That will likely compress the hell out of it.Its to be 20 MB or less, or you can always send it through Facebook Messenger to us as well.

-Anthony

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MDT ACC Elite

- Thread starter Davehc130

- Start date

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Likely, but for the most part, we can still see what we need to.That will likely compress the hell out of it.

-Anthony

I may not work for the CSIS, but nevertheless, I don’t have Facebook either.

I’m currently conversing with the gentleman from your support desk who has recommended I pull the springs out of the mechanism to see if that suddenly fixes the issue about being able to properly torque down the thumb screw.

To be honest, I kind of find that to be more than a little kludgy. I’ll do it for testing purposes, but that’s not a great solution.

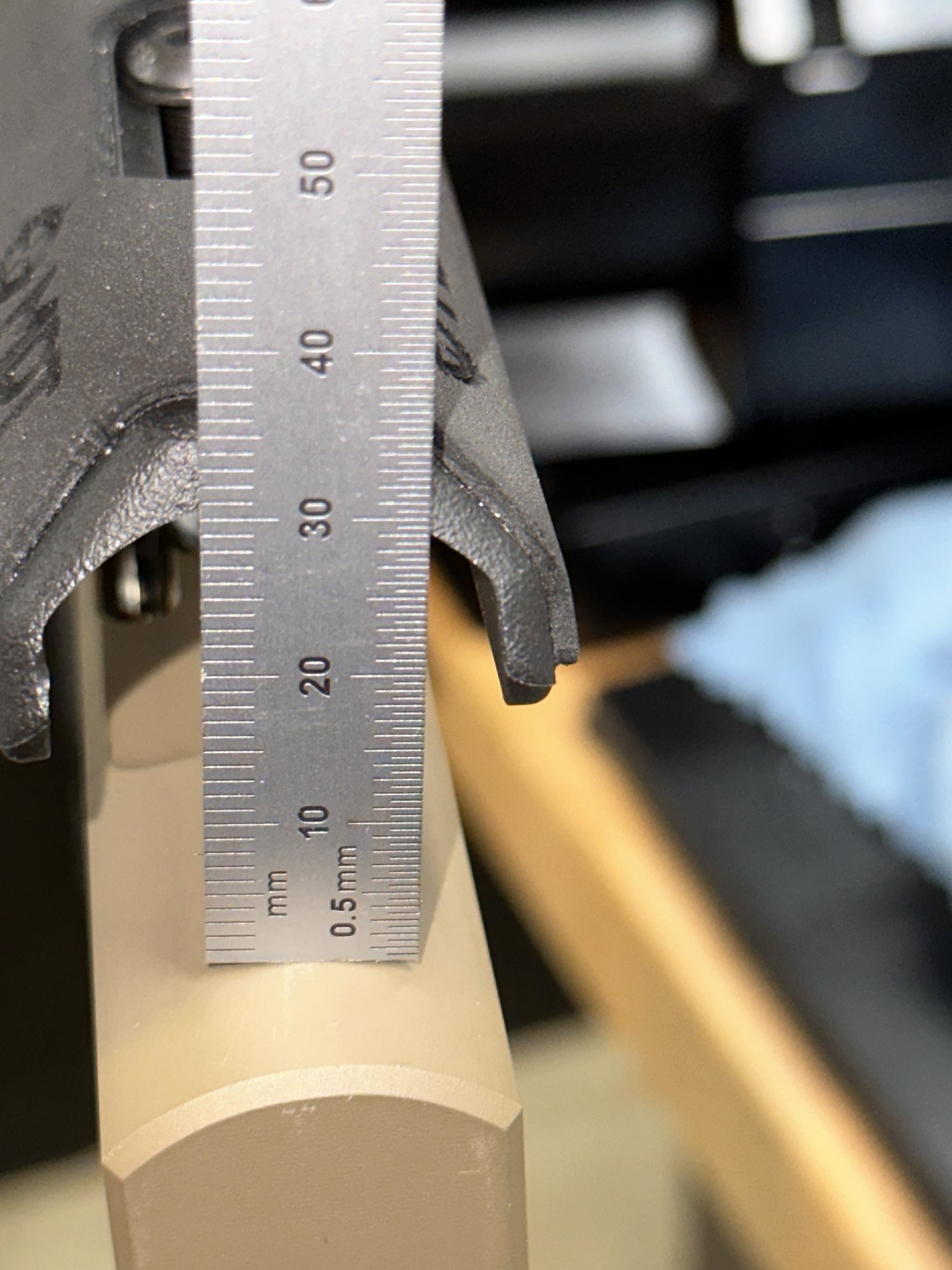

Part of the problem is likely because the bottom part of the cheek piece studs is not treaded for what appears to be about 1 to 2 mm. My suspicion is that it gets stuck into the mechanism, preventing it from being able to properly grab the studs, and requiring enough extra pressure that it’s probably not good for the overall mechanism.

I’m currently conversing with the gentleman from your support desk who has recommended I pull the springs out of the mechanism to see if that suddenly fixes the issue about being able to properly torque down the thumb screw.

To be honest, I kind of find that to be more than a little kludgy. I’ll do it for testing purposes, but that’s not a great solution.

Part of the problem is likely because the bottom part of the cheek piece studs is not treaded for what appears to be about 1 to 2 mm. My suspicion is that it gets stuck into the mechanism, preventing it from being able to properly grab the studs, and requiring enough extra pressure that it’s probably not good for the overall mechanism.

Last edited:

I’m a millennial of course I do.@TheOE800 - you have FB acct? Perhaps you can send @GBMaryland vid to MDT?

If you're at the point at which you're trying to use the very last grooves on the cheekriser rods, then you're definitely running your cheekriser SUPER high! This is not a case that we ran into anytime during the chassis/buttstock development, so I am intrigued on your optic, base and ring height setup that requires you to run the cheekriser so high?I may not work for the CSIS, but nevertheless, I don’t have Facebook either.

I’m currently conversing with the gentleman from your support desk who has recommended I pull the springs out of the mechanism to see if that suddenly fixes the issue about being able to properly torque down the thumb screw.

To be honest, I kind of find that to be more than a little kludgy. I’ll do it for testing purposes, but that’s not a great solution.

Part of the problem is likely because the bottom part of the cheek piece studs is not treaded for what appears to be about 1 to 2 mm. My suspicion is that it gets stuck into the mechanism, preventing it from being able to properly grab the studs, and requiring enough extra pressure that it’s probably not good for the overall mechanism.View attachment 8176104

If this is a common occurrence, we can always look at building extenders for the cheekriser, but this is a first for me!

- Josh

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

For right now, since we haven't seen this issue, we are exploring the possibilities, so it's just ruling out there isn't an issue that is causing it to bind or the spring rate is too high to overcome.I’m currently conversing with the gentleman from your support desk who has recommended I pull the springs out of the mechanism to see if that suddenly fixes the issue about being able to properly torque down the thumb screw.

-Anthony

I sent the OE800 the video... mayhaps the younger crowd can post it for you.I’m a millennial of course I do.

ARC 1.5in 34mm 20moa mount, S&B 6-36x56 PM IIIf you're at the point at which you're trying to use the very last grooves on the cheekriser rods, then you're definitely running your cheekriser SUPER high! This is not a case that we ran into anytime during the chassis/buttstock development, so I am intrigued on your optic, base and ring height setup that requires you to run the cheekriser so high?

If this is a common occurrence, we can always look at building extenders for the cheekriser, but this is a first for me!

- Josh

And while those are high rings they are not unusually high and, IMO, they are not a corner of the operating envelope case.ARC 1.5in 34mm 20moa mount, S&B 6-36x56 PM II

And the tube is 34mm and not 36 like a ZCO so there is an extra mm compared to that big tube scope.

It's not necessarily the height of the scope that is surprising to us, as you're right, 1.50" high rings are fairly standard. The very surprising part is that we intentionally raised the buttstock height to be more in line with the bore, and as such, the minimum/maximum height of the cheekriser also shifted upwards 0.5 in or so. That being said, everyone runs their rifles a little different and everyone has different preferences, so we're working on a solution to raise the maximum height just that little bit more!And while those are high rings they are not unusually high and, IMO, they are not a corner of the operating envelope case.

And the tube is 34mm and not 36 like a ZCO so there is an extra mm compared to that big tube scope.

- Josh

Springs multiple? I removed the knob of my riser assembly (and the spring it compresses) to pull out the locking clamp with the two studs and flipped its orientation. Without getting back on the range I think my problems are mitigated; however, you’ll notice the cheek piece is adjusted as rearwards as it will go and this leaves the rear fairly unsupported thus prone to flex. So there’s @GBMaryland and his wobble issue, but also the issue of innate flex IMO. P

It’s sent.I sent the OE800 the video... mayhaps the younger crowd can post it for you.

Last edited:

@GBMaryland and I both have high super model cheekbones so we need a high comb.It's not necessarily the height of the scope that is surprising to us, as you're right, 1.50" high rings are fairly standard. The very surprising part is that we intentionally raised the buttstock height to be more in line with the bore, and as such, the minimum/maximum height of the cheekriser also shifted upwards 0.5 in or so. That being said, everyone runs their rifles a little different and everyone has different preferences, so we're working on a solution to raise the maximum height just that little bit more!

- Josh

Don't hate us because we are beautiful! LOLOLOL And if you ever actually saw me you would know how funny that line is! haha

Cheers and look forward to seeing the solution you come up with.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Can I hate you for something else? Kidding!@GBMaryland and I both have high super model cheekbones so we need a high comb.

Don't hate us because we are beautiful! LOLOLOL And if you ever actually saw me you would know how funny that line is! haha

Cheers and look forward to seeing the solution you come up with.

Josh is hard at work on it, so give us some time. We can also send you the rods from the LOP portion in the meantime, as they are slightly longer, and it may make up the difference for you.

-Anthony

Sure...why not...everybody else does! hahahaCan I hate you for something else?

As for LOP rods, not for me....but perhaps @GBMaryland would like to try them as interim solution. And I believe @TheOE800 has same issue but perhaps to a lesser extent after he reversed the orientation of the mechanism. Both GB and TheOE are home boys to me.

Me....I'm planning to buy another chassis soon, looked at and handled @GBMaryland 's and compared it to another top shelf chassis that he has, and I really liked the ACC Elite more.

But, I do need a very high comb...really higher than most folks I know of. Hence my keen interest.

Thanks for the reply....I've always found you guys to be very responsive here on the Hide and for the few inquiries I've sent to MDT on other subjects.

Cheers

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Hmm, so many things to choose from, then...Sure...why not...everybody else does! hahaha

As for LOP rods, not for me....but perhaps @GBMaryland would like to try them as interim solution. And I believe @TheOE800 has same issue but perhaps to a lesser extent after he reversed the orientation of the mechanism. Both GB and TheOE are home boys to me.

Me....I'm planning to buy another chassis soon, looked at and handled @GBMaryland 's and compared it to another top shelf chassis that he has, and I really liked the ACC Elite more.

But, I do need a very high comb...really higher than most folks I know of. Hence my keen interest.

Thanks for the reply....I've always found you guys to be very responsive here on the Hide and for the few inquiries I've sent to MDT on other subjects.

Cheers

No worries, we're happy to do it, I did ask it to be stackable if you really need so I guess we're moving in the right direction.

-Anthony

Like I said, I think my wobble is mostly resolved and I run my cheek riser probably lower than @GBMaryland as I simply have a smaller build and wide rather than high cheekbones. That said, with the rods more solidly retained in the clamp I’m able to create deflection in the riser as pretty much half of it is unsupported once adjusted all the way rearward, as would be common to most any short action.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Fair; our idea for the highest position is actually probably going to help you out with that as well.Like I said, I think my wobble is mostly resolved and I run my cheek riser probably lower than @GBMaryland as I simply have a smaller build and wide rather than high cheekbones. That said, with the rods more solidly retained in the clamp I’m able to create deflection in the riser as pretty much half of it is unsupported once adjusted all the way rearward, as would be common to most any short action.

-Anthony

… So I took it apart and I don’t see any springs, plural.

Removing the individual spring makes no difference whatsoever… unfortunately.

Removing the individual spring makes no difference whatsoever… unfortunately.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Best to keep it in the e-mail so we have a direct line of communication, but swap the spring. There is one on the LOP as well; swap their positions.@MDT_OFFICIAL Any thoughts?

-Anthony

For anyone wondering about the bag riders from Australian Tactical Precision, here they are. Aluminum so they're lightweight.

I ordered 3 of the largest sizes. Shipping was 5 days from Australia.

Fit was perfect and is now completely parallel to the forearm.

I ordered 3 of the largest sizes. Shipping was 5 days from Australia.

Fit was perfect and is now completely parallel to the forearm.

So you got one for me and one for @GBMaryland ?For anyone wondering about the bag riders from Australian Tactical Precision, here they are. Aluminum so they're lightweight.

I ordered 3 of the largest sizes. Shipping was 5 days from Australia.

Fit was perfect and is now completely parallel to the forearm.

View attachment 8180844

View attachment 8180840View attachment 8180843

So the official deal with the spring is that it didn’t work at all…Best to keep it in the e-mail so we have a direct line of communication, but swap the spring. There is one on the LOP as well; swap their positions.

-Anthony

what seems to be going on is the lip on the bottom of the threads for the cheek piece posts is getting caught in the mechanism, preventing it from allowing the proper tightening of the mechanism.

Support is sending me the posts from the LOP adjuster, and we’re gonna try those on the cheek piece…

Fair; our idea for the highest position is actually probably going to help you out with that as well.

-Anthony

I finally got the pins from the what of the stock, and they are sufficiently longer to the point where they absolutely allow proper adjustment via the thumbscrew.

100% solves the problem.

No, what’s more interesting, is that the pins actually recess perfectly into the cheek piece part of the stock. Honestly, MDT could machine one set of pins, and it would work for both functions and give you more height of the cheek piece/comb.

100% solves the problem.

No, what’s more interesting, is that the pins actually recess perfectly into the cheek piece part of the stock. Honestly, MDT could machine one set of pins, and it would work for both functions and give you more height of the cheek piece/comb.

So a follow on to the overall Status of using the ACC Elite:

It’s a pretty nice stock overall and it comes in number at #2 in the availability of stocks that seem to work very well.

The primary concern I have is that if you are not using the night vision bridge, or any of the other bridges over the forearm… the stock has an insane amount of flexibility that causes you an issue when you have a bipod attached to the forearm.

The amount of movement back-and-forth of the forearm / buttstock interface is substantial. You can see this when you lock the front of the forearm into an arca clamp in a vice, and then grab the barrel, and gently move it back-and-forth. What you see is the whole forend twist away from the buttstock, which clearly effects accuracy.

Edit: Initially, the ACC Premier didn't seem to have this issue. However, when I double checked… it’s significantly worse than the elite.

The vision chassis has a little bit of that but it’s substantially less.

Obviously, a Centurion stock doesn’t have this issue at all. (That sucker is insanely heavy, but insanely robust as well.)

The MPA BA Competition doesn’t suffer from a twisting motion between the front and rear of the stock either. (You can’t add length of pulled the thing without going through hoops….)

The thing that’s interesting is that if you install the night vision bridge and/or control bridges the problem gets resolved, but at a significant cost.

My big issue is with the amount of money that you were paying for the stock, and the amount of extras you end up having to buy in order to get it where you want it.

It’s not like you’re paying $1500 and you’re getting everything you need. Not even remotelly.

This is especially the case if it turns out that you have a long length of pull… If you have a long length of pull and are using 1.5” scope mounts, you’re gonna find yourself needing to do a variety of things to get that rifle to fit you properly.

By comparison, if you spend that money and buy some thing like a vision chassis, you get a folder and you get whatever length of pull you’re gonna need unless you happen to be André the giant.

I love the ACC elite stock, I am unimpressed with the amount of stuff I had to go and order to get the thing to actually fit me. I’m also very unhappy with the amount of flex in the stock unless you have the control Bridges installed all the way down the forearm

@Baron23

It’s a pretty nice stock overall and it comes in number at #2 in the availability of stocks that seem to work very well.

The primary concern I have is that if you are not using the night vision bridge, or any of the other bridges over the forearm… the stock has an insane amount of flexibility that causes you an issue when you have a bipod attached to the forearm.

The amount of movement back-and-forth of the forearm / buttstock interface is substantial. You can see this when you lock the front of the forearm into an arca clamp in a vice, and then grab the barrel, and gently move it back-and-forth. What you see is the whole forend twist away from the buttstock, which clearly effects accuracy.

Edit: Initially, the ACC Premier didn't seem to have this issue. However, when I double checked… it’s significantly worse than the elite.

The vision chassis has a little bit of that but it’s substantially less.

Obviously, a Centurion stock doesn’t have this issue at all. (That sucker is insanely heavy, but insanely robust as well.)

The MPA BA Competition doesn’t suffer from a twisting motion between the front and rear of the stock either. (You can’t add length of pulled the thing without going through hoops….)

The thing that’s interesting is that if you install the night vision bridge and/or control bridges the problem gets resolved, but at a significant cost.

My big issue is with the amount of money that you were paying for the stock, and the amount of extras you end up having to buy in order to get it where you want it.

It’s not like you’re paying $1500 and you’re getting everything you need. Not even remotelly.

This is especially the case if it turns out that you have a long length of pull… If you have a long length of pull and are using 1.5” scope mounts, you’re gonna find yourself needing to do a variety of things to get that rifle to fit you properly.

By comparison, if you spend that money and buy some thing like a vision chassis, you get a folder and you get whatever length of pull you’re gonna need unless you happen to be André the giant.

I love the ACC elite stock, I am unimpressed with the amount of stuff I had to go and order to get the thing to actually fit me. I’m also very unhappy with the amount of flex in the stock unless you have the control Bridges installed all the way down the forearm

@Baron23

Last edited:

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Thank you for the review and very interesting outcome. Not familiar with the other chassis systems, so I can't really comment about, but it's strange you were able to do this on the Elite and not the Premier, as the Elite is substantially thicker and stiffer in all regards. Do you run weights in the premier but not in the Elite?

-Anthony

-Anthony

Besides the whole cerakote blunder, and the ever increasing money invested once you add things to the chassis, I’d say I’m overall very happy with mine after… looks like about 4 months since I got mine.

I can’t pin any degradation in precision on the chassis, it enables the rest of the equipment to do its job. I’ve only had the buttstock come loose once after flying with it. I’m still not thrilled about the less than ideal angle you have to try and tighten it, but I put red loctite on it this time so I think it’ll stay tight better.

Another minor issue, which is more of an issue with my action than the chassis I believe, is the lone peak rear tang with its faceted faces tends to start digging into the aluminum of a chassis (had it happen on multiple) and then loosen enough to slide ever so slightly under recoil. I did a skim bed (which I had to do with it before on another aluminum chassis) and that solved the issue.

I’m happy, lackluster cerakote response and price aside.

I can’t pin any degradation in precision on the chassis, it enables the rest of the equipment to do its job. I’ve only had the buttstock come loose once after flying with it. I’m still not thrilled about the less than ideal angle you have to try and tighten it, but I put red loctite on it this time so I think it’ll stay tight better.

Another minor issue, which is more of an issue with my action than the chassis I believe, is the lone peak rear tang with its faceted faces tends to start digging into the aluminum of a chassis (had it happen on multiple) and then loosen enough to slide ever so slightly under recoil. I did a skim bed (which I had to do with it before on another aluminum chassis) and that solved the issue.

I’m happy, lackluster cerakote response and price aside.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Besides the whole cerakote blunder, and the ever increasing money invested once you add things to the chassis, I’d say I’m overall very happy with mine after… looks like about 4 months since I got mine.

I can’t pin any degradation in precision on the chassis, it enables the rest of the equipment to do its job. I’ve only had the buttstock come loose once after flying with it. I’m still not thrilled about the less than ideal angle you have to try and tighten it, but I put red loctite on it this time so I think it’ll stay tight better.

Another minor issue, which is more of an issue with my action than the chassis I believe, is the lone peak rear tang with its faceted faces tends to start digging into the aluminum of a chassis (had it happen on multiple) and then loosen enough to slide ever so slightly under recoil. I did a skim bed (which I had to do with it before on another aluminum chassis) and that solved the issue.

I’m happy, lackluster cerakote response and price aside.

That's fair feedback; we do recommend a 5/16 Allan key to give it the last little bit since, yes, the ball end we include can make it a bit more difficult to get that last little bit.

Interesting on the action. We did add some new features to the ACC ELite to better support the action screws. Specifically, they are resting on a steel bushing, and supplied washers are meant for tuning the screw height relative to the needs of the action. What other chassis systems did it loosen up in?

-Anthony

It would dig two “tracks” at the contact points in the rear tang area of my whiskey 3 also. Let me grab a pic to show what I’m talking about.That's fair feedback; we do recommend a 5/16 Allan key to give it the last little bit since, yes, the ball end we include can make it a bit more difficult to get that last little bit.

Interesting on the action. We did add some new features to the ACC ELite to better support the action screws. Specifically, they are resting on a steel bushing, and supplied washers are meant for tuning the screw height relative to the needs of the action. What other chassis systems did it loosen up in?

-Anthony

Pic is of another lone peak action, but it has the same geometry. Those two red lines are where the tang would rest in the rear bedding area, and because they’re hard steel on softer aluminum, they would dig two parallel divots into the chassis as movement happens during use. Once enough of this aluminum is moved, the tension on the rear tang screw becomes less and it starts wiggling side to side and making the divots a little wider (also impacting repeatability). Sure you could just keep checking that it’s tight constantly, but that kind of sucks.

I’ve been having to skim bed at least my rear tang to keep it from happening, as now the tang’s force is distributed more equally and hugged by epoxy so it doesn’t wiggle around or dig in.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

Strange, we haven't had any issues with the Lone Peaks before, but we have coming for some staff members we will take a look when they come in.

-Anthony

-Anthony

I saw this myself at @GBMaryland house just a week or two ago.Thank you for the review and very interesting outcome. Not familiar with the other chassis systems, so I can't really comment about, but it's strange you were able to do this on the Elite and not the Premier, as the Elite is substantially thicker and stiffer in all regards. Do you run weights in the premier but not in the Elite?

-Anthony

I didn’t take notes…and I have a 70 y.o. memory, but my dim recollection is that it appeared that the forend twisted along its longitudinal axis with gentle movement of the barrel muzzle.

I must be admit I was gobsmacked when observing this.

And when he put on NVG/control bridge parts the flex went away in his gun room and the silly group sizes at the e range came back to expected.

If you say the Elite is beefier, I’ll certainly not cast doubt on your honesty. But apparently they didn’t beef it up in the right place(s).

As far as I can see, there are two main reasons to use a chassis. 1) configurability and 2) it should be a stiff, non-flexing, hunk of aluminum.

Try what @GBMaryland described as a test. It was very easily apparent when he did it.

Cheers.

Last edited:

I just think MDT needs to expedite this one piece top cover, make it a fair price, then we can all just run that

I am running a one piece weight in the fore end and have no flex. I did notice some flex without the weight but it was not a lot. I wonder if you got a bad one. Maybe a little video of the flex would help.

Oh and here is another CDG/Elite build to look at.

Last edited:

That is a nice looking gun.Oh and here is another CDG/Elite build to look at.

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

I saw this myself at @GBMaryland house just a week or two ago.

I didn’t take notes…and I have a 70 y.o. memory, but my dim recollection is that it appeared that the forend twisted along its longitudinal axis with gentle movement of the barrel muzzle.

I must be admit I was gobsmacked when observing this.

And when he put on NVG/control bridge parts the flex went away in his gun room and the silly group sizes at the e range came back to expected.

If you say the Elite is beefier, I’ll certainly not cast doubt on your honesty. But apparently they didn’t beef it up in the right place(s).

As far as I can see, there are two main reasons to use a chassis. 1) configurability and 2) it should be a stiff, non-flexing, hunk of aluminum.

Try what @GBMaryland described as a test. It was very easily apparent when he did it.

C

Re-reading the test or somehow how this conclusion was reached seems to be pretty unrealistic, and without seeing it I honestly can't say there is anything that is alarming to me. I will say this the ACC Elite has an 18" forend, so depending on where you clamp it and try this you can increase your mechanical leverage, but in shooting conditions, I highly doubt you would be able to replicate this.

But it is interesting feedback, and when we designed the ACC Elite, this issue was addressed. There would be no way it could even be machined wrong since the extra thickness of the material alone makes a huge difference. And as far I can tell the rifle is shooting?

-Anthony

@GBMaryland

Please address @MDT_OFFICIAL (Anthony’s) question about “the rifle is shooting”. Think you had a startling difference in group size with the Elite without and then with the NVG and Control Bridges installed.

Both were with bipod installed at the far end of the ARCA as would most any of us do.

Also, when I’m over your place today, if you want to make a vid of this, I’m willing to help.

Cheers

Please address @MDT_OFFICIAL (Anthony’s) question about “the rifle is shooting”. Think you had a startling difference in group size with the Elite without and then with the NVG and Control Bridges installed.

Both were with bipod installed at the far end of the ARCA as would most any of us do.

Also, when I’m over your place today, if you want to make a vid of this, I’m willing to help.

Cheers

MDT_OFFICIAL

Official Account of Modular Driven Technologies

Supporter

Minuteman

Commercial Supporter

And that is fair, but that bipod isn't mounted to a bench; it supports the weight of the rifle, but not a bench that would be considerably heavier and likely bolted to something. My bench at home I use is 300 pounds and has 4" framing screws going into studs.@GBMaryland

Please address @MDT_OFFICIAL (Anthony’s) question about “the rifle is shooting”. Think you had a startling difference in group size with the Elite without and then with the NVG and Control Bridges installed.

Both were with bipod installed at the far end of the ARCA as would most any of us do.

Also, when I’m over your place today, if you want to make a vid of this, I’m willing to help.

Cheers

Im not disputing the fact that you can muscle the barrel around when leveraging the chassis at maximum mechanical effort. Im saying I don't agree with the testing conditions that fact that weren't able to be replicated on an ACC Premier. It seems like there is a lot of information that hasn't been stated here.

-Anthony

I don’t have to muscle it… All I have to do is take my index finger and slightly push on the end of the barrel, and the whole rear of the gun will move a quarter of an inch from side to side. It can also be done if I grab the end of the butt stock and twist it slightly. (the lack of significant force required to do this cannot be overstated.)And that is fair, but that bipod isn't mounted to a bench; it supports the weight of the rifle, but not a bench that would be considerably heavier and likely bolted to something. My bench at home I use is 300 pounds and has 4" framing screws going into studs.

Im not disputing the fact that you can muscle the barrel around when leveraging the chassis at maximum mechanical effort. Im saying I don't agree with the testing conditions that fact that weren't able to be replicated on an ACC Premier. It seems like there is a lot of information that hasn't been stated here.

-Anthony

It would be mechanically impossible, if I were putting a load on the bipod, by pushing into it to stabilize my shooting stance, and not create some sort of flex.

in theory, since the scope is mounted to the action and the barrel is as well, it might not make any difference. But in reality things tighten up substantially when you actually have the control Bridges installed.

It’s sort of ironic to me that the ACC premiere is definitely more stiff, and doesn’t flex anywhere near as much if you’re simply take your index finger and touch the end of the barrel.

Also, shooting groups is proving to be substantially more consistent with the control bridges installed.

Last edited:

Similar threads

- Replies

- 1

- Views

- 101