Recently bought a KRG Whiskey-3 Comp pack. First time installing the spigot to the chassis, found the spigot is not super align with the barrel tunnel.

Contacted KRG, sent it back, and they fixed it. All good! I can't be more happy with their CS.

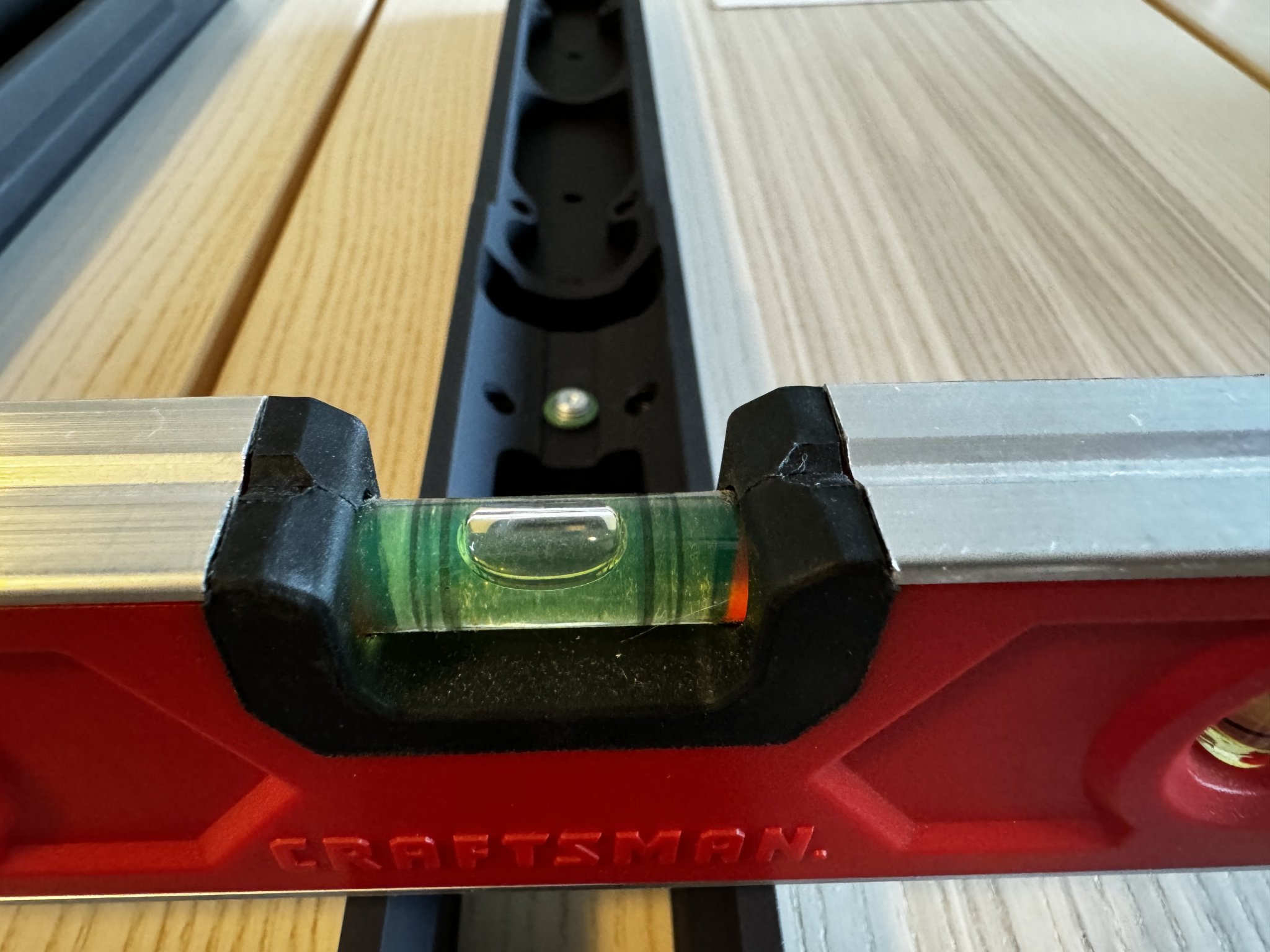

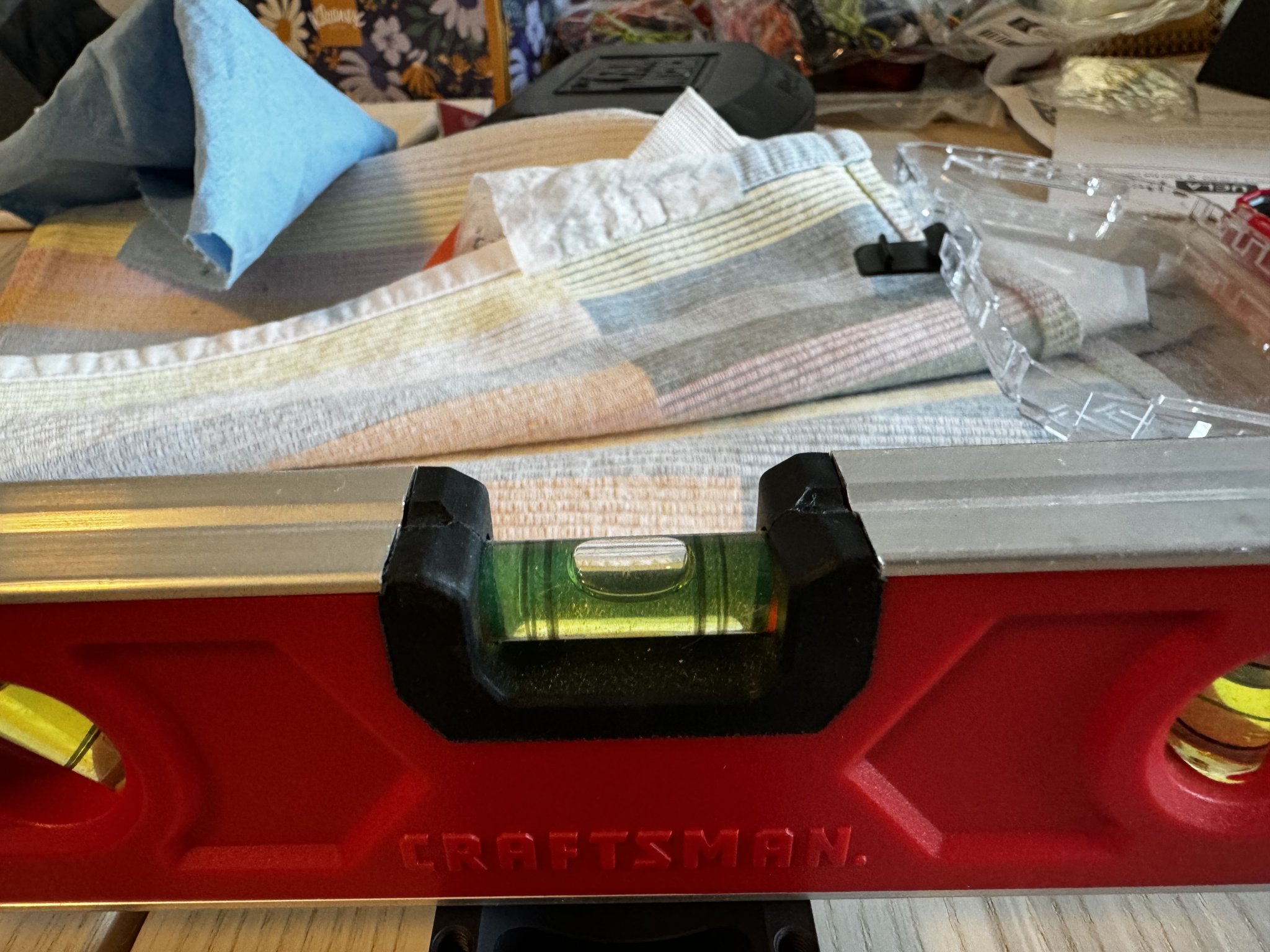

However, my initial guess on the misalignment is due to something wrong with the backbone, like the angular error. I did put a bubble measure on different parts of the backbone and can confirm the backbone is twisting counterclock-wise from rear to the front. This tilt is still present after their service. I did measure the forend and the backbone separately today, both of them have this counterclock-wise twist.

Forend Rear

Forend Rear

Forend Front

Forend Front

Backbone Rear

Backbone Rear

Backbone Front

Backbone Front

I know the chassis, though precision machined, is not holding as tight tolerance as the action or the barrel. But is this type of twist considered normal in machining tolerance? or I'm just being too perfectionist?

If you folks have the KRG chassis, especially W3, and a bubble level on hand, would you mind measuring yours as well?

Contacted KRG, sent it back, and they fixed it. All good! I can't be more happy with their CS.

However, my initial guess on the misalignment is due to something wrong with the backbone, like the angular error. I did put a bubble measure on different parts of the backbone and can confirm the backbone is twisting counterclock-wise from rear to the front. This tilt is still present after their service. I did measure the forend and the backbone separately today, both of them have this counterclock-wise twist.

I know the chassis, though precision machined, is not holding as tight tolerance as the action or the barrel. But is this type of twist considered normal in machining tolerance? or I'm just being too perfectionist?

If you folks have the KRG chassis, especially W3, and a bubble level on hand, would you mind measuring yours as well?

Last edited: