When I went to Remingtons Armorer School circa 1994 I asked the head smith why they used a long action. I was told it was because the Army wanted to possibly chamber in 300wm. No mention of 30-06 was ever mentioned

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lets argue about the M24

- Thread starter Zigjib

- Start date

I read an article once that the reason we have the 65 in/lbs standard for action screws is because of the M24's HS Precision stock. The story goes that during testing they found that the rifle got the best accuracy with the action screws torqued to something in the low 60 in/lb range but at the time there wasn't a fixed torque wrench that met that setting. Seekonk had a 65 in/lbs torque wrench and they determined that there wasn't a significant reduction in accuracy going to 65 so that's how that came to be. As the civilian world so much likes to emulate what the military does, people started torquing action screws to 65 in/lbs and here we are. I'm paraphrasing the article from memory but it seems plausible, if not a little bit lore-like.

c'mon...I'm sure we can get a couple more good kicks in on this horse.

c'mon...I'm sure we can get a couple more good kicks in on this horse.

That may be right, but if I may digress a little bit to a 1981 article in the defunct Gung-Ho magazine on the then new USMC M40A1, it also specifies 65 in/lbs for the action screws.I read an article once that the reason we have the 65 in/lbs standard for action screws is because of the M24's HS Precision stock

…and here’s the voodoo part…

…just a random digression re this arcane topic.

For clarification, the dead horse I was referring to is the 30-06/M72 myth regarding the M24.

c'mon...I'm sure we can get a couple more good kicks in on this horse.

…the M24 rifle itself deserves a few more kicks, cause it’s a great vintage sniper rifle with a rich history. Kick away…

Last edited:

That's a cool article, I liked the part in the second column where they talked about adjusting the torque pressure to dial the rifle in to shoot 1 MOA at 300 yards. One thing I've always found interesting was the polar opposite position the two branches took when it came to what snipers could and couldn't do with the rifles. In the Army, I was provided parts and tools to do user level maintenance on the M24 just short of rebarreling it but my understanding is that in the USMC the sniper could basically remove the bolt from the rifle for cleaning and that was about it. I guess that little tid bit there sheds some light on that because if some grunt messes with the action screw torque taking it out of the stock then it could impact that rifle's accuracy.

One thing I've always found interesting was the polar opposite position the two branches took when it came to what snipers could and couldn't do with the rifles. In the Army, I was provided parts and tools to do user level maintenance on the M24 just short of rebarreling it but my understanding is that in the USMC the sniper could basically remove the bolt from the rifle for cleaning and that was about it.

That is true. My theory? Glass-bedding.

The M40A1/A3/A5 McMillan stocks were carefully glass bedded to the Remington actions by USMC MOS 2112s (Precision Weapon Armorers) beginning in the late 1970s. The sniper was not allowed to remove it from the stock - only an RTE/PWS trained USMC 2112 was authorized to remove the action. Not even the 2111s were allowed to mess with the USMC sniper rifles - only the 2112s, who had been trained on the tedious art of the glass-bedding processes. (Note: this also applied to the glass-bedded USMC M14 DMR rifles - per the manual, only a 2112 was supposed to remove the action from the stock). That’s the difference in philosophy.

In contrast, the US Army M24 was mounted in basically a “v-block” within the HS Precision stock. There is no bedding involved. So removing it won’t mess-up any bedding or related hand-fitting. Remington did the major work, but as you noted, the M24 came with proper tools for field Maintenance by the sniper, as needed. The kit for the M24 was VERY different from the M40A1/3/5 - including that SeekOn T-shaped torque wrench set at 65 inch/lbs:

Last edited:

When we were getting trained on the M24 we didn't have time to go into the history of the rifle or why things were what they were so it's been fun to research it over the years. Other than the long action receiver I believe the M24 was a well thought out system for the day but it's also interesting to note that in the lifespan of the M24 it was largely unchanged while the M40 went through A1, A3, and in to the A5 iterations. There was the M24A2 that would've caught up a bit but that wasn't official so there was no widespread distribution of that upgrade before the Army nixed it but they were trying.

it's also interesting to note that in the lifespan of the M24 it was largely unchanged while the M40 went through A1, A3, and in to the A5 iterations. There was the M24A2 that would've caught up a bit but that wasn't official so there was no widespread distribution of that upgrade before the Army nixed it but they were trying.

Well, the procurement lifecycle for Big Army is pretty long, measured in years, two at a minimum. (The M24 procurement process lasted from 1986-1988, with the rifles finally procured in volume in 1989). In contrast, the USMC had been recycling their old 1966 era M40 receivers with the A1/A3/A5s, and buying new replacement receivers ad hoc without any "free and open competition" as the new M700 receivers were just replacement parts from a procurement perspective. So the USMC had some flexability since it has the authority to build sniper rifles in-house (at PWS via 2112s). No unit in Big Army has the authority to make or modify combat weapon systems. TACOM is the one exception, and I don’t think they are reluctant to approve any modifications to combat weapons in an ex post facto manner. (Crane is the other entity with authority to modify or manufacture SOCOM weapons). So any changes to the M24 required Big Army to formally/contractually work it out with Big Green (aka Remington Arms/Remington Defense).

That said, the USMC didn't get the M40A5 until 2009, which finally introduced a box magazine and a sound suppressor. Big Army wasn't far behind, as they had just adopted XM2010s the following year (2010), which had the box magazine and sound suppressor, but also a very advanced Leupold optic system and in 300 WinMag for a 1500 meter effective range. My suspicion is that while Remington Defense was presumably promoting the M24A2 in the 2004-2007 era, their might have been an underlying desire by some knowledgeable Army folks to just go ahead and update all the rifles to 300 WinMag, since all the SOCOM guys (including Army Rangers) really liked those MK 13 rifles in 300 WIn Mag. Remington also developed the M24A3 concept in 338 Lapua, but that apparently didn’t get traction with Big Army.

In addition to that desire for 300 WinMag, the second generation 300 WinMag cartridge's with a 1500 meter effective range was in development at Crane in the late 200Xs (Mk 248 Mod 1, which came out in 2009). So, I'm guessing Remington Defense and Big Army worked out the "big bang" upgrade path in the late 200Xs, resulting in the M2010, rather than incremental changes like the USMC did with the M40A3 to A5 update. That's my theory at least, but as I noted, the volume and procurement life cycles for Big Army are long and likely more complicated than the USMC deciding internally to update the M40Ax to a different version. In contrast, Crane only has one Procurement office and they can create their own local NSNs, so they have the quickest procurement life cycle in the military. In basically one decade Crane/SOCOM made the Mk 13 Mod 0/1/2/3/5...but Big Army of course doesn't work like that....

Last edited:

Some notes concerning bullet selection from earlier in the thread…

Every one seems baffled why the 190/220 SMKs were selected for the Mk248 loads over so many other options that seem to have such obvious advantages in B.C.

The short answer is that one has to get their nose out of the ballistic charts, off the reloading bench, away from the flat range and into the field. The gains of modern VLD projectiles over older BTHP is factual but in reality is marginal to the Sierra Match Kings tolerance and consistency in regards to accuracy and precision particularly through the progression of the barrels life.

Anyone who’s spent enough time playing with SMKs for load development will come to the realization that you can pretty much fill a case with H1000 and slap a SMK on top and you’ll have a respectable .300WM load.

Ok Yes some exaggeration here, but not that far off . A lot of these “choice” VLD bullets require a little bit more attention to development a load that is consistent and stable across a massive range of conditions, in 1000s of rifles, all across various arcs of their life spans. So much so, it’s actually not feasible (circa 2000s), and don’t get me started about solids like the 198 Flatlines.

. A lot of these “choice” VLD bullets require a little bit more attention to development a load that is consistent and stable across a massive range of conditions, in 1000s of rifles, all across various arcs of their life spans. So much so, it’s actually not feasible (circa 2000s), and don’t get me started about solids like the 198 Flatlines.

Simply put VLDs wins on the ballistic tables, it wins points and matches but reality is a good-ish SMKs was a superior strategy for fielding in mass during the Mk248 development timeframe.

Every one seems baffled why the 190/220 SMKs were selected for the Mk248 loads over so many other options that seem to have such obvious advantages in B.C.

The short answer is that one has to get their nose out of the ballistic charts, off the reloading bench, away from the flat range and into the field. The gains of modern VLD projectiles over older BTHP is factual but in reality is marginal to the Sierra Match Kings tolerance and consistency in regards to accuracy and precision particularly through the progression of the barrels life.

Anyone who’s spent enough time playing with SMKs for load development will come to the realization that you can pretty much fill a case with H1000 and slap a SMK on top and you’ll have a respectable .300WM load.

Ok Yes some exaggeration here, but not that far off

Simply put VLDs wins on the ballistic tables, it wins points and matches but reality is a good-ish SMKs was a superior strategy for fielding in mass during the Mk248 development timeframe.

10th Mountain Division was fortunate in that the US Army Special Operations Command small arms requirements guy left Bragg around 2007 for Fort Drum (after he wrote USASOC's requirements document) and knew Defense Acquisition ABCs.My suspicion is that while Remington Defense was presumably promoting the M24A2 in the 2004-2007 era, their might have been an underlying desire by some knowledgeable Army folks to just go ahead and update all the rifles to 300 WinMag, since all the SOCOM guys (including Army Rangers) really liked those MK 13 rifles in 300 WIn Mag. Remington also developed the M24A3 concept in 338 Lapua, but that apparently didn’t get traction with Big Army.

In addition to that desire for 300 WinMag, the second generation 300 WinMag cartridge's with a 1500 meter effective range was in development at Crane in the late 200Xs (Mk 248 Mod 1, which came out in 2009). So, I'm guessing Remington Defense and Big Army worked out the "big bang" upgrade path in the late 200Xs, resulting in the M2010, rather than incremental changes like the USMC did with the M40A3 to A5 update. That's my theory at least, but as I noted, the volume and procurement life cycles for Big Army are long and likely more complicated than the USMC deciding internally to update the M40Ax to a different version. In contrast, Crane only has one Procurement office and they can create their own local NSNs, so they have the quickest procurement life cycle in the military. It's measured in just a few months in some cases.

Outside of USASOC the Leg Army had a need but no formal written requirement to keep bolt actions or to upgrade to 300 Win Mags -- until he wrote them and the 10th Mountain Division Commanding General signed the letters and sent them to Forces Command, starting the ball rolling.

USASOC had already re-chambered a number of their rifles and were using SOCOM (Crane contract) ammunition.

The result was XM-2010. M24A3 (in 338 Lapua) was Remington's submission for the USSOCOM Precision Sniper Rifle, which won but SOCOM cancelled because the SEALs were invested in 300 Win Mag. Note the Army never spec-ed 300 Win Mag -- they simply adopted SOCOM's load as Army standard (the two types are Navy "Marks" (certified by Crane) and not Army "Models" or "M-s". Mark 248 was standardized in 1999, and MK 248 Mod 1 was certified in March 2009.

November 2010:

USSOCOM has service-like Research and Development and buying power, and their R&D and certification process is much shorter because they don't have to outfit 12 divisions. Their system is why Leg Army is always playing catch-up for things like Gore-Tex; Panama sole jungle boots; MICH helmets; the M4 carbine and SOPMOD gadgets; hard armor plates; Peltor and MSA headsets; MBITR and PRC-117 (ASIP) radios; Multicam uniforms; and a whole train-load of other projects-turned standard issue.

Last edited:

Maybe. Every coffin had a small pelican case that had some parts in in like previously mentioned. I remember my Warrant said when the guns go back for refit (new barrel) everything had to go as a system. And I asked him why there was a wm bolt in the kit. He said the army may switch to that caliber. I said it was stupid to include a bolt for a barrel that wasn’t available.Perhaps you got a unicorn at your unit but I can only go by my experience and our unit never issued the M24's with an extra bolt assembly in .300WM and nothing of the like was mentioned in the TM, no line item or NSN was available for just the bolt assembly.

I’m sure that after awhile the bolts disappeared so that’s probably why you guys didn’t see any. This was when the M24 was fairly new.

100% the SMK are similar to a football and are very easy to tune. VLD on the other hand shoot great but sometimes when you increase the jump as in from a worn barrel they go down hill quick.Some notes concerning bullet selection from earlier in the thread…

Every one seems baffled why the 190/220 SMKs were selected for the Mk248 loads over so many other options that seem to have such obvious advantages in B.C.

The short answer is that one has to get their nose out of the ballistic charts, off the reloading bench, away from the flat range and into the field. The gains of modern VLD projectiles over older BTHP is factual but in reality is marginal to the Sierra Match Kings tolerance and consistency in regards to accuracy and precision particularly through the progression of the barrels life.

Anyone who’s spent enough time playing with SMKs for load development will come to the realization that you can pretty much fill a case with H1000 and slap a SMK on top and you’ll have a respectable .300WM load.

Ok Yes some exaggeration here, but not that far off. A lot of these “choice” VLD bullets require a little bit more attention to development a load that is consistent and stable across a massive range of conditions, in 1000s of rifles, all across various arcs of their life spans. So much so, it’s actually not feasible (circa 2000s), and don’t get me started about solids like the 198 Flatlines.

Simply put VLDs wins on the ballistic tables, it wins points and matches but reality is a good-ish SMKs was a superior strategy for fielding in mass during the Mk248 development timeframe.

A former US Army sniper who graduated from Ft Benning's sniper school in 2009 had to turn in his M24 in 2010 for it to be converted into an M2010. In 2015 he provided me with his old tool kit for my M24R. It came with two of basically everything. (The plastic bag behind the small Pelican case has 2 of all small parts except the torque wrench). It didn't come with two bolts, but definitely had 2 firing pin assemblies. Just my observation re extra parts...Maybe. Every coffin had a small pelican case that had some parts in in like previously mentioned.

Last edited:

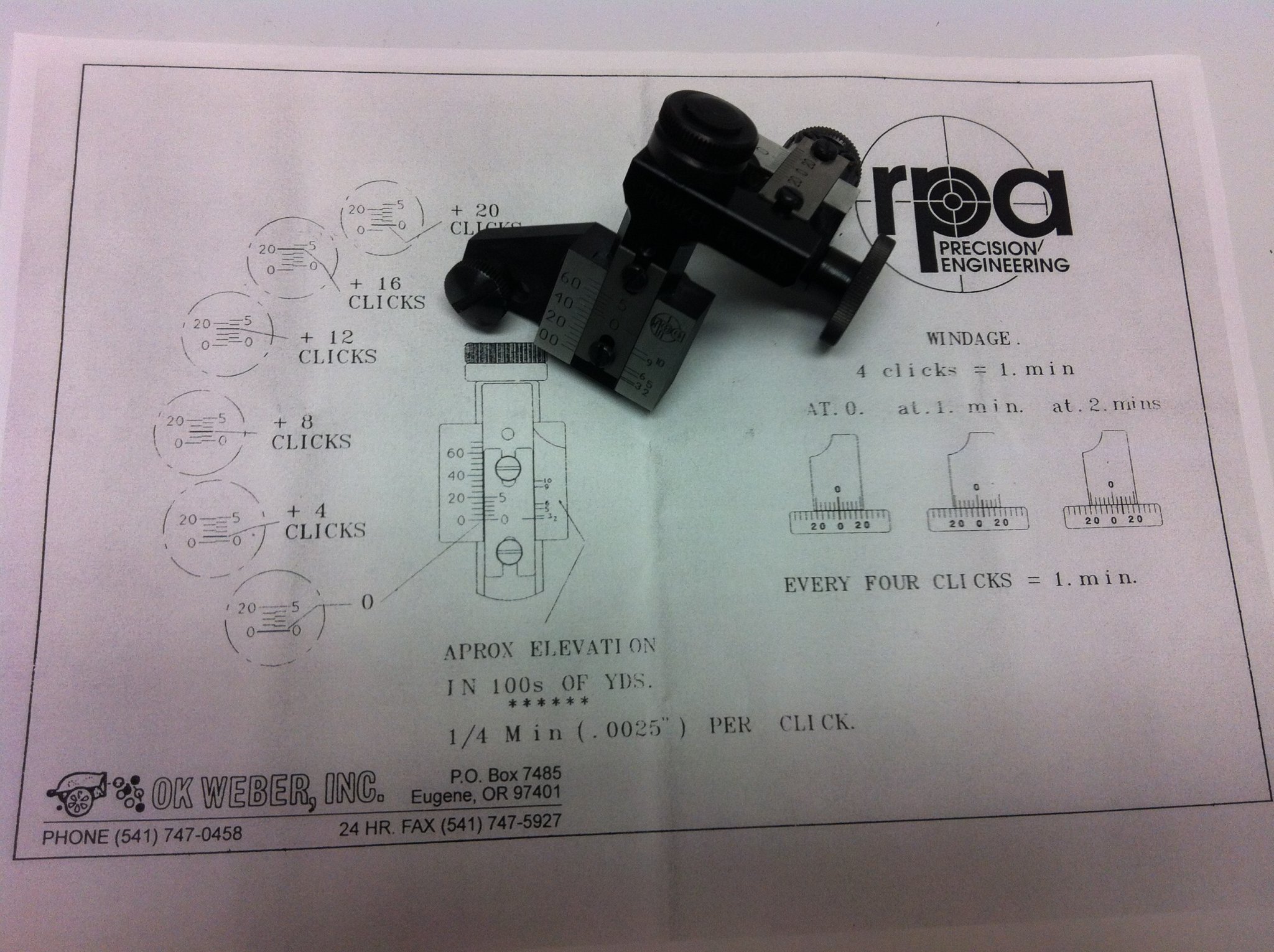

Yea, back in 2015 or 16 I got lucky and bought the last RPA sight set that the late Mr Weber had. (He thought they were long gone when I called him, but he found one last set, and contacted me). He told me that it has a steel base and was leftover from the Army's M24 program. The current ones made in the UK have an aluminum base. I got the instruction sheet from the UK. I spent a while hunting for these misc M24 goodies.

Last edited:

I know the guy who was the action officer on the M24, LTC Nate Miller USA Retired. That means he specked the rifle. He wanted to chamber it in 300 Win Mag. The Army would not let him. The round was not "proven" they told him. He knew that sooner or later the Army would see the light, he used the long action so that when they did a new action would not be required. In 2010 out comes the new rifle in guess what, 300 Win Mag.

That was a good article from the Infantry museum . SFC William Knox, the first NCOIC of the Army sniper school after Viet Nam was a friend of mine. I did an obit for him on this forum. He was a good man.

Non sniper, issued an m24 in 08-11". I was a CBTRY 1/37 "SDM". PFC Warner and I both got a m24 from 1-23 INF Recon section. I know they got the new 110's and i dont know what bolt guns they upgraded too. I wish I had pictures of them.

Both black HS stocks. Warners had scuffed horrendously green camo. Mine looked less well used then him, I painted Mine tan and brown. That's what supply had. Did it infront of the barracks And my team SGT came by and walked away. Painting was a no no haha.

Mine had a new in plastic and paper wrapped 473 bolt in 308. It only had one firing pin spare and didn't have the torque wrench. Thankfully I had a extensive "cleaning kit" at the time.

The D kit was mostly complete. Not sure what iron sights it had but they were zerod and worked. Every time we shot the it would hold 1 moa for the most part.

Both black HS stocks. Warners had scuffed horrendously green camo. Mine looked less well used then him, I painted Mine tan and brown. That's what supply had. Did it infront of the barracks And my team SGT came by and walked away. Painting was a no no haha.

Mine had a new in plastic and paper wrapped 473 bolt in 308. It only had one firing pin spare and didn't have the torque wrench. Thankfully I had a extensive "cleaning kit" at the time.

The D kit was mostly complete. Not sure what iron sights it had but they were zerod and worked. Every time we shot the it would hold 1 moa for the most part.

Did Not build a M24, but I have 8 308s and one is a long action 30" 8 twist barrel in an aluminum chassis, with detachable mags with 3.4" cartridge overall length. Built for newer high BC bullets like, 200 SMK .715 at 2856 fps, 225 ELDM 2675 fps, or 230 SMK .8 BC and .823 BC 230 Atip at 2620 fps.

If ya like 22" barrels it shoots the 715 BC 200 gr SMK 2740 fps this is a 9 twist, required for this bullet. Never found the 198 Flatline 308 bullet available, to even try. Heavy bullets give up less velocity than lighter bullets in short barrels...

This should give you an idea of what a long action 308 will do and still feed out of the detachable mags, with more extended range, flatter trajectory, and more energy, with less wind drift. A Long action has benefits.

If ya like 22" barrels it shoots the 715 BC 200 gr SMK 2740 fps this is a 9 twist, required for this bullet. Never found the 198 Flatline 308 bullet available, to even try. Heavy bullets give up less velocity than lighter bullets in short barrels...

This should give you an idea of what a long action 308 will do and still feed out of the detachable mags, with more extended range, flatter trajectory, and more energy, with less wind drift. A Long action has benefits.

I saw an M24 chambered in 7mag. The team was high up in the pecking order of counter-sniper teams.

I recall Marty at Badger Ordinance said he converted a M24 to 7mm Mag through a special request from a unit in the Army. He completed it and sent it back to them only to get threatened with legal action. He said he kept copies of the request which saved his butt.

Last edited:

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 29

- Views

- 1K

- Replies

- 8

- Views

- 2K