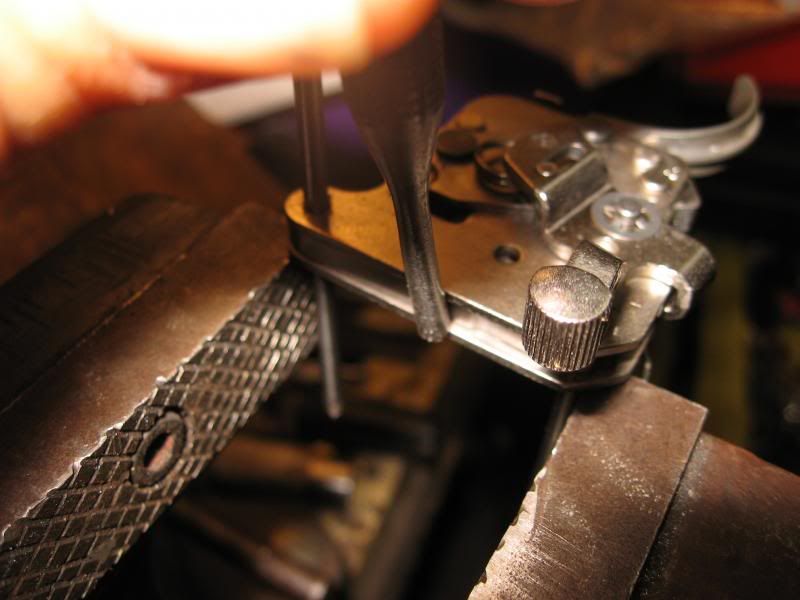

I just installed a Jewell HVR on my Remington 700. Initially the inside of the manners stock had to be cut back in order to allow the safety tang to function smoothly and not "hang". Resolved in short order with a Dremel Tool.

My issue now is that the trigger will fire when the bolt is closed (if the safety is off). If the gun is not put back on safety between each bolt cycle the firing pin will "fire" when the bolt is closed. Upon closer inspection I've found that by placing the gun on "safe" the firing pin block is pushed back into the proper position - if not it stays "down".

For a single shot or for the first initial shot this would not be an issue, however, if taking a string of shots the gun would have to be placed on safety between every shot. If it isn't then I'm certain it would "slam fire" when closing the bolt.

Can anyone give some advice or guidance on how to resolve the issue? What am I missing?

-I've attempted to clean it (without taking the assembly COMPLETELY apart).

-I've checked the sear engagement

-I've checked the over travel

-I've checked the trigger weight

Thanks

My issue now is that the trigger will fire when the bolt is closed (if the safety is off). If the gun is not put back on safety between each bolt cycle the firing pin will "fire" when the bolt is closed. Upon closer inspection I've found that by placing the gun on "safe" the firing pin block is pushed back into the proper position - if not it stays "down".

For a single shot or for the first initial shot this would not be an issue, however, if taking a string of shots the gun would have to be placed on safety between every shot. If it isn't then I'm certain it would "slam fire" when closing the bolt.

Can anyone give some advice or guidance on how to resolve the issue? What am I missing?

-I've attempted to clean it (without taking the assembly COMPLETELY apart).

-I've checked the sear engagement

-I've checked the over travel

-I've checked the trigger weight

Thanks