So I just went on to LaRue Tactical website to see if they publish my 3 star review of his new Grendel Builders kit, and to no surprise it's not published.. But take a look at this Beauty that was posted in the review section. If any of you have ever read Mark Larue write-ups you know this reads suspiciously similar to his writing style and detail.

Reviewed by LRRPF52 4 days ago

Wow. What a superb piece of craftsmanship and mechanical engineering. As I pulled this rifle from the plastic inside the hard case it was shipped in, I notice the exceptional fit, feel, and finish of the components. Right off the bat, you visually appreciate how the FDE furniture and Cerakote all match perfectly. As you hold the rifle, there is no play in the receivers, stock-to-extension tube fit, and handguard-to-upper. It has a solid overall feel testament to the billet construction and extreme pursuit of precision fitting of all the parts, not just some of the pars like with many other rifles. Retracting the charge handle and BCG to the rear feels like glass riding on oil, as if the rifle was tuned and polished for optimal coefficient of friction in the cycling parts from the factory. The FDE RAT stock slides smoothly on the extension tube, without the typical rattle I commonly see on other AR15s. It has the nice touch of including laser-etched numerical position indicators on the comb of the tube. The elastomer buttplate has very positive purchase to your shoulder without any indication of slipping. In the sea of various after-market stocks for the AR15, I immediately regret overlooking this one. The rifle includes the MBT-2S superb 2-stage trigger with amazingly crisp and short 2nd stage. No need to mess with fire control on this rifle, as it has a world-class trigger in it designed, tested, and built in-house by LaRue. Looking over the lower receiver, I notice that there is a recess cut into the pivot pin detent spring channel boss for the ejection port door plunger assembly plate. Normally, this plate will impact your finish and begin to mar it over time. Not so on the LaRue rifle. So many little details like this have been accounted for and intelligently solved with CNC precision. Upon actuation of the ejection port door, the inside is etched with "LaRue", a nice touch. The entire port door assembly is also Cerakoted in Flat Dark Earth, unlike most other rifles that include Cerakote. Port doors are one of the first steel components on the AR15 to experience corrosion in a high humidity environment in my experience, so it's a testament to a shop that likes to go above and beyond when applying their finishes to small parts that would normally be overlooked. As you push out the takedown pin and shotgun the receivers, it's like cracking open a vault door at NORAD. Instead of giving a little and then slamming open, it doesn't move, then slowly begins to just barely break the seal, then smoothly pivots like it's on oiled ball bearings. There is no left-to-right play, let alone seam-play like on most other AR15 receiver sets. Someone went through extra trouble getting these receivers to fit this tightly. Looking at the barrel extension, the ramps appear to be polished to me, which is something I normally do on my custom builds, but never really see on factory guns. Inspecting the bolt, I see that the extractor face ramp is absolutely polished for smooth cycling during snap-over on the fatter Grendel cartridge rims-another custom feature I've never seen on factory AR15s covering the past 4 decades of studying the AR15 market inside and out. The bolt is marked "MP" indicating Magnetic Particle inspection, has a very deep black sheen to it, and has other features to it I'll let LaRue keep close to the vest that are important for reliability with the 6.5 Grendel cartridge. I can tell right away that somebody has been paying attention and did more than their due diligence in ensuring this rifle would be ideally set up to feed and function on 6.5 Grendel as if the AR15 was meant to run on 6.5 Grendel all along. Inside the receiver set, I notice that the aircraft grade aluminum parts were first anodized in FDE, then Cerakoted FDE over this. This allows the internal critical dimensions for the FCG and bolt carrier raceway to be controlled tightly, unlike Cerakote applied inside, which will gall against the carrier rails and cause sluggish operation of the BCG. Again, we see attention to detail in not only aesthetics, but critical processes, alloys, dimensions, and overall execution of a combined symphony of master craftsmanship in the CNC and injection-molding era. Moving forward, the Stealth 2.0 upper/handguard fit is perfect when looking at the upper receiver rail and handguard rail. You have to look for the seam to confirm that they are 2 separate pieces if you look at the rail from the rear and try to find the interruption. The handguard is very lightweight and slim profile, with a feel in the hands that promotes pointing and carrying. Looking under the handguard, you see that there is something different going on with the gas system at the gas tube/gas block junction. There is a little ferrule that seals the gas tube into the low profile gas block, preventing gas leakage common to many other factory rifles. Firing the Stealth 2.0 Grendel with several different types of ammunition, (to include a slower-burning propellant hand load that generates higher port pressure) showed no signs at all of any leakage from this area. The functional result is that you have a very consistent gas system circuit, leading to consistent carrier inertia and reliable cycling right out of the gate. On personal custom builds, I have attempted to mitigate this issue with adhesives, but have still seen leakage. Not so with the LaRue Stealth 2.0 Grendel. Finally, at the muzzle, the Tranquillo muzzle brake is perfectly timed to Top Dead Center. It has some unique features that appear to aid in mounting and keeping a square muzzle device arrangement, and also has 4 flats on its base circumference. The included barrel nut wrench has flats for this muzzle device as well, with specs etched onto the wrench-another indication of a level of attention to detail not seen in this market. I got the package with the FDE Cerakoted LT-104 scope mount and Burris 1.5-6x MTAC optic. The LT-104 matches the finish of the rest of the rifle perfectly, and I would love to see this option for ordering LT mounts in the future. The rifle was shipped with 2 magazines, 1 an Elander 17rd smooth black enamel-coated with smooth white follower, and 1 5rd CProducts mag. On my initial range trip, I was shocked at how smoothly and effortlessly this rifle handles and cycles. Having built and test-fired countless 6.5 Grendel AR15s, I have to say that this rifle cycles so smoothly, it reminds me of a tuned .223 Wylde race gun shooting 55gr loads, and I was shooting 120gr and 123gr factory and hand loads. With the 6x Burris MTAC, I was able to hammer 5rd group after 5rd group into tight clusters at 100yds, everything within 1.5 MOA of the original POI of the test group Mark shot with the rifle. What was scary was how the first group printed dead-on where Mark's test fire group was, and I got the rifle and optics in separate shipments! I will follow-up with a more in-depth accuracy analysis once I've mounted a higher magnification optic, but so far, the rifle is very consistent and easy to hit POA with, even when rapid-fired, without losing sight picture. As shipped, I could have taken the rifle out immediately and filled tags, or cleared small steel plate racks. The reticle does not move more than 1.5" off the target under recoil (there's hardly any recoil at all), and I was shooting off a shaggy carpet range block since I forgot my bipod at home. Having built so many different AR15s and 6.5 Grendel AR15s, I honestly have to say that I've never had one of them turn out like this one when looking at how perfectly it cycles in that happy window of AR15 cyclic rate. I'm guessing it has to be somewhere around 700rpm, which is a sweet spot really. Ejection was right around 3:00 to 4:30 as best as I could tell with the range net, and all my brass came out without any damaged rims. Firing pin indentations were almost perfectly concentric with the primer, indicating excellent bolt alignment with the bore. All in all, this rifle has made me realize that if I ever want a 6.5 Grendel, LaRue is at the top of the list. It's like a custom-built rifle with tools and techniques available to the custom shop that small shops simply don't have. When you realize that LaRue designed and built every major component from butt plate to the muzzle, there is no competition I'm aware of with that capability. This rifle is a custom shop production rifle really, for a price at least half of what you would normally pay for half the features. This is truly my new favorite 6.5 Grendel.

****************************************

Anyway..... I took the Grendel to the range today to break in the barrel and zero my scope. This is some of the conclusions I've come to.

First off pulling the charging handle to rear doesn't feel like "glass riding on oil" more like wiping your ass with shards of glass!! The charging handle that was supplied in the kit has a rough textured anodize finished and so does the upper receiver so until those two break-in it's not a pleasant feeling.

The upper receiver and handguard do come together nicely but far from seamless..

After a quick cleaning I began sighting in my Razor Gen 1 and conducting Barrel Break in using wolf gold 120 grain ammo.. shot one and cleaned for 5 rounds, and locked in my Zero.

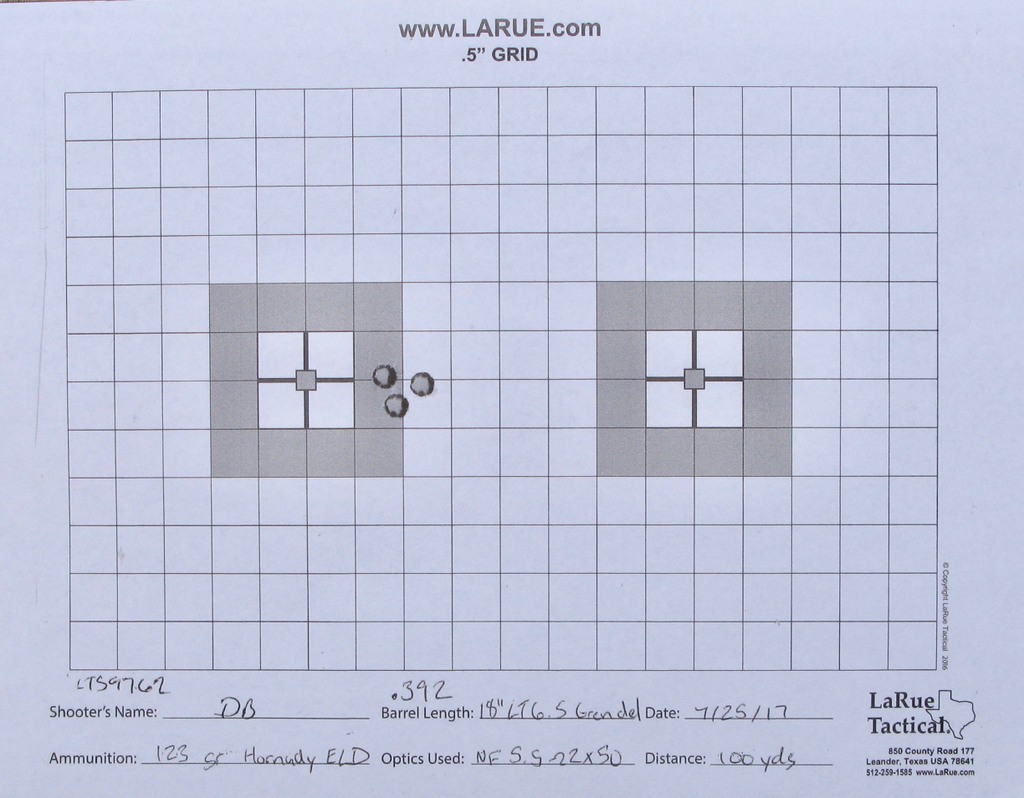

I shot my first 5 round group with the wolf gold 120 grain hollow point and It produced a solid 1.70 MOA group. Then cleaned again.

Next up was Hornady 123 Amax Factory ammo I conducted two 5 shot groups both of which set at 1.5 MOA, after the two five round groups I let her cool for about 20 minutes and conducted my last cleaning for break in.

Last up was my handloads I use in my Les Baer .264,

123gr Amax, 28.2grs RamShot Tac, Horn Brass, CCI BR4 .

Shot two more 5 shot with my hand loads both groups we're at 1.5-1.7 MOA.. Grrrrrrrr

At this point I was sick and fucking tired of listening to that TWANG!! from the mil-spec buffer system. I replaced the LaRue buffer and spring with a JP Silent Captured Spring and also swapped out the LaRue M16 full Mass bolt carrier and installed my JP LOMAS carrier with the LaRue Bolt, and let the barrel cool for another 20 minutes.

I started up again with two 5 shot groups with the Hornady 123 Amax Factory ammo and the group's shrunk considerably to a solid 1 MOA.

I waited five minutes and then went back to my hand loads, again two 5 Shot groups but this time both groups sat at .5 MOA

The JP SCS and LOMAS Carrier made a huge difference in the performance of the rifle and overall pleasantry of shooting.

Just a side note all groups were shot without the provided muzzle brake and a AR gold trigger.

Overall I feel this will make a GREAT hunting rifle and extremely convenient that it likes the same Hand loads as my Les Baer .264, but definitely not something I would consider for intermediate precision shooting. I will be conducting a few more upgrades. I'll be sending in the upper receiver to my Smith to make sure the Receiver Face is true before bedding the barrel extension and installing an SLR adjustable gas block.

Oh.. MSTN If you feel like this is thread Crashing I sincerely apologize and will remove it immediately..

Jake