no dog (or stick) in this hunt.

But, that's just me. I have no dog (or stick) in this hunt.

Why did it get locked?Dear Mods,

For Christmas and in good faith, can you please unlock my thread?

Thread drift? Bitching? No actual valuable information?Why did it get locked?

And I keep using my V4 month after month after...Emailed Paul to get an updated ETA and was told after the first of the year now for first orders to ship out.

If anyone is interested in purchasing the cup:

However, there is a much better one on eBay.

However, there is a much better one on eBay.

That's a great question. The only answer I have is people pointing out the obvious - a product that was heavily promoted as virtually "ready to ship" is still being promoted as virtually "ready to ship" over a year later.Why did it get locked?

I am just a bit disappointed in the lack of updates - it's been a year on the 20th (German timezone) and the pledge to provide regular updates hasn't been upheld. I still like to get this unit since I sold my Super Trickler a year-ish ago in anticipation of this one - but as the saying goes "Everything has been said. Just not by everyone, yet" and I just await the formal mail with the payment link.

to state the obvious, I don't think Paul even knows when he's going to be ready to ship, and even if he thought he did he'd likely be wrong, and just eating his words again in a few months. OTOH, if he told us what was the hold-up, we could make our own reasonable estimates of how long those obstacles might take to overcome. But, he ain't gonna do it. He ain't gonna say, "we have 1500 housings machined, but we're waiting for XYZ, or we had to return a batch of ABC and change subcontractors, or we stumbled on 6 more powders it's struggling with and we're working on a solution for that, or the 3-D printed hopper is having static issues..."

Last edited:

I'd 3D print my own draft shield, if we could get the STL. getting circuit boards made seems to be easier than getting molded plastic parts. Thats just going off of the struggles the Supertrickler had with their molded plastic. I assume/bet a big hold up is on the molded plastic parts, but I was wrong once in 84.

I have a super nice setup. So if it takes to mid year I don’t care. But an update on Facebook or his site every month I think would keep him from getting bugged and having to answer emails. Yeah I know it’s no obligation. But that doesn’t mean you shouldn’t give an update occasionally.

Has Paul figured out the powder issues?View attachment 8563845

Checking out the packaging.

View attachment 8563852

Parts in production.

Soon guys.

N150 is one.

Has Paul figured out the powder issues?

N150 is one.

What is the issue with N150? I assume you are referring to the trickler itself, as no one has the bulk dispenser yet to test?

Yes…the kernels bind agains the side of the trickler and stop the plate from turning…I have some 4350 and varget with odd shaped kernels that does the same thing.What is the issue with N150? I assume you are referring to the trickler itself, as no one has the bulk dispenser yet to test?

I ran some N150 yesterday and it’s was bad I finally just hooked the V3 trickler back up to finish my loading.

I've had Varget and 4350 run perfect, but i've seen issues with XBR which is getting jammed because its too small vs too large.Yes…the kernels bind agains the side of the trickler and stop the plate from turning…I have some 4350 and varget with odd shaped kernels that does the same thing.

I ran some N150 yesterday and it’s was bad I finally just hooked the V3 trickler back up to finish my loading.

Thank you for an honest answer. I wonder if more plates will have to be developed as more people use it with various powders? I also wonder if manufacturers use shape to compensate for other tolerances in a batch to maintain a particular burn speed? I guess it really becomes a problem if/when a powder manufacturer significantly changes kernel dimensions.Yes…the kernels bind agains the side of the trickler and stop the plate from turning…I have some 4350 and varget with odd shaped kernels that does the same thing.

I ran some N150 yesterday and it’s was bad I finally just hooked the V3 trickler back up to finish my loading.

Not sure I just know that the N150 I have is a no go….literally every 3-4 charges jam up I loaded 10 rounds this morning and stopped and used the V3 trickler to finish the other 30…I’ve just started trying VV powders but the kernels remind me of RL powders…15, 16.Thank you for an honest answer. I wonder if more plates will have to be developed as more people use it with various powders? I also wonder if manufacturers use shape to compensate for other tolerances in a batch to maintain a particular burn speed? I guess it really becomes a problem if/when a powder manufacturer significantly changes kernel dimensions.

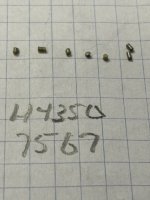

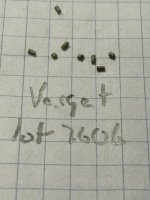

@ma smith this is the first time I’ve seen 4350 and varget like this, all sorts of different sized kernels, its not consistent kernels I’m use to seeing.

The Varget and H4350 I have has been size-consistent, and trickles well. It always seemed to me the disc was made for these sized kernels.@ma smith this is the first time I’ve seen 4350 and varget like this, all sorts of different sized kernels, its not consistent kernels I’m use to seeing.

The XBR cut size is smaller, but more inconsistent. It also seemed to have a mix of sizes like you mention IIRC. I would put the frequency of jams closer to 1:12 to 1:20 round. Whatever is is, it hasn't completly gone away.

I'm wondering if theres some kind of issue with "variable cut sizes"...?

Last edited:

Oh. My. God.

Every system seems to have its Achilles’ heel.

Is the IP going to be no different?

Can it please just meter all Hodgkin powders with a burn rate greater than or equal to VARGET? Please please please

Every system seems to have its Achilles’ heel.

Is the IP going to be no different?

Can it please just meter all Hodgkin powders with a burn rate greater than or equal to VARGET? Please please please

Oh. My. God.

Every system seems to have its Achilles’ heel.

Is the IP going to be no different?

Can it please just meter all Hodgkin powders with a burn rate greater than or equal to VARGET? Please please please

At this price point, yes they all have an Achilles' heel.

I think a lot of the issues with the different systems is that they are built around a particular powder. What works for Varget doesnt work for N570, or H4198, etc.

The Varget and H4350 I have has been size-consistent, and trickles well. It always seemed to me the disc was made for these sized kernels.

The XBR cut size is smaller, but more inconsistent. It also seemed to have a mix of sizes like you mention IIRC.

I would put the frequency of jams closer to 1:12 to 1:20 round. Whatever is is, it hasn't completly gone away.

I'm wondering if theres some kind of issue with "variable cut sizes"...?

I use the same disc for Varget, 4350, 8208, 4831SC, 4895. Everytime I've swapped discs I've swapped back. WAC, Titegroup, and E3 absolutely choke the trickle.

I’ve run H4350, IMR4895, Varget, N140, and N150. Never once have I had the IP trickler jam or bind.Not sure I just know that the N150 I have is a no go….literally every 3-4 charges jam up I loaded 10 rounds this morning and stopped and used the V3 trickler to finish the other 30…I’ve just started trying VV powders but the kernels remind me of RL powders…15, 16.

@ma smith this is the first time I’ve seen 4350 and varget like this, all sorts of different sized kernels, its not consistent kernels I’m use to seeing.

Oh dang n150 is what I’m bout to run next yearYes…the kernels bind agains the side of the trickler and stop the plate from turning…I have some 4350 and varget with odd shaped kernels that does the same thing.

I ran some N150 yesterday and it’s was bad I finally just hooked the V3 trickler back up to finish my loading.

So, it looks like we have reports of the trickler both working great, and having issues with the same powder. In this case N-150.I’ve run H4350, IMR4895, Varget, N140, and N150. Never once have I had the IP trickler jam or bind.

Has anyone ever experienced different lots of the same powder behaving differently in the trickler?

Ok and your point is? I will say that even with the Varget and 4350 occasionally binding the trickler it is still fast and does not happen like it does with the N150 that I have. I am happy with the IP trickler and don't mind using the V3 trickler with the N150 as it meters well.I’ve run H4350, IMR4895, Varget, N140, and N150. Never once have I had the IP trickler jam or bind.

Plus I'm not sure I will continue using the VV powders anyway, I will know for sure next Saturday when I try different primers.

I am assuming your running the 7545 disk?

Last edited:

You see @jimsair is running N150 with no issues in his IP trickler so I would'nt worry about it to much...I think I just get all the odd shit LOL!Oh dang n150 is what I’m bout to run next year

What are you going to run the N150 in?

Oh there is but they are all in my jugs LOL!The Varget and H4350 I have has been size-consistent, and trickles well. It always seemed to me the disc was made for these sized kernels.

The XBR cut size is smaller, but more inconsistent. It also seemed to have a mix of sizes like you mention IIRC. I would put the frequency of jams closer to 1:12 to 1:20 round. Whatever is is, it hasn't completly gone away.

I'm wondering if theres some kind of issue with "variable cut sizes"...?

Loaded 200 last night with h4350 and the 7545 - works great. Clean with alcohol if you’re having troubleOh there is but they are all in my jugs LOL!

Its not that its dirty its that the kernels are odd/different sizes so for sake of an explanation...a small and a medium size kernel get into the same notch and bind against the side of the trickler, it very rarely binds against the wiper, when it does bind I can rotate the bottom trickler wheel forward or backward and it clears itself most times.Loaded 200 last night with h4350 and the 7545 - works great. Clean with alcohol if you’re having trouble

And yes I've tried every disk Paul makes some are a little better and some are a little worse the 7545 works the best for me.

Here’s pictures of some kernels from my current jugs of 4350 and varget....the varget has the same really small kernels like the 4350 so 2 of those will get in the same notch and bind against the housing on the trickler or a small one and gets in then a long one gets in standing up and either binds on the housing or against the wiper but binding against the wiper does not happen very often.

Also with these 2 powders its not a huge deal its no where near as bad as the N150....

Also I am in no way trying to shit on Paul or the IP trickler or system I am just pointing out a few issues I have run into.

Can you guys having no issues check your powder and see if your kernels look the same I am curious to see if I just have the special Charlie Brown lots.

Also with these 2 powders its not a huge deal its no where near as bad as the N150....

Also I am in no way trying to shit on Paul or the IP trickler or system I am just pointing out a few issues I have run into.

Can you guys having no issues check your powder and see if your kernels look the same I am curious to see if I just have the special Charlie Brown lots.

Attachments

Last edited:

The inconsistency in kernel size for Hodgdon powders started during COVID and start of the war in Ukraine. I have jugs of powder prior that are very consistent and anything I have purchased in the last few years has had some inconsistencies in kernel size. Nothing that has impacted the performance of the trickler. RL26 for me has been one of the worst in kernel size but that shouldn’t be a problem for most since it’s no longer being sold to the public. I don’t run VV powders so I can’t comment on it.

For @LR1845 I would recommend using up that lot or sell it and buy new stuff. It looks like you got stuck with a Lot of powder with inconsistencies and there is not much that can be done about it.

For @LR1845 I would recommend using up that lot or sell it and buy new stuff. It looks like you got stuck with a Lot of powder with inconsistencies and there is not much that can be done about it.

25gtYou see @jimsair is running N150 with no issues in his IP trickler so I would'nt worry about it to much...I think I just get all the odd shit LOL!

What are you going to run the N150 in?

I believe you are correct and like I said this is the first time in 21yrs I have seen Hodgdon powders like this, normally very consistent kernel size.The inconsistency in kernel size for Hodgdon powders started during COVID and start of the war in Ukraine. I have jugs of powder prior that are very consistent and anything I have purchased in the last few years has had some inconsistencies in kernel size. Nothing that has impacted the performance of the trickler. RL26 for me has been one of the worst in kernel size but that shouldn’t be a problem for most since it’s no longer being sold to the public. I don’t run VV powders so I can’t comment on it.

For @LR1845 I would recommend using up that lot or sell it and buy new stuff. It looks like you got stuck with a Lot of powder with inconsistencies and there is not much that can be done about it.

Not sure how the N150 going to do in the 25GT my buddy @John Glidewell is running a 25GT right now and pretty much uses VV powders exclusively maybe he can chime in here with what hes running.25gt

Similar threads

- Replies

- 7

- Views

- 322

- Replies

- 92

- Views

- 3K